Spraying material receiving port dust collecting device capable of preventing ammonium salt byproduct leakage

A technology of dust collection device and by-products, which is applied in the direction of the device where the axis of the swirl can be reversed, the swirl device, etc., can solve the problems affecting the health of the staff, the deterioration of the working environment, and air pollution, etc., to protect the body Effects on health, pollution reduction, and corporate income increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

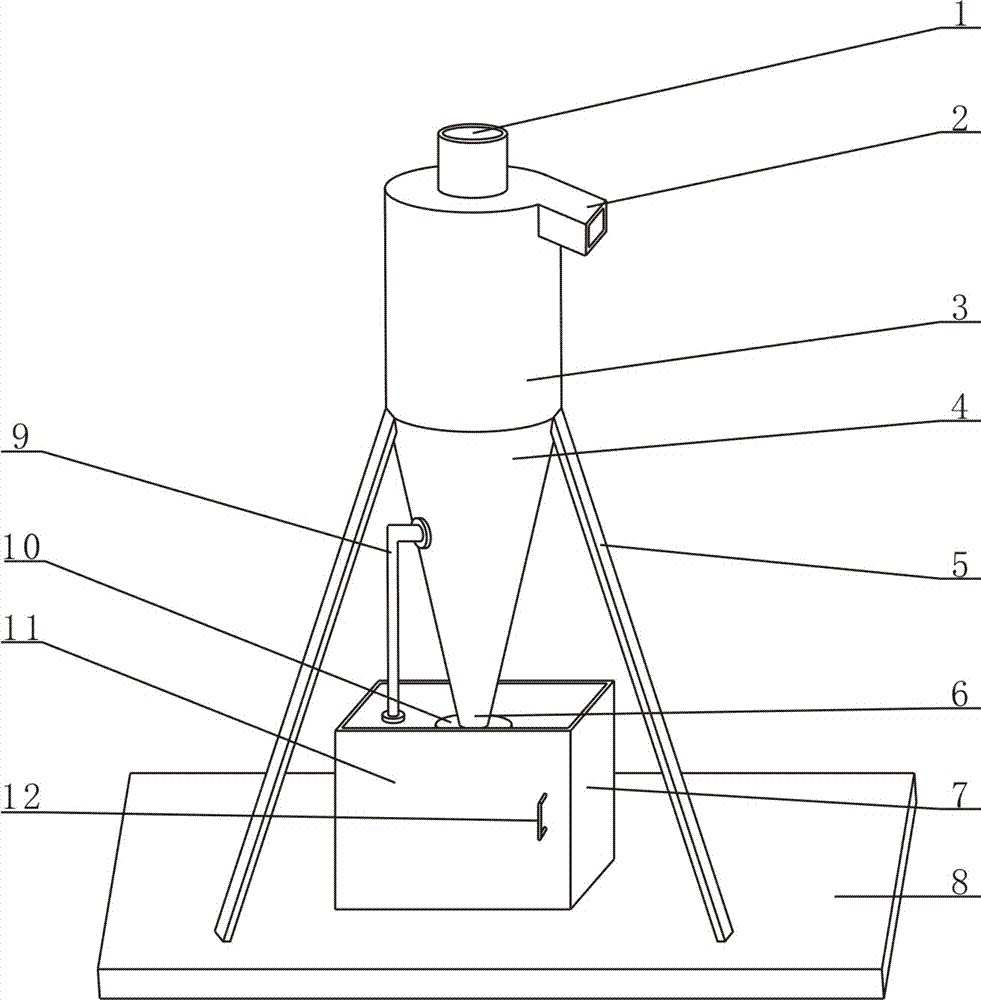

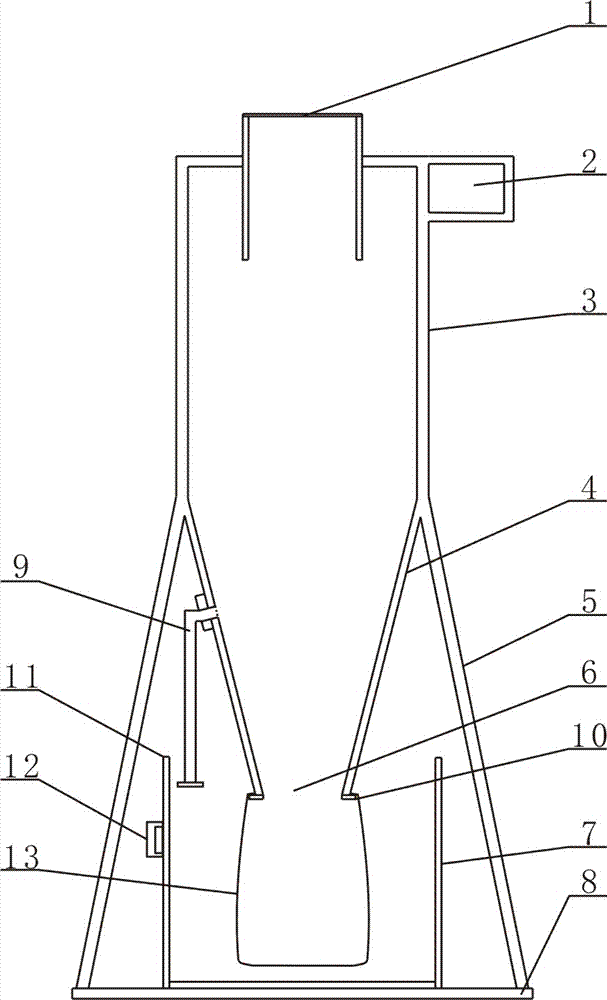

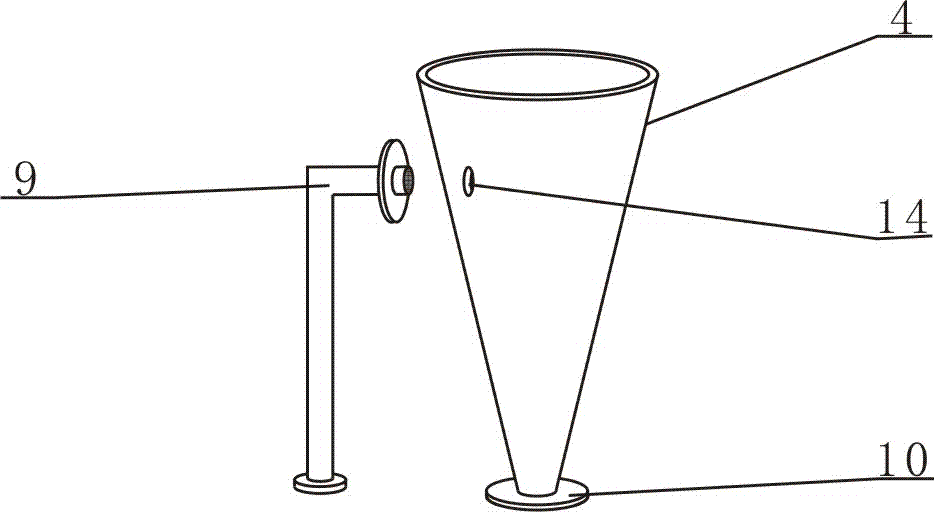

[0027] combined with Figure 1~4 A dust collection device at a spray inlet to prevent leakage of ammonium salt by-products, comprising a supporting device, a collecting device, a feeding device and an air outlet barrel 1, a collecting device is provided on the supporting device, a feeding device is provided on the collecting device, and a feeding device is provided on the collecting device. The feeding device is provided with an air outlet barrel 1, the supporting device is composed of a base 8 and a bracket 5, the base 8 is provided with a bracket 5, and the feeding device is composed of an air inlet barrel 2 and an upper tank body 3, and the upper tank body 3 is provided with Air inlet barrel 2, collection device is made of lower tank body 4, dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com