Patents

Literature

43results about How to "Meet replacement needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

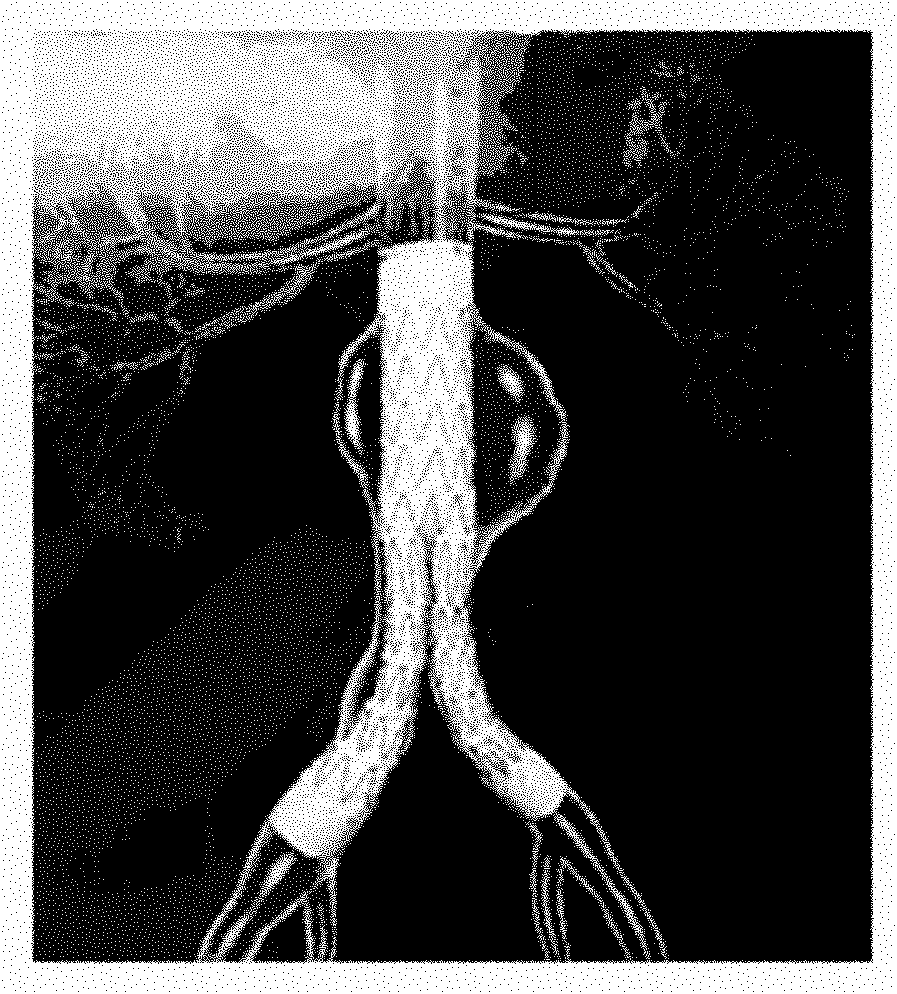

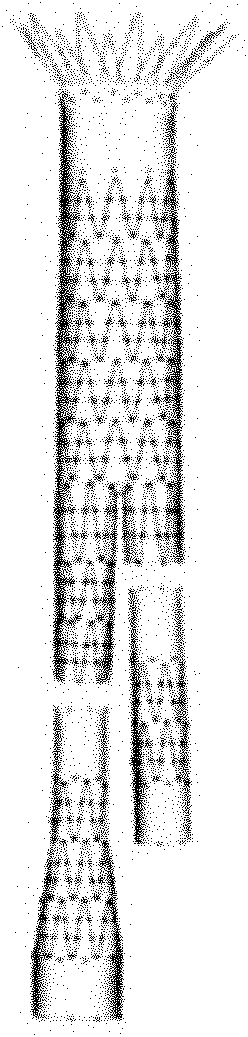

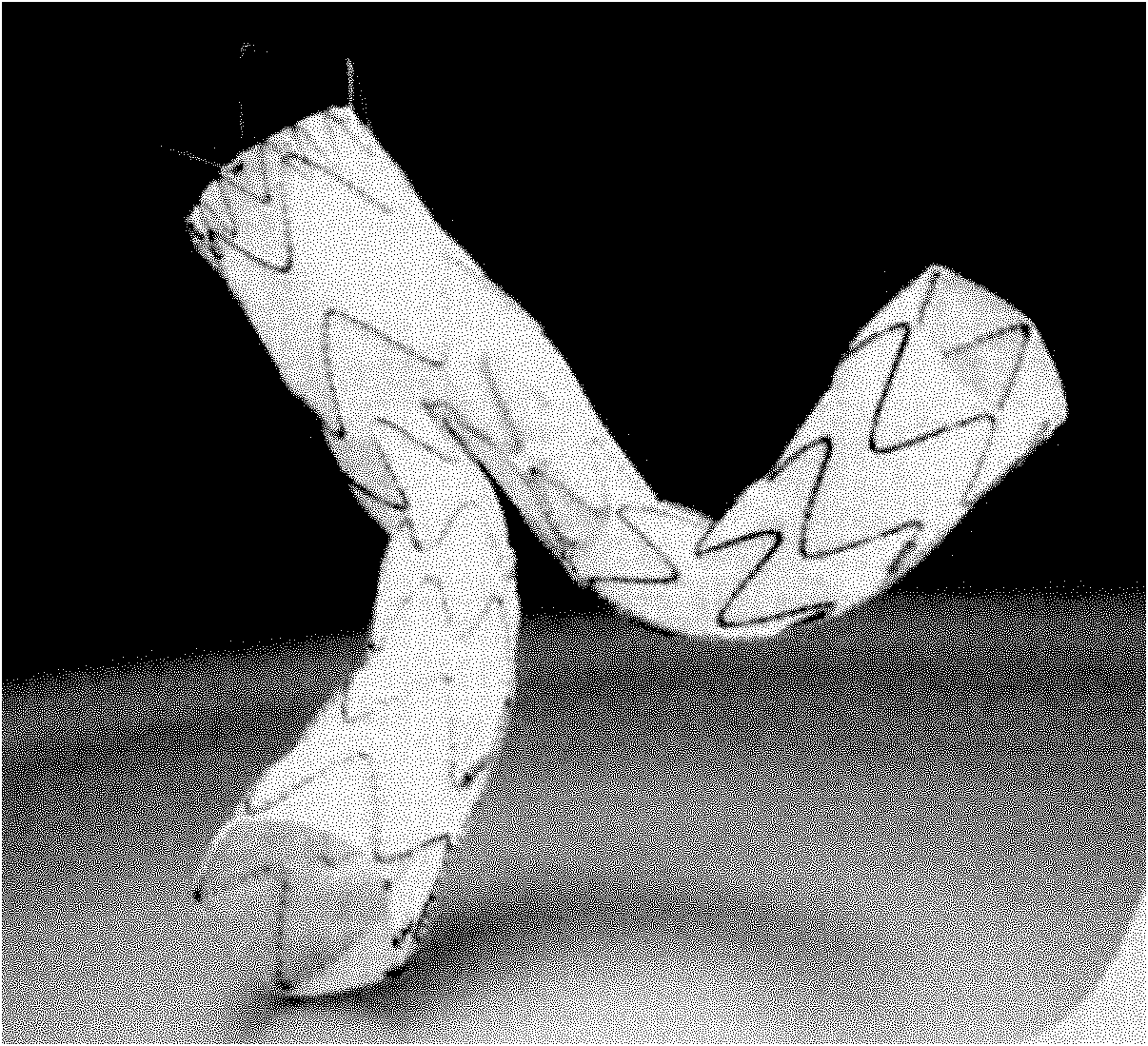

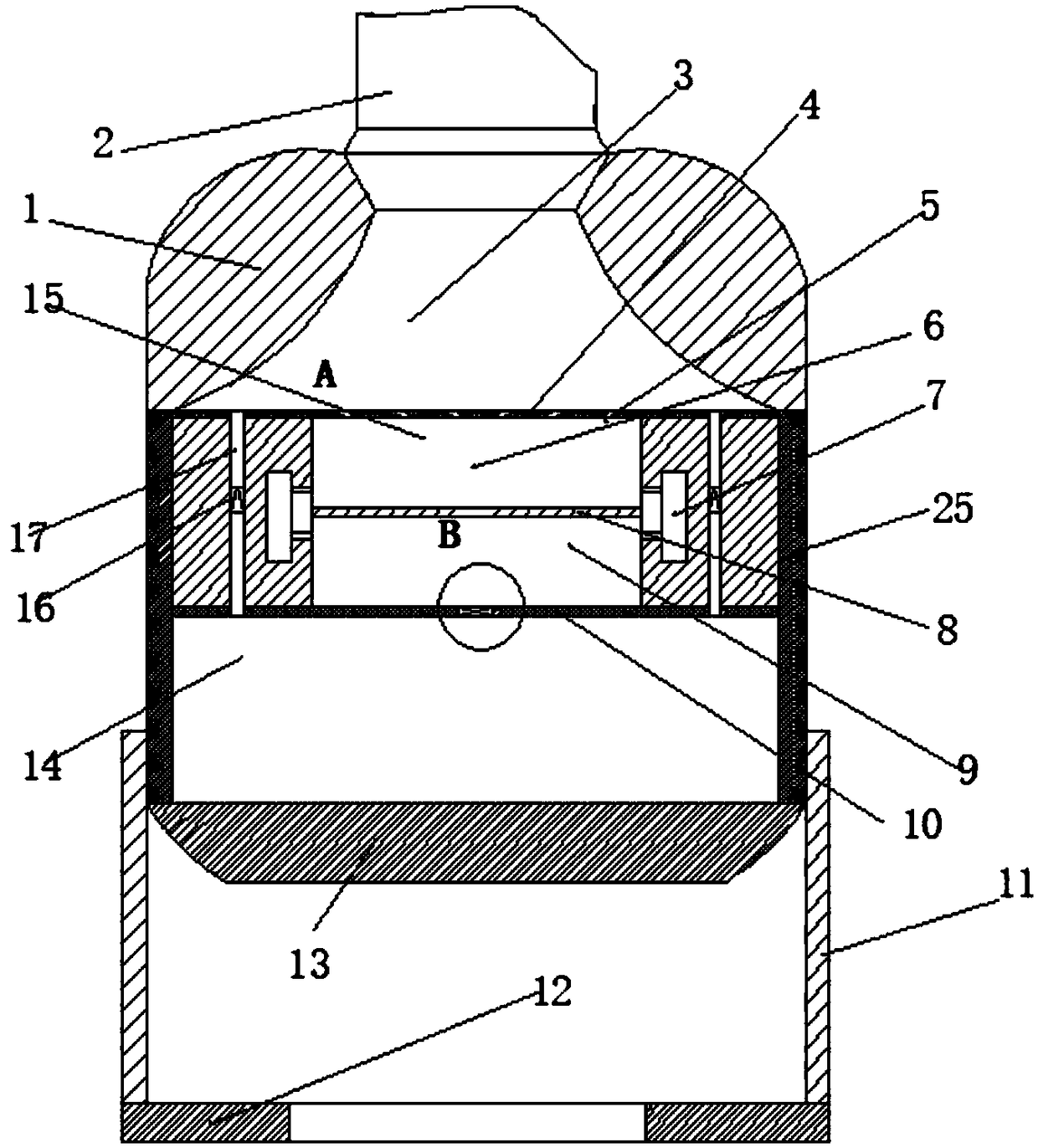

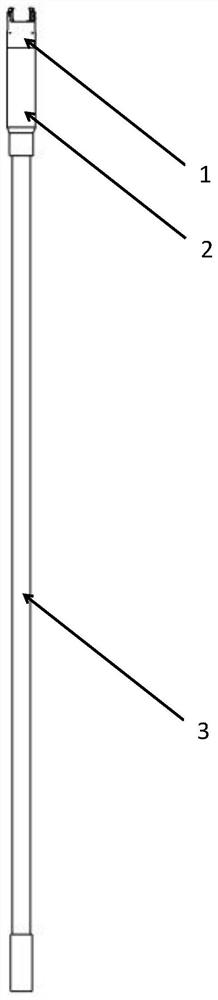

Stent vessel and dedicated traction tool for implanting stent vessel into human body

ActiveCN102125470ASimple structureEasy to manufactureStentsBlood vesselsInsertion stentInterventional therapy

The invention relates to a stent vessel for interventional therapy and a dedicated traction tool for implanting the stent vessel into a human body. The stent vessel comprises an artificial or animal vessel and support rings, wherein the support rings in three structures are used for fixation and respectively arranged at the outlet end and the inlet end of the artificial or animal vessel, and in the support rings, a detachable support ring with radial resilience force is further provided. The dedicated traction tool is especially suitable for dragging a Y-shaped stent into circuitous or narrow parts of the human body. The stent vessel provided by the invention is extremely flexible and easy to be implanted into a branch vessel until to the circuitous part. Because the main part and the branch of the stent vessel are integrated, the stent vessel is easy to position and safe and reliable without leakage after being implanted into the human body; and as the structure is simple and the cost is low, stent vessels in various diameters, variable diameters and lengths are be made, and the application range is wide because of no limit to lengths.

Owner:王嘉贤 +1

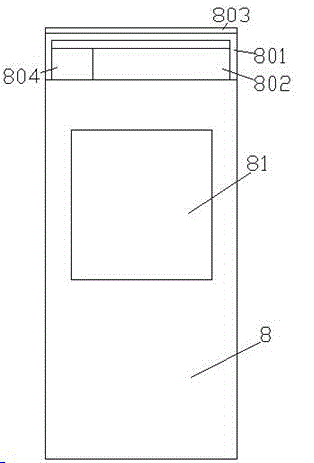

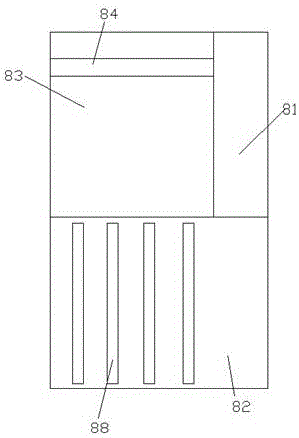

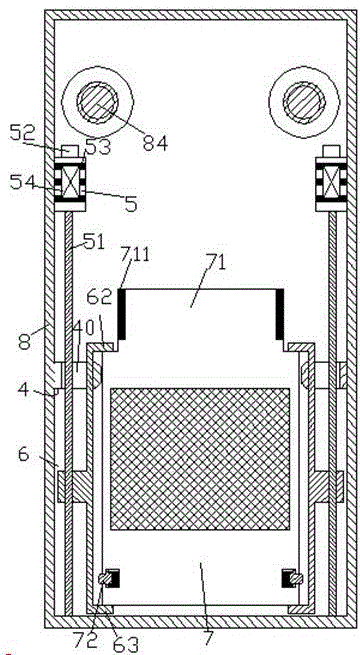

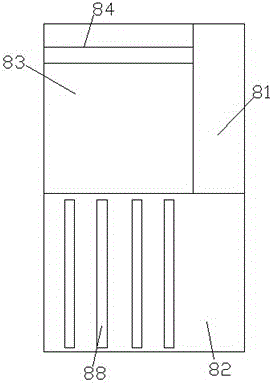

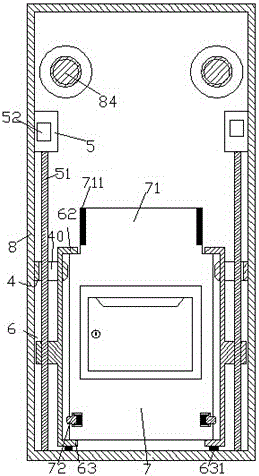

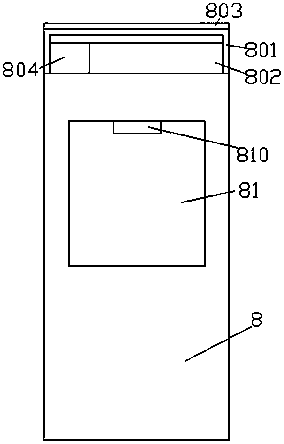

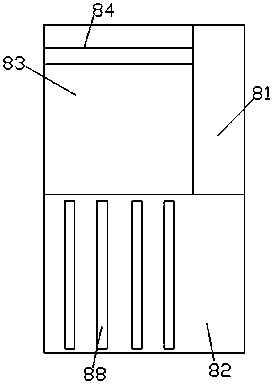

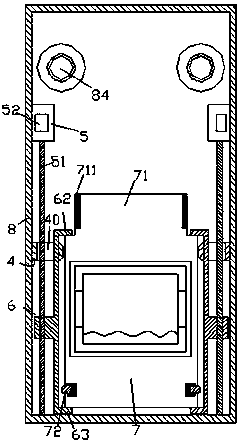

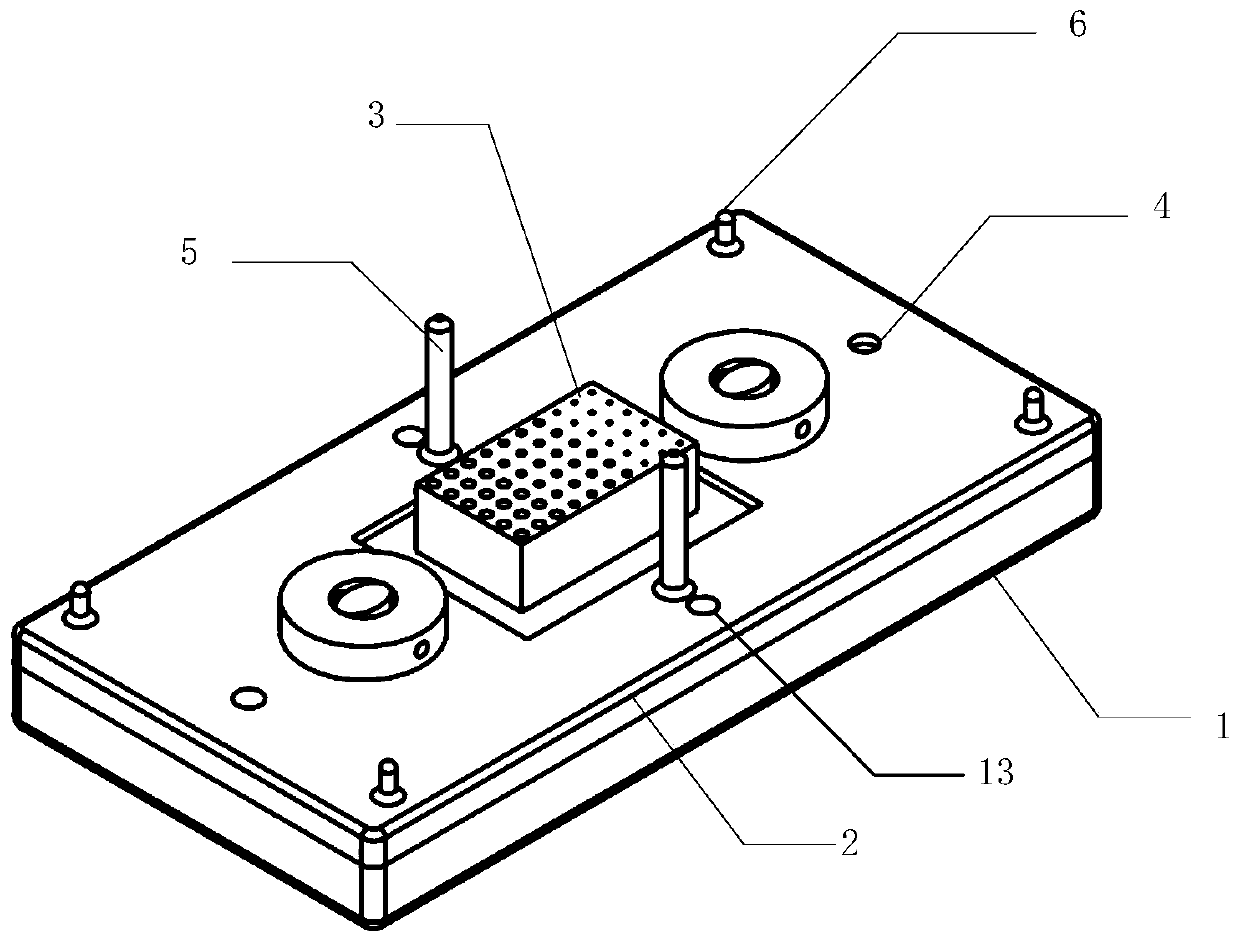

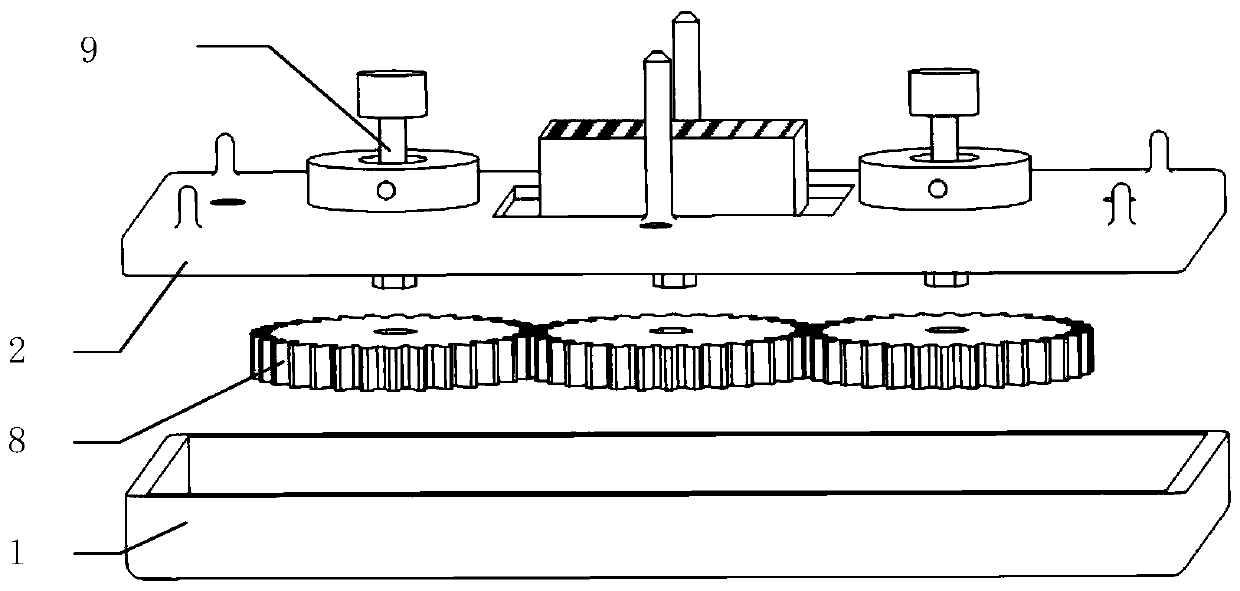

Air purification device with replaceable filter screen

ActiveCN106422551AMeet replacement needsPlanarity effectDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

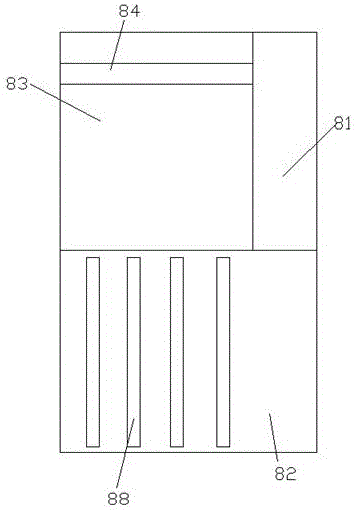

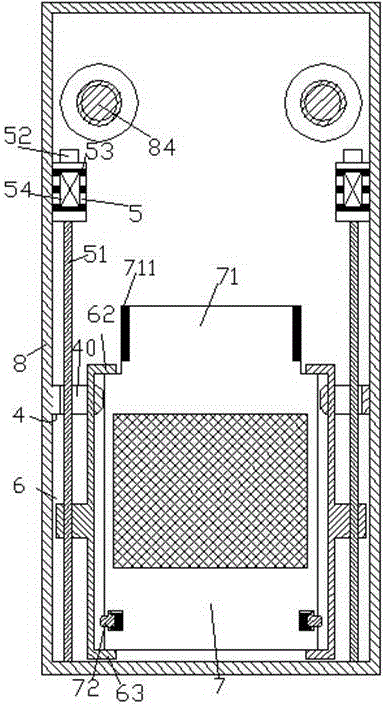

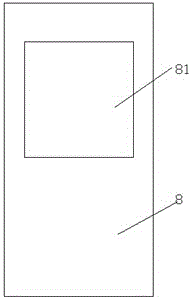

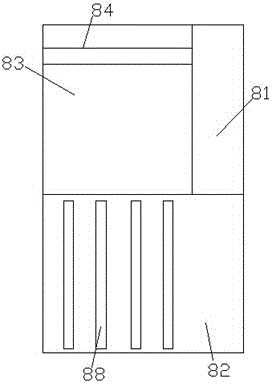

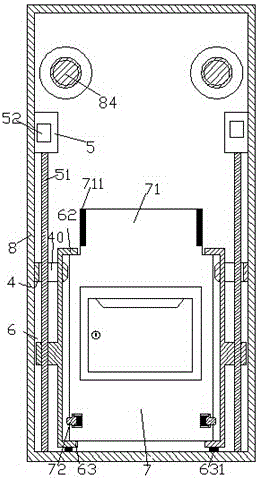

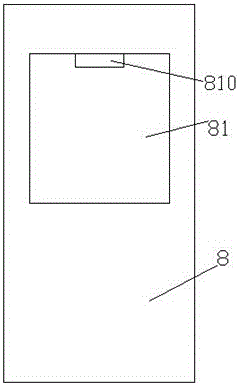

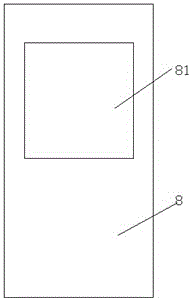

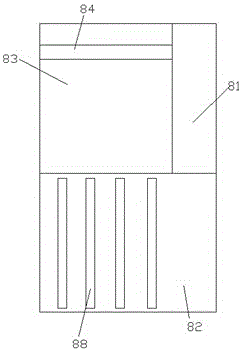

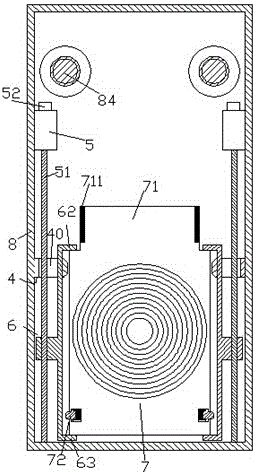

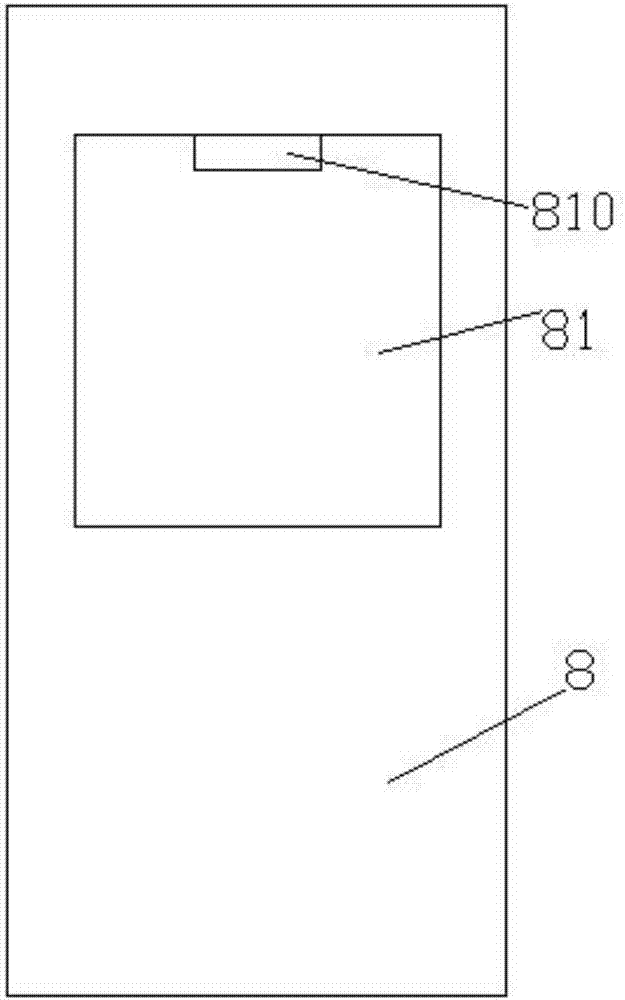

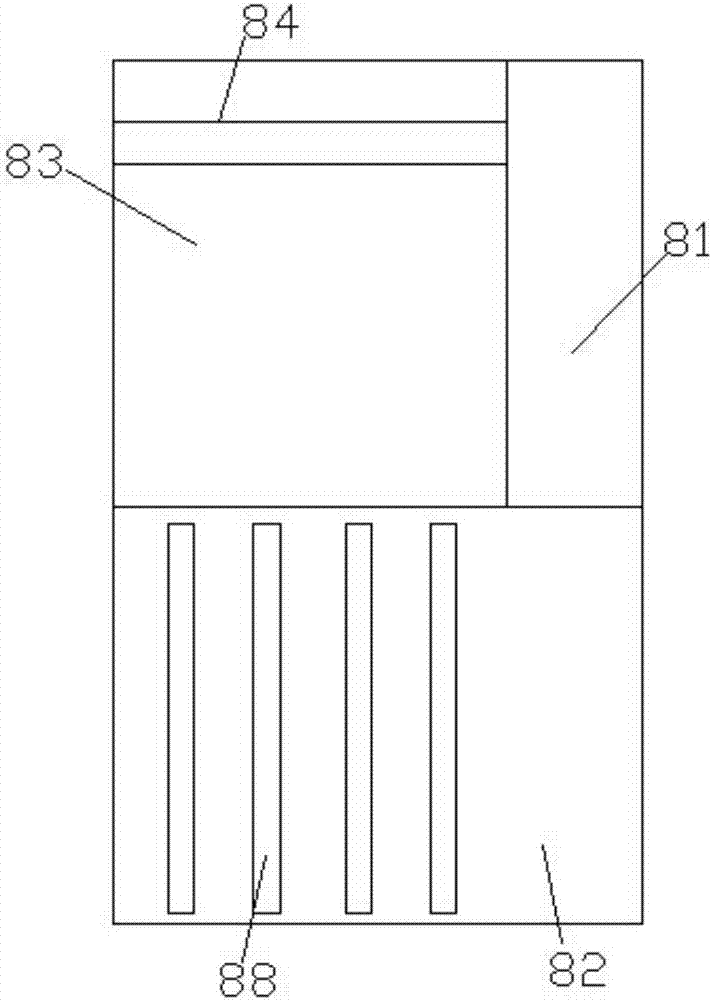

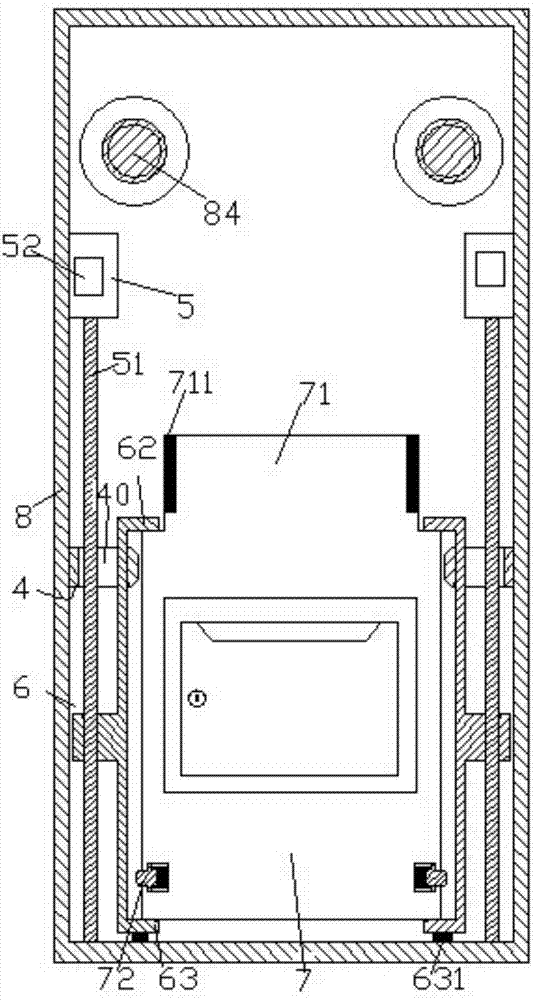

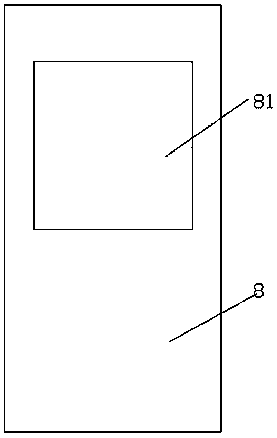

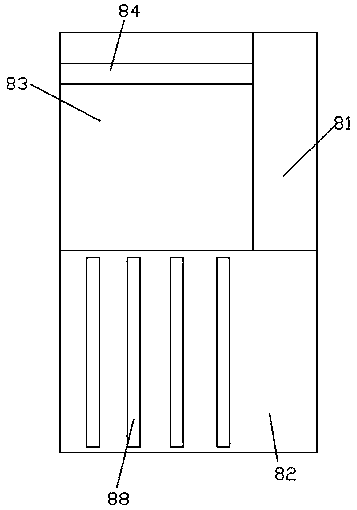

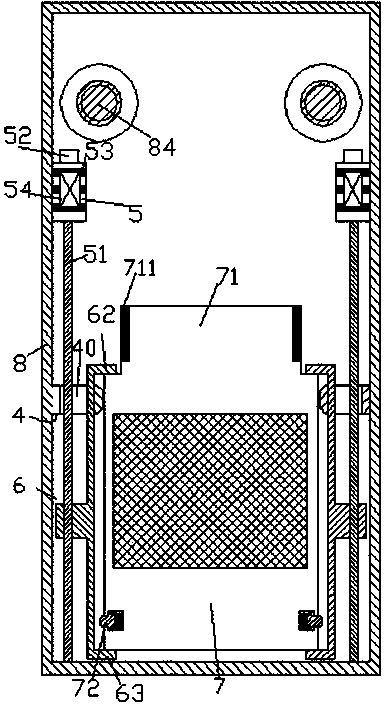

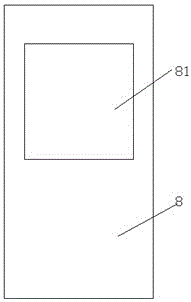

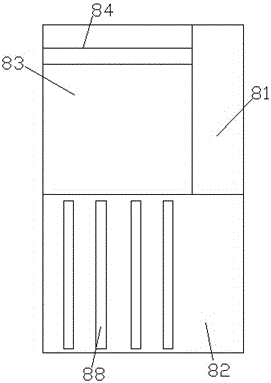

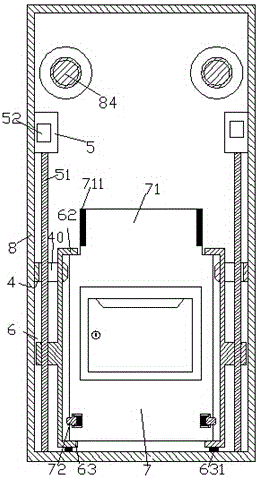

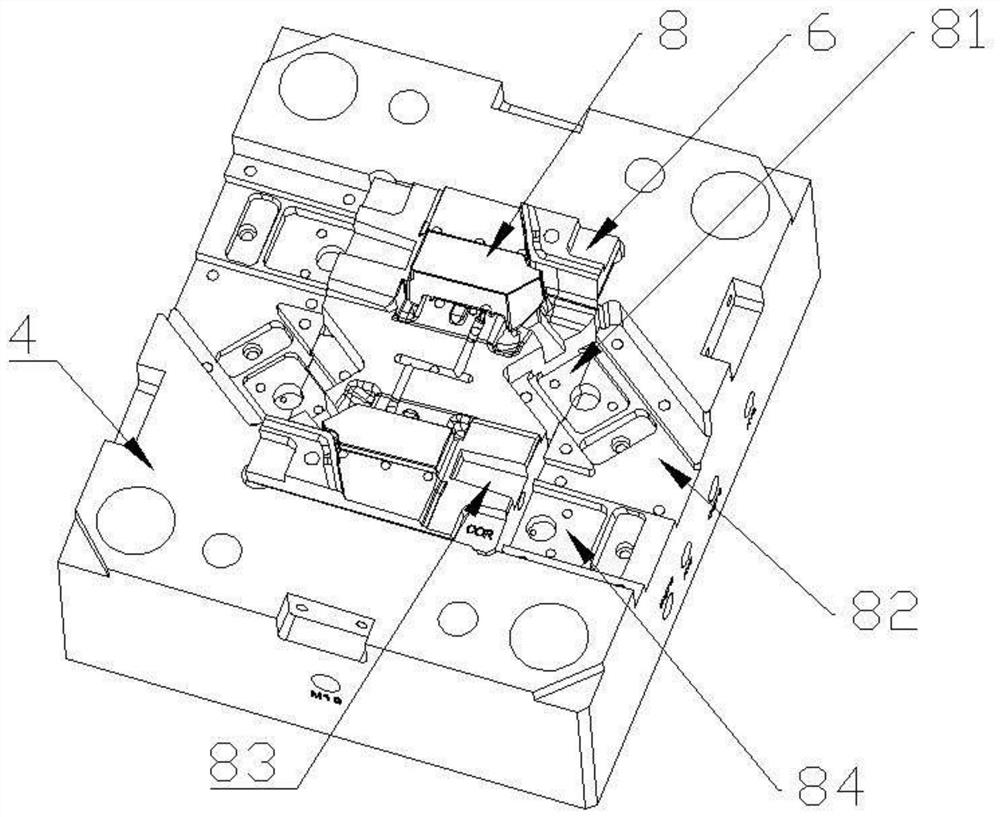

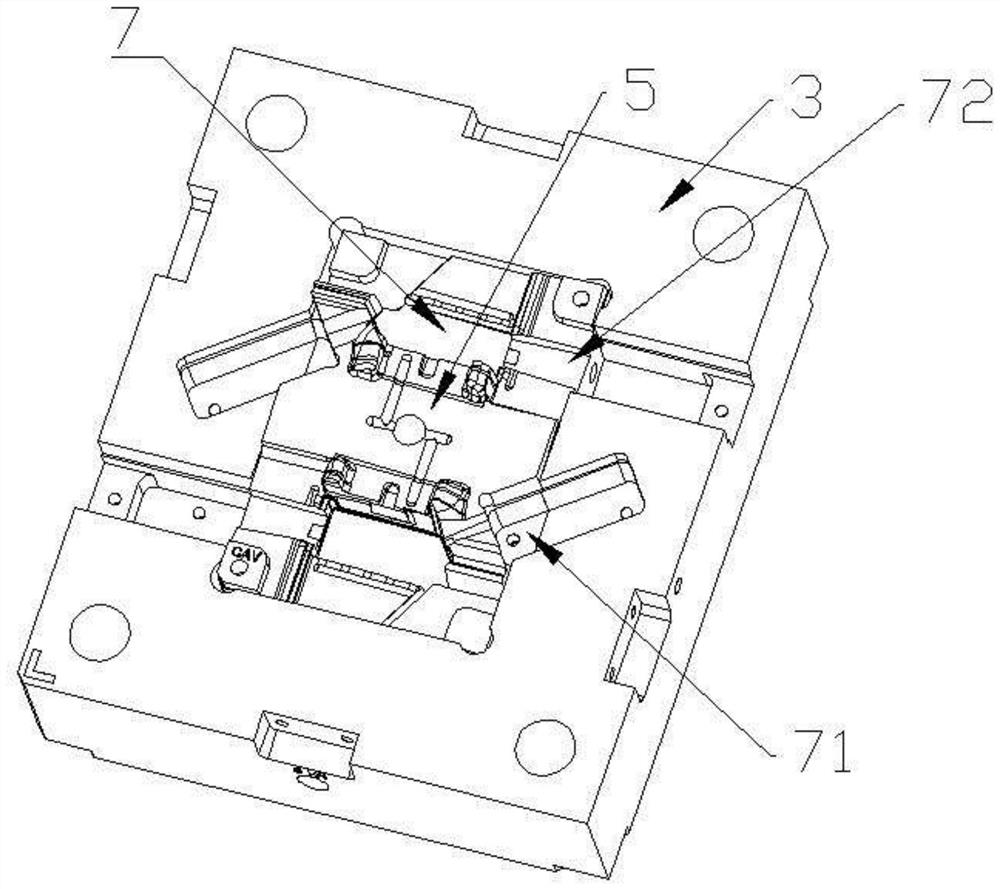

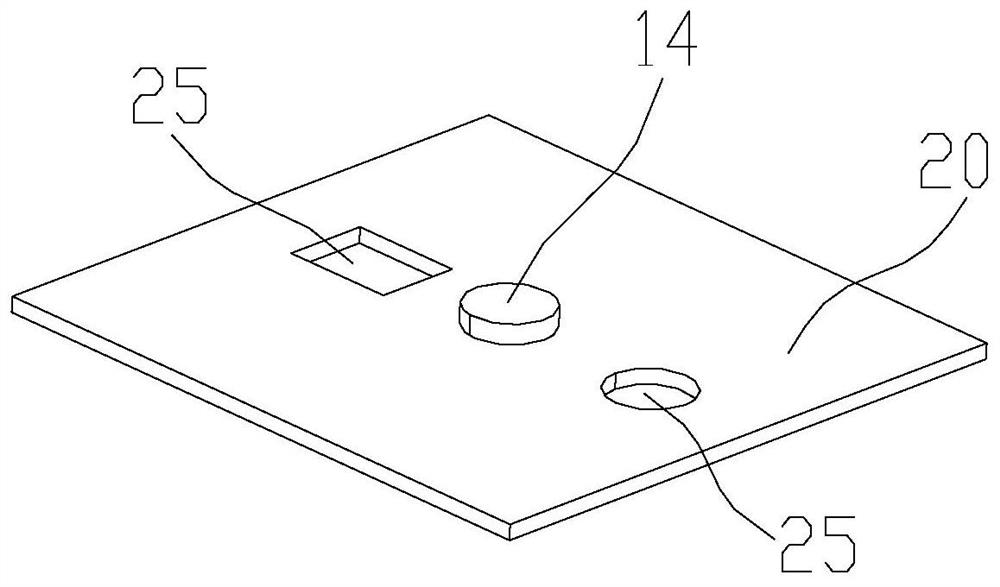

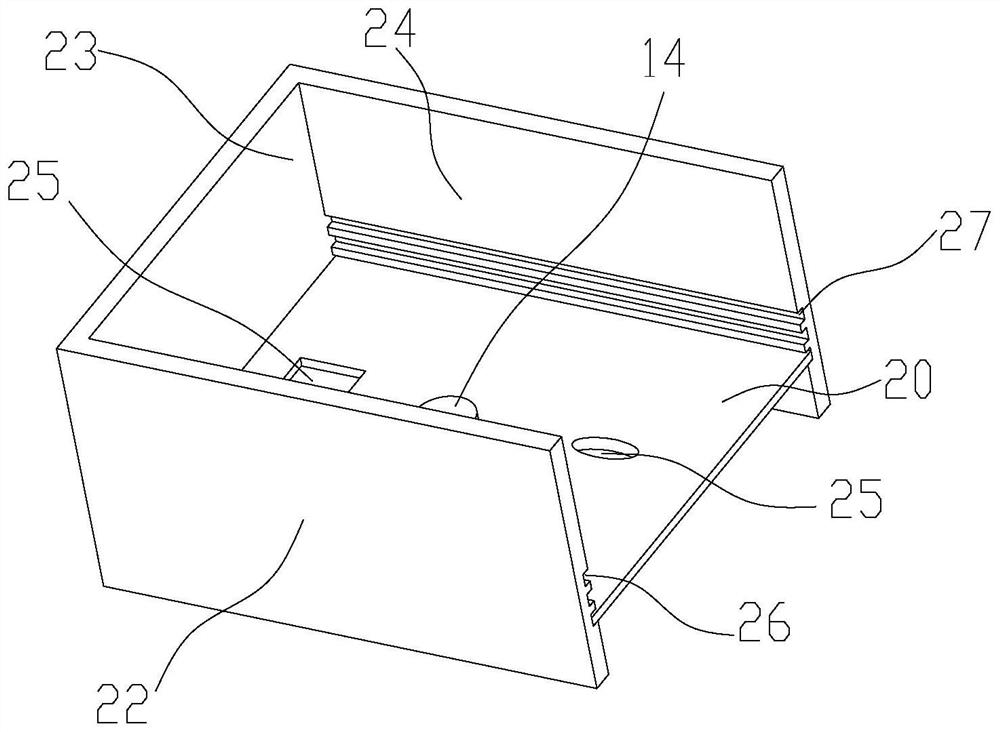

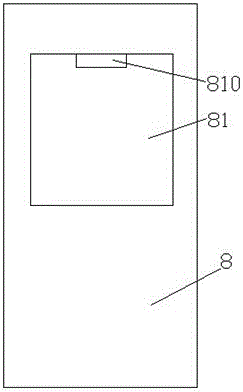

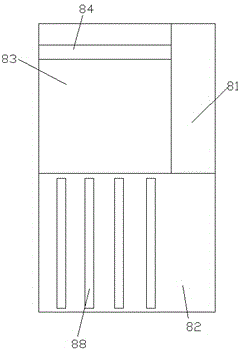

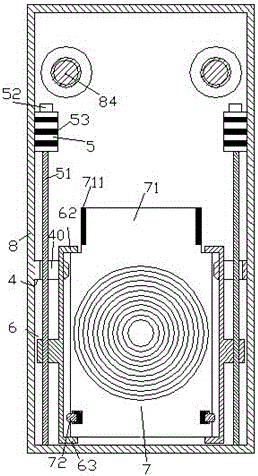

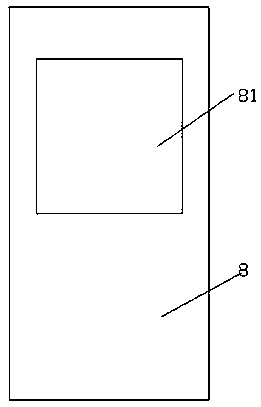

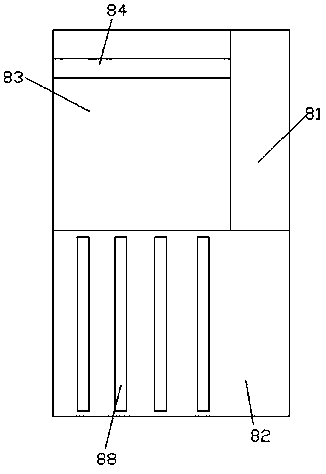

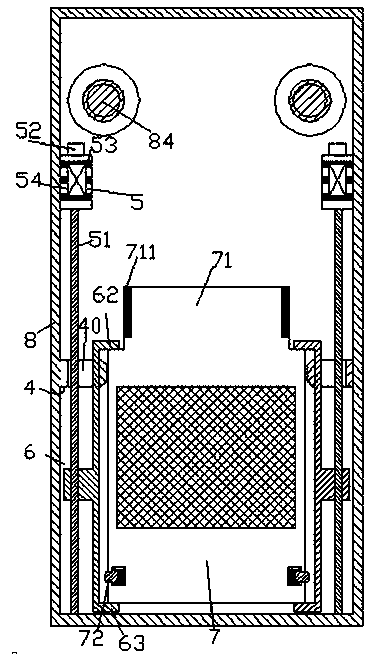

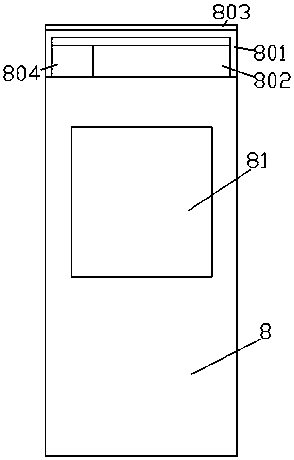

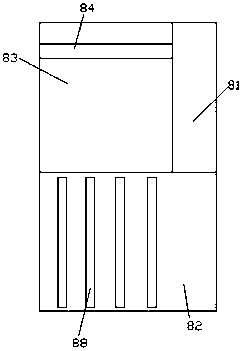

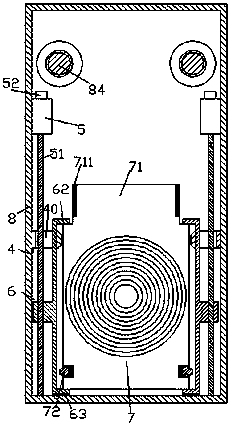

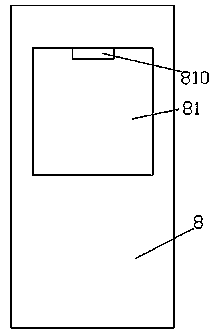

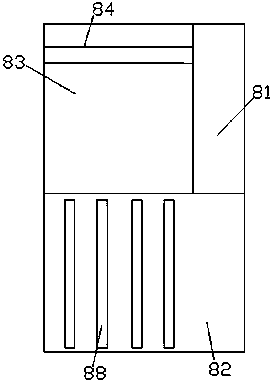

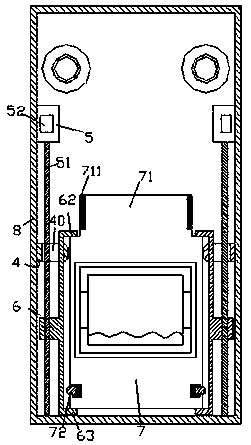

The invention discloses an air purification device with a replaceable filter screen. The purification device comprises a substrate (8), wherein the inner space of the substrate (8) comprises a bottom storage area (82), an upper front-side air purification area (81) and an upper rear-side filter screen sliding path area (83), wherein the bottom storage area (82) is used for containing a plurality of filter screen components (88); the upper front-side air purification area (81) is used for installing the selected filter screen; a sliding driving component (84) which extends in a front-back direction is arranged in the filter screen sliding path area (83) for enabling the selected filter screen to slide in a front-back direction; each filter screen component (88) comprises a filter screen installation plate (7), lifting driving screw rods (51) and a lifting rack (6), wherein the lifting driving screw rods (51) of each filter screen component (88) are positioned on two sides of the corresponding filter screen installation plate (7); each lifting rack (6) is driven by the corresponding lifting driving screw rods (51).

Owner:江西山形环保能源集团有限公司

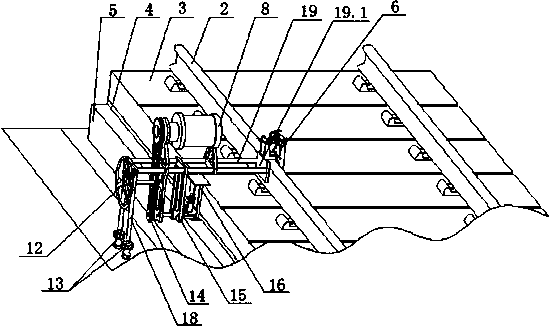

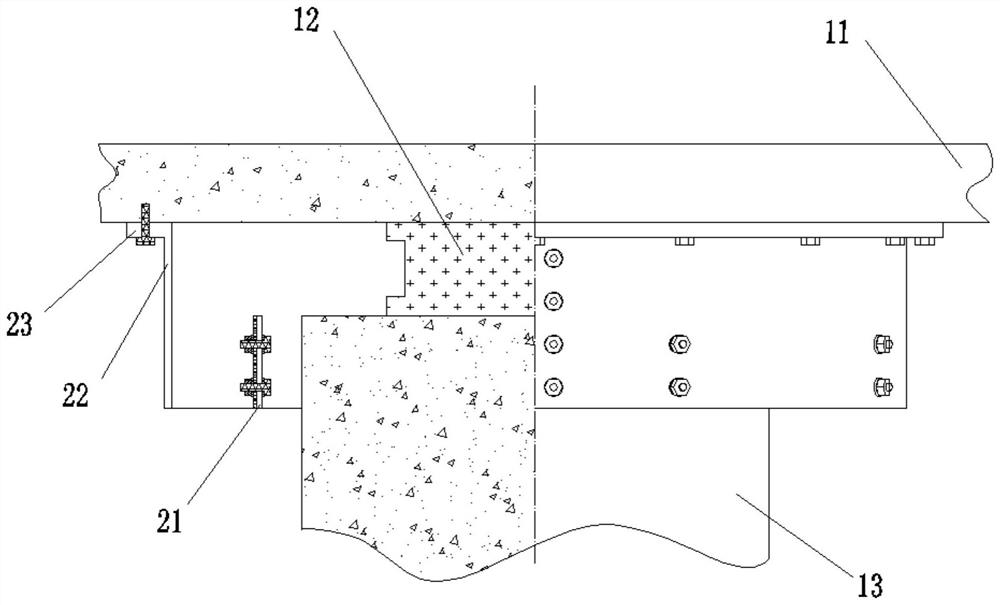

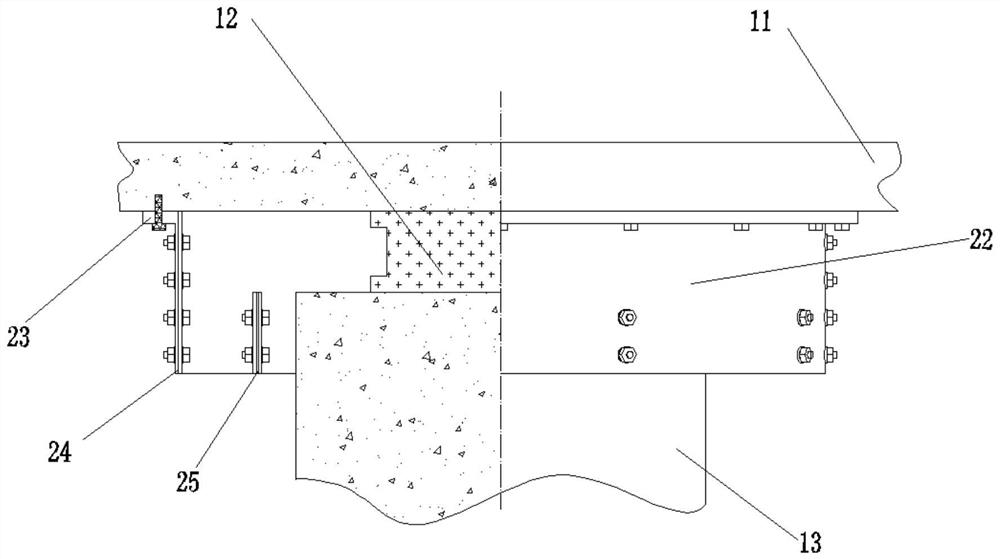

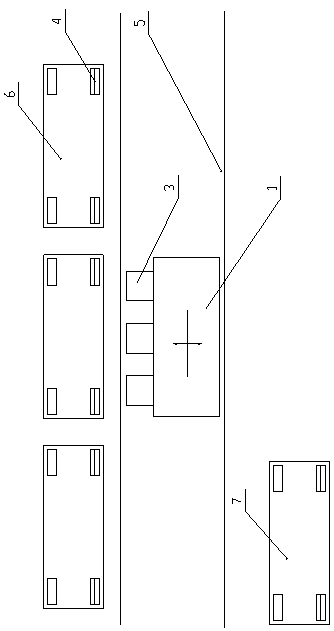

Replacement system and replacement method for long and huge components of high-speed turnout

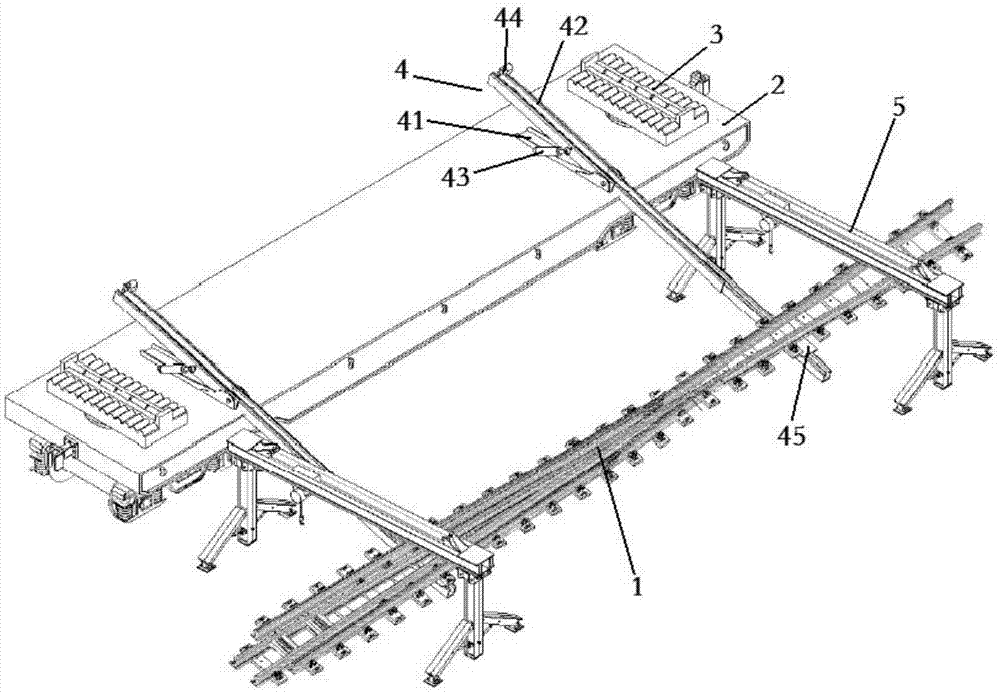

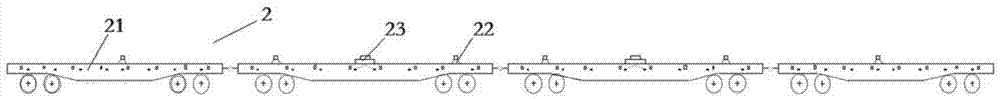

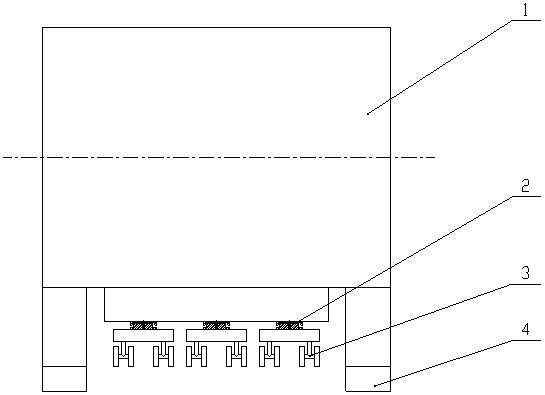

ActiveCN104775341AImprove reliabilitySimple structureRailway track constructionReplacement methodGantry crane

The invention discloses a replacement system for long and huge components of a high-speed turnout. The replacement system comprises a transport cart, rail material supports, expansion devices and combined gantry cranes; meanwhile, according to the system, the invention discloses a replacement method for the long and huge components of the high-speed turnout. The replacement system for the long and huge components of the high-speed turnout according to the invention is simple in structure and high in reliability, and can meet the replacement requirements of various components of a site turnout; meanwhile, a lorry-mounted mode is adopted by the replacement method for the long and huge components of the high-speed turnout, disclosed by the invention, site assembly is not needed, the manual labor is saved, and the operation time is shortened.

Owner:CHINA RAILWAYS CORPORATION +2

Convenient air purifying device capable of filter screen replacement

ActiveCN106390613AMeet replacement needsPlanarity effectDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

A convenient air purifying device capable of filter screen replacement comprises a substrate (8), wherein an inner space of the substrate (8) includes a storage area (82) at the bottom and for containing a plurality of filter screen assemblies (88), an air purification area (81) at the front side of the upper part and for mounting selected filter screens, and a filter screen sliding path area (83) at the rear side of the upper part; the filter screen sliding path area (83) is provided with a slide drive assembly (84) extending in the forward and backward directions, and the slide drive assembly (84) is used for making the selected filter screens slide in the forward and backward directions; each of the plurality of filter screen assemblies (88) comprises a filter screen mounting plate (7), lifting driving screws (51) located at two sides of the filter screen mounting plate (7), and a lifting frame (6) driven by the lifting driving screws (51).

Owner:苏州恒优净净化设备有限公司

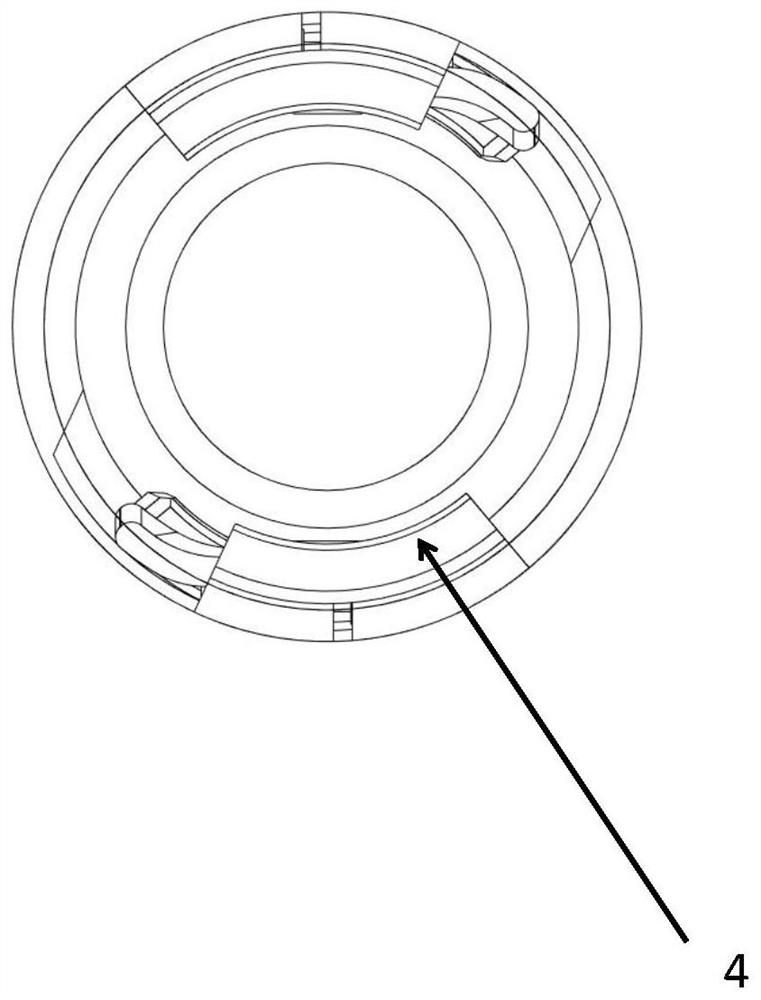

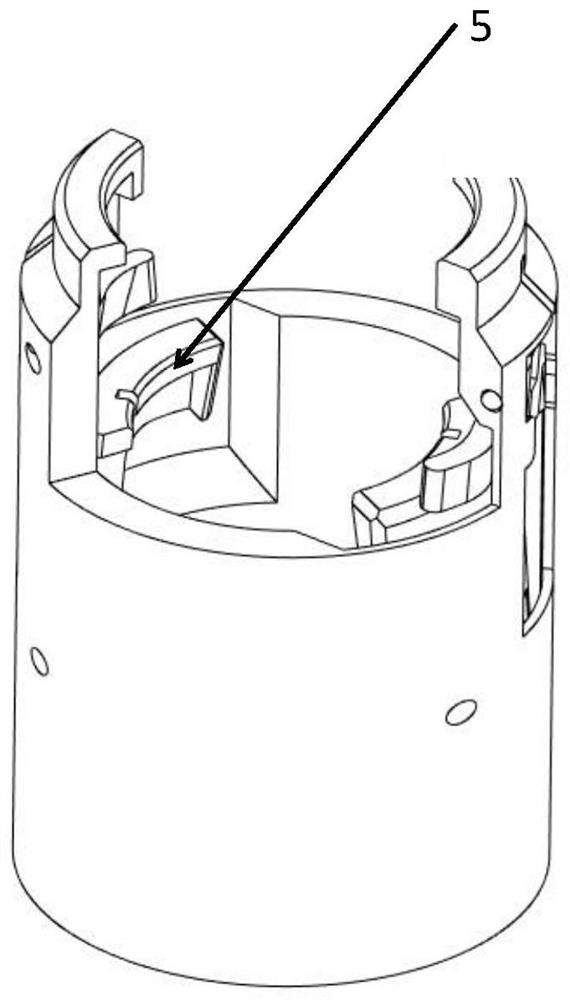

Universal fixture for replacement of self-explosion insulator of power transmission line and application method of universal fixture

PendingCN107147035ALarge adjustment rangeStrong applicabilityApparatus for overhead lines/cablesPower transmissionBolt connection

The invention relates to a universal fixture for replacement of a self-explosion insulator of a power transmission line and an application method of the universal fixture. The fixture comprises a front clamp and a rear clamp, wherein the front clamp and the rear clamp are connected by a lead screw, the front clamp comprises an outer clamp and an inner clamp, the outer clamp comprises an upper clamp and a lower clamp, the upper clamp and the lower clamp are connected by a bolt, the inner clamp comprises four arc movable clamping blocks, two movable clamping blocks are respectively arranged in the upper clamp and the lower clamp, an outer arc and an inner arc of each movable clamping block and an inner-hole arc of the outer clamp are concentrically arranged, a movable connection rod is arranged at an outer side of each movable clamping block, the other end of the movable connection rod is clamped in a corresponding sliding way in the outer clamp, a limitation bolt is arranged at an outer side of the outer clamp, penetrates through the outer clamp and then props against the movable connection rod, the movable clamping block can move along a radial direction under adjustment of the limitation bolt, and a spring is also arranged between the movable connection rod and the outer clamp. The inner clamp of the fixture disclosed by the invention employs a structure of the four movable clamping blocks, the fixture is large in adjustment range and high in universality, and the replacement demands of all insulators of 16t or below can be completely satisfied by employing the same fixture.

Owner:CHAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Building letter box device capable of achieving storage selecting and convenient and fast to use

ActiveCN106264035AReduce the area occupied by public activitiesImprove securityKitchen equipmentDomestic articlesEngineeringMechanical engineering

A building letter box device capable of achieving storage selecting and convenient and fast to use comprises a shell (8). Inner space of the shell (8) comprises a storage area (82) which is arranged at the bottom and used for containing a plurality of letter box assemblies (88), an operation area (81) which is arranged on the front side of the upper portion and used for mounting of selected letter boxes, and a letter box sliding path area (83) arranged on the rear side of the upper portion. A sliding drive assembly (84) extending in the front-and-back direction is arranged in the letter box sliding path area (83) and used for enabling the selected letter boxes to slide in the front-and-back direction. Each of the letter box assemblies (88) comprises a letter box mounting plate (7), lifting drive screws (51) located on the two sides of the letter box mounting plate (7) and a lifting rack (6) driven by the lifting drive screws (51).

Owner:铜陵市恒威包装材料有限公司

Storage-selective and safe building mailbox apparatus

InactiveCN106473566AMeet replacement needsDriver does not affectKitchen equipmentDomestic articlesEngineeringLed illumination

A storage-selective and safe building mailbox apparatus comprises a housing. Internal space of the housing is formed by a storage area mounted on the bottom and capable of accommodating a plurality of mailbox assemblies, an operation area arranged on the front side of the upper part and used for an installation of a selected mailbox, and a mailbox sliding path area arranged on the back side of the upper part, wherein a sliding driving assembly extending back and forth is arranged in the mailbox sliding path area to enable the selected mailbox to slide back and forth; an illuminating light device is disposed in the operation area; the illuminating light device can be utilized for illumination for the operation area upon night or dark natural lights; the illuminating light device is an LED illuminating lamp; each mailbox assembly comprises a mailbox installation plate, elevating driving screw rods arranged on two sides of the mailbox installation plate, and an elevating rack driven by the elevating driving screw rod.

Owner:林浩钊

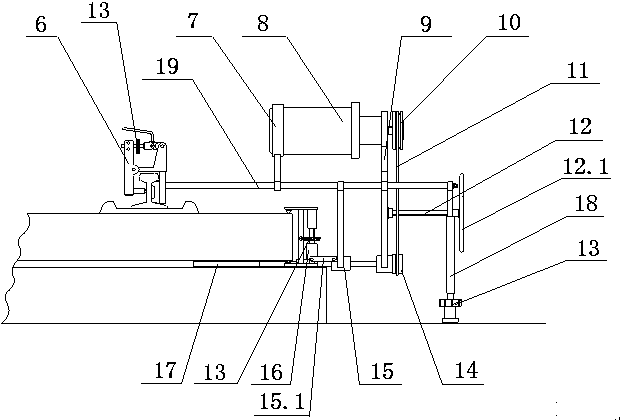

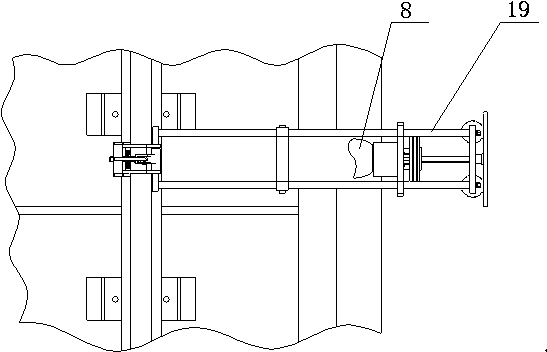

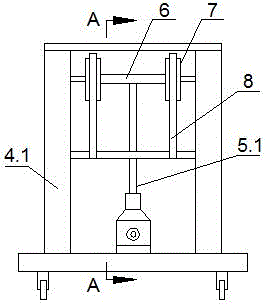

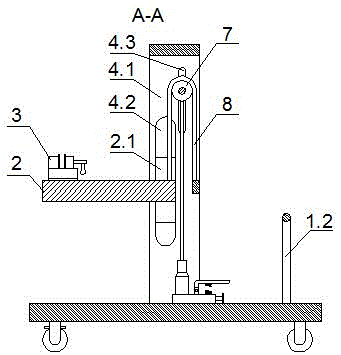

High-speed railway ballastless track mortar layer horizontal drilling machine tool

ActiveCN104213479AAchieve the purpose of correctionMeet the requirements of horizontal drilling constructionRailway track constructionDrive wheelDrilling machines

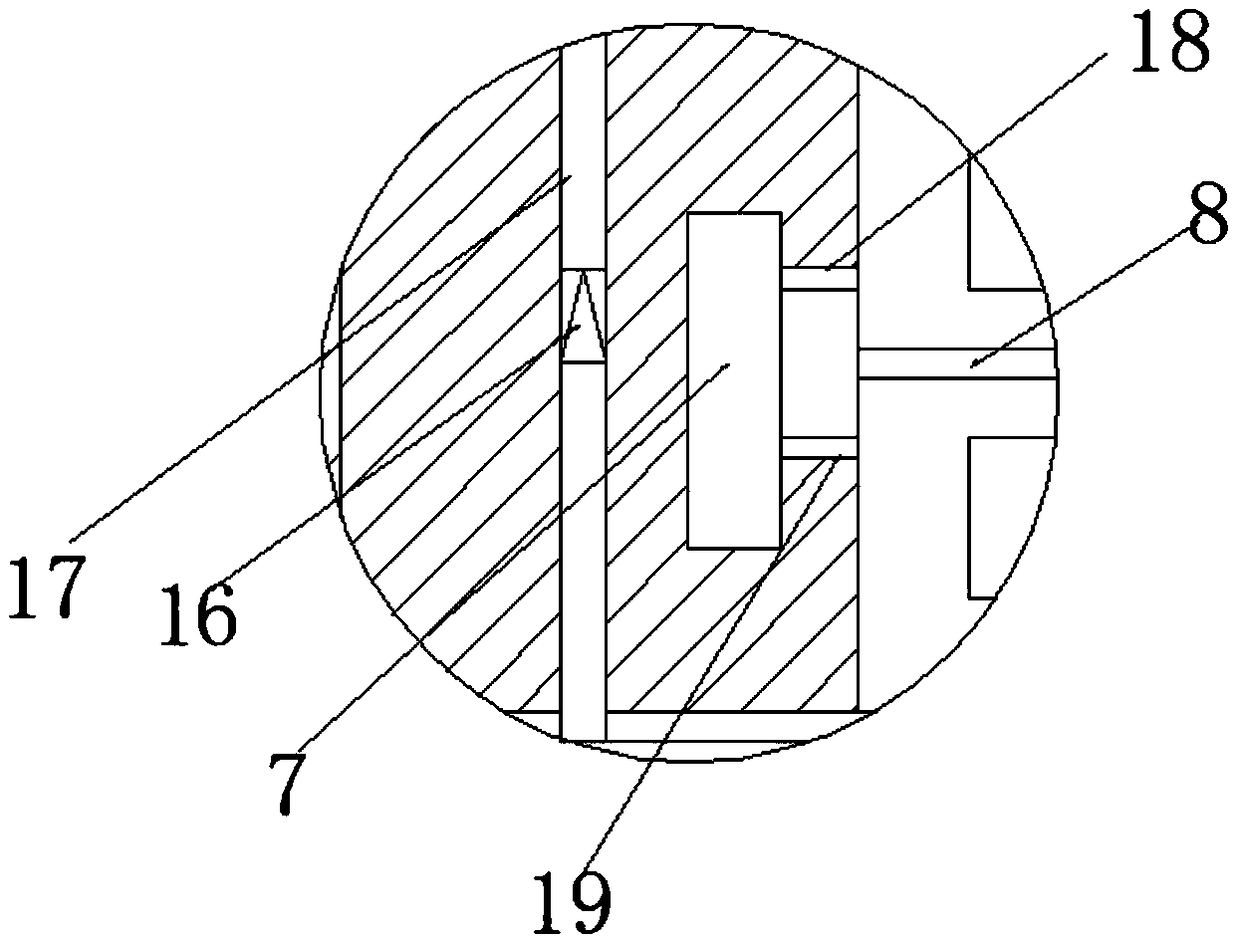

The invention discloses a high-speed railway ballastless track mortar layer horizontal drilling machine tool which comprises an articulation fixed base I (6), a motor left end fixing rack (7), a motor (8), a motor right end fixing rack (9), a driving wheel (10), a driving band (11), a rotating handle (12.1), a driven wheel (14), a drill stem fixing rack (15), an articulation fixed base II (16), a drill rod (17), a bracket (18) and a sliding rod (19). The high-speed railway ballastless track mortar layer horizontal drilling machine tool can be used for horizontally drilling a mortar layer by use of a limited construction space under the condition of not greatly changing a railway major structure, thereby providing a guarantee for subsequent construction and achieving the purpose of correcting a track plate; when in operation, the high-speed railway ballastless track mortar layer horizontal drilling machine tool has the characteristics of simple structure, short readiness time, convenience in operation and control, no region restriction and the like, can be used for performing horizontal drilling operation on the mortar layer under the condition of not damaging major structures, such as the track plate, the base and a bridge, and is capable of improving the stability in operation.

Owner:徐州徐工能源装备有限公司

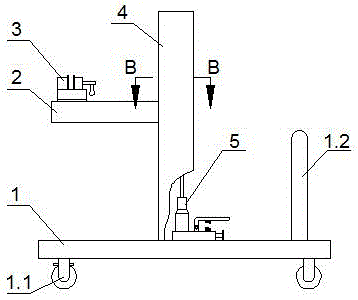

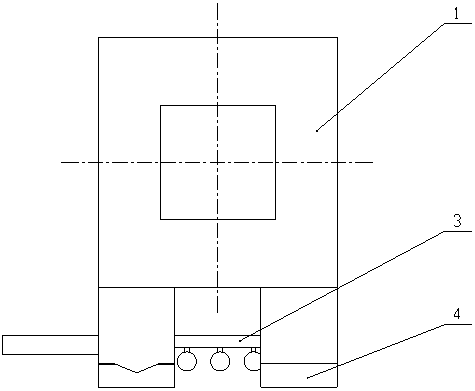

Quick replacement device for furnace roller of thermal treatment furnace

ActiveCN105567936AMeet replacement needsEasy to installFurnace typesHeat treatment furnacesThermal treatmentMechanical engineering

The invention discloses a quick replacement device for a furnace roller of a thermal treatment furnace. The quick replacement device comprises a clamping device, a mobile guide device and a fixed guide device. The clamping device comprises a trolley and a demounting platform fixedly provided with sliding blocks, and a gantry framework is fixed to the trolley. A bench clamp is fixed to the demounting platform. The quick replacement device further comprises a hydraulic jack fixed to the trolley; the hydraulic jack is connected with the demounting platform through a chain and a chain wheel. The mobile guide device comprises a first U-type bolt and a first cross beam in threaded connection with the first U-type bolt. The two ends of the first cross beam are in rolling connection with furnace rollers arranged on two sides of a furnace roller needing to be replaced in an adjacent mode correspondingly. The fixed guide device comprises a second U-type bolt and a second cross beam in threaded connection with the second U-type bolt. The arc section of the second U-type bolt is provided with at least one second idler wheel. The two ends of the second cross beam are fixedly provided with second supporting frames with magnets.

Owner:LAIWU IRON & STEEL GRP

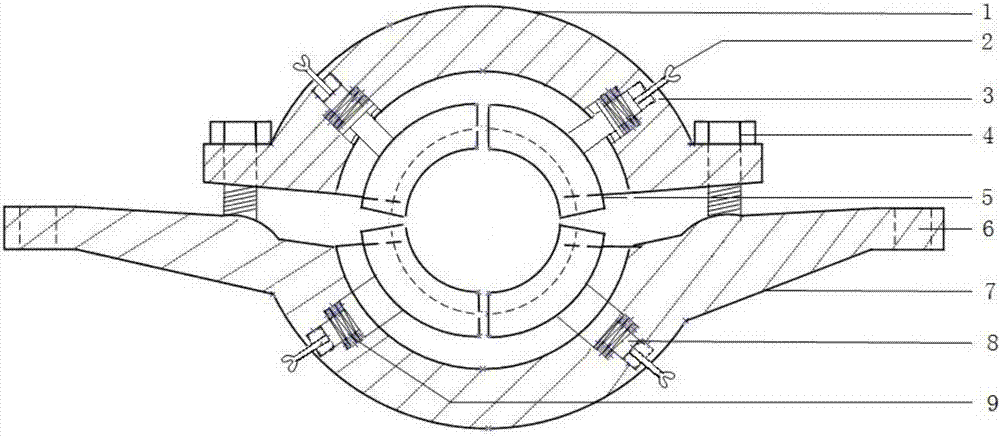

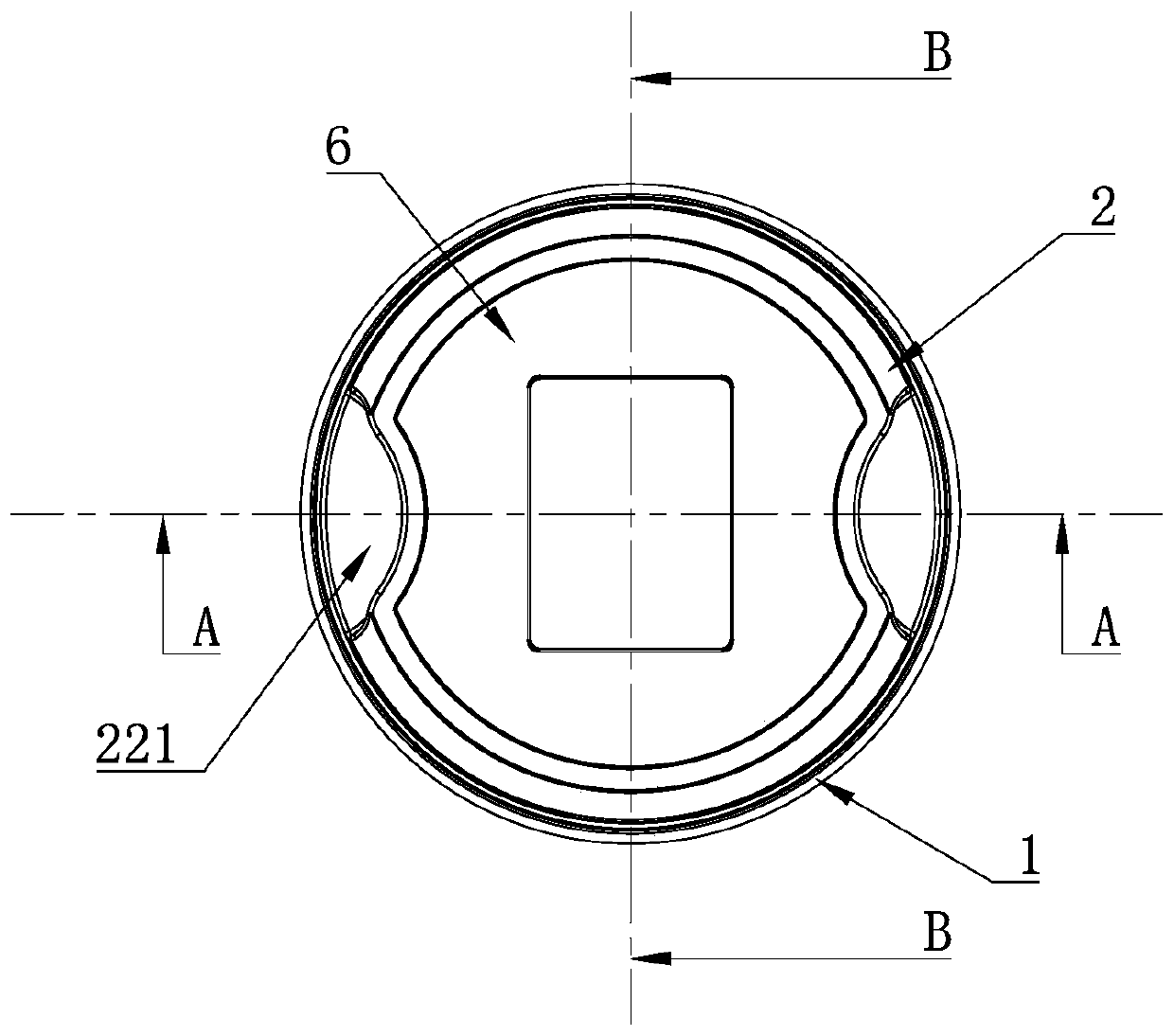

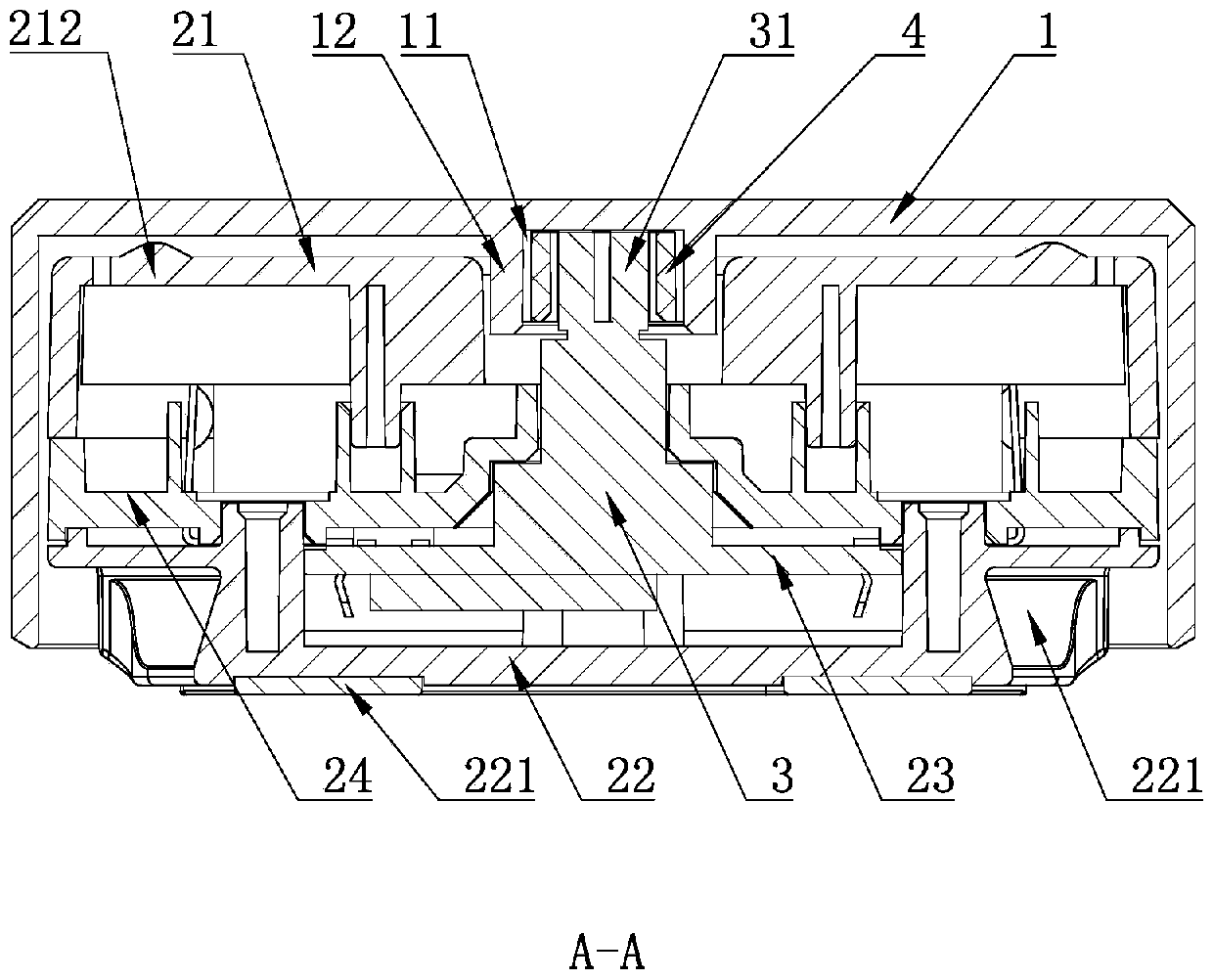

Bridge shock absorber

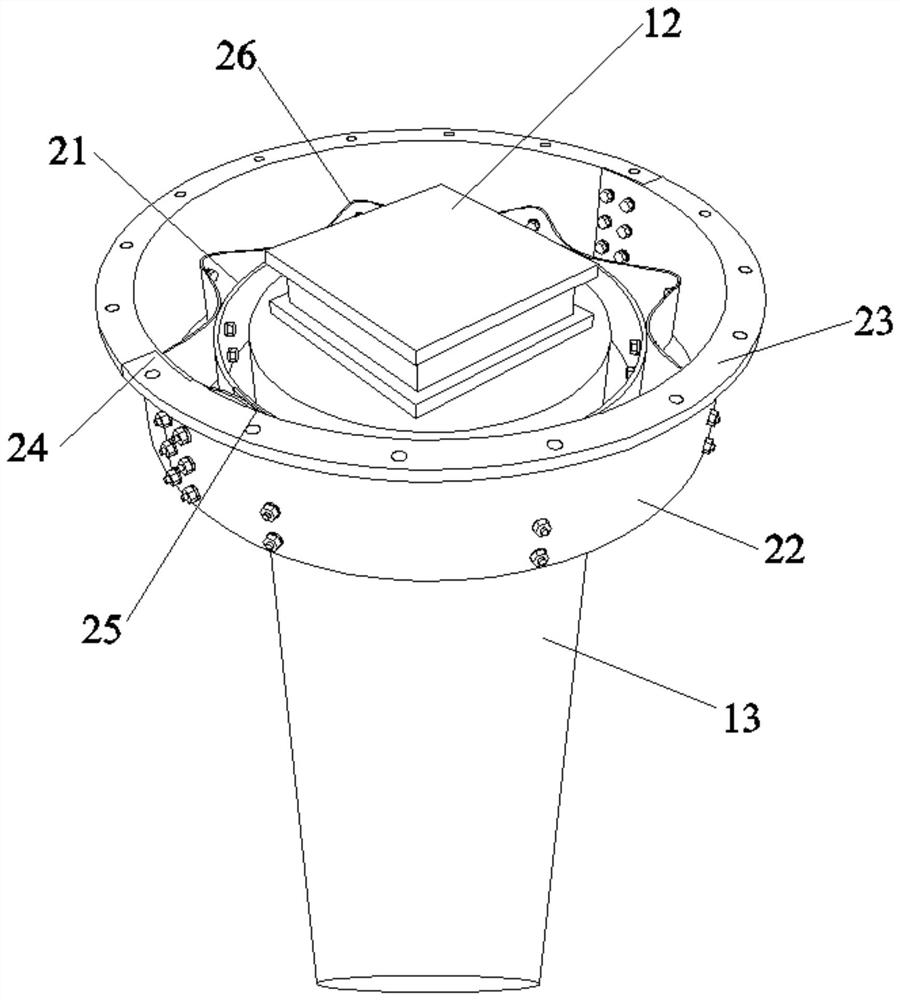

PendingCN112962425AImprove convenienceMeet replacement needsBridge structural detailsArchitectural engineeringContinuous beam

The invention discloses a bridge shock absorber which comprises an inner hoop, an outer hoop, a shock absorption support and a flange ring, and the inner hoop and the outer hoop are each formed by splicing a left semi-arc piece and a right semi-arc piece; the left semi-arc piece of the inner hoop and the left semi-arc piece of the outer hoop are connected into a whole through the shock absorption support; the right semi-arc piece of the inner hoop and the right semi-arc piece of the outer hoop are connected into a whole through the shock absorption support; and the flange ring is vertically fixed to the top end of the outer hoop. The invention discloses a bridge shock absorber which can meet the requirement for support replacement, has a good energy dissipation capacity, can respond to 360-degree displacement of a beam body, enables sliding piers to participate in cooperative shock resistance, is beneficial to preventing the beam body from sliding off and is suitable for new construction and seismic reinforcement of railway bridges, highway bridges, urban viaducts and various continuous beam bridges.

Owner:BEIJING UNIV OF TECH

Building letter box device capable of achieving selectable storage and safe

InactiveCN107259958AMeet replacement needsDriver does not affectKitchen equipmentDomestic articlesMechanical engineeringLed illumination

The invention provides a building letter box device capable of achieving selectable storage and safe. The device comprises a shell. Internal space of the shell comprises a storage region used for containing multiple letter box assemblies and located at the bottom, an operating region used for installation of selected letter boxes and located on the front side of the upper portion, and a letter box sliding path region located on the rear side of the upper portion. Sliding driving assemblies stretching in the front-and-back direction are arranged in the letter box sliding path region and used for enabling the selected letter boxes to slide in the front-and-back direction, a lighting lamp device is arranged in the operating region and used for lighting the operating region at night or in dark natural light, and the lighting lamp device is an LED light lamp. Each letter box assembly comprises a letter box installing plate, lifting driving screws located on the two sides of the letter box installing plate, and a lifting rack driven by the lifting driving screws.

Owner:合肥龙精灵信息技术有限公司

An air purification device capable of replacing filter screens

ActiveCN106422551BMeet replacement needsPlanarity effectDispersed particle filtrationTransportation and packagingAir cleaningEngineering

An air purification device capable of replacing filter screens, comprising a base body (8), wherein the inner space of the base body (8) includes a bottom storage area (82) for accommodating multiple filter screen assemblies (88), an upper The air purification area (81) on the front side for installing the selected filter screen and the filter screen sliding path area (83) on the upper rear side, the filter screen sliding path area (83) is provided with slides extending in the front and rear directions The drive assembly (84) is used to make the selected filter screen slide in the front and back directions; wherein, each of the filter screen assemblies (88) includes a filter screen installation plate (7) and a screen located on the filter screen installation plate (7) The lifting drive screw (51) on both sides and the lifting frame (6) driven by the lifting drive screw (51).

Owner:江西山形环保能源集团有限公司

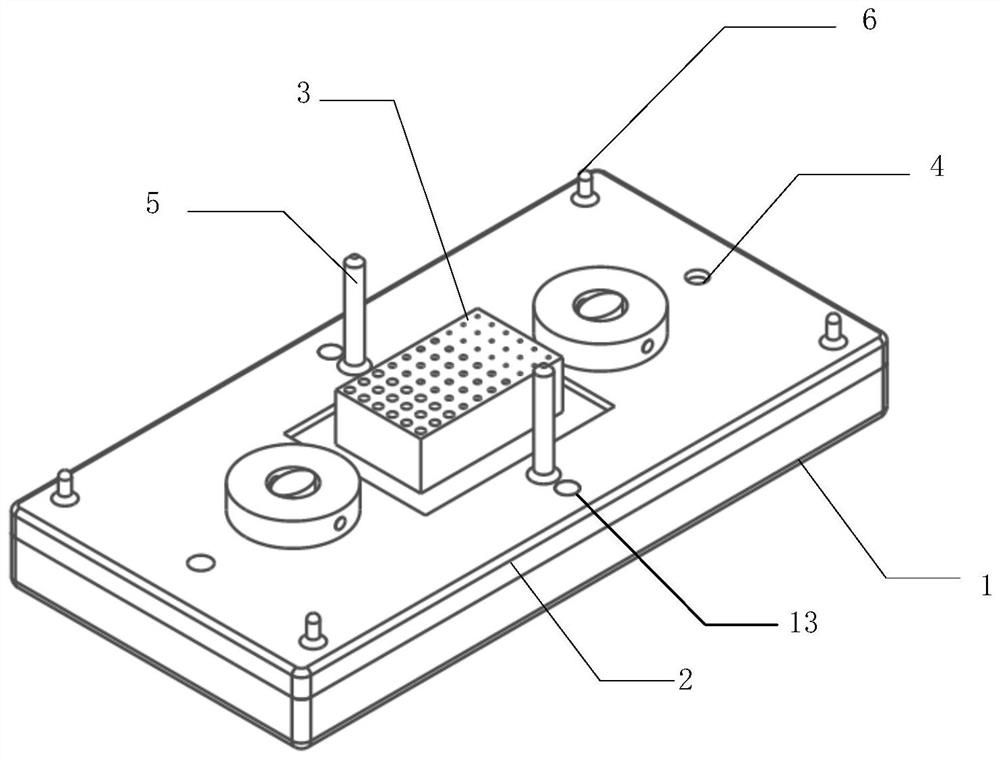

Storied building mailbox device with selective storage function

ActiveCN106377148AReduce the area occupied by public activitiesImprove securityKitchen equipmentDomestic articlesMechanical engineering

The invention provides a storied building mailbox device with a selective storage function. The storied building mailbox device with the selective storage function comprises a casing (8), wherein the inside space of the casing (8) comprises a storage region (82), an operation region (81) and a mailbox sliding path region (83), wherein the storage region (82) is arranged at the bottom and is used for accommodating a plurality of mailbox assemblies (88); the operation region (81) is arranged at the front side of the upper part and is used for installing the selected mailbox; the mailbox sliding path region (83) is arranged at the back side of the upper part; a sliding driving assembly (84) which extends in the front and back directions is arranged in the mailbox sliding path region (83) and is used for enabling the selected mailbox to upward slide in the front and back direction, wherein each mailbox assembly (88) comprises a mailbox installing plate (7), ascending and descending driving screw rods (51) and an ascending and descending machine frame (6); the ascending and descending driving screw rods (51) are positioned at the two sides of the mailbox installing plate (7); the ascending and descending machine frame (6) is driven by the ascending and descending driving screw rods (51).

Owner:铜陵市恒威包装材料有限公司

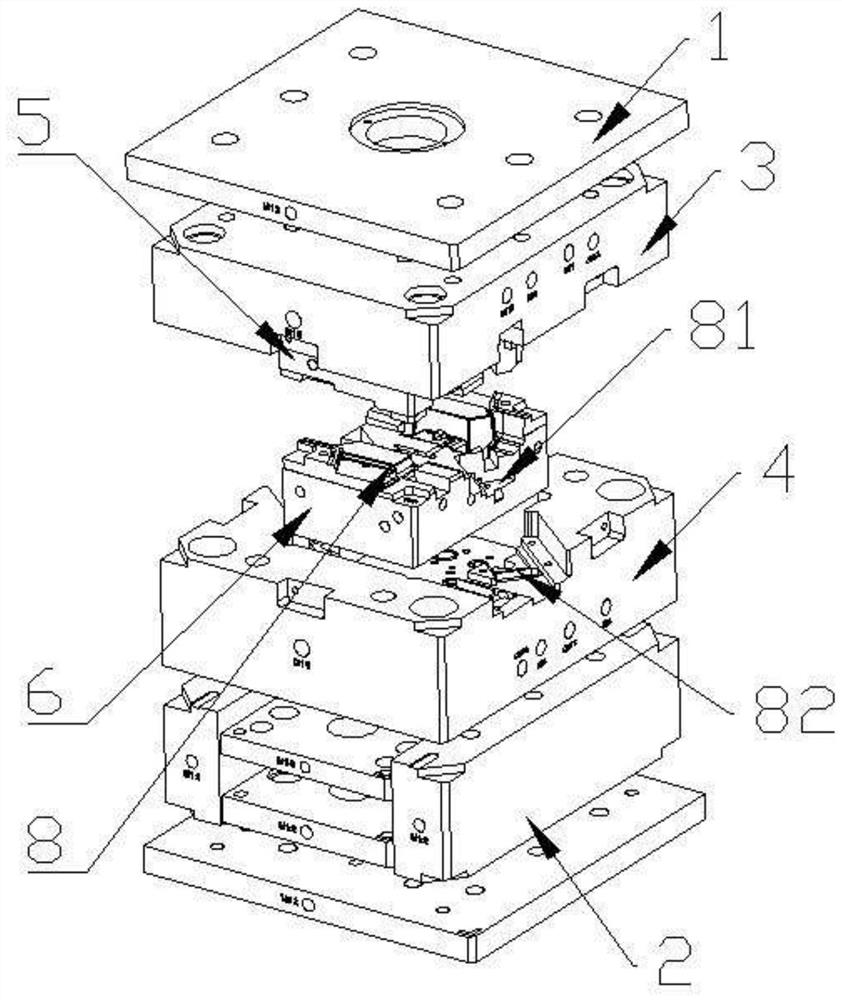

Injection mold frame matched with inclined top

The invention discloses an injection mold frame matched with an inclined top. The injection mold frame comprises a top mold frame and a bottom mold frame; a top mold base is arranged on the top mold frame; a bottom mold base is arranged on the bottom mold frame; a top mold core is arranged on the top mold base; a bottom mold core is arranged on the bottom mold base; two bottom mold core injectionmolding stations are arranged on the bottom mold core; each bottom mold core injection molding station at least comprises an inclined top movable mold block; an inclined top cavity groove is formed ineach bottom mold core injection molding station; an inclined top matching cavity groove is formed in the bottom mold base; each inclined top cavity groove and the inclined top matching cavity grooveare spliced to form a guide sliding groove; a top mold core injection molding station is arranged on the top mold core; an avoiding guide groove is formed in the top mold core injection molding station; and an inclined top driving block is arranged on the top mold base. According to the injection mold frame, the design that the guide groove is spliced by the mold base and the mold core is adopted,the size of the mold core is reduced, guide driving of the movable mold block is easy to achieve, the cost of the injection mold frame is reduced, and the mold core replacement requirements of products in different specifications are met. The injection mold frame is provided with a pneumatic pin telescopic structure, the demolding matching requirement of the specific tubular buckling end can be met, and the design is ingenious.

Owner:昆山机器人模具科技有限公司

In-situ monitoring method for crevice corrosion

InactiveCN112014307AMeet replacement needsSimple processWeather/light/corrosion resistanceElectrolytic agentMechanical engineering

The invention provides an in-situ monitoring method for crevice corrosion. The method comprises the following steps of: 1) taking a tank body; (2) taking a bottom plate, installing a working electrode, detachably connecting the bottom plate to a bottom plate base, and horizontally placing the bottom plate in the tank body; 3) taking a cover plate, installing a micro pH electrode, connecting one side of the cover plate with a vertical moving mechanism, and connecting the other side of the cover plate with a horizontal moving mechanism, making the cover plate arranged above the bottom plate andparallel to the bottom plate; adjusting the vertical displacement of the cover plate, and adjusting the horizontal displacement of the cover plate; 4) injecting an electrolyte, suspending a referenceelectrode and a counter electrode, and connecting an electrochemical workstation; 5) hanging a constant-temperature heater and adjusting experiment temperature, (6) adjusting the vertical displacementand / or the horizontal displacement of the cover plate and / or the temperature of the constant-temperature heater again and / or replacing the bottom plate and / or replacing the working electrode on the bottom plate; and (7) repeating the step (6) multiple times to obtain an experiment result. The method is simple, convenient to operate, accurate and reliable in result and high in guidance.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +2

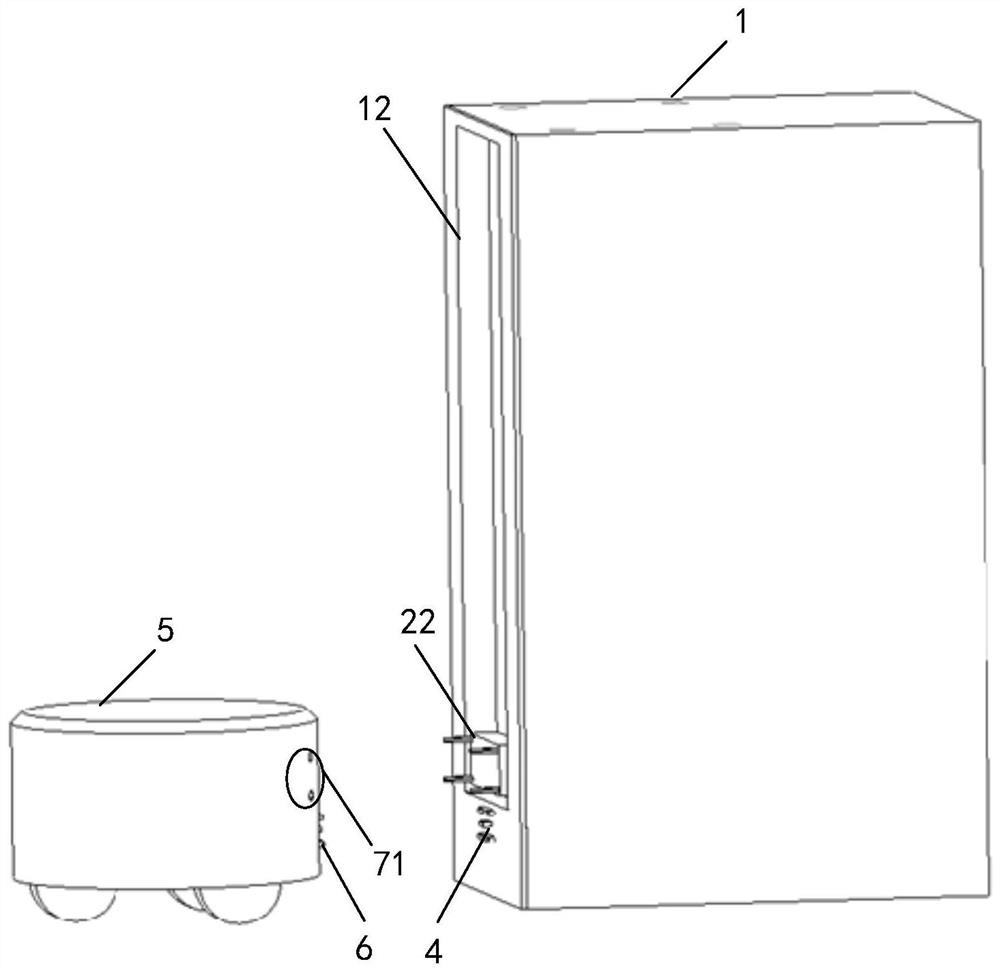

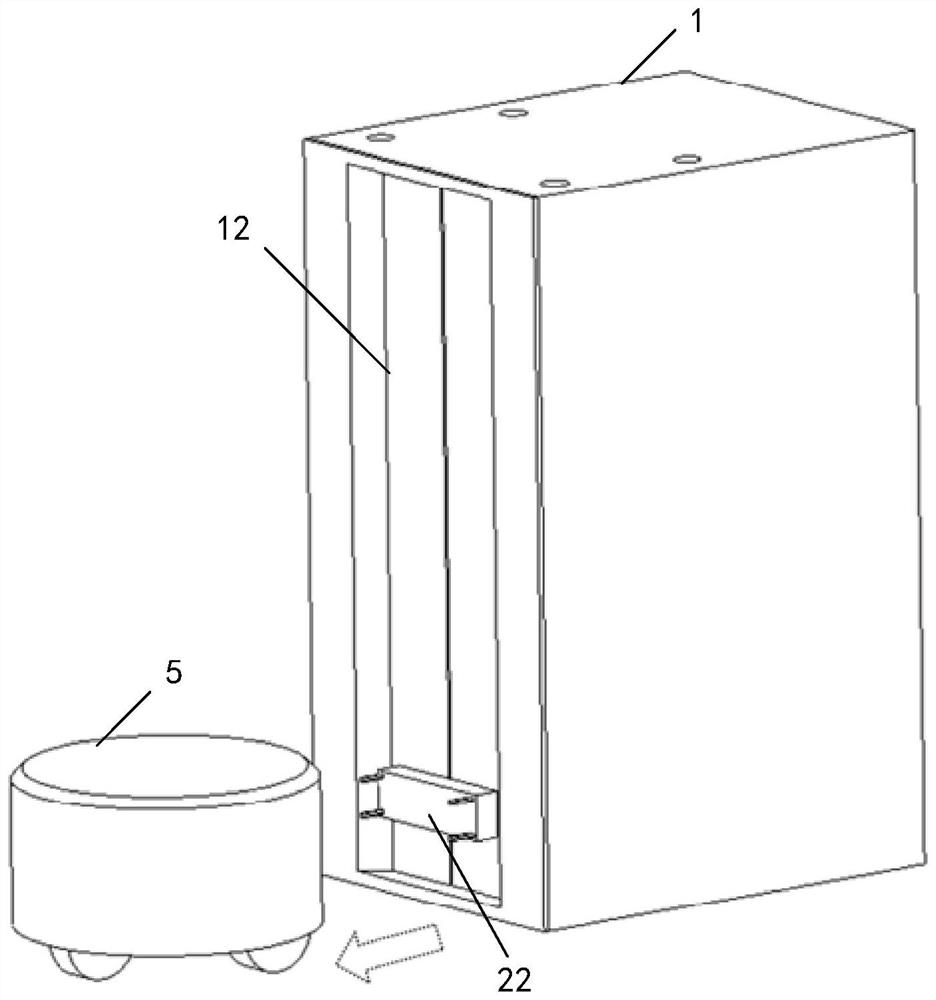

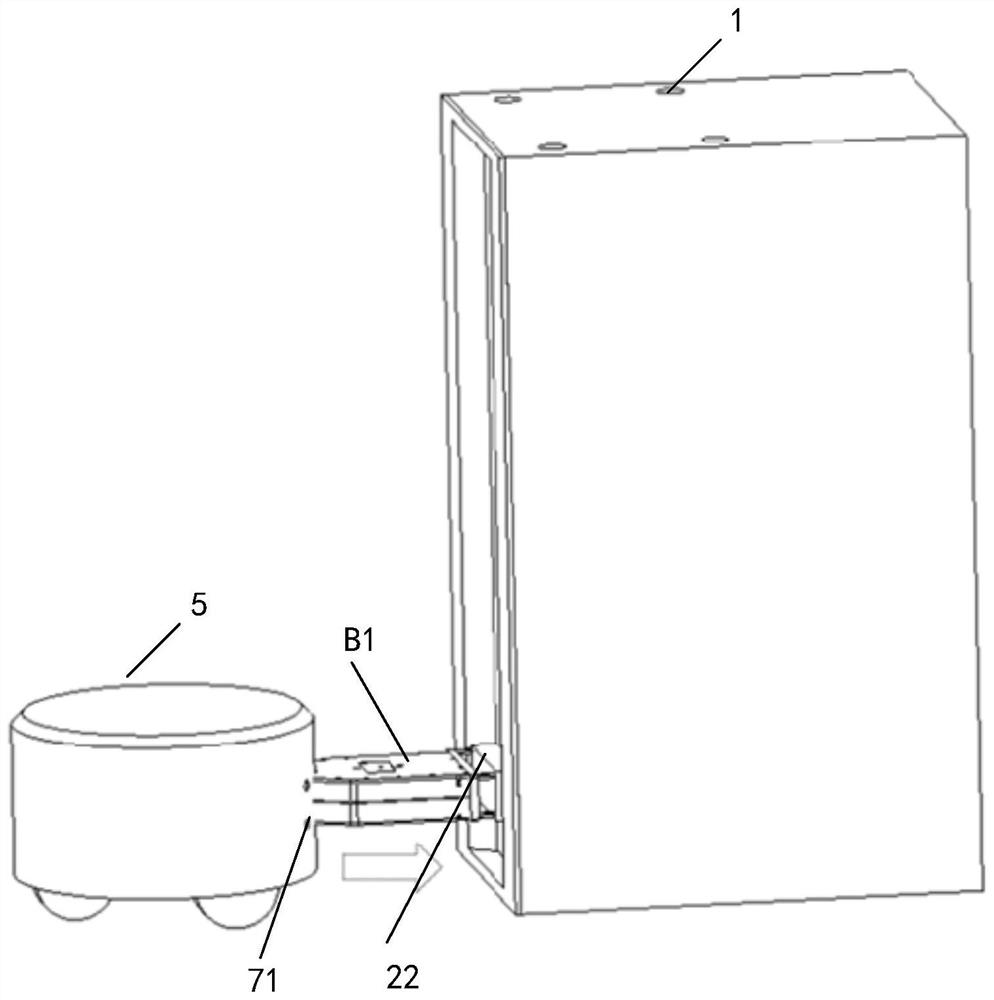

Robot battery replacing method and robot battery replacing station

PendingCN114290947AShorten the timeMeet replacement needsCharging stationsVehicular energy storageControl engineeringBattery cell

The embodiment of the invention relates to the field of robots, and discloses a robot battery replacing method and a robot battery replacing station. The robot battery swap station comprises a battery swap cabinet, an operation table arranged in the battery swap cabinet and a plurality of battery jars, and the battery swap cabinet is further provided with a first charging interface for supplying power to a robot. The operation table carries out battery replacement operation on the robot close to the battery replacement cabinet, specifically, the operation table takes a first battery from the robot, the first battery is placed in an idle battery jar, a second battery is taken out from the other battery jar, and the second battery is installed on the robot; and in the battery replacement operation process, the first charging interface is in butt joint with a second charging interface of the robot to supply power to the robot. According to the scheme, the battery can be replaced while a power supply is provided for the robot, so that the robot does not need to interrupt tasks in the battery replacement process, and the robot can quickly recover to work in a short time.

Owner:CLOUDMINDS SHANGHAI ROBOTICS CO LTD

Rotary remote controller for lifting platform and control method thereof

PendingCN109903543AInhibit sheddingFirmly connectedTransmission systemsInterference fitElectrical battery

The invention discloses a rotary remote controller for a lifting platform. The remote controller includes a base, an encoder arranged on the base and a turn button in rotation connection with the basethrough the encoder, wherein the encoder includes an input shaft, an elastic connection member is connected between the input shaft and the turn button, the elastic connection member is in interference fit with the input shaft and the turn button, the elastic connection member is in interference fit with the encoder and the turn button, the turn button is prevented from spontaneously falling offthe encoder while the turn button is turned and pressed, so connection between the encoder and the turn button is made to be more stable. When a cell is replaced, only pulling the turn button with force from the base is needed to replace the cell, requirements for firmly mounting the remote controller and replacing the cell can be both met through the structure, and the remote controller is more convenient to use. The invention further provides a control method of the rotary remote controller for the lifting platform, and the control method is more convenient to use.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Shooting training device easy to replace shooting target and smooth in operation

The invention relates to a shooting training device easy to replace a shooting target and smooth in operation. The shooting training device comprises a housing, wherein the inner space of the housing comprises a bottom storage area which is used for containing a plurality of shooting target assemblies, an upper front display area which is used for displaying a selected shooting target and an upper back shooting target sliding path area, a sliding driving assembly which extends in a forward and backward direction and is used for enabling the selected shooting target to slide in the forward and backward direction is arranged in the shooting target sliding path area, a floodlight device is arranged in the display area and is used for illuminating the display area at night or when natural light is dark, the floodlight device is an LED (Light Emitting Diode) floodlight, and each shooting target assembly comprises a shooting target mounting plate, lifting driving screws located on both sides of the shooting target mounting plate and a lifting support frame driven by the lifting driving screws.

Owner:范爱苏

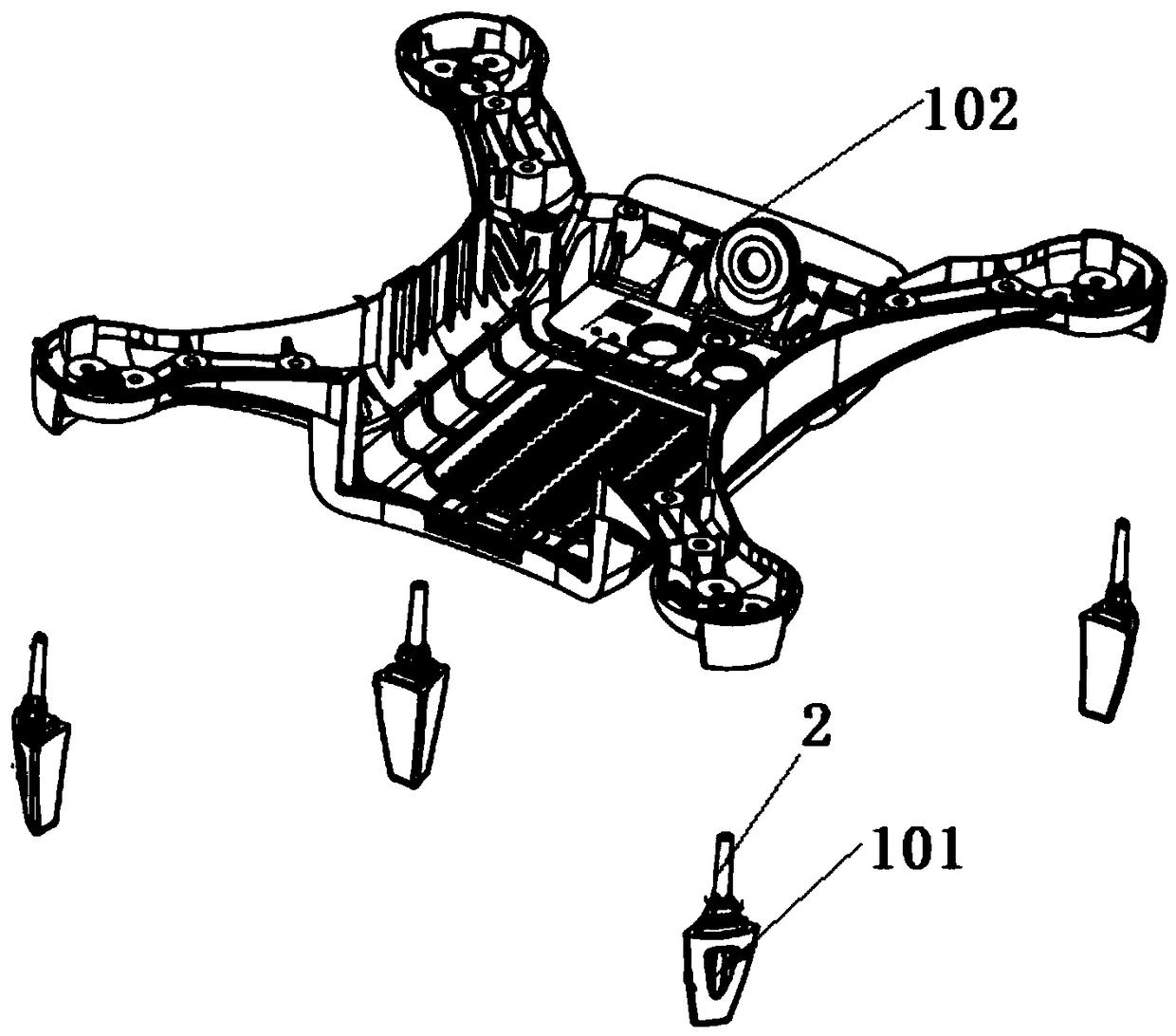

Unmanned aerial vehicle with buffering function

InactiveCN109305343AExtended service lifeNot easy to damageAlighting gearMultiple bufferingUncrewed vehicle

The invention relates to the field of unmanned aerial vehicles, specifically to an unmanned aerial vehicle with a buffering function. The unmanned aerial vehicle with the buffering function comprisesan unmanned aerial vehicle main body; multiple buffering supporting feet are arranged at the lower end of the unmanned aerial vehicle main body; the buffering supporting feet comprise rubber main springs; the rubber main springs are connected with the unmanned aerial vehicle main body; rigid sleeves are connected to the rubber main springs; and rubber supports are connected to one ends, far away from the rubber main springs, of the rigid sleeves. The invention discloses an unmanned aerial vehicle structure with the buffering function; and the multiple buffering supporting feet are arranged onthe unmanned aerial vehicle. By arranging the buffering supporting feet, the influence of an impact force on components in the unmanned aerial vehicle during the landing of the unmanned aerial vehiclecan be reduced, and the service life of the unmanned aerial vehicle can be prolonged; and meanwhile, the unmanned aerial vehicle is not likely to be damaged when suffering a higher impact force, andtaking-off and landing demands of the unmanned aerial vehicle are met; as a supporting mechanism is replaceable, a replacing demand is met; and the structure is simple and skillful, and the implementation, popularization and application are easy to realize.

Owner:芜湖民星信息科技有限公司

Stop-free valve electric actuator replacing method, debugging assembly and electric actuator

PendingCN113685601AAccelerateEasy to set upOperating means/releasing devices for valvesControl engineeringVALVE PORT

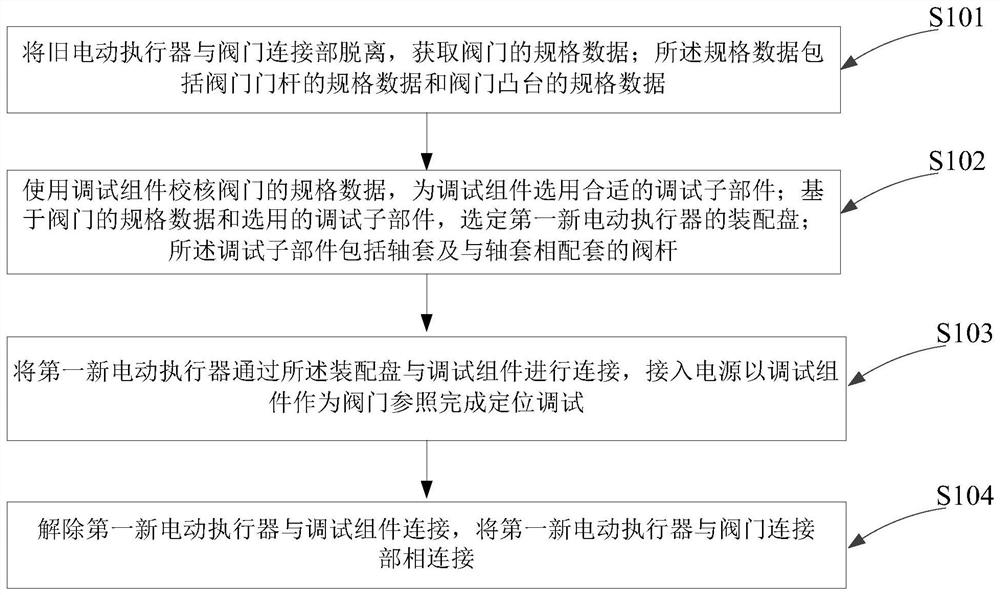

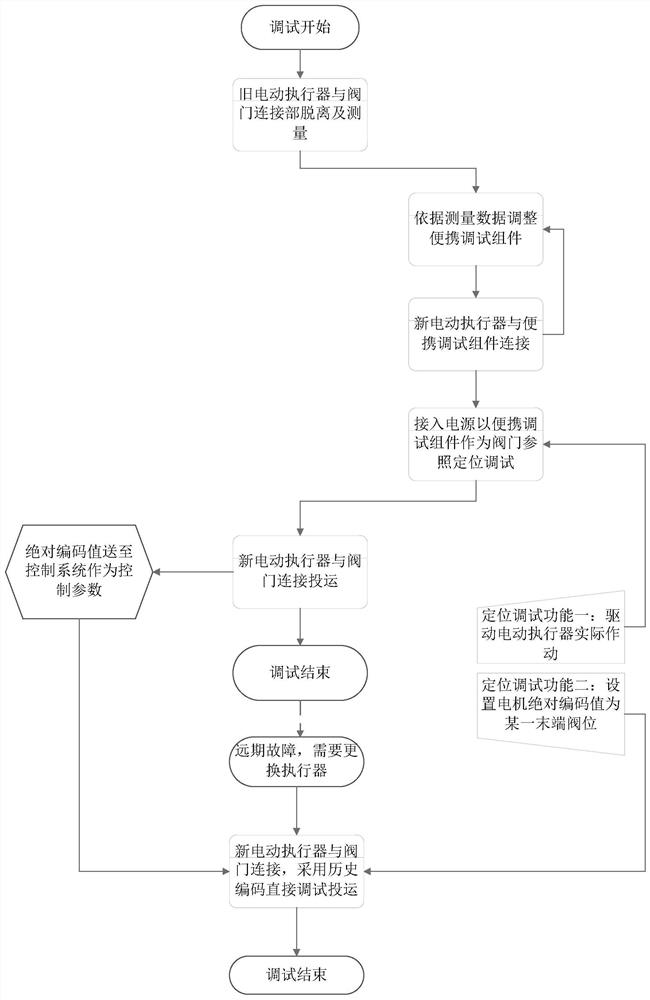

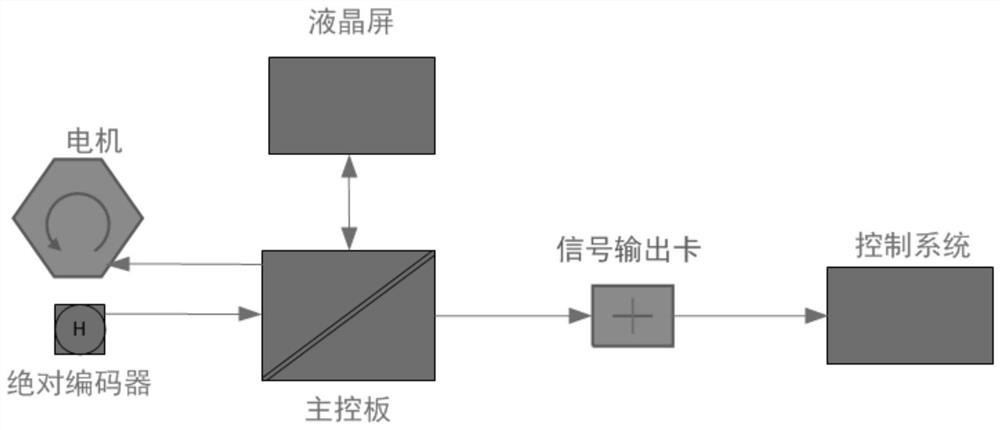

The invention discloses a stop-free valve electric actuator replacing method, a debugging assembly and an electric actuator. The method comprises the steps that an old electric actuator is separated from a valve connecting part, and specification data of a valve are obtained; the specification data comprise specification data of a valve rod and specification data of a valve boss; the specification data of the valve are checked through the debugging assembly, and a proper debugging sub-component is selected for the debugging assembly; an assembly disc of a first new electric actuator is selected on the basis of the specification data of the valve and the selected debugging sub-component; the debugging sub-component comprises a shaft sleeve and a valve rod matched with the shaft sleeve; the first new electric actuator is connected with the debugging assembly through the assembly disc, a power source is connected, and positioning debugging with the debugging assembly as a valve reference is completed; and the connection between the first new electric actuator and the debugging assembly is removed, and the first new electric actuator is connected with the valve connecting part. According to the stop-free valve electric actuator replacing method, replacement of the valve electric actuator can be achieved under the condition that a production system is not stopped.

Owner:XIAMEN HUAXIA INT POWER DEV +1

Jet type fuse insulation operating rod

The invention relates to an insulated operating rod of a jet fuse, and the operating rod comprises an insulated pull rod and is characterized by further comprising an extension tube and a clamping joint; the extension tube is mounted at the upper part of the insulated pull rod in a threaded manner, and the clamping joint is mounted at the upper end of the extension tube in a threaded manner; the clamping connector is mainly composed of a barrel, clamping arc plates, holding teeth and clamping jaws, the clamping arc plates which are oppositely arranged at intervals are arranged on the upper end face of the barrel, mounting openings are formed in the barrel wall, under the two clamping arc plates, of the barrel, the holding teeth are mounted in the mounting openings through first torsion springs, and the clamping jaws are connected with the clamping arc plates. clamping jaws are mounted on the inner wall of the cylinder body below the holding teeth through second torsion springs; and the torsion of the first torsion springs is greater than that of the second torsion springs. The injection type fuse insulating pull rod is scientific and reasonable in design, has the advantages of being high in universality, convenient to install, capable of improving installation efficiency and easy to achieve, and has high innovativeness.

Owner:JINGHAI ELECTRIC POWER SUPPLY COMPANY OF STATE GRID TIANJIN ELECTRIC POWER +1

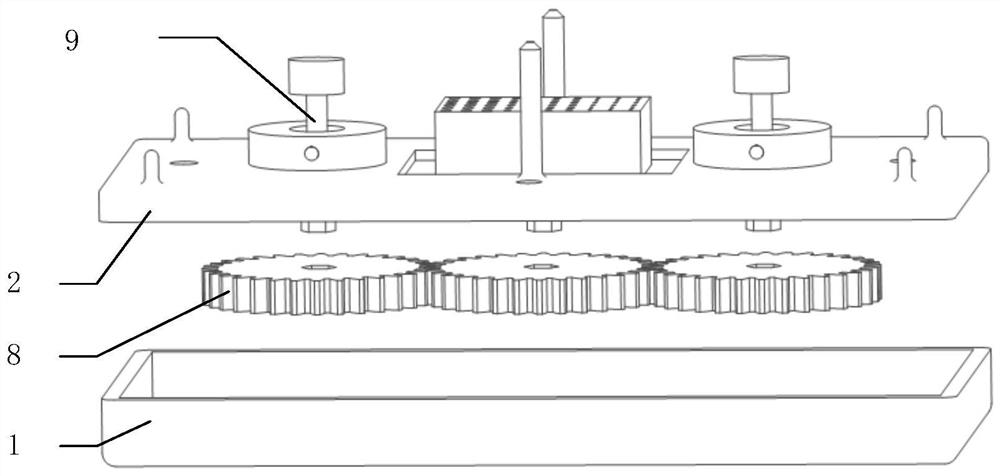

Public roll stand device convenient and rapid to select to change

ActiveCN106473651AMeet replacement needsReduce waiting timeDomestic applicationsInterior spaceEngineering

A public roll stand device convenient and rapid to select to change comprises a casing, wherein the internal space of the casing comprises a storage area, an operating area and a roll stand sliding path area; the storage area is positioned at the bottom and is used for accommodating a plurality of roll stand assemblies; the operating area is positioned on the front side of the upper part and is used for mounting the selected roll stand; the roll stand sliding path area is positioned on the back side of the upper part; a sliding driving assembly which extends in a forward and backward direction is arranged in the roll stand sliding path area and is used for enabling the selected roll stand to slide in the forward and backward direction; a lighting lamp device is arranged in the operating area and is used for lighting the operating area at night or when the natural light is dark; the lighting lamp device is an LED lighting lamp; each of the plurality of roll stand assemblies comprises a roll stand mounting frame, a lifting driving screw rod positioned on the two sides of the roll stand mounting plate, and a lifting machine frame driven by the lifting driving screw rod.

Owner:福州市长乐区长胜信息技术有限公司

Adapter mechanism

ActiveCN109969429AAvoid direct assembly on railSimple designCosmonautic vehiclesCosmonautic partsEngineeringComputer module

The invention discloses an adapter mechanism, comprising a case, a base plate, an interface, electric bolt holes and a position-fixing mechanism, wherein the case is a hollow structure which is provided with an opening at one end; the base plate is arranged at the opening of the case; the case and the base plate form an intelligent insertion plate main body; a storage space is arranged in the intelligent insertion plate main body; the interface is arranged on the base plate; the electric bolt holes are arranged on the base plate; and the position-fixing mechanism is arranged on the base plate.Compared with the prior art, the adapter mechanism solves the problem that a single machine module is generally assembled onto a satellite platform only on the ground and can not be directly assembled onto a satellite through on-orbit insertion and extraction due to the complicated mechanical, electrical and thermal connection relation between the single machine module and the satellite. The adapter mechanism for on-orbit replacement of the single machine module provided by the invention changes an on-orbit replacement problem of the single machine module into a replacement problem of a combination of the adapter mechanism and the healthy single machine module, thereby avoiding the on-orbit direct assembly of the single machine module and facilitating the engineering implementation of theon-orbit replacement of the single machine module.

Owner:SHANGHAI SATELLITE ENG INST

Transfer mechanism

ActiveCN109969429BAvoid direct assembly on railMeet replacement needsCosmonautic vehiclesCosmonautic partsTransfer mechanismSatellite bus

The switching mechanism of the present invention includes: a housing, the housing is a hollow structure with an opening at one end; a base plate, the base plate is arranged at the opening of the housing, the housing and the base plate form the main body of the smart plug-in board, and an object is arranged in the main body of the smart plug-in board space; an interface, the interface is set on the base plate; an electric bolt hole, the electric bolt hole is set on the base plate; a positioning mechanism, the positioning mechanism is set on the base plate. Compared with the prior art, the present invention has the following advantages: due to the complicated mechanical, electrical and thermal connections between the stand-alone module and the satellite, usually the stand-alone module and the satellite platform can only be assembled on the ground, and cannot be directly assembled to the satellite platform through on-orbit plugging and unplugging. on the satellite. The present invention provides a transfer mechanism for on-rail replacement of single-machine modules, which converts the problem of on-rail replacement of stand-alone modules into the replacement problem of the combination of the transfer mechanism and healthy single-machine modules, and avoids the direct on-rail replacement of single-machine modules. Assembly is beneficial to the engineering realization of on-orbit replacement of stand-alone modules.

Owner:SHANGHAI SATELLITE ENG INST

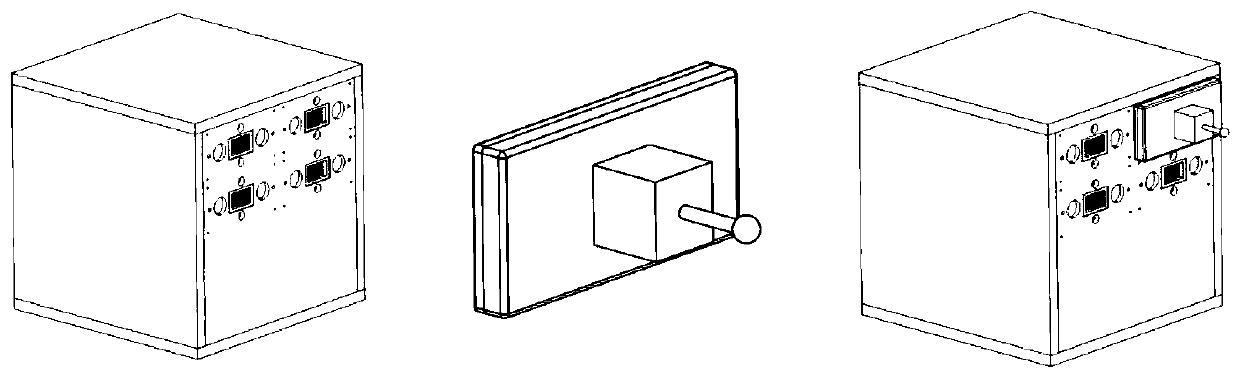

An air purification device capable of replacing the filter screen and having a stable structure

ActiveCN106403249BMeet replacement needsPlanarity effectMechanical apparatusLighting and heating apparatusEngineeringAir purification

The invention discloses an air purifying device with a replaceable filter screen and being stable in structure. The air purifying device comprises a substrate (8), wherein the inner space of the substrate (8) comprises a storage area (82) which is located at the bottom part and is used for allowing a plurality of filter screen assemblies (88) to be accommodated, an air purifying area (81) which is located on the upper front side and is used for allowing a selected filter screen to be mounted, and a filter screen sliding path area (83) on the upper rear side; slide driving assemblies (84) extending in a front-rear direction are arranged in the filter screen sliding path area (83), and are used for enabling the selected filter screen to slide in the front-rear direction; and each of the filter screen assemblies (88) comprises a filter screen mounting plate (7), elevating driving screw rods (51) located on the two sides of the filter screen mounting plate (7), and elevator frames (6) driven by the elevating driving screw rods (51).

Owner:武汉昱然智能科技有限公司

A stable shooting training device that is easy to replace shooting targets

The invention discloses a stable shooting training device easy to replace shooting targets. The device comprises a shell (8), wherein internal space of the shell (8) includes a storage area (82) at the bottom for accommodating multiple shooting target modules (88), a display area (81) on the front side of the upper part for displaying selected shooting targets, and a shooting target slide path area (83) on the back side of the upper part; a slide driving module (84) extending in the front-back direction is arranged in the shooting target slide path area (83) for sliding the selected shooting targets in the front-back direction; and each of the multiple shooting target modules (88) includes a shooting target mounting plate (7), lift driving screw rods (51) positioned on two sides of the shooting target mounting plate (7), and lift support frames (6) driven by the lift driving screw rods (51).

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

A selectable and replaceable public roll holder device

ActiveCN106388670BMeet replacement needsReduce waiting timeDomestic applicationsPulp and paper industryLed illumination

Provided is a public paper roll device capable of optional replacement. The public paper roll device includes a shell, wherein, the inside space of the shell includes a bottom storage area used to withhold a plurality of paper roll frame components, an upper front operation area used to install the selected paper roll frame and an upper back side sliding route area for paper roll frame, a sliding and driving component that extends along the front and back direction is placed in the sliding route area of the paper roll frame and is used to make the selected paper roll frame to slid along the front and back direction, a lighting lamp device is placed in the operation area, the lighting lamp device is used for lighting use during the night or when the natural light is dim, the lighting lamp device is an LED lighting lamp; wherein, each of the plurality of paper roll frame components includes a paper roll installation board, and a lifting and driving screw rod located on two sides of the paper roll installation board, and a lifting body frame driven by the lifting and driving screw rod.

Owner:南陵县生态旅游资产运营有限公司

A method for replacing a wind tunnel test section

ActiveCN108896267BQuick changeSafe replacementAerodynamic testingMode of transportMarine engineering

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

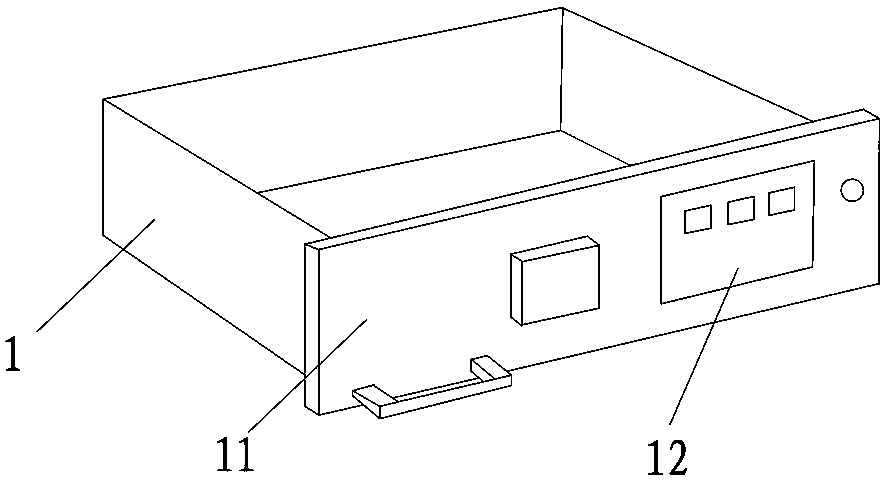

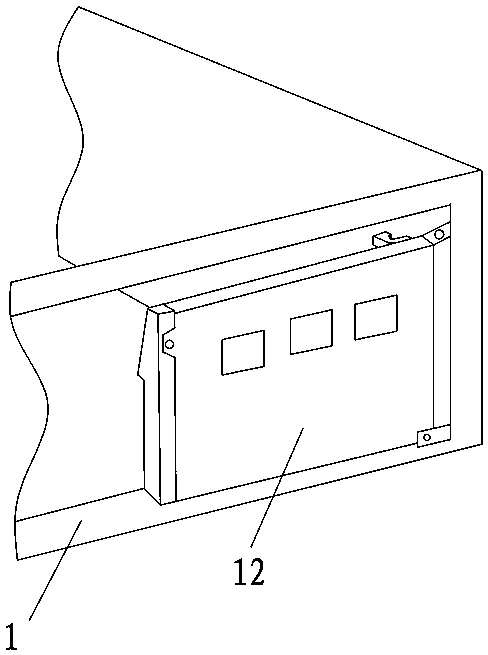

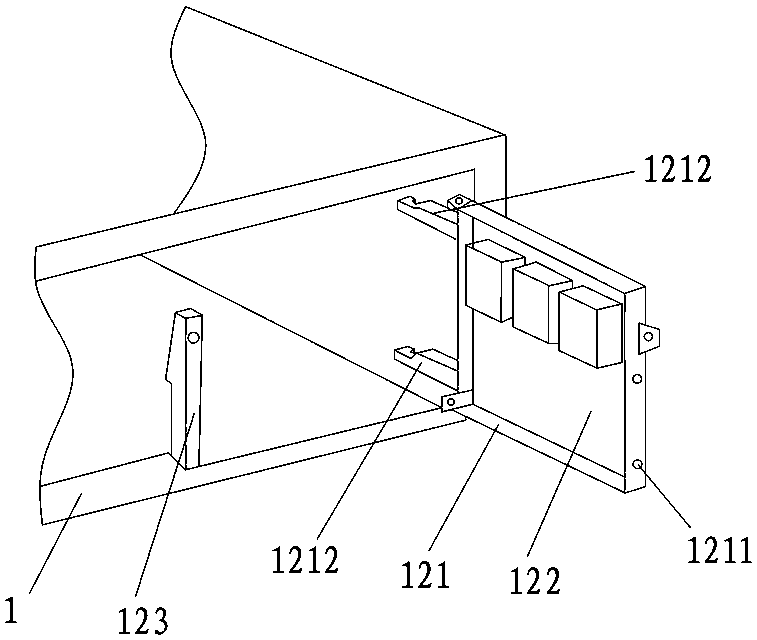

A drawer type switch cabinet

ActiveCN105305282BOpen flexibleClose flexibleSubstation/switching arrangement detailsSwitchgear with withdrawable carriageElectronic componentFront panel

The invention discloses a drawer type switch cabinet. The drawer type switch cabinet comprises a drawer body provided with electronic components; an observation window is formed at the movable front panel of the drawer body; the drawer body is provided with a movable multi-functional board assembly for mounting multi-functional meters and signal lamps; and the movable multi-functional board assembly is hinged to the drawer body. The drawer type switch cabinet of the invention has the advantages of simple structure, convenient operation and flexible movement. The multi-function board of the drawer type switch cabinet can be replaced, and therefore, device installation and maintenance can be facilitated.

Owner:ZHUZHOU CSR ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com