Stop-free valve electric actuator replacing method, debugging assembly and electric actuator

A technology for electric actuators, replacement methods, applied in the direction of engine components, valve details, valve devices, etc., to achieve the effects of speeding up, portability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

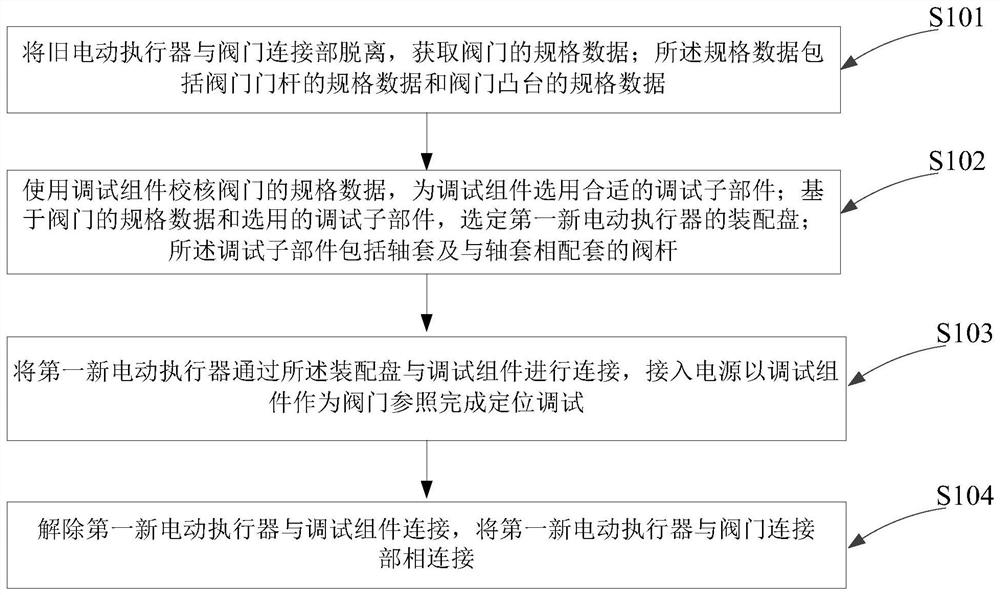

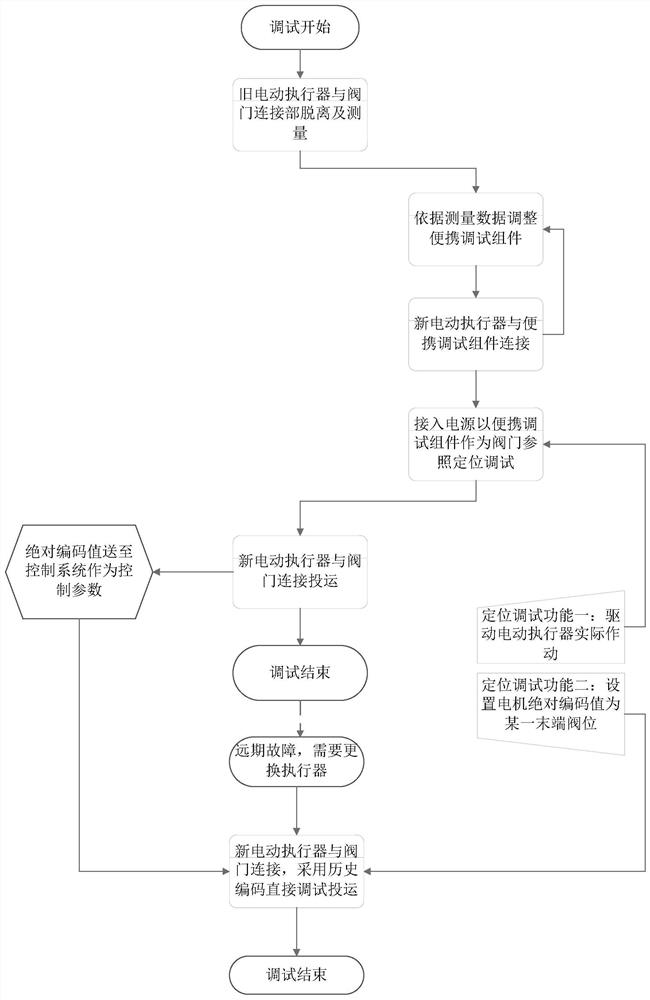

[0052] see figure 1 and figure 2 As shown, a replacement method of valve electric actuator without shutdown, including:

[0053] S101, disengage the old electric actuator from the valve connection part, and obtain the specification data of the valve; the specification data includes the specification data of the valve stem and the specification data of the valve boss;

[0054] S102, use the debugging component to check the specification data of the valve, and select a suitable debugging sub-component for the debugging component; based on the specification data of the valve and the selected debugging sub-component, select the assembly plate of the first new electric actuator; the debugging sub-component The components include the shaft sleeve and the valve stem matched with the shaft sleeve;

[0055] S103, connect the first new electric actuator with the debugging component through the assembly plate, connect the power supply and use the debugging component as a valve referen...

Embodiment 2

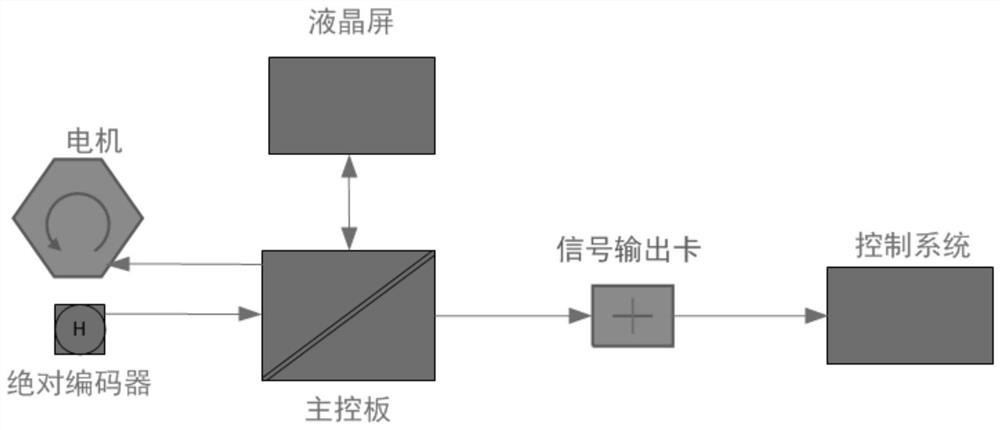

[0089] see image 3 As shown, an electric actuator includes a LCD screen, a main control board, a motor, an absolute encoder and a signal output card;

[0090] The liquid crystal screen is used to receive the input absolute code value corresponding to the valve positions at both ends of the valve, and send the absolute code value to the main control board;

[0091] The main control board is used to receive the absolute code value corresponding to the valve positions at both ends of the valve sent by the liquid crystal screen, and control the motor to rotate;

[0092] The absolute encoder is used to detect the amount of rotation of the motor, and output serial port signals or other electrical signals to the main control board;

[0093] The main control board is also used to send the serial port signal or other electrical signals to the signal output card;

[0094] The signal output card is used to receive the signal output by the main control board, and convert it into a 4-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com