Bridge shock absorber

A technology of shock absorbers and bridges, which is applied in the direction of bridges, bridge parts, bridge construction, etc. It can solve the problems of increasing the difficulty of maintenance and replacement of bearings, and the lack of functions to prevent beams from slipping, so as to improve convenience and good performance. The effect of energy consumption and shock absorption, reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

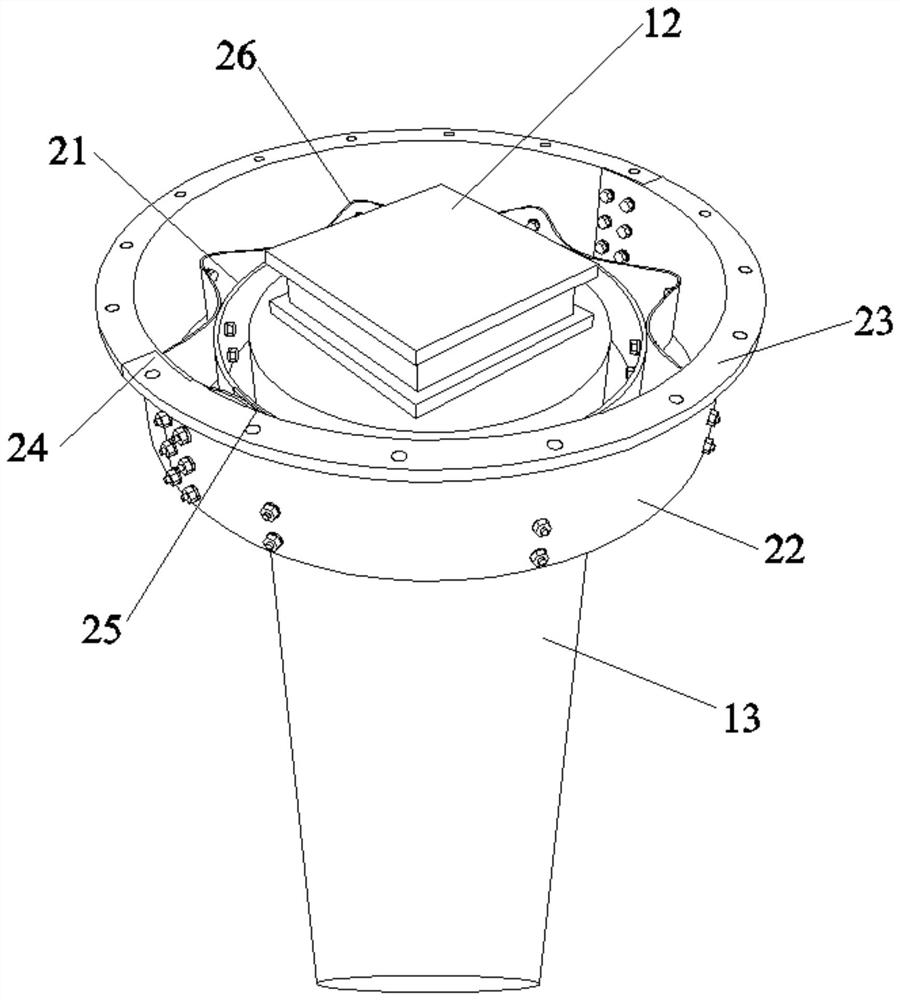

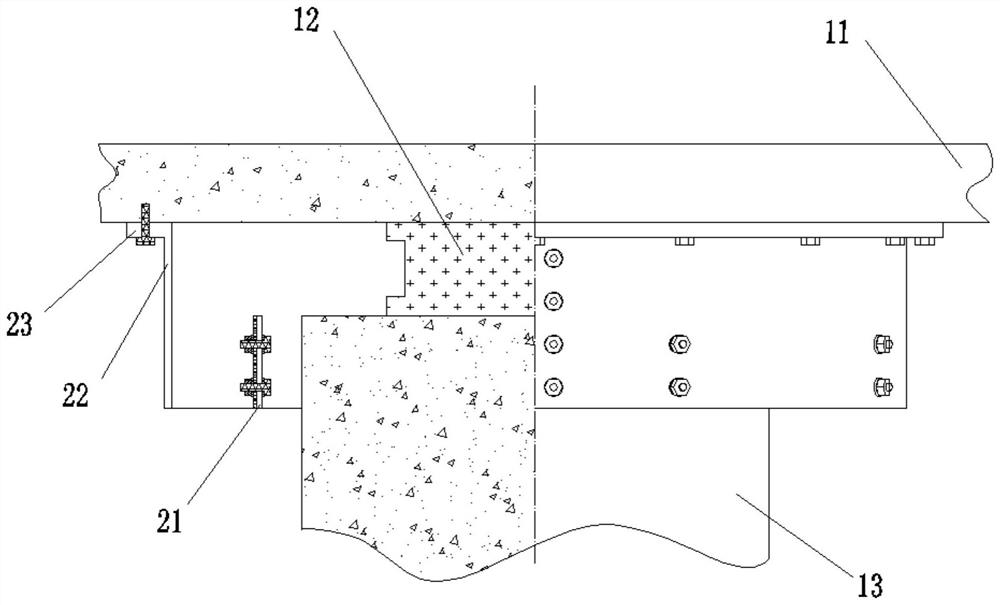

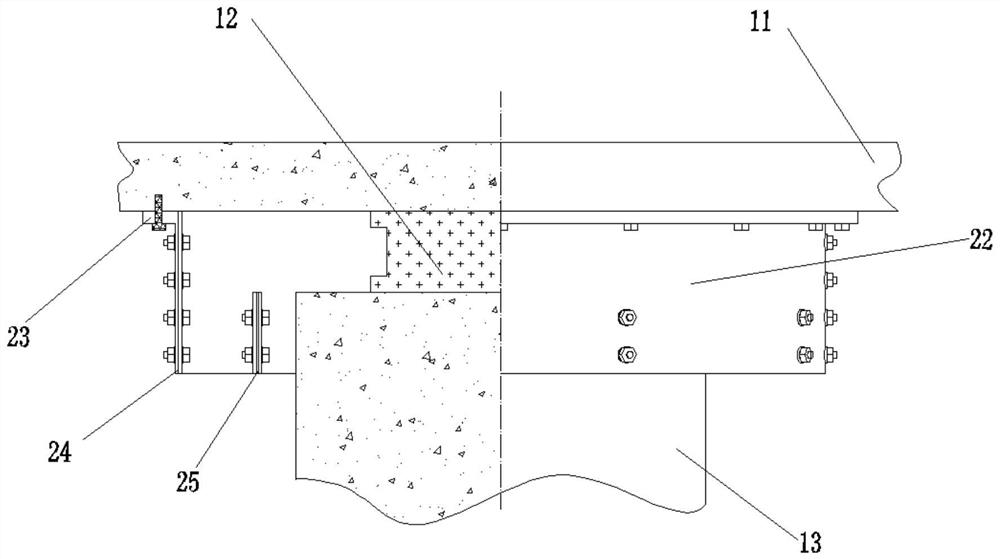

[0024] refer to Figure 1 to Figure 4 , the bridge shock absorber is used to be arranged at the junction of the pier 13 and the beam body 11, including an inner hoop 21, an outer hoop 22, a shock absorber bracket and a flange ring 23, and between the inner hoop 21 and the outer hoop 22 Connected into one body by the shock-absorbing bracket, the flange ring 23 is vertically fixed on the top of the outer hoop 22,

[0025] Among them, the pier 13 and the beam body 11 are provided with a support 12,

[0026] The outer hoop 22 surrounds the support 12;

[0027] The flange ring 23 is fixed on the bottom surface of the beam body 11 above the support 12 by bolts;

[0028] The inner hoop 21 surrounds the outer side of the pier 13 and reserves a telescopic gap between the pier 13 and the pier 13 which can play a shock-absorbing role.

[0029] As a specific embodiment, the top outer rings of the left semi-circular part and the right semi-circular part of the outer hoop 22 protrude out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com