Quick replacement device for furnace roller of thermal treatment furnace

A technology for heat treatment furnaces and furnace rolls, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as long time for changing rolls, damage to refractory materials in the furnace, and heavy workload, and achieve simple installation, reduced labor intensity, and reduced The effect of small labor risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

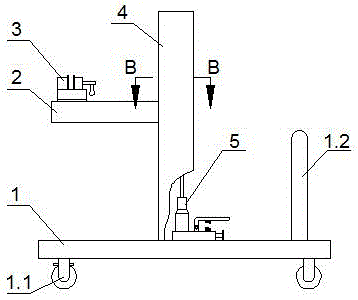

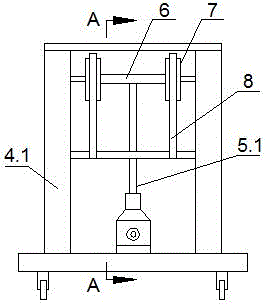

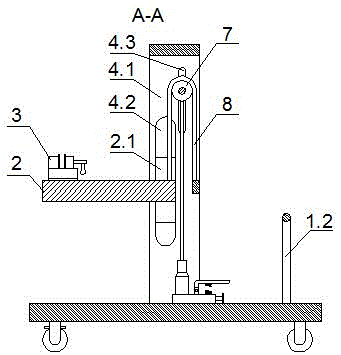

[0021] like figure 1 A heat treatment furnace roller quick replacement device is shown, including a clamping device, a moving guide device and a fixed guide device, such as figure 1 The clamping device shown includes a trolley 1 fixed with a gantry-shaped frame 4 and a disassembly platform 2 with a slider 2.1 fixed thereon. A vise 3 is fixed on the disassembly platform 2, and columns 4.1 on both sides of the gantry-type frame 4 are Both are provided with a vertical groove 4.2 adapted to the slider 2.1, and the slider 2.1 slides into the vertical groove 4.2; a hydraulic jack 5 is also fixed on the trolley 1, and the upper end of the ejector rod 5.1 of the hydraulic jack 5 is fixedly connected There is a cross bar 6, on which two sprockets 7 are connected through bearings, and chains 8 are meshed on the sprockets 7, one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com