Suction type glass cleaning device

A cleaning device and adsorption technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of large manpower, high risk factor, increase construction cost, etc., to save manpower and material resources, reduce risks, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

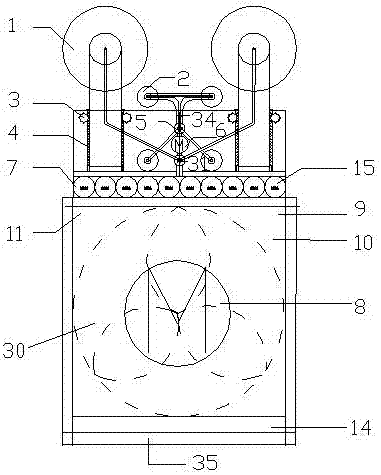

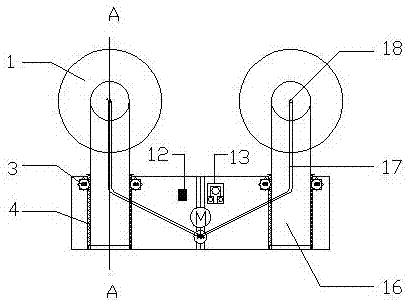

[0029] Such as Figure 1~9 Shown, a kind of adsorption type glass cleaning device, this device comprises two big suction cups 1 that are used to advance, two telescopic guide rails 16, four small suction cups 2, cleaning room 10, battery pack 14 and place in the driver's instrument 11 navigation system 12 and single-chip microcomputer 13.

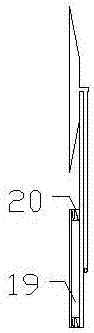

[0030] The front end of each telescopic guide rail 16 is provided with a large sucker 1, and the two sides of the rear part are provided with telescopic guide rail gear 4; Chassis 19, the two ends of this chassis 19 are provided with spring 20; Chassis 19 is provided with big sucker air duct 17, and one end of this big sucker air duct 17 communicates with big sucker 1, and its other end is connected with suction pump I 5; The small suction cup 2 is fixed on the support frame 21, and the support frame 21 is provided with 4 small suction cup air guide pipes 22; one end of each small suction cup air guide pipe 22 is connected with a small suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com