Full-length anchoring self-drilling anchor rod and anchoring method

A full-length anchoring, self-drilling technology, applied in the installation of bolts, earthwork drilling, wellbore/well components, etc., can solve the problem of insufficient support strength, easy debris to block bolt holes, and uneven mixing of anchoring agents and other problems, to achieve the effect of improving operational safety, realizing mechanized operations, and reducing labor risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

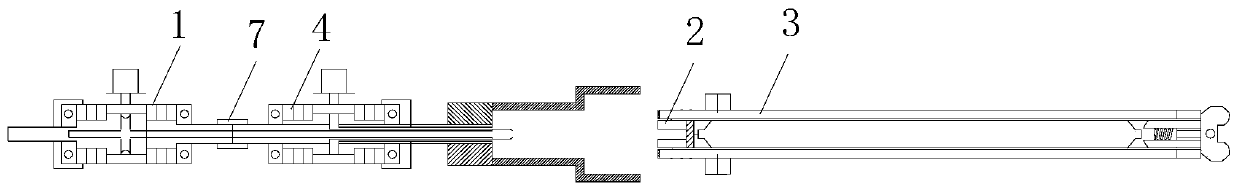

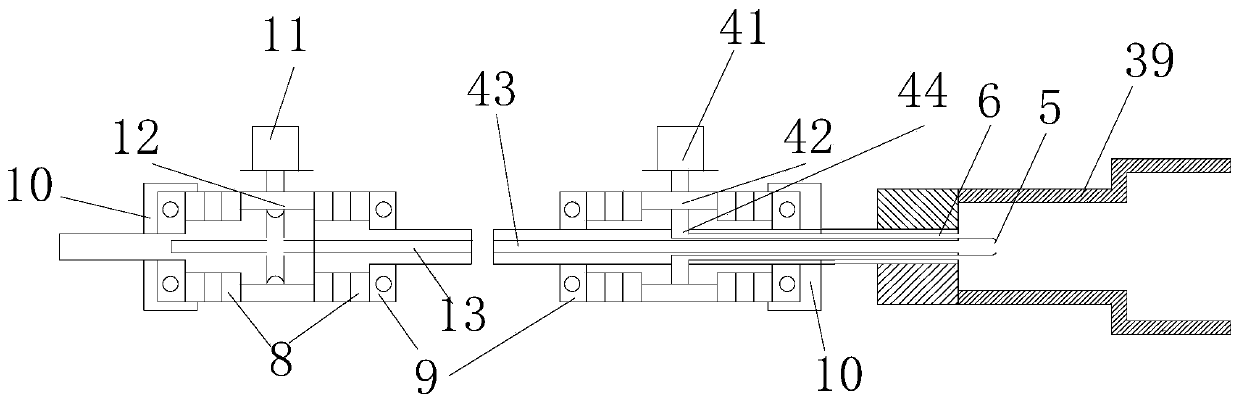

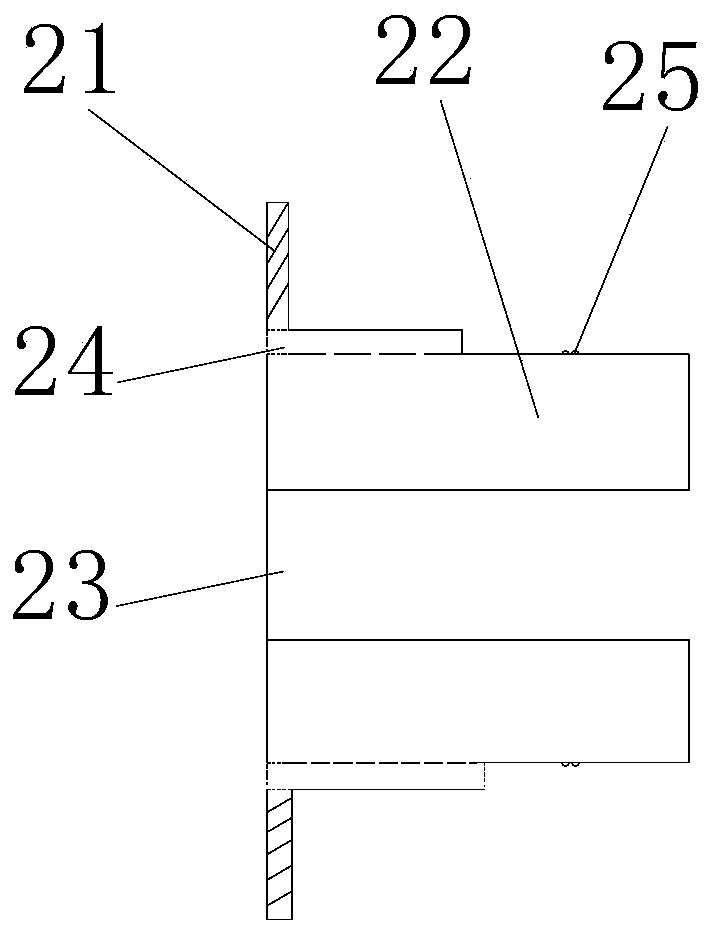

[0029] like Figures 1 to 5 As shown, this embodiment includes a two-way adapter, a water distributor 2 and an anchor body 3; the two-way adapter includes a second adapter 1, a first adapter 4, and the first adapter 4 of this embodiment includes a first quick connector 41 and The first connecting shaft 42, the first connecting shaft 42 is provided with a first through hole 43 and a first ring hole 44 which are not connected to each other along the axial direction, and the first ring hole 44 is coaxially arranged in the first through hole. Outside the hole 43, the first quick connector 41 passes through the first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com