Patents

Literature

42results about How to "Change contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

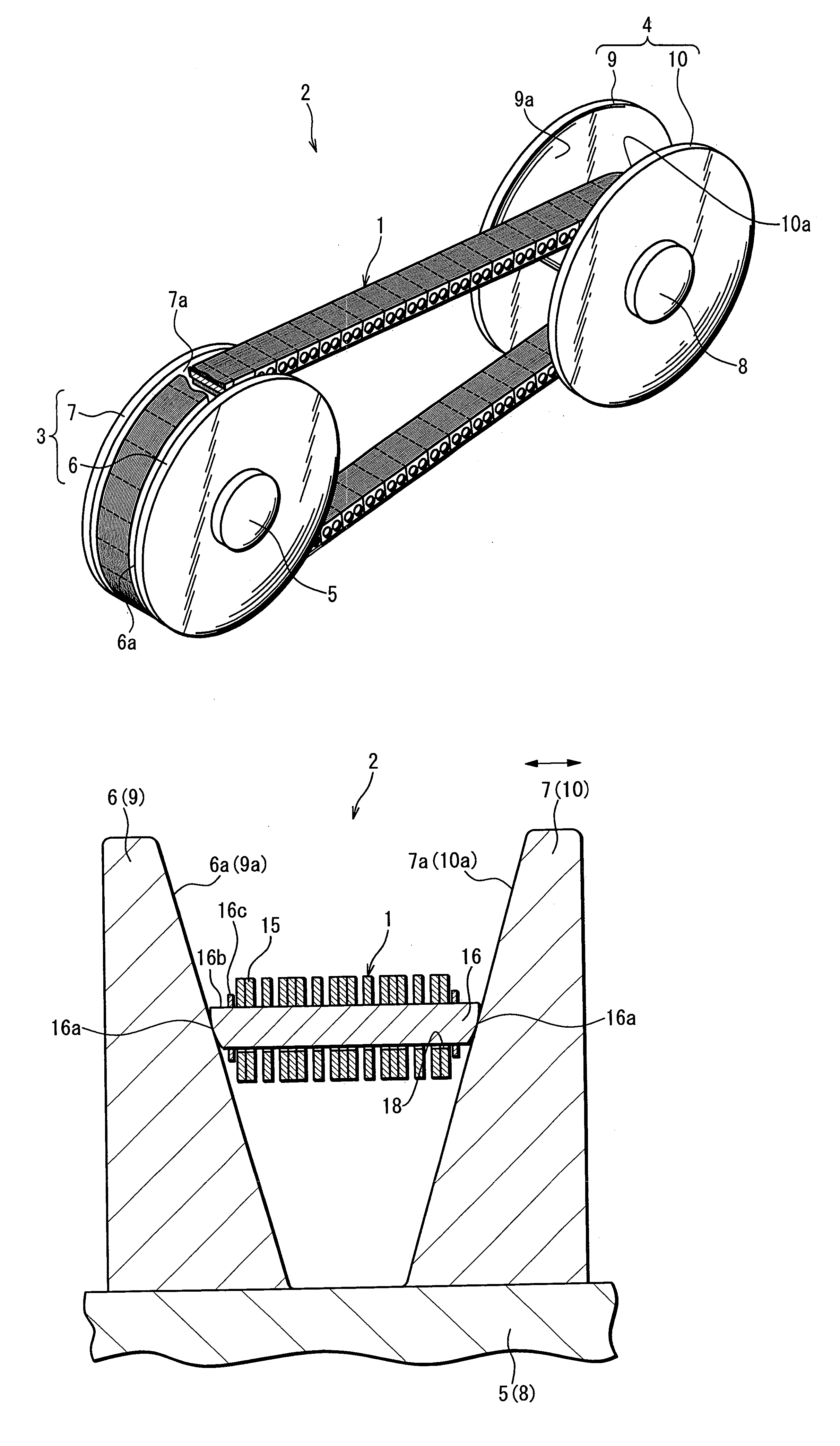

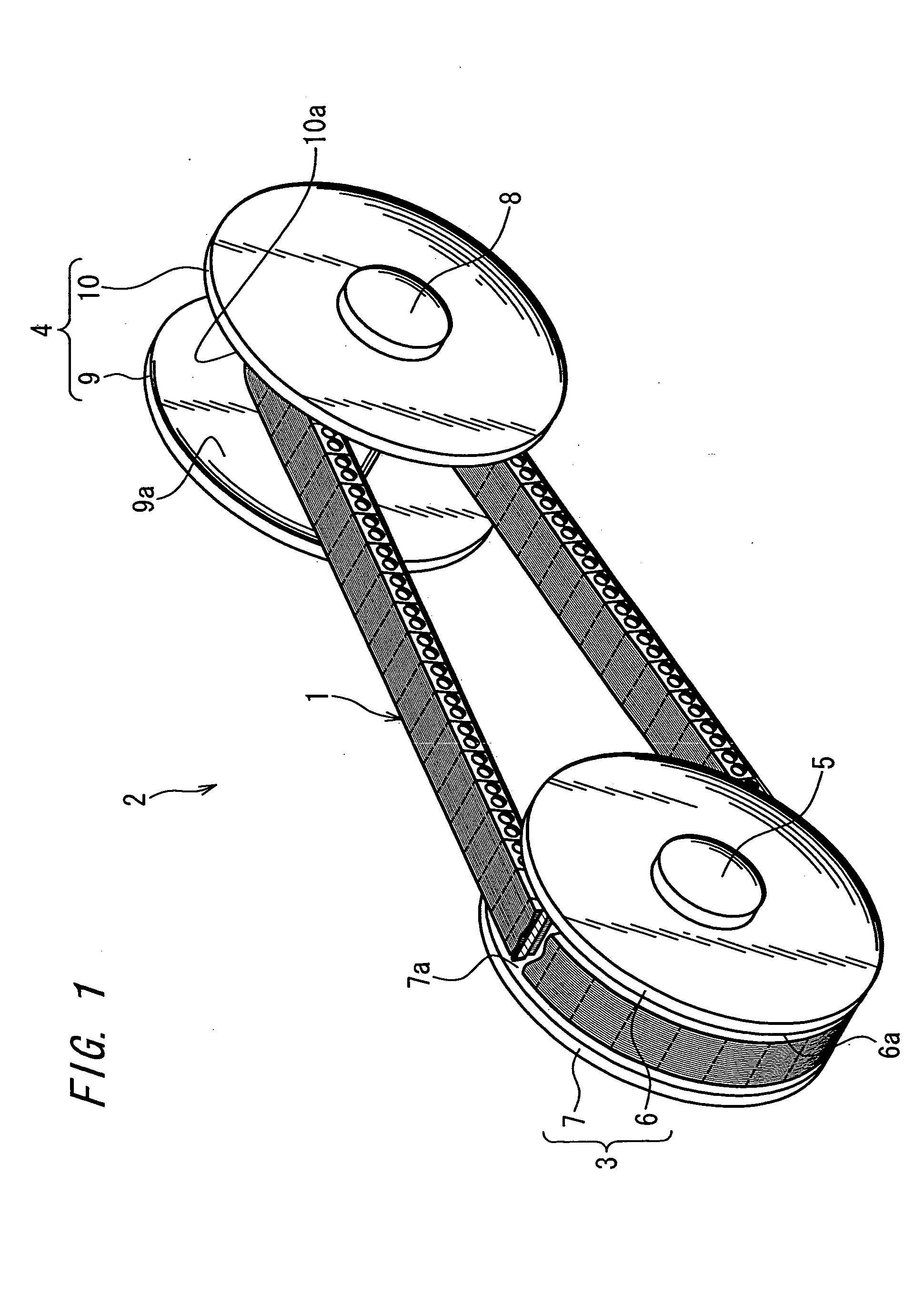

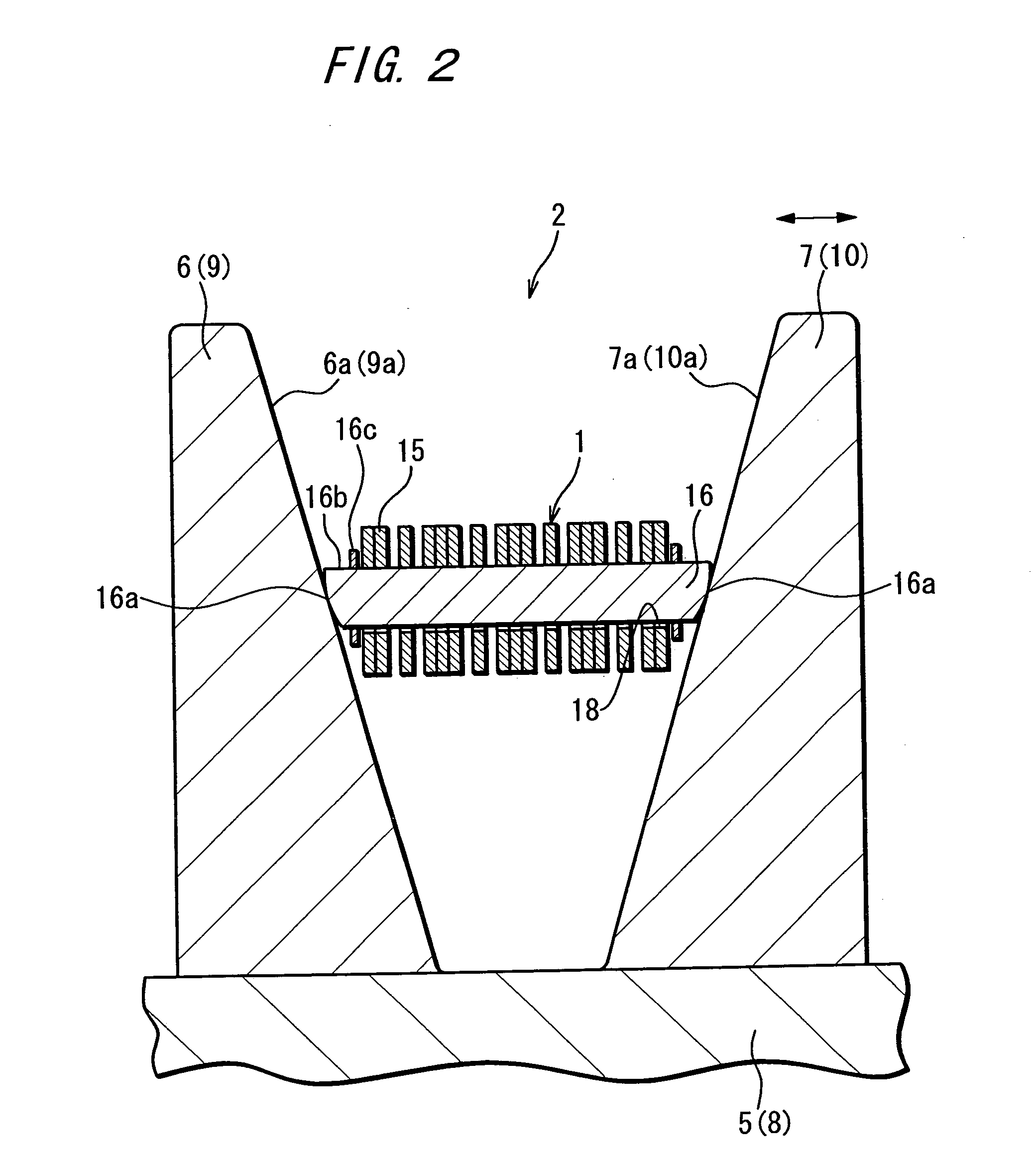

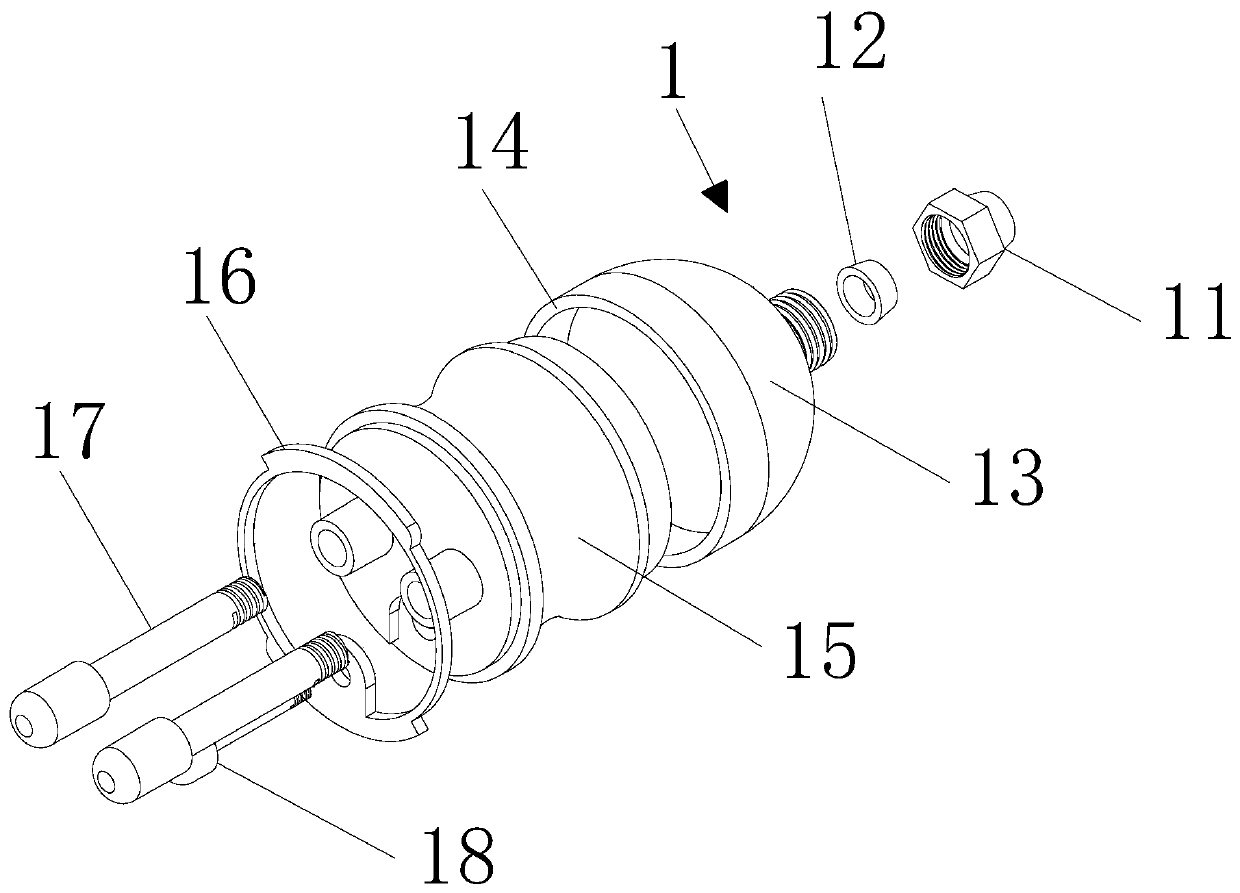

Power transmission chain and power transmission apparatus using same

This power transmission chain has a plurality of links, and a plurality of pins mutually joining this plurality of links. The power transmission chain is used to span a first pulley having a sheave face of conical shape, and a second pulley having a sheave face of conical shape, and power is transmitted by contact of both end faces of the pins, and the sheave faces of the first and second pulleys. Contact points are formed at both ends of this pin such as to contact the sheave face forward of the center position of the relevant end face.

Owner:JTEKT CORP

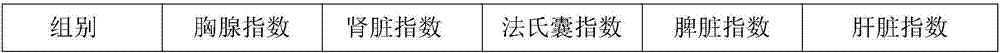

Special nutrition strengthening solution for livestock and poultry and preparation method thereof

The invention relates to a special nutrition strengthening solution for livestock and poultry and a preparation method thereof, belonging to the technical field of functional nutritional products. The special nutrition strengthening solution for the livestock and the poultry, provided by the invention, comprises the following components: 3%-12% of vitamins, 1%-5% of amino acids, 5%-30% of emulsifier, 2%-5% of co-emulsifier, 0.1%-0.5% of antimicrobial preservative and the balance of purified water. The specific preparation method comprises the following steps: firstly adding the emulsifier, the co-emulsifier and the purified water, stirring, then adding the vitamins, the amino acids and the antimicrobial preservative, dissolving and stirring for 10-30 minutes to get the special nutrition strengthening solution for the livestock and the poultry. The special nutrition strengthening solution for the livestock and the poultry, prepared by the preparation method provided by the invention, can improve water solubility, dispersion and absorptivity of the vitamins, thoroughly solve the problem of bioavailability of the fat-soluble vitamins and provide the nutrition strengthening solution which can be highly absorbed and utilized for the livestock and the poultry with liver and gallbladder diseases.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

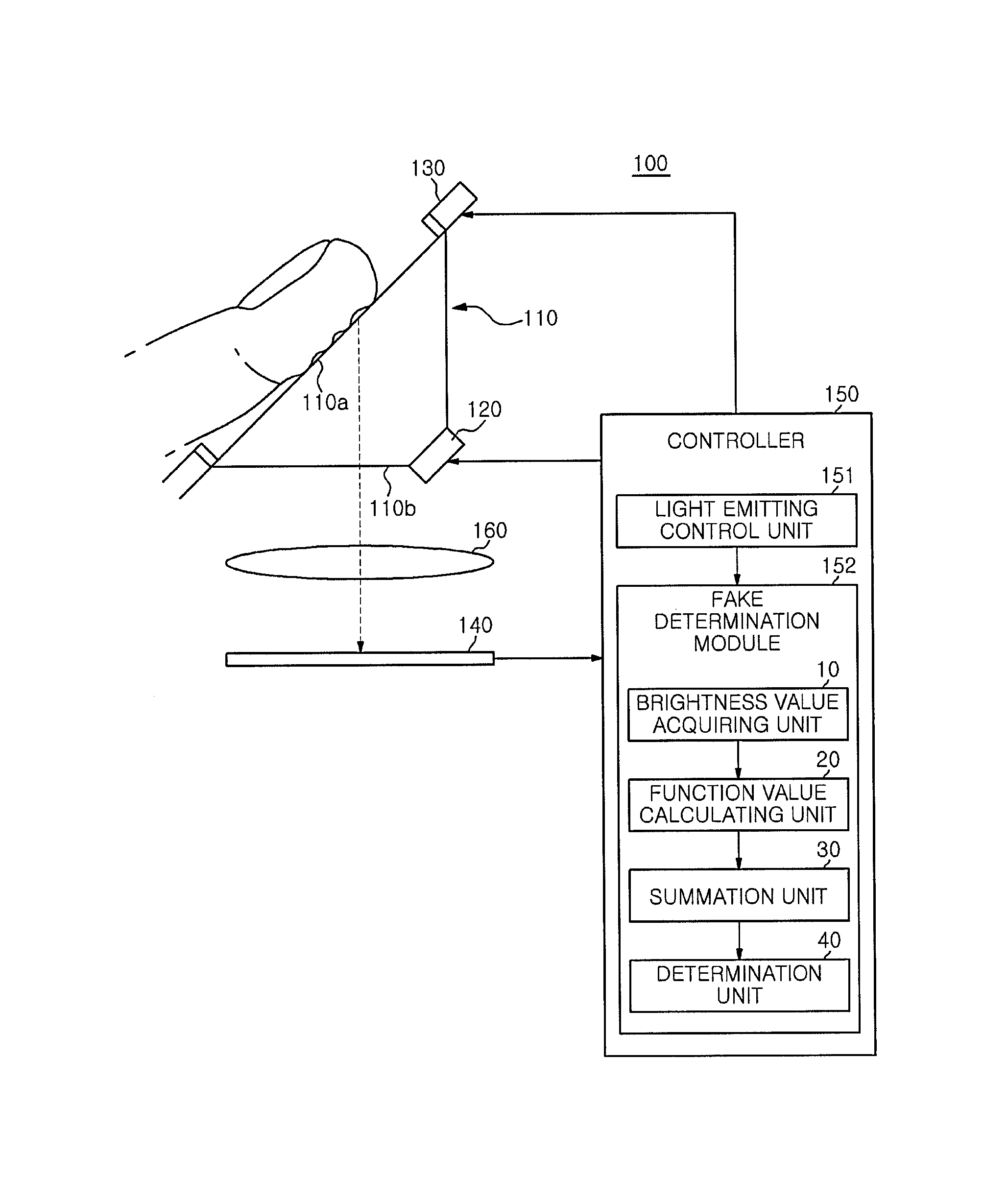

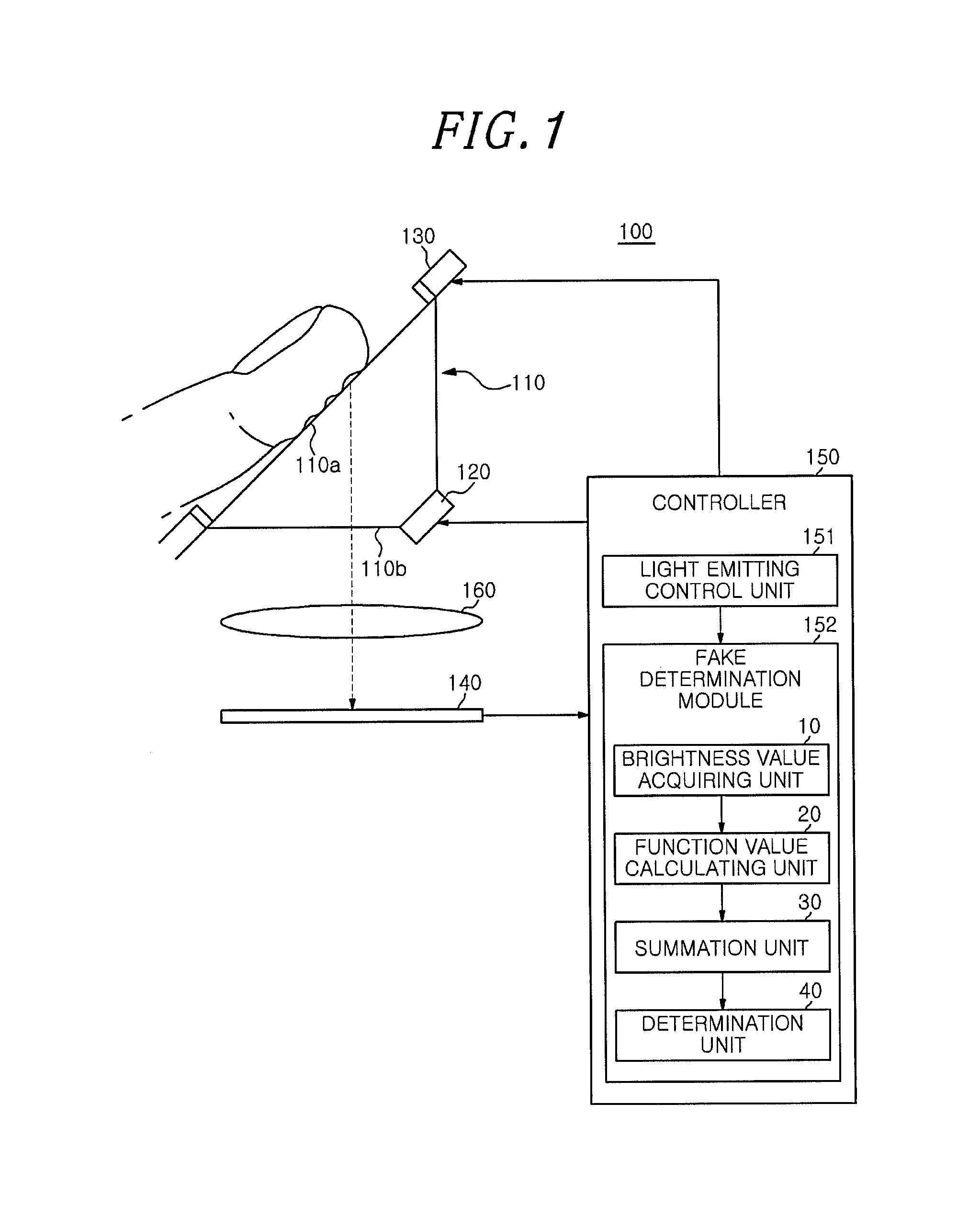

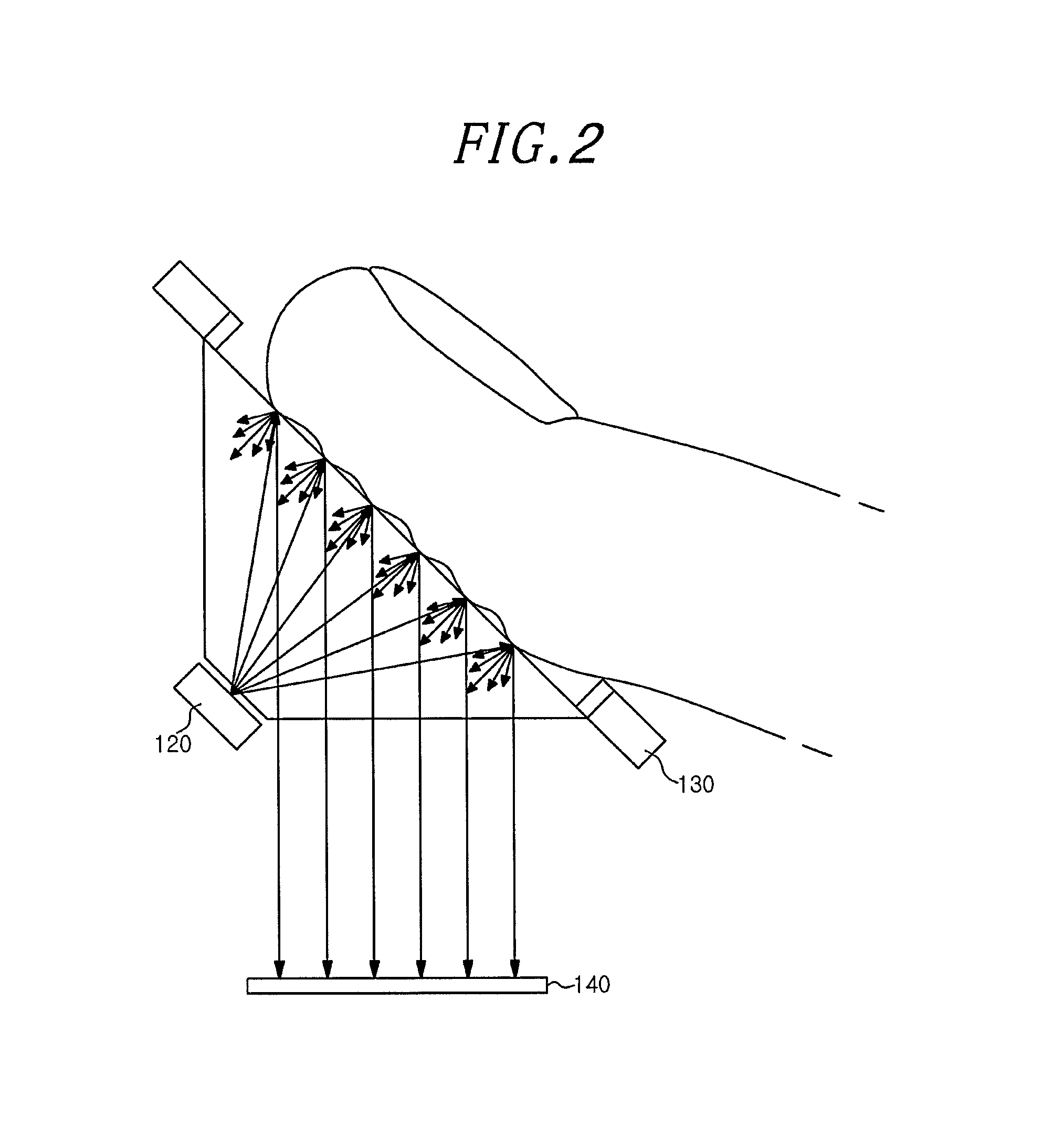

Method and apparatus for identifying fake fingerprint

An apparatus for identifying a fake fingerprint, the apparatus comprising: a prism having a fingerprint contact surface with which a fingerprint comes in contacted; an internal light source configured to irradiate light from the inside of the prism; an external light source configured to irradiate light from the outside of the prism; an image sensor configured to acquire diffused light image by the internal light source and transmitted light image by the external light source; and a controller configured to compare the diffused light image and the transmitted light image acquired by the image sensor to determine whether the fingerprint is a fake fingerprint or not.

Owner:SUPREMA INC

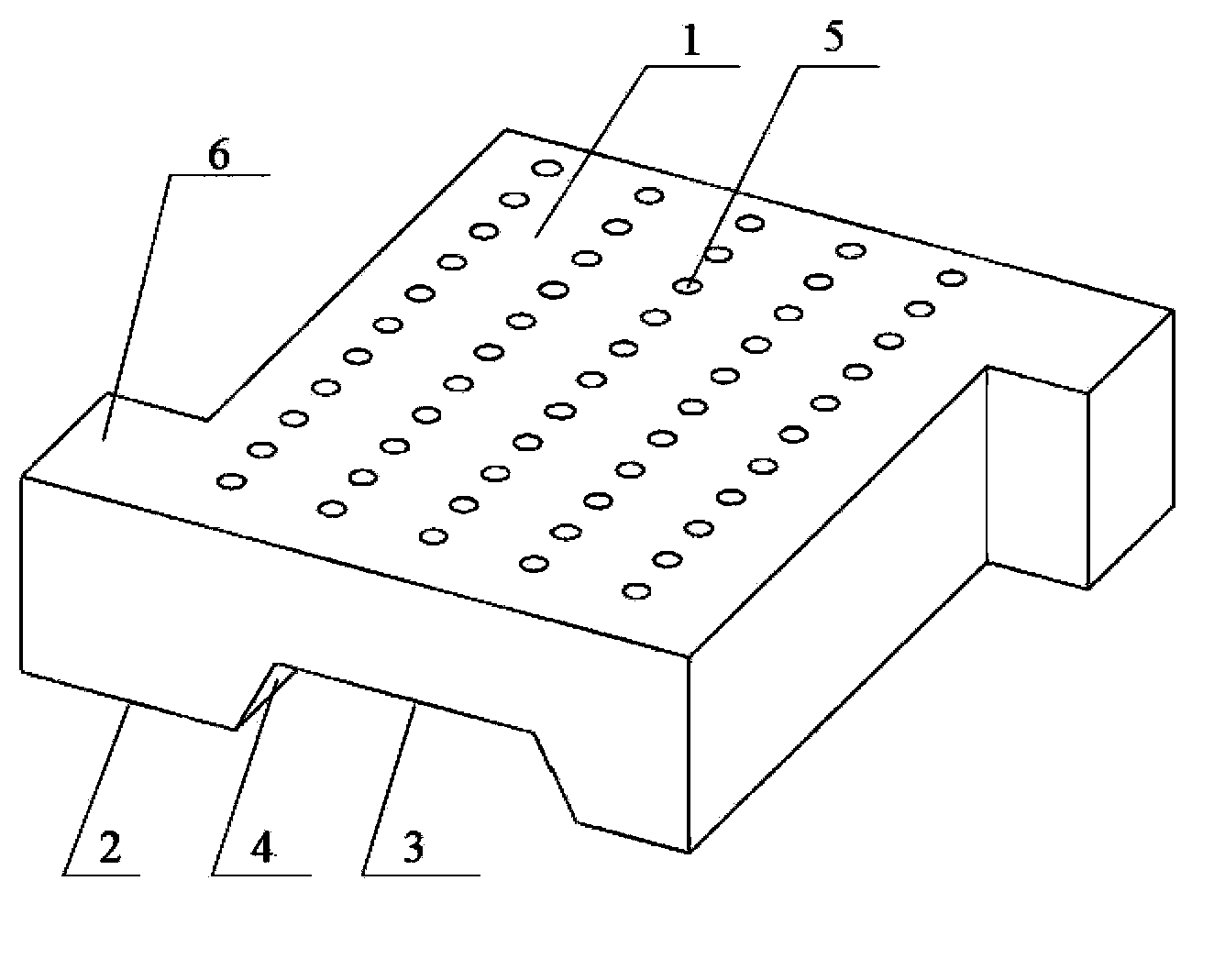

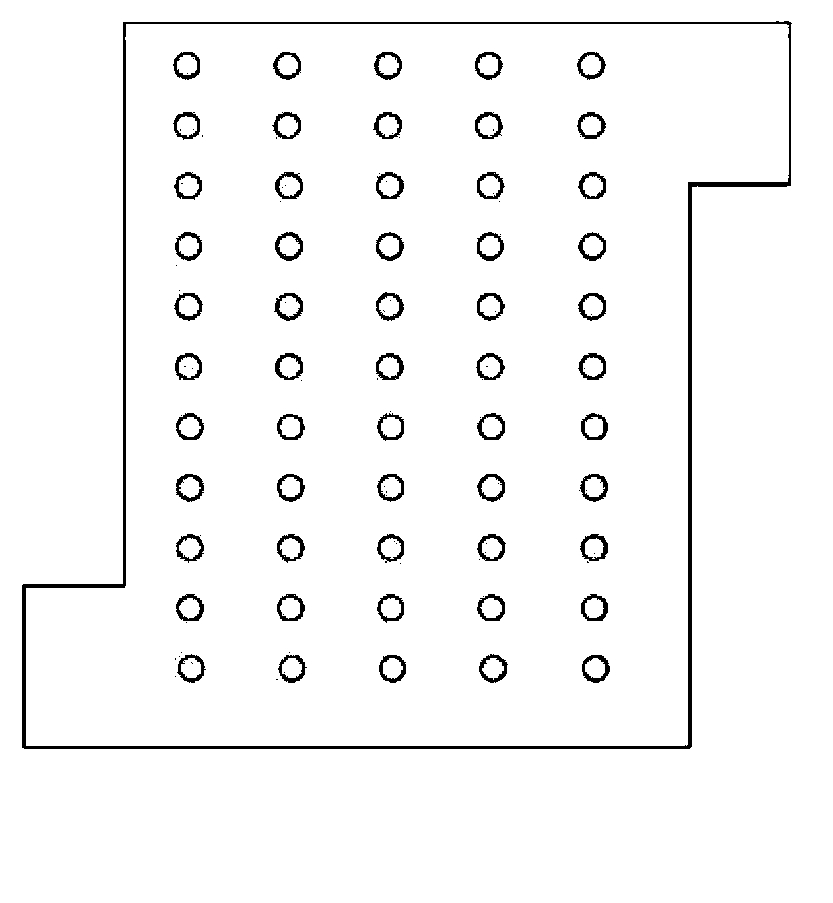

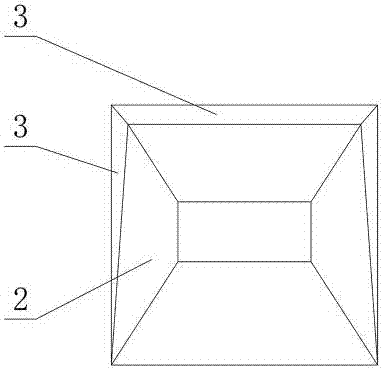

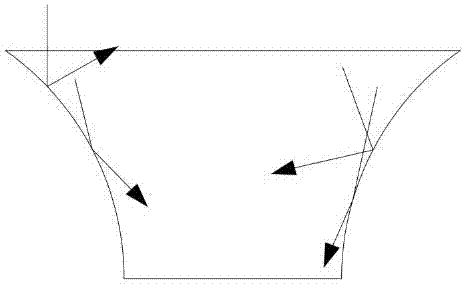

Novel water-permeable brick

The invention provides a novel water-permeable brick. The brick body of the water-permeable brick is a cuboid. The bottom surface is provided with an inward trapezoid concave surface. The included angle between the concave side faces of the concave surface and the horizontal surface is about 60 degrees. The top surface of the water-permeable brick is provided with drain holes penetrating the whole brick. Locating wings are disposed at the two sides of the water-permeable brick. The whole brick is obtained by subjecting concrete to pressure sintering. The bottom surface of the brick is provided with the inward concave surface so that the soil in a levelling layer when the brick is paved onto the levelling layer can be fixed well. The locating wings at the two sides of the brick can facilitate location of the brick when the brick is paved. The through holes distributed on the top surface of the brick can rapidly guide water accumulated on the surface into the earth's surface, thus achieving rapid water drainage.

Owner:天津市华鑫吊装运输有限公司

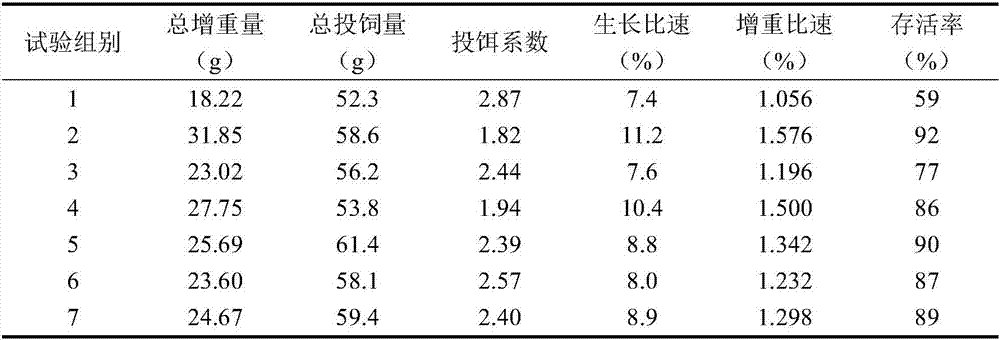

Nutrient enrichment solution special for aquaculture products and preparation method thereof

InactiveCN106962683AImprove stabilityImprove solubilityHydroxy compound active ingredientsMetabolism disorderIntestinal structureHigh energy

The invention discloses a nutrient enrichment solution special for aquaculture products and a preparation method thereof. The nutrient enrichment solution is prepared from 5%-26% of vitamins, 1.5%-13% of amino acid, 4%-13% of minerals, 5%-35% of emulsifier, 1.8%-14% of co-emulsifier, 0.1%-0.8% of antibacterial preservative and the balance purified water. The nutrient enrichment solution special for aquaculture products is an oil-in-water nanoemulsion, is good in stability, can make fat soluble vitamins quickly released in the stomach and intestine, has good contact with the upper mucous membrane layer of the gastrointestinal tract, enters the blood circulation through the gastrointestinal epithelium mucosa mesenchymal cells, thus changes the physiological and biochemical process of the vitamins in the body, eliminates the absorption and utilization differences between individuals, and improves the bioavailability. In addition, the preparation method of the nutrient enrichment solution is simple and easy to operate, does not need high-pressure homogenizing, heating, cooling and other high-energy-consuming processes and is low in production cost and suitable for industrial production.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

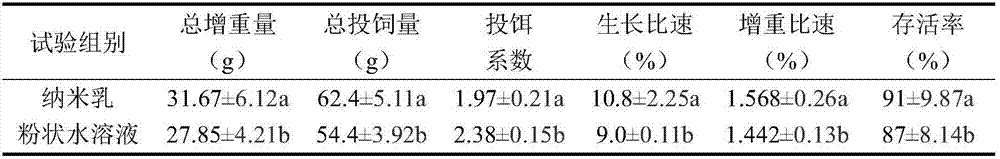

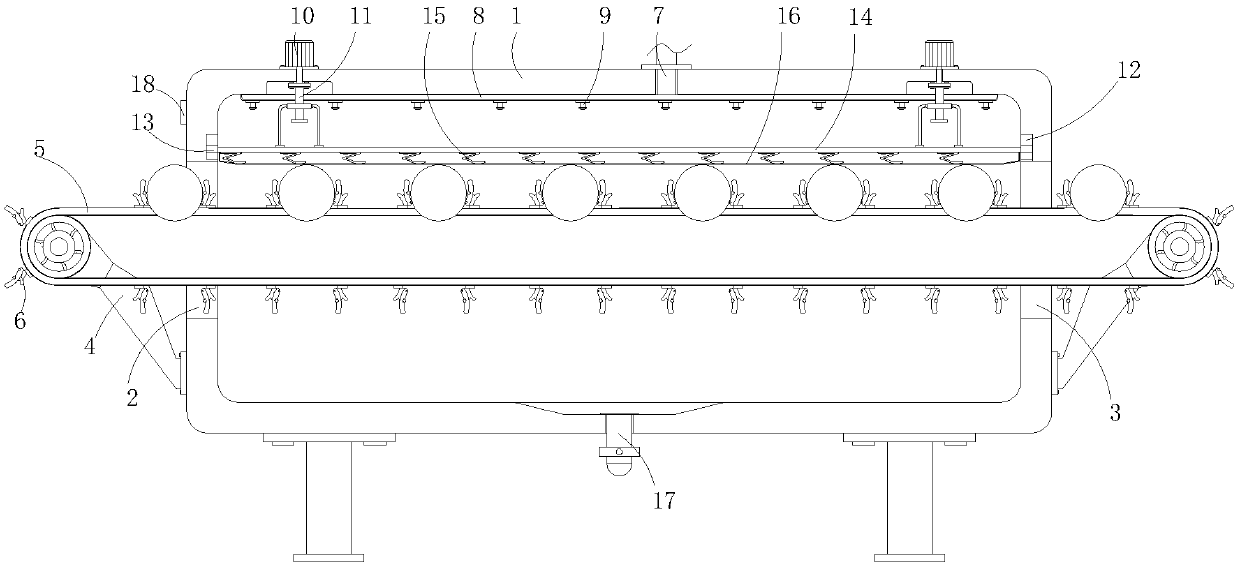

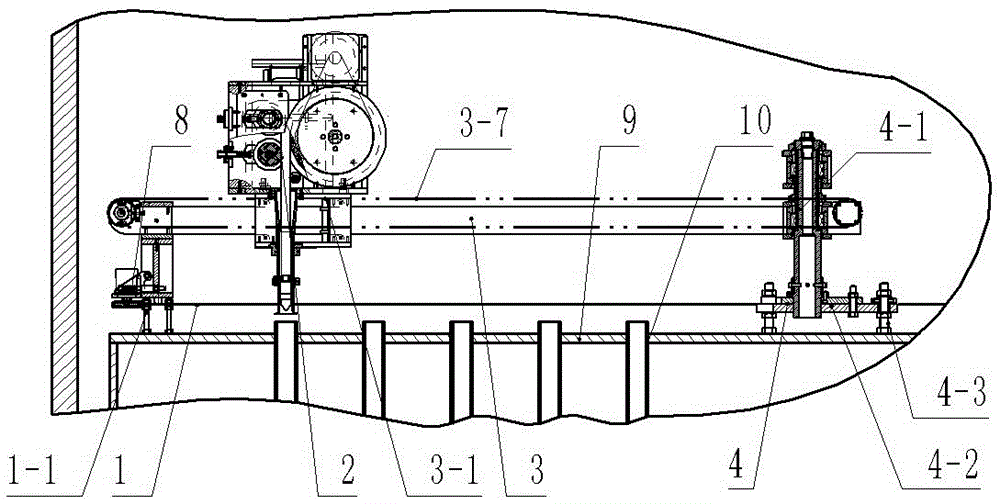

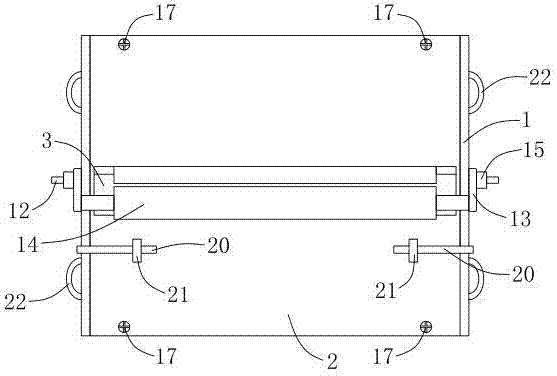

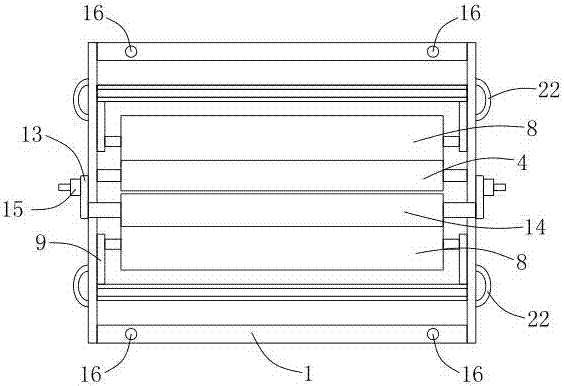

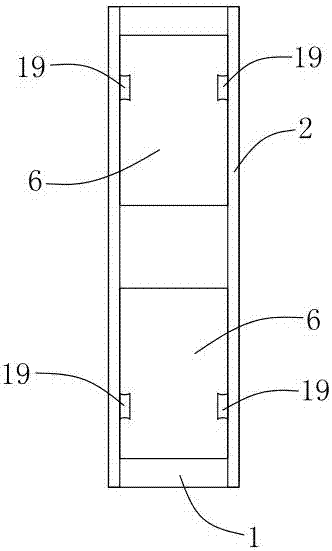

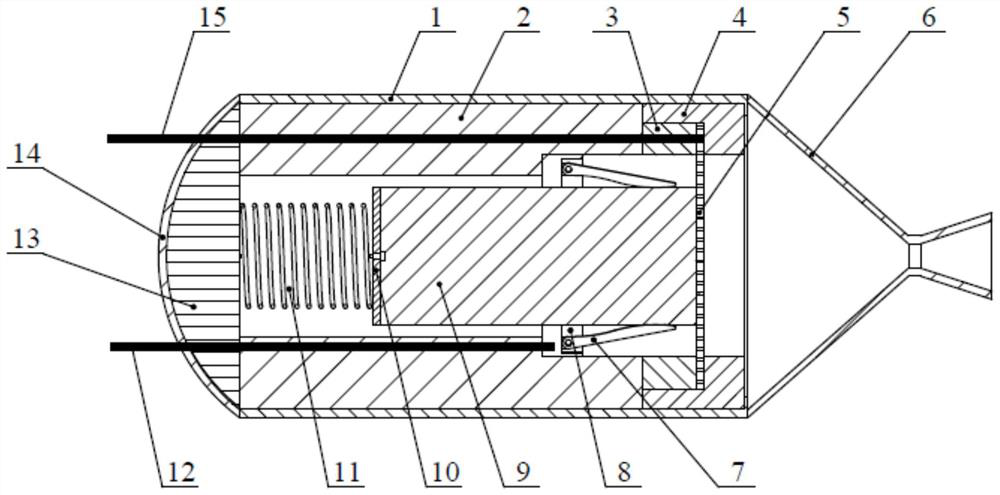

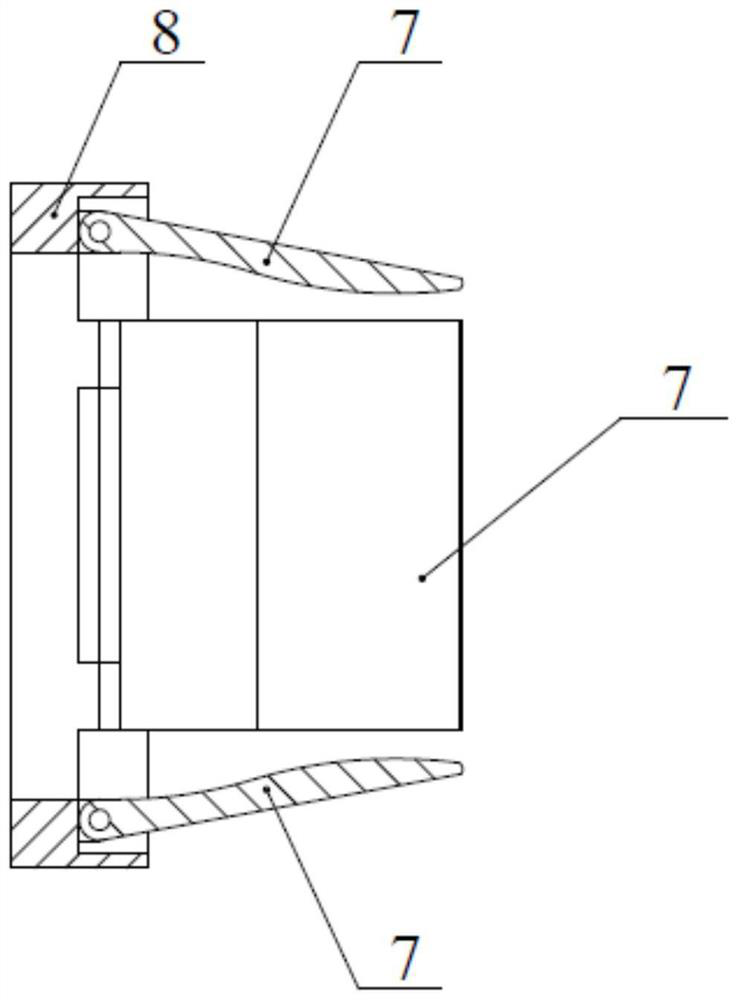

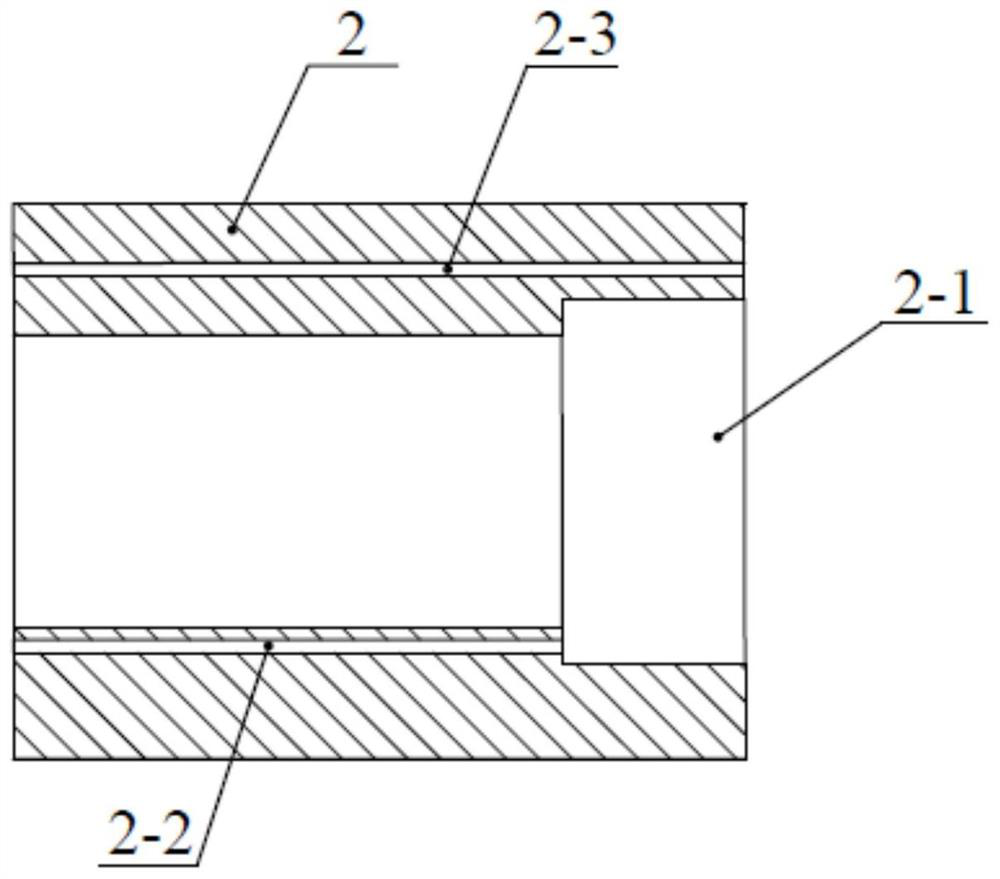

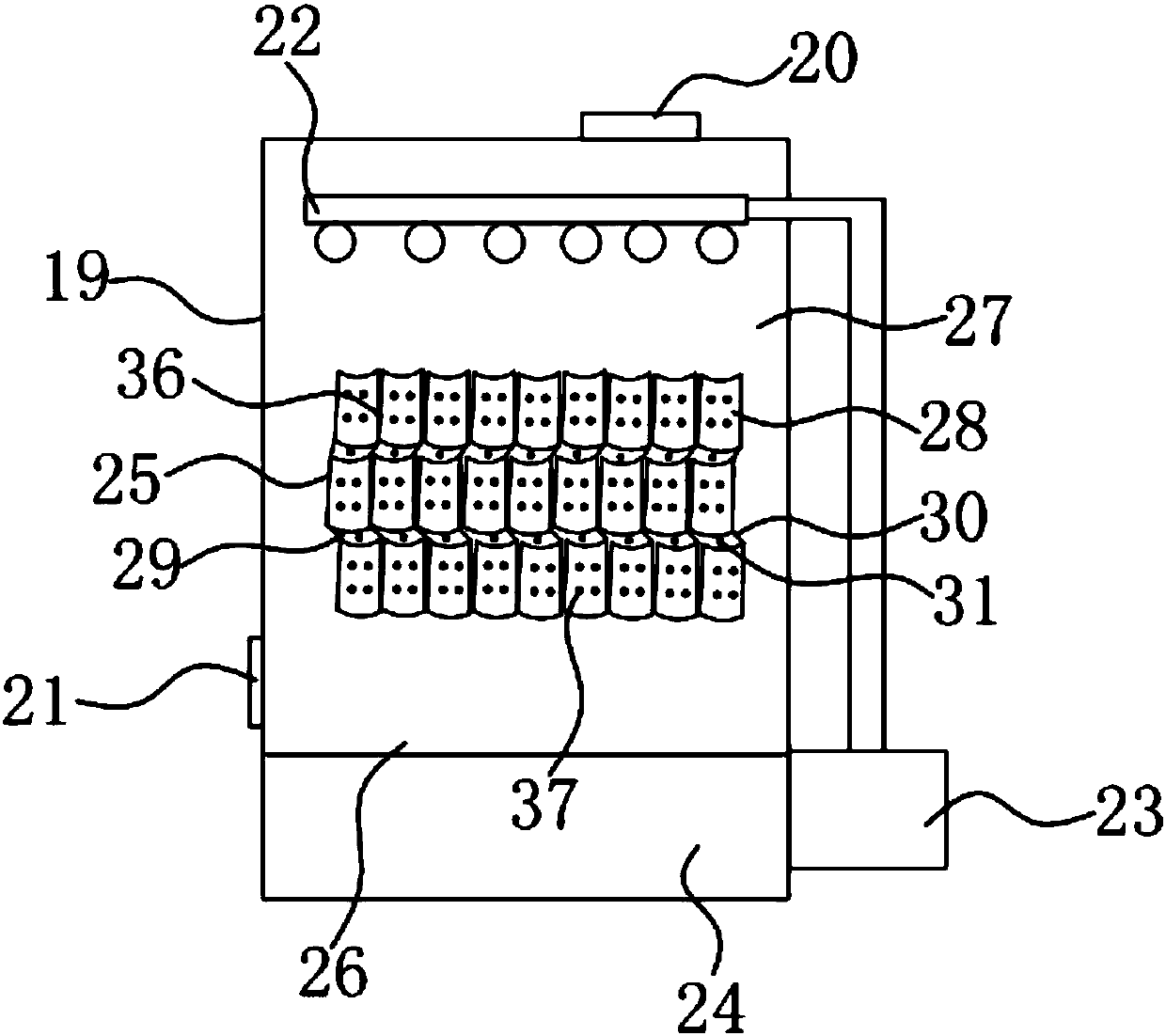

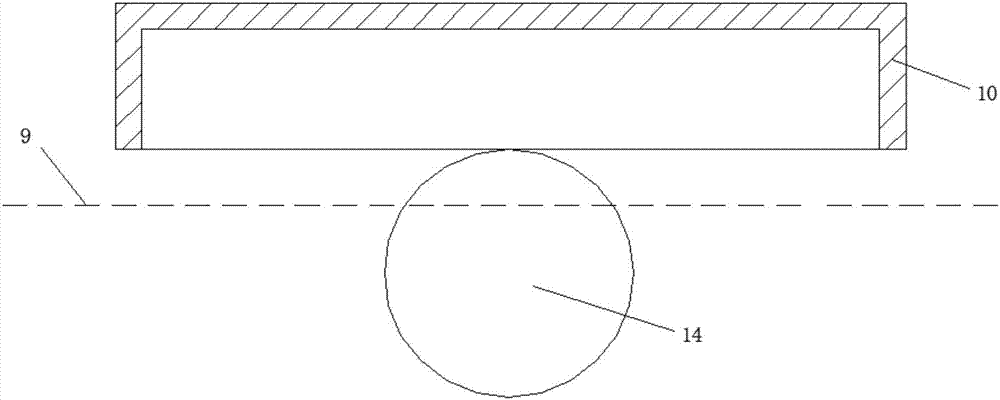

Cooling equipment for special type copper rod smelting forming

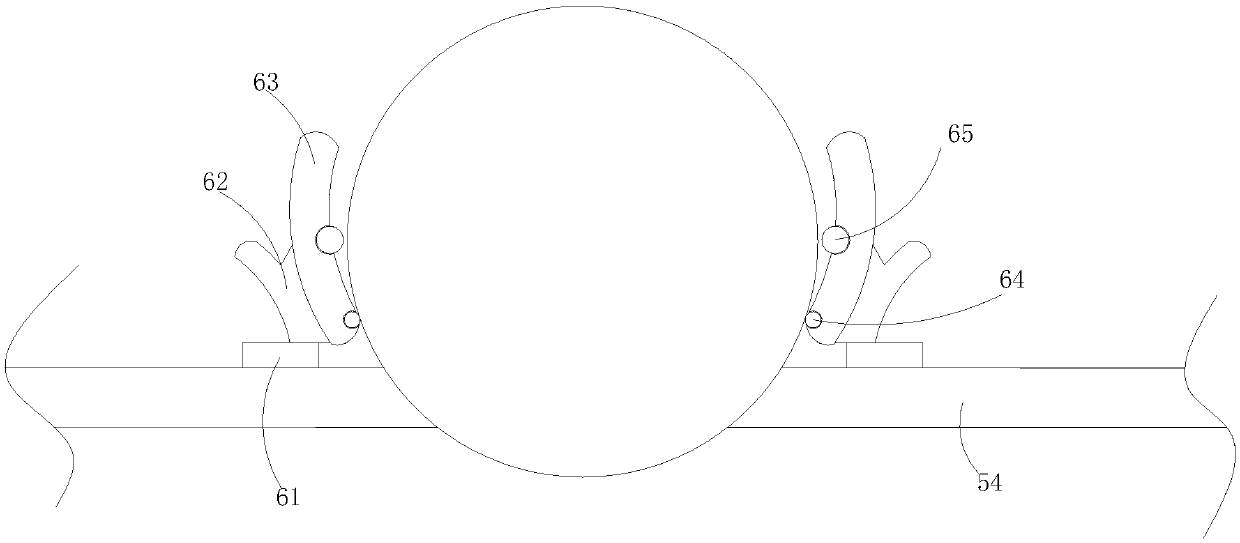

ActiveCN109518105AChange contactReduce contact surfaceFurnace typesHeat treatment furnacesFixed frameEngineering

The invention relates to the technical field of machining of tube rod blanks of aluminum bronze, special brass and the like, and discloses cooling equipment for special type copper rod smelting forming. A guide inlet and a guide outlet are arranged in the left side and the right side of a machine body correspondingly; two fixing frames are fixedly installed at the guide inlet and the guide outleton the left side and the right side of the machine body through bolts correspondingly; two transmission mechanisms penetrate through the inner side of the machine body to be connected through the twofixing frames, and eighteen positioning mechanisms are installed on the two transmission mechanisms; and a water guide connector is installed at a water guide opening in the top of the machine body and penetrates through the top of the machine body to be connected with a transverse multi-way pipe. According to the cooling equipment for special type copper rod smelting forming, traditional surfacecontact or line contact is converted into point contact, the contact surfaces between the positioning mechanisms and copper rods are decreased, accordingly, the contact surface between cooling liquidand the side surfaces of the copper rods when the equipment conducts cooling is increased, and the problem that when the copper rods are subjected to cooling, metal structures on the sides of the copper rods are not synchronously cooled, and thus, the machining quality of the copper rods is influenced is solved.

Owner:贵溪骏达特种铜材有限公司

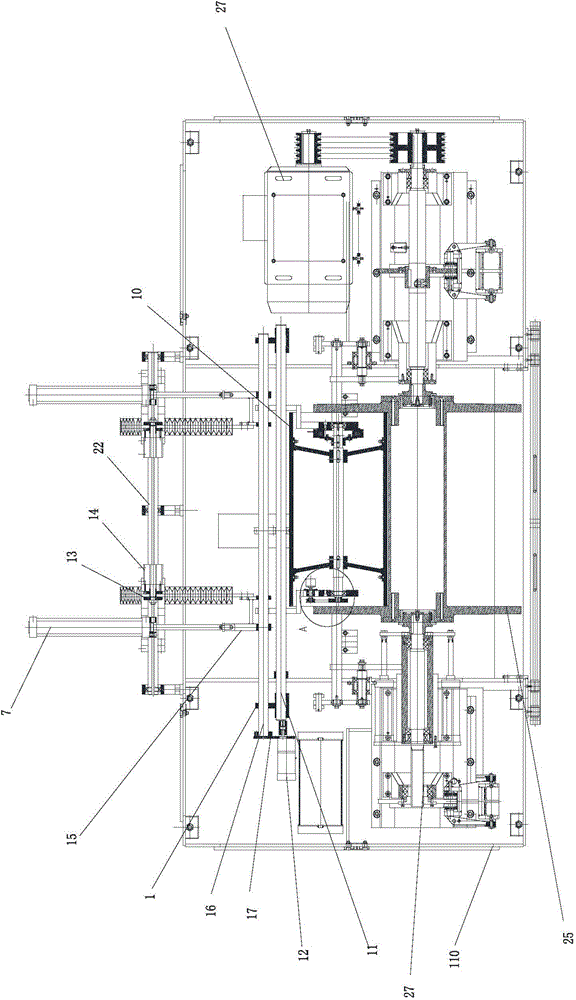

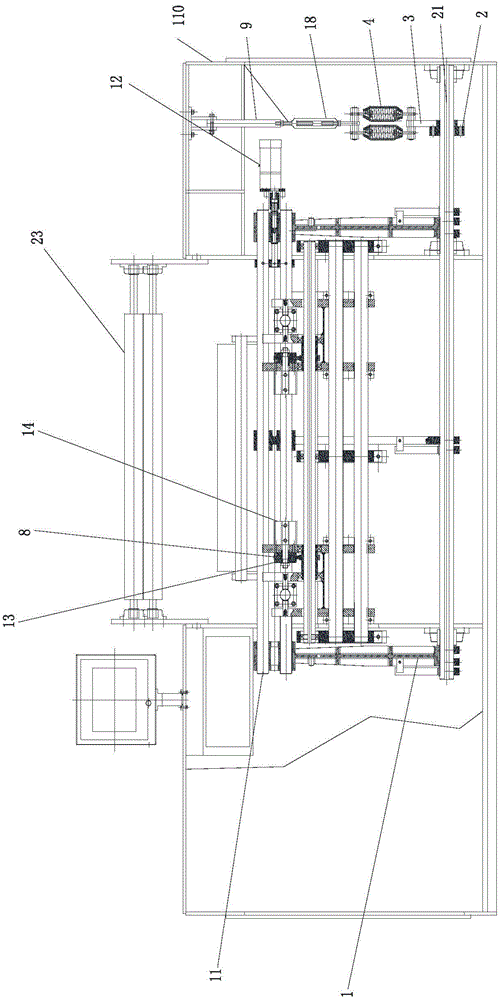

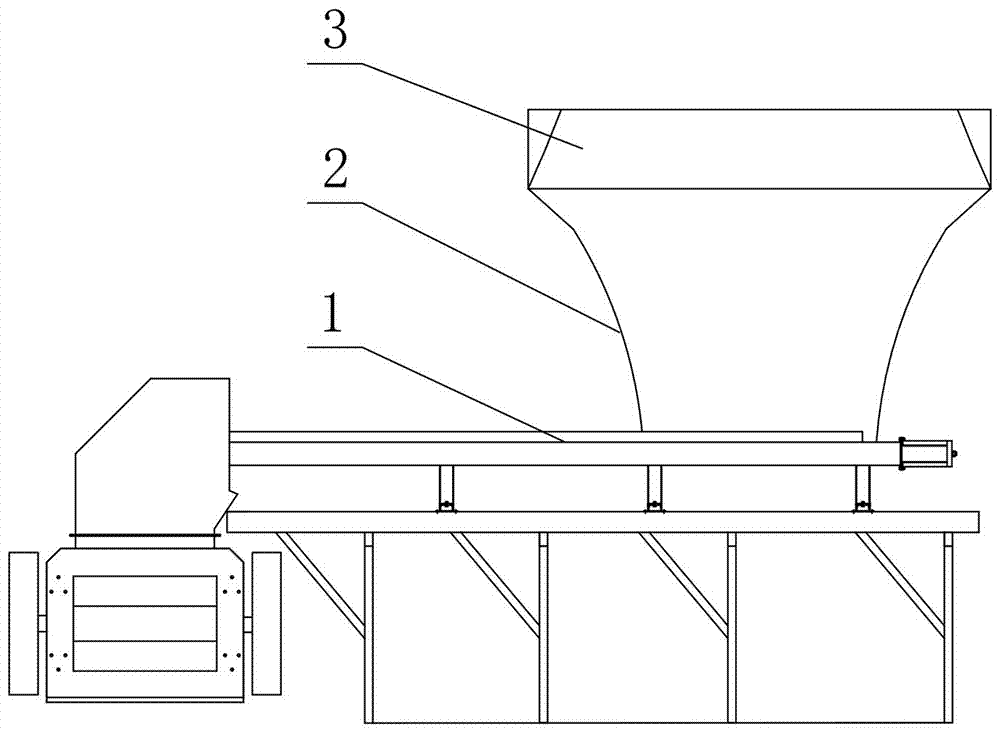

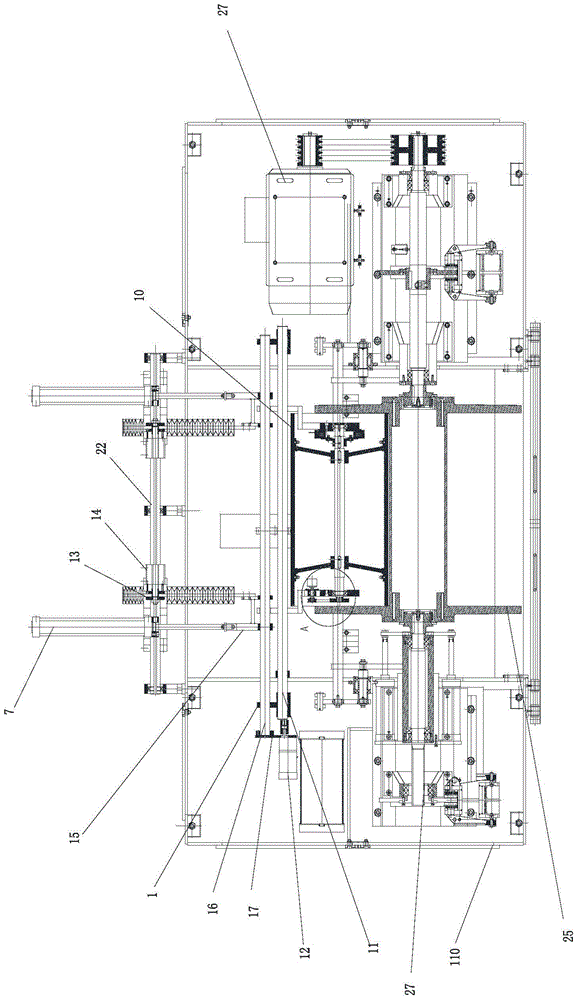

Flat-filament warping machine

ActiveCN104357993APrevent fallingAvoid warping quality problemsWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention relates to the field of a warping machine, in particular to a flat-filament warping machine for warping the flat filaments. The flat-filament warping machine comprises a compression roller adjusting mechanism and a group of edge yarn devices, wherein the compression roller adjusting mechanism is arranged on a stander and used for adjusting the position and pressure of the compression roller, the edge yarn devices are arranged on the stander and arranged above a warping disc head and above the end part of the compression roller, each edge yarn device comprises an installation shaft which is fixed on the stander, a side yarn roller is arranged on the installation shaft on one side of the stander, a roller installation plate is arranged on the installation shaft on one side of the side yarn roller, a slide shaft is arranged on the roller installation plate, the other end of the slide shaft is fixedly provided with a baffle plate, a threaded shaft is arranged between the baffle plate and the roller installation plate, a slide seat which is used for guiding the flat filaments is arranged on the threaded shaft, the slide shaft also sleeves the slide shaft, and an adjusting hand wheel is arranged on the end part of the threaded shaft. By adopting the flat-filament warping machine, the warping of the flat filaments is realized, and the quality of the warping disc head is guaranteed.

Owner:NEWTRY COMPOSITE

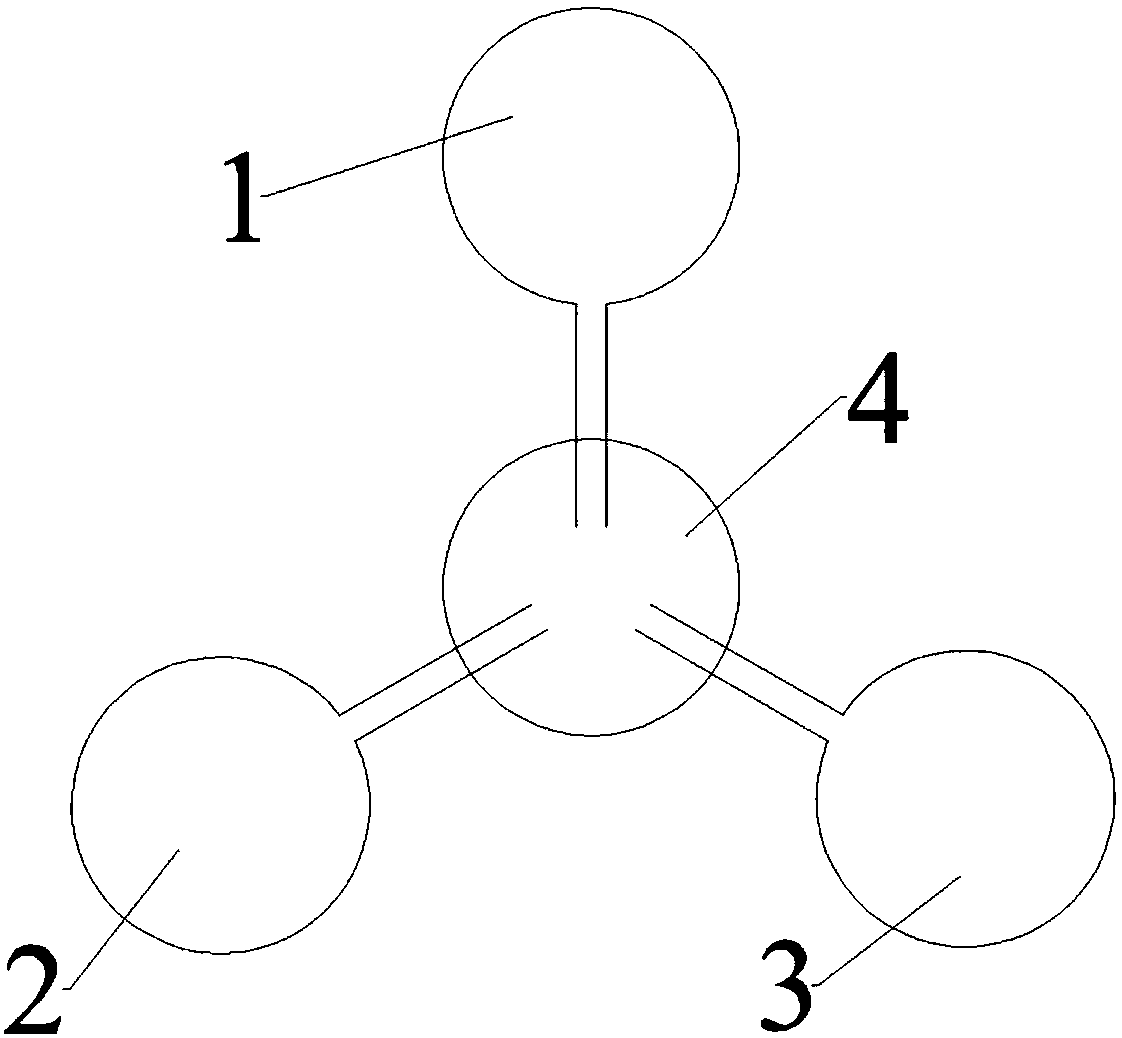

Pulling-pressing shaft type monorail beam supporting seat

PendingCN107447603AReduce frictionChange contactRailway tracksPhotovoltaic energy generationClassical mechanicsEngineering

The invention discloses a pulling-pressing shaft type monorail beam supporting seat, which comprises a supporting seat upper pendulum and a lower supporting seat plate; the supporting seat upper pendulum comprises an upper top plate and column surfaces, in a transverse bridge direction, which are fixedly arranged on the lower side of the upper top plate; the column surfaces are divided into a middle positioning column surface and rotary column surfaces which are arranged on the two ends of the positioning column surface and are coaxially arranged with the positioning column surface; the diameter of the positioning column surface is smaller than that of each rotary column surface to form a step surface; the positioning column surface is embedded into a positioning groove, in the transverse bridge direction, of a cross-shaped positioning block; the two end parts, in a longitudinal bridge direction, of the positioning block are limited by positioning bosses; the rotary column surfaces extend out of two sides to form cantilever shafts; and the surfaces of the cantilever shafts are fixed on the lower supporting seat plate through portal frames respectively after being wrapped with an upper column panel and a lower column panel. According to the pulling-pressing shaft type monorail beam supporting seat, vertical load and drawing force load produced by tensioning are transferred by adopting a mode similar to contact between a shaft and the column surface, and a stress surface is large; matching among the cantilever shafts of the upper pendulum of the supporting seat, the upper column panel and the lower column panel can adapt to surface contact transfer of a beam rotation angle, a bending moment and a load; and an anchoring mode of the lower supporting seat plate and a cover beam is simple.

Owner:CHENGDU XINTU TECH

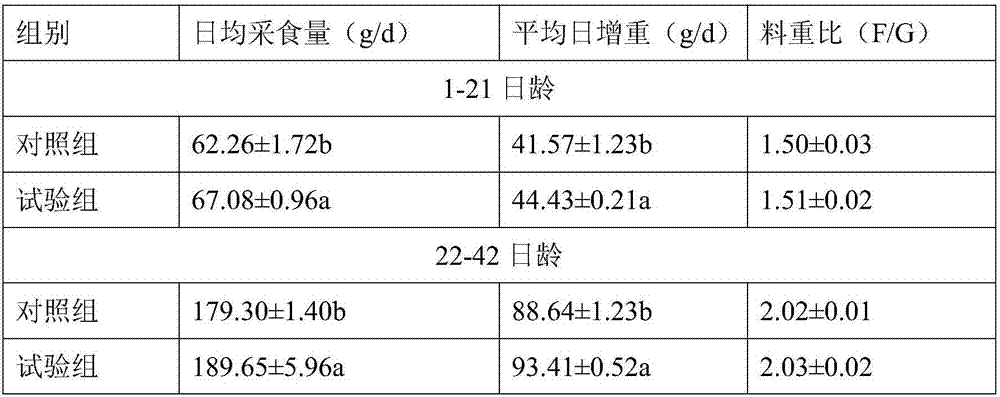

Nanometer compound nutrient solution preparation special for broiler chicken and preparation method thereof

InactiveCN107041482AQuality is easy to controlImprove solubilityAccessory food factorsDispersitySolubility

The invention discloses a nanometer compound nutrient solution preparation special for broiler chicken and a preparation method thereof. The nanometer compound nutrient solution disclosed by the invention contains 3%-15% of vitamins, 1%-8% of amino acid, 1%-6% of nucleotide, 1%-3% of prebiotics, 6%-30% of surfactant, 2%-12% of cosurfactant, 0.1%-0.5% of anti-bacteria preservative and the balance of purified water. A nanometer technology is adopted for compounding the nutrient substances, such as, vitamins, amino acid, nucleotide and prebiotics into a nanometer emulsion according to the requirement of the broiler chicken for the nutrient substances and the nanometer emulsion is a safe, efficient, stable and quality-controllable compound nutrient nanometer emulsion special for broiler chicken. The compound nutrient solution disclosed by the invention can improve the water solubility, dispersity and absorption rate of the nutrient substances, such as vitamins, and can thoroughly solve the problem of bioavailability of the nutrient substances, such as, lipid-soluble vitamins. A nutrition enriched solution which can be highly absorbed and utilized is supplied for the broiler chicken.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

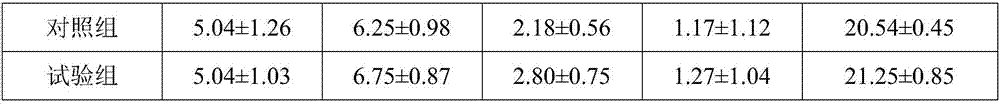

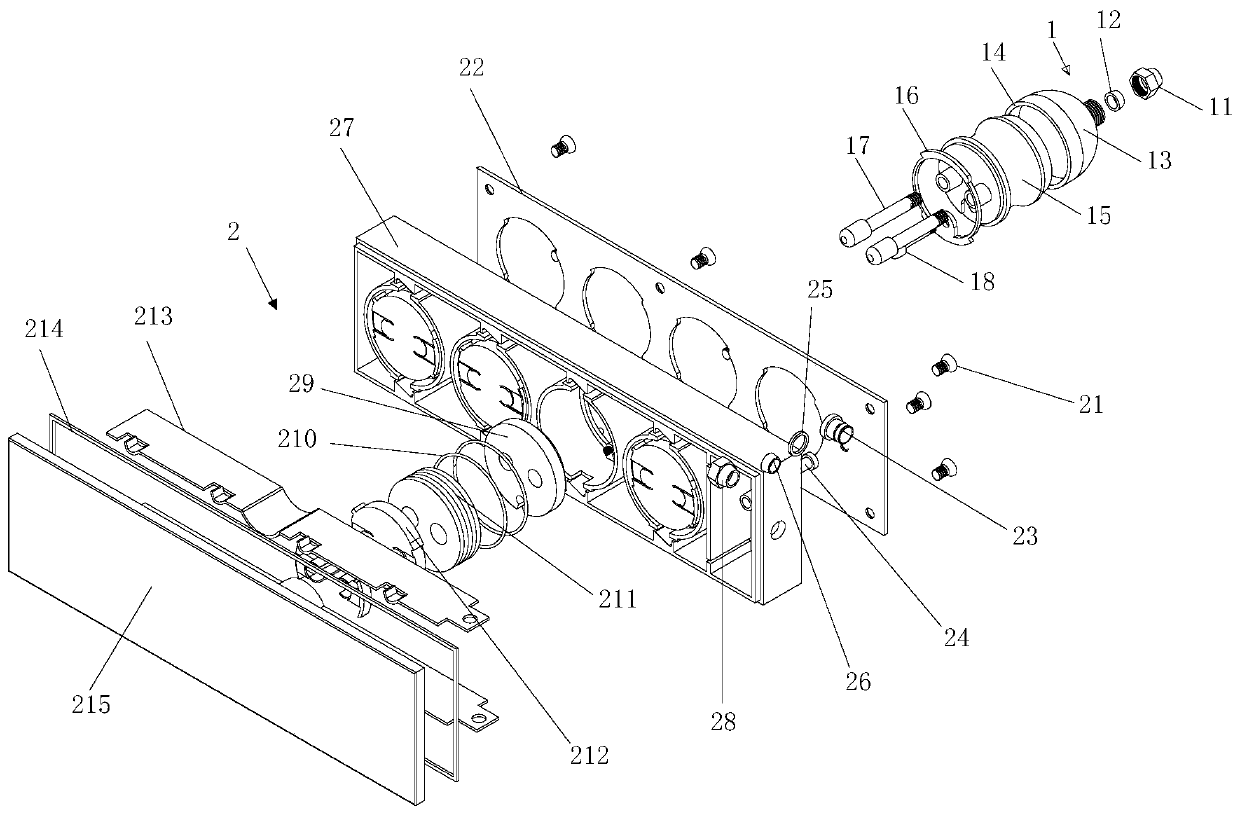

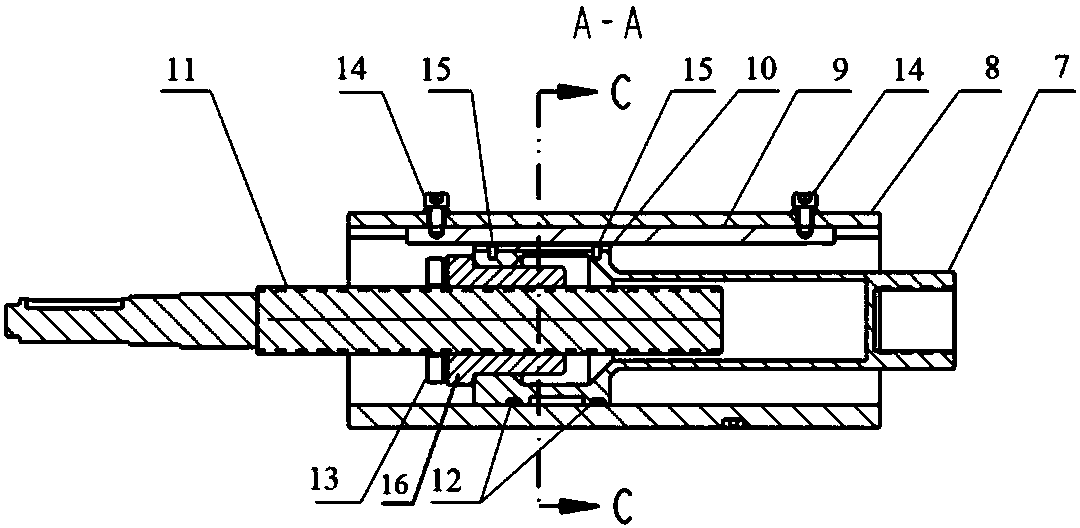

Waterproof socket and waterproof plug capable of being operated underwater

PendingCN111244672AImprove safety and usabilityProtection Against Electric Shock HazardsCouplings bases/casesTwo-part coupling devicesElectrically conductiveContact position

The invention discloses a waterproof socket and plug capable of being operated underwater. The waterproof socket comprises a plug, a row type socket matching the plug, and a wall socket matching the plug. The plug comprises a taper hole sealing nut, a silica gel taper plug, a junction box cover, a sealing silica gel ring, a junction box insertion fixing seat, a metal ground wire buckle, a conductive contact and a ground wire connecting insert. The silica gel conical plug is clamped in a conical hole sealing cap; the taper hole sealing cap is in threaded connection with one side of the junctionbox cover, the other side of the junction box cover is connected with the junction box insert fixing seat in a clamped mode, a sealing silica gel ring is arranged at the contact position of the junction box cover and the junction box insert fixing seat, and two conductive contacts are in threaded connection with the side, away from the junction box cover, of the junction box insert fixing seat. The waterproof socket and plug capable of being operated underwater have the advantages of being operated underwater, preventing misplug by children, being not easy to loosen when the wire socket and plug are pulled, preventing electric arcs from being generated and the like.

Owner:黄小平 +1

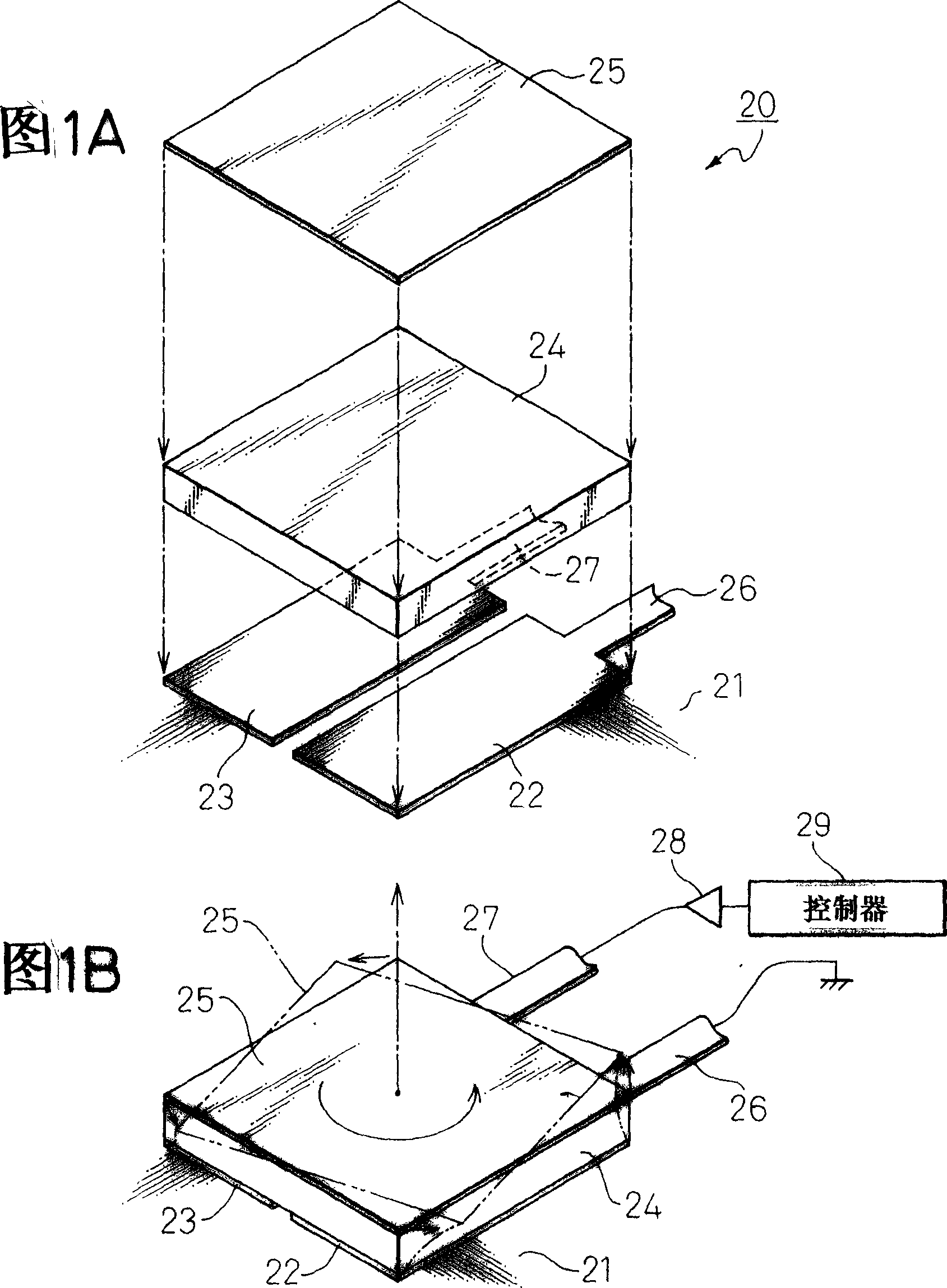

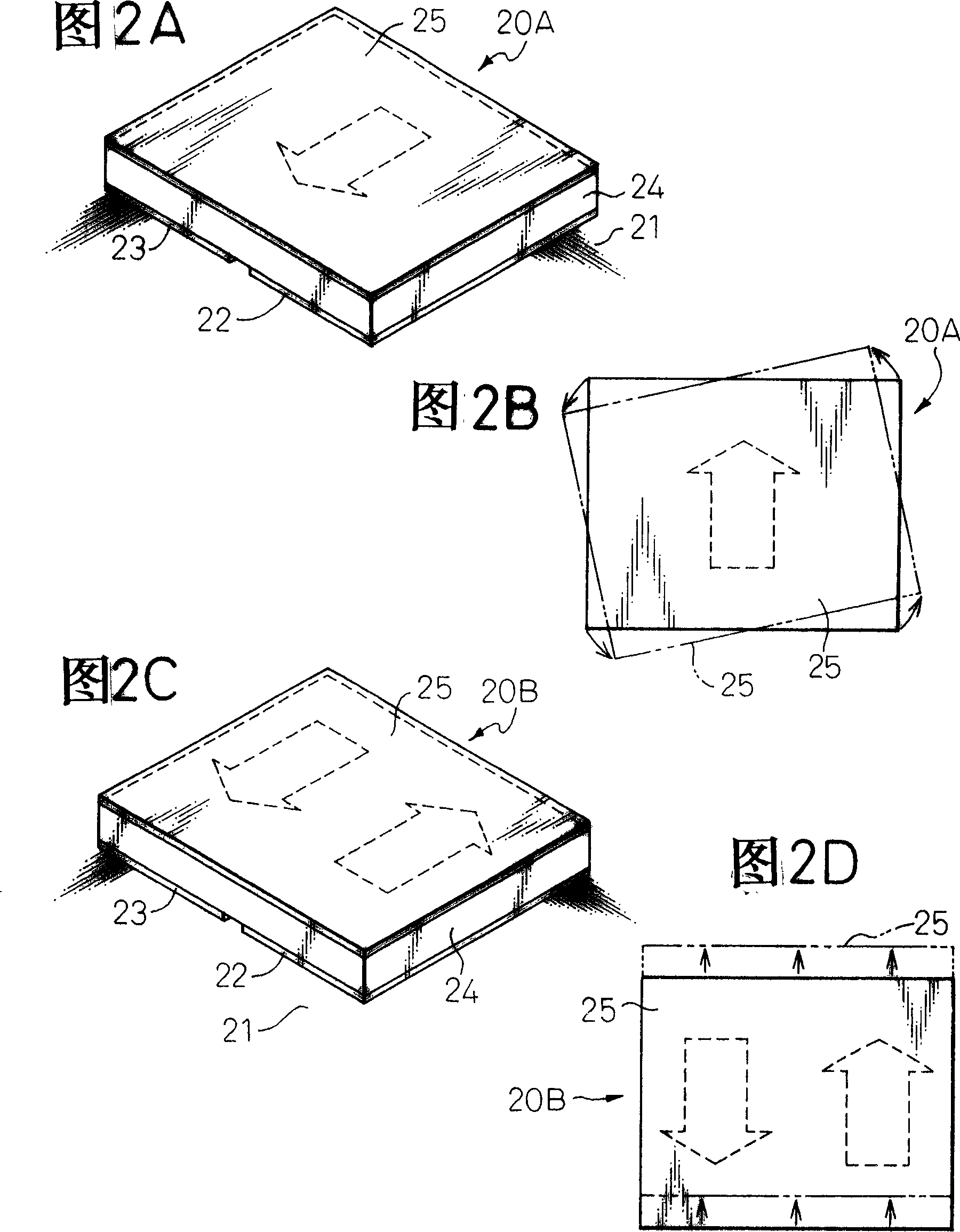

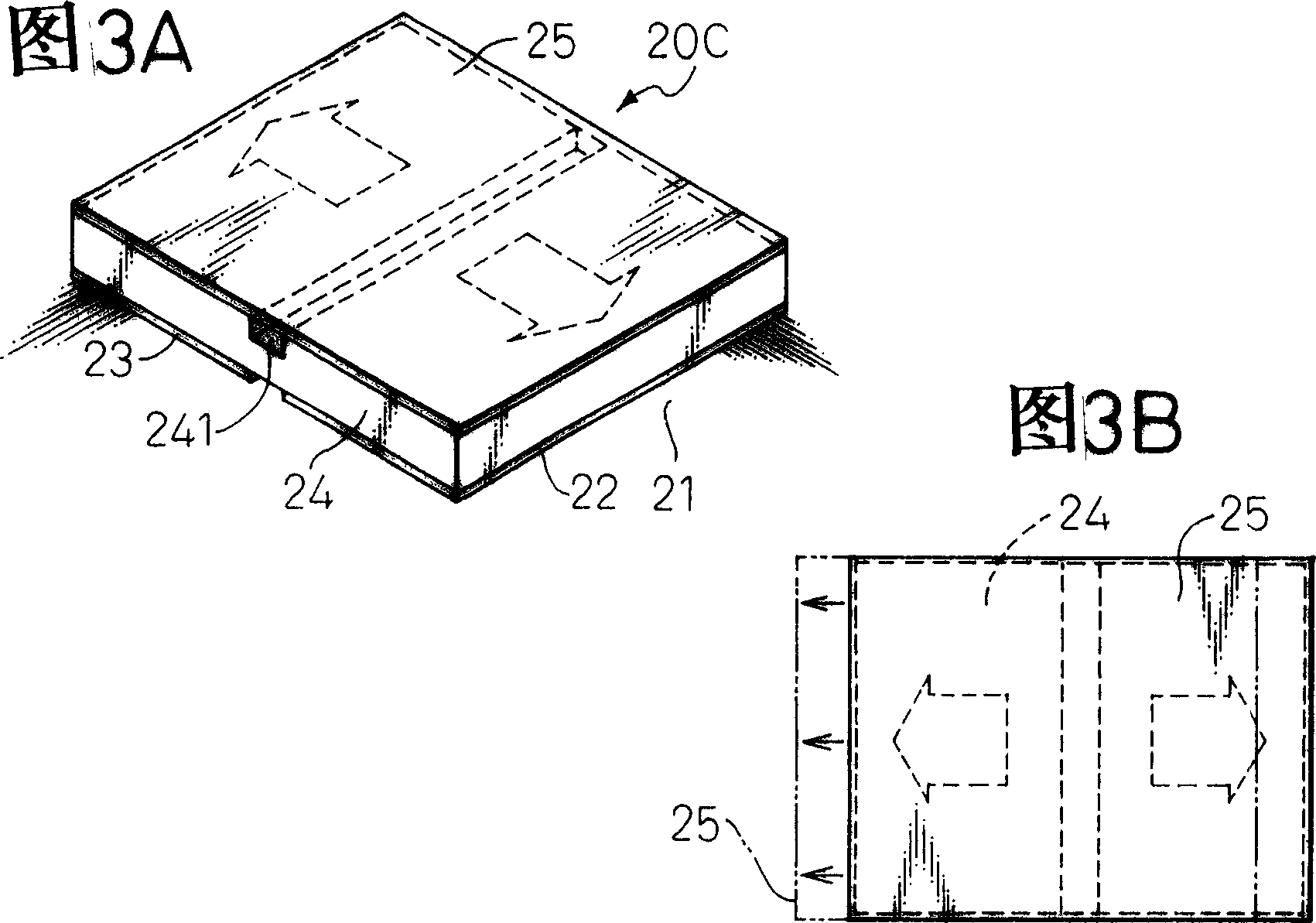

Actuator using piezoelectric element and head-positioning mechanism using the actuator

InactiveCN1523577ALow costHigh precisionTrack finding/aligningPiezoelectric/electrostriction/magnetostriction machinesEngineeringActuator

An actuator having a simple configuration requiring no high dimensional accuracy, high in positioning accuracy and low in cost, and a head-positioning mechanism using the actuator are disclosed. An actuator according to a first application comprises a shear-type piezoelectric element of predetermined thickness and an opposed electrode formed on two electrodes in spaced relationship on a base member. The opposed electrode is displaced in accordance with the direction of polarization of the shear-type piezoelectric element upon applying a voltage between the two electrodes. The opposed electrode thus constitutes an operating section of the actuator. An actuator according to a second application comprises a movable member arranged on a drive member including a shear-type piezoelectric element on a base member. The drive member includes a plurality of layers of piezoelectric elements polarized in alternately opposite directions perpendicular to the thickness of the devices. A plurality of conductive layers are formed adjacently to the respective layers of the devices to permit voltage application thereto. The movable member can be driven in parallel to the base member upon application of a voltage between the conductive layers. Any one of these actuators can be incorporated as a part of the head actuator to constitute a head-positioning mechanism capable of displacing the head by a minuscule distance independently of the operation of the head actuator.

Owner:TOSHIBA STORAGE DEVICE CORP +1

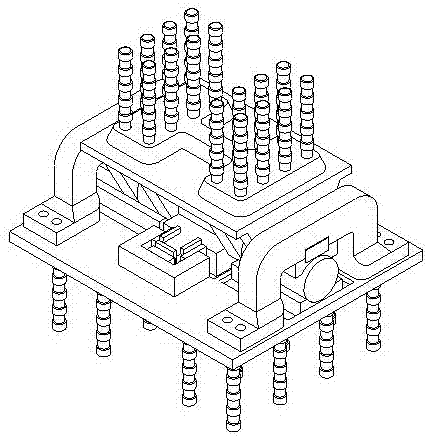

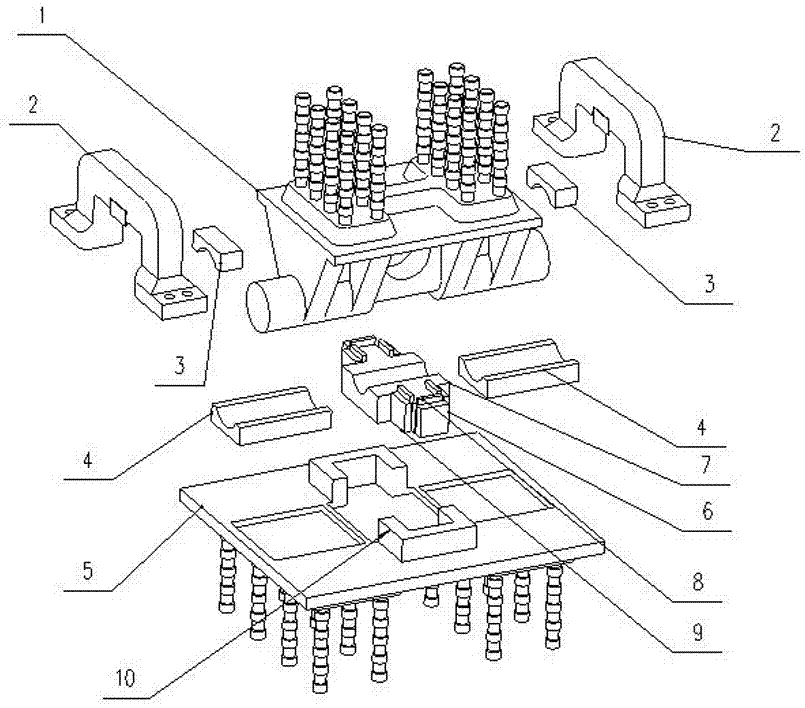

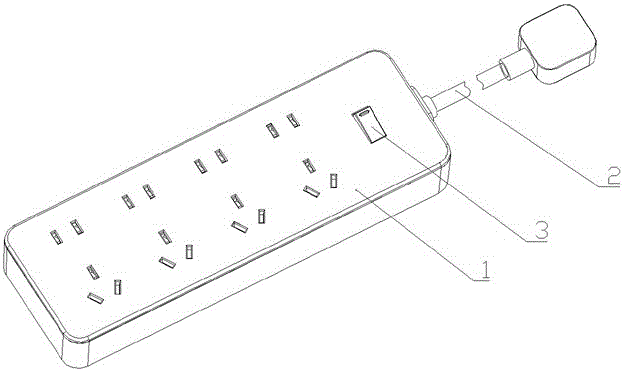

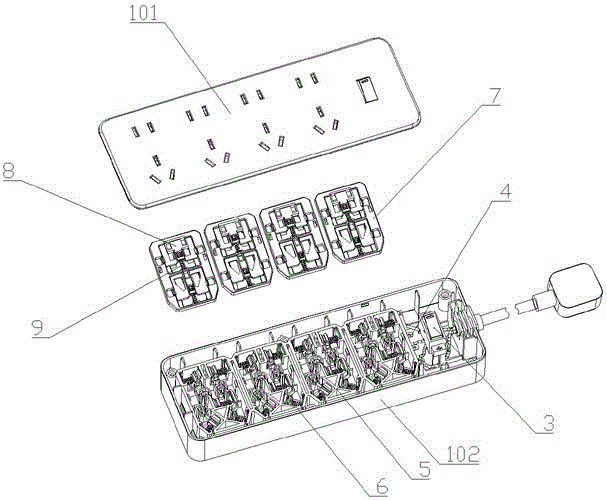

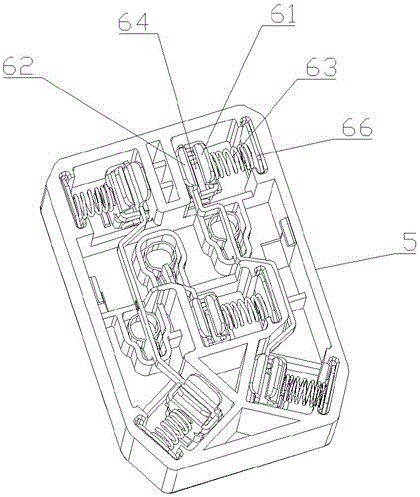

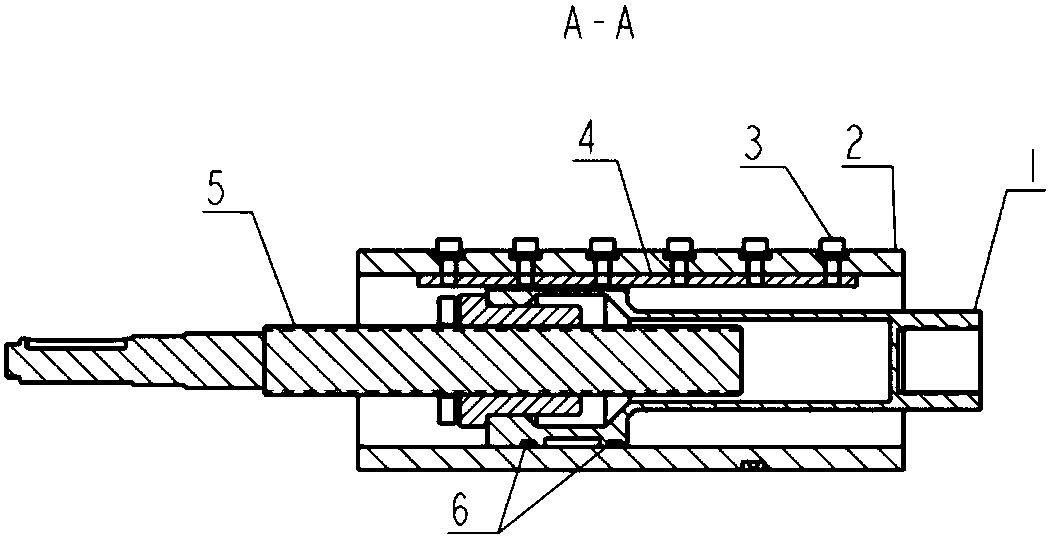

Modular socket

ActiveCN106532338ARealize automated assemblyLow input costCoupling contact membersModularityEngineering

The invention aims at providing a modular socket, which is simple in structure, low in cost and reliable in performance and can achieve massive production. The modular socket comprises a housing (1), a plug connection line (2), a switch (3), at least one conducting module arranged in the housing (1) and a plurality of conductive connection plates (4) located at the lower part of the conducting module, wherein the plug connection line (2) is electrically connected with the switch (3); the conducting module comprises a module box body (6) and at least one plug conducting unit arranged in the module box body (6); the plug conducting unit comprises at least two conducting devices (7); and the conductive connection plates (4) are connected with the conducting devices (7) in a one-to-one correspondence manner and then electrically connected with the switch (3). The modular socket can be used for the field of electric equipment.

Owner:刘杰

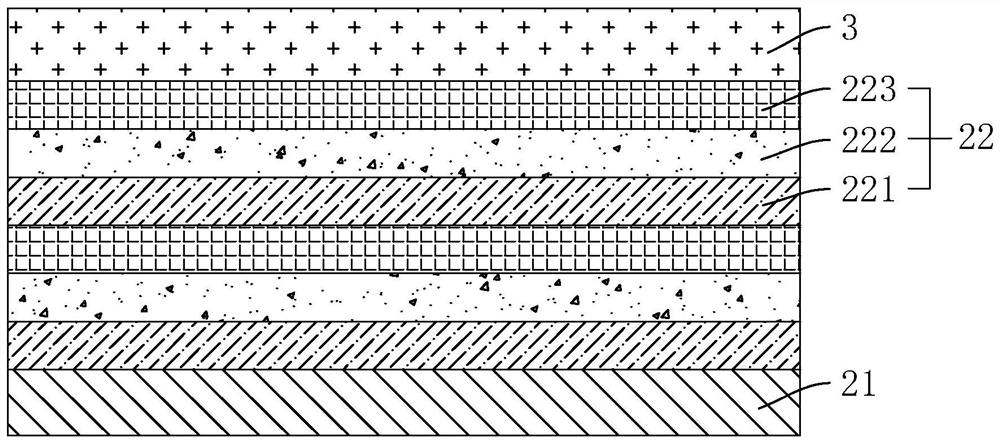

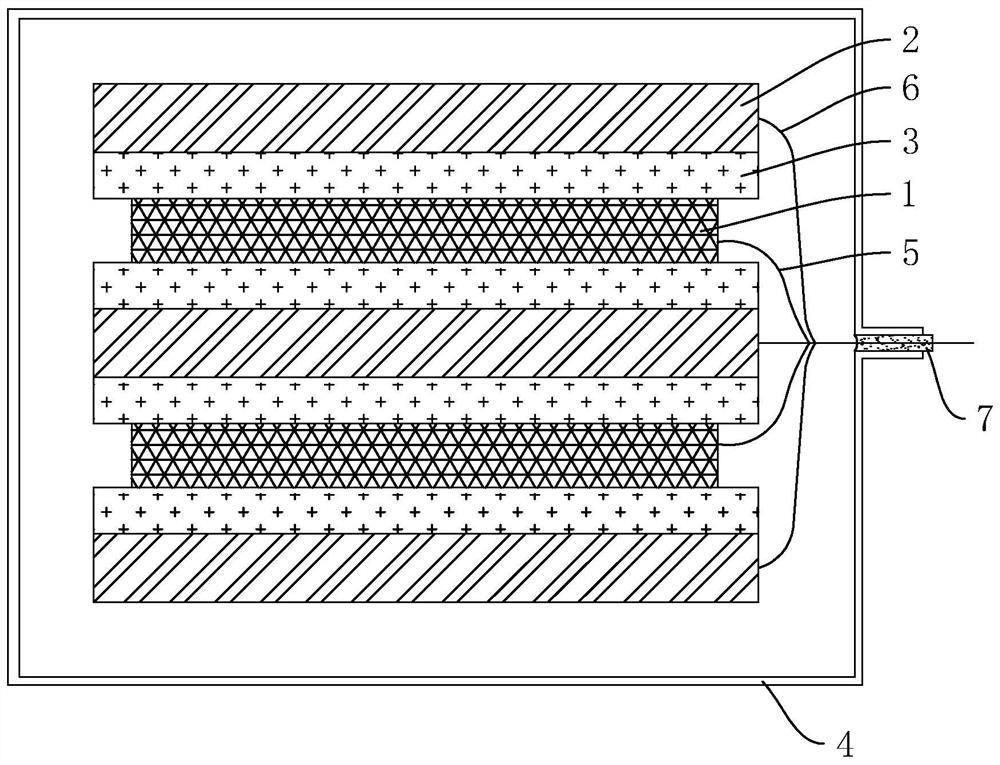

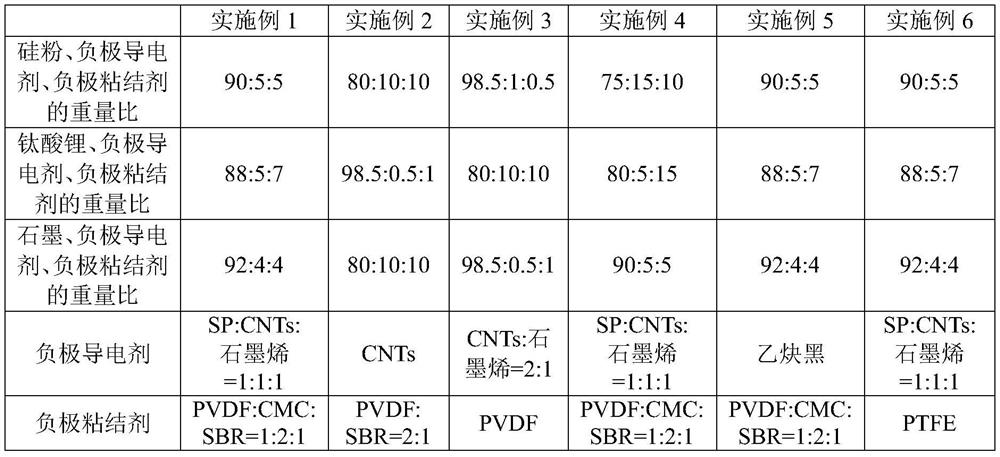

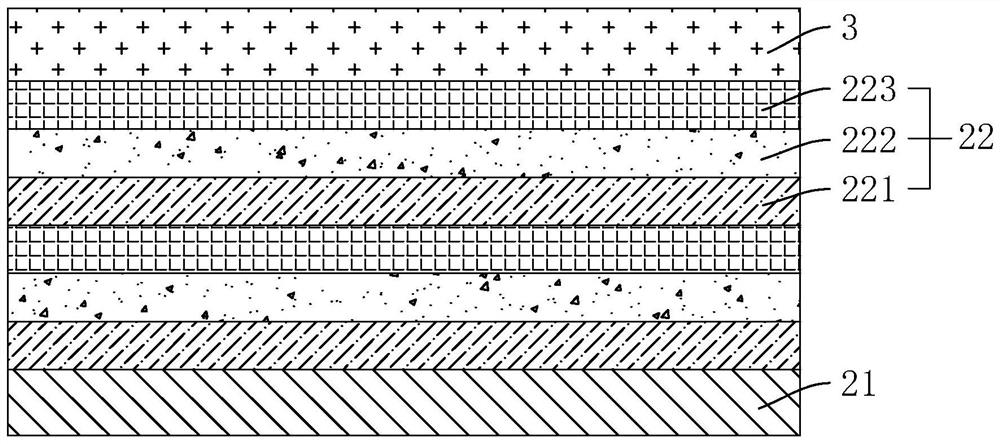

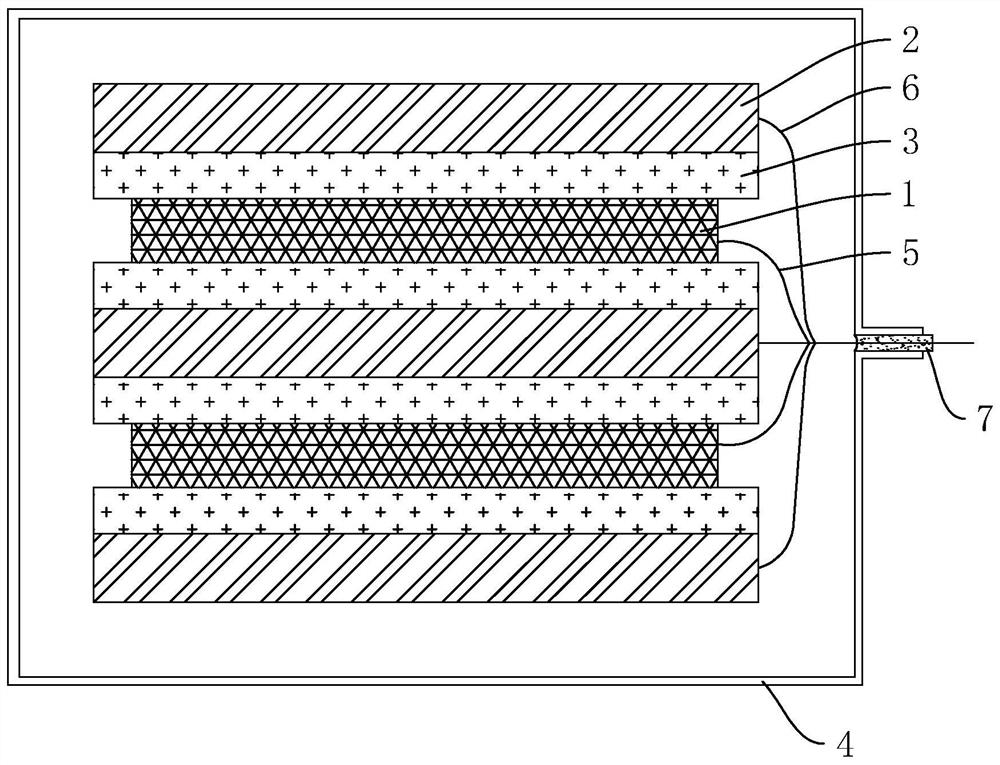

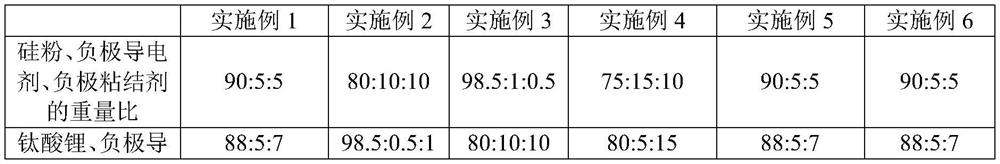

Negative plate with multilayer film structure and mixed solid-liquid electrolyte lithium storage battery thereof

ActiveCN112151757AIncrease energy densityImprove cycle lifeCell electrodesSecondary cellsNew energyHigh energy

The invention belongs to the technical field of new energy lithium secondary batteries, and particularly relates to a negative plate with a multilayer film structure and a mixed solid-liquid electrolyte lithium storage battery thereof, which have the characteristics of high energy density, long cycle life, excellent rate capability and high safety performance. The negative plate comprises a current collector and a plurality of negative composite layers arranged on the current collector, each negative composite layer comprises a silicon layer, a lithium titanate layer and a graphite layer whichare sequentially compounded, and the silicon layers are fixed on the current collector. The lithium storage battery comprises a positive plate, the negative plate, a mixed solid-liquid electrolyte membrane, an outer packaging membrane, a positive tab and a negative tab, the mixed solid-liquid electrolyte membrane is arranged between the graphite layers of the positive plate and the negative plate; the outer packaging film coats the outer sides of the positive plate and the negative plate; one end of the positive tab is connected to the positive plate, and the other end of the positive tab extends out of the outer packaging film; one end of the negative tab is connected to the negative plate, and the other end of the negative tab extends out of the outer packaging film. The invention discloses the negative plate and the lithium storage battery.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

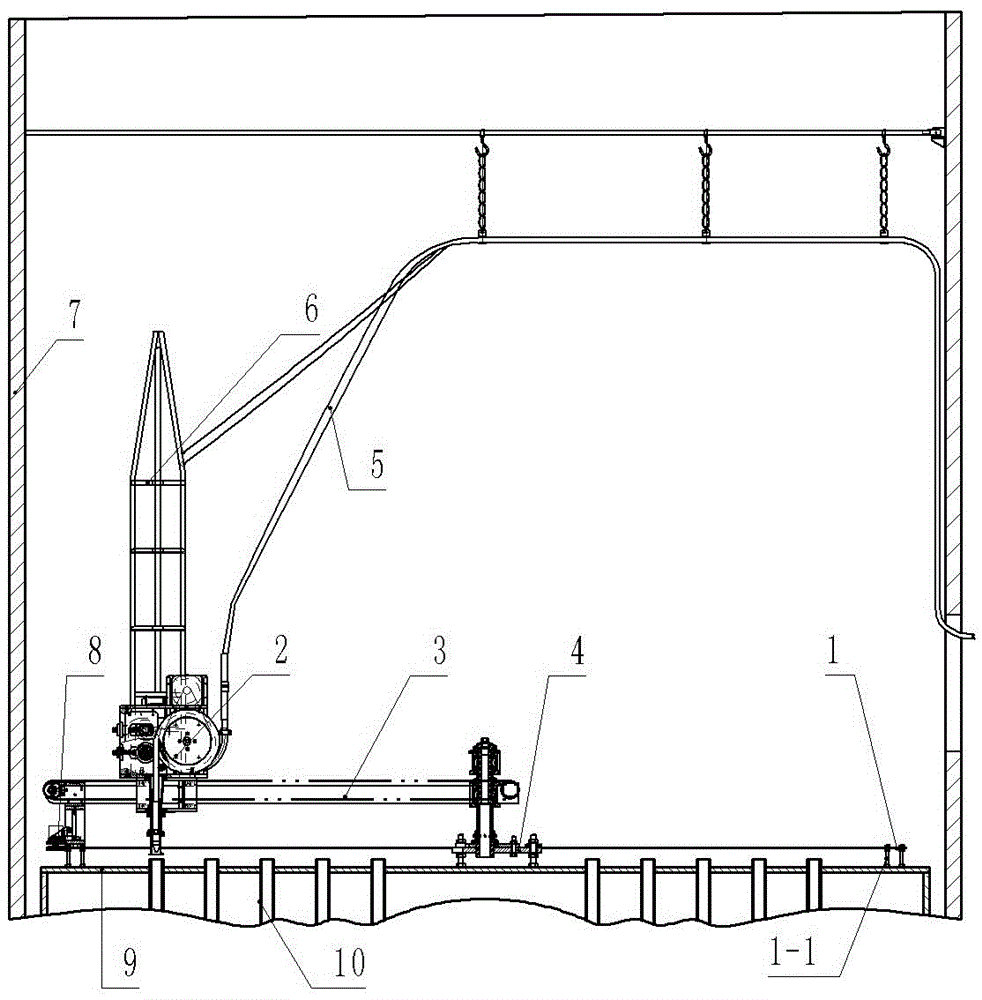

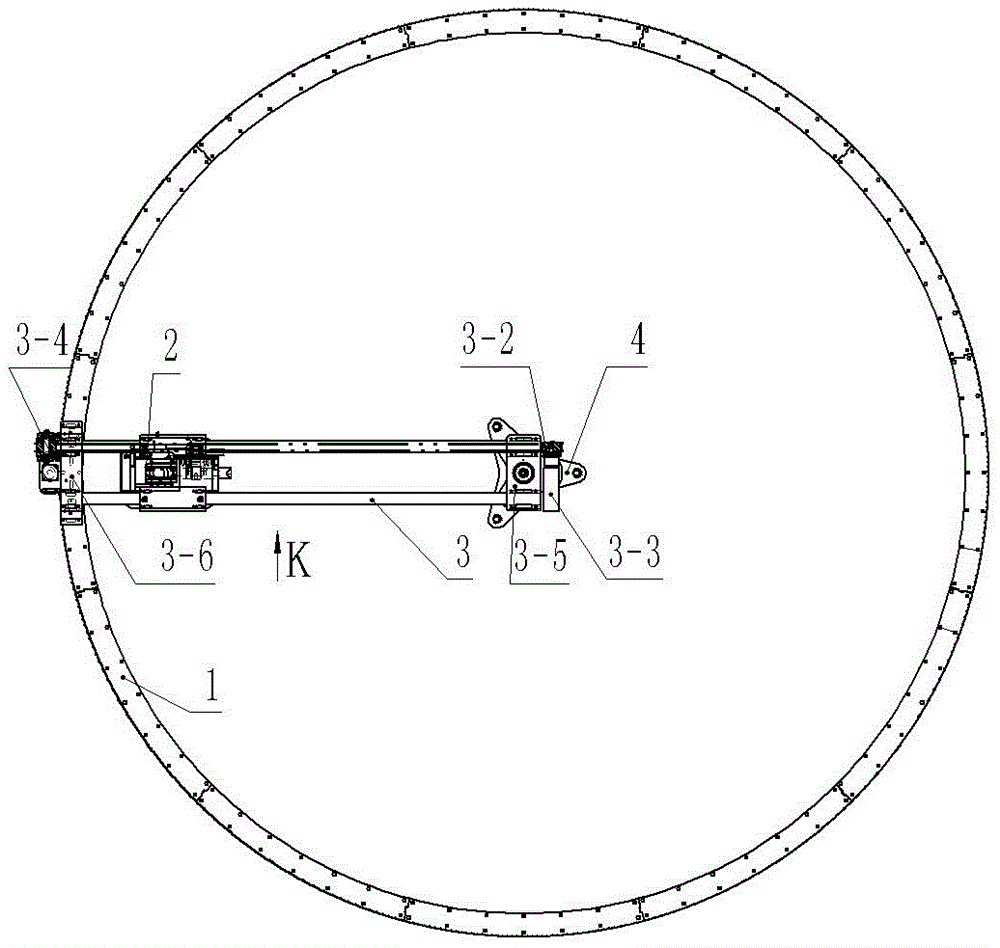

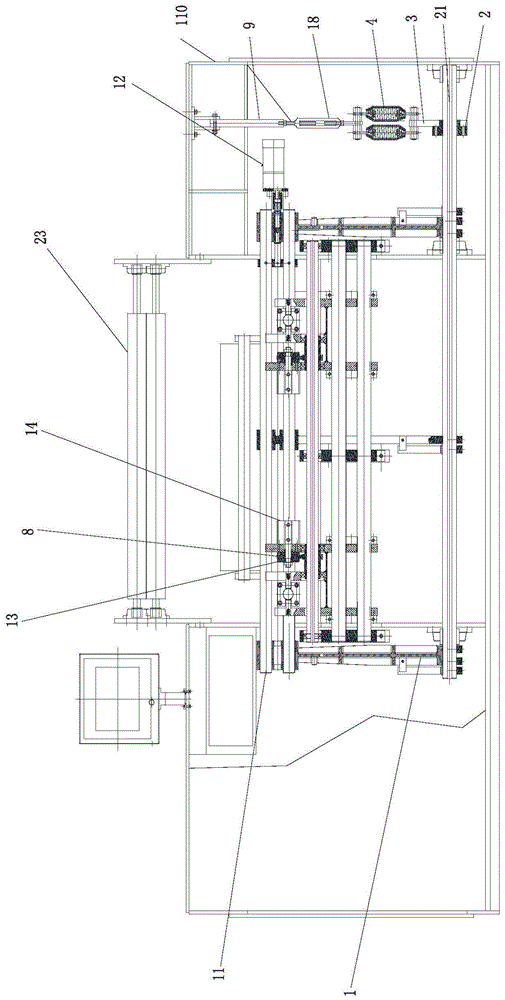

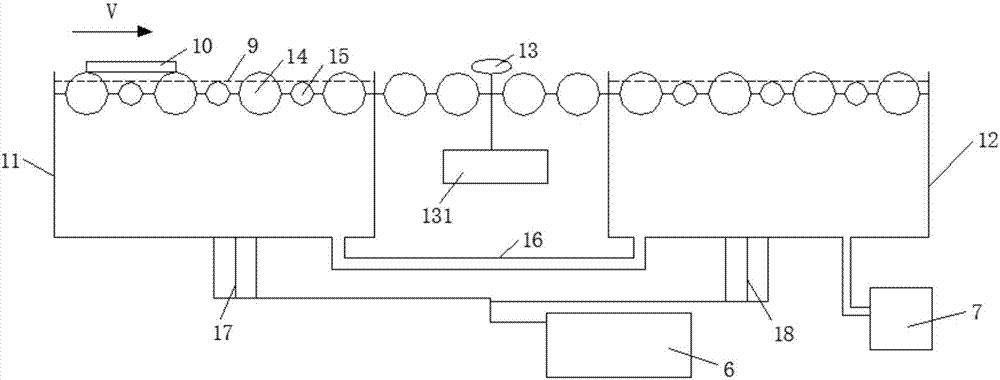

Heat exchange tube cleaning machine

The invention discloses a washing machine for heat exchange tubes and relates to the technical field of washing equipment manufacturing. The washing machine for the heat exchange tubes comprises an end plate arranged in a barrel and multiple heat exchange tubes extending out of the end plate, wherein an annular guide rail is arranged on the position, close to the side wall of the barrel, of the end plate. One end of a sliding rail frame walks on the annular guide rail through a small rail car driven by a car driving motor, the other end of the sliding rail frame is installed in the center of the end plate through a rotary shaft, two sliding rails which are arranged in parallel are arranged on the sliding rail frame, and a high-pressure water gun driving device which is driven by a sliding rail driving device is installed on a sliding frame of the sliding rails. A high-pressure water pipe collection frame is arranged on the position, above the high-pressure water gun, of the sliding frame. Comparing with the prior art, the washing machine for the heat exchange tubes solves the problems that gravity shift often occurs when the high-pressure water gun driving device of the existing washing machine slides on the sliding rails and the high-pressure water pipe often slips when moving up and down.

Owner:LIUZHOU LIANMENG SIPHUNCULUS EQUIP MFG +1

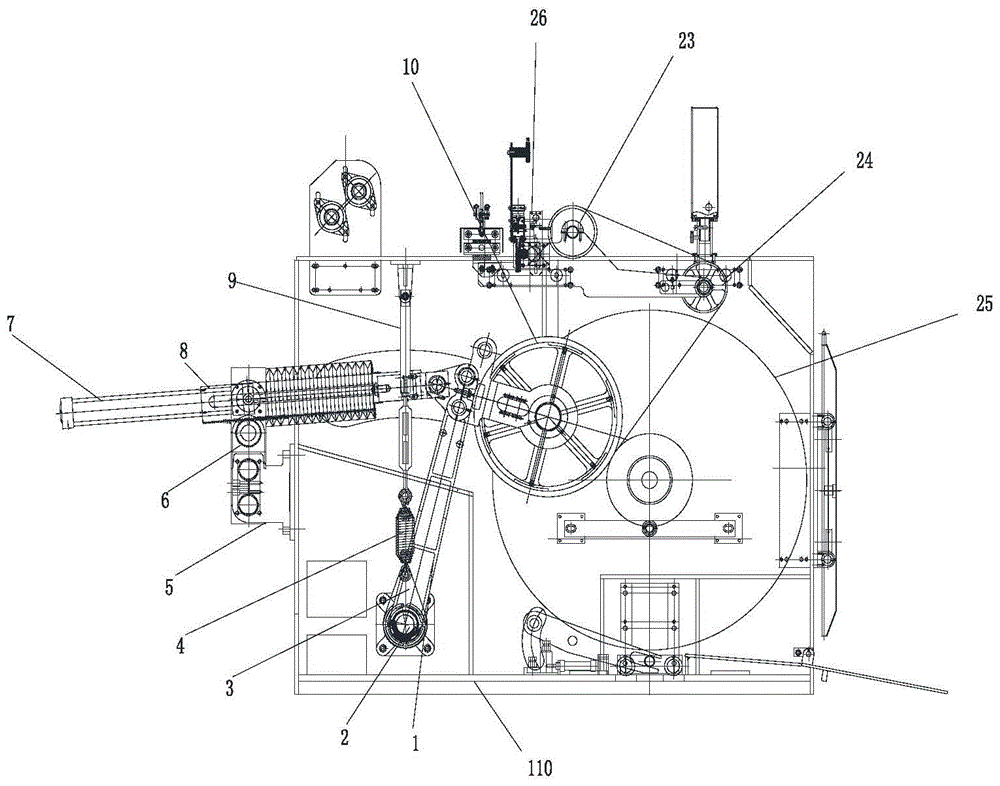

Dust removal device of printing machine

InactiveCN106926575AEasy to installEfficient removalPrinting press partsPulp and paper industryEngineering

The invention discloses a dust removal device of a printing machine, which comprises a machine body, dust removal rollers are arranged in the body, film coils are driven between the dust removal rollers, a drawing hole is provided in the machine body, and an installation base is slidably connected to the drawing hole , There is a dust collection paper roll on the installation base, a card slot is fixedly connected to the installation base, an elastic pressure plate is provided on the inner wall of the card slot, and a limit block is provided on the dust collection paper roll, and the limit block is limited to the elastic pressure plate. In between, the body is provided with a fixed shaft, the fixed shaft is provided with a rotating rod, a brush roller is arranged between the rotating rods, and a fastener is provided on the fixed shaft, and the fastener is fixedly connected to the brush roller on the body. The invention is simple and convenient to install the dust collecting paper roll, can quickly and efficiently remove the dust on the film coil, and improve the cleanliness of the product surface; at the same time, adjust the angle of the brush roller, change the contact and pressure between the brush roller and the film coil, and improve Dust removal effect, to avoid damage to the film coil.

Owner:全南县智护力工业产品设计有限公司

Electric control solid thruster

InactiveCN114278463AChange thrustNo change in resistanceRocket engine plantsThermal insulationElectric control

The invention discloses an electric control solid thruster, belongs to the field of special solid propellant rocket engines, and aims to solve the problem of unstable thrust control of an existing end face combustion type thruster. According to the scheme, the square annular electrode comprises four electrode plates and a square fixing frame, and the four electrode plates define a square area which is adjustable in size and axially through; a heat insulation sleeve and a combustion electrode fixing sleeve are arranged in the shell side by side, the combustion electrode fixing sleeve clamps and fixes a combustion electrode, a square annular electrode is installed in a groove in the tail end of the heat insulation sleeve, the square annular electrode is of a structure with the two ends open, and the combustion electrode fixing sleeve is arranged at the tail end of an inner cavity of the shell and provided with an annular notch. The combustion electrode is clamped and fixed at the annular gap, and the annular gap is blocked, filled and leveled up by using the electrode pressing sheet; the tail end of the electric control solid propellant grain penetrates through a square area defined by the four electrode slices and abuts against the end face of the combustion electrode, and an axial working gap is formed between the square annular electrode and the combustion electrode.

Owner:HARBIN INST OF TECH

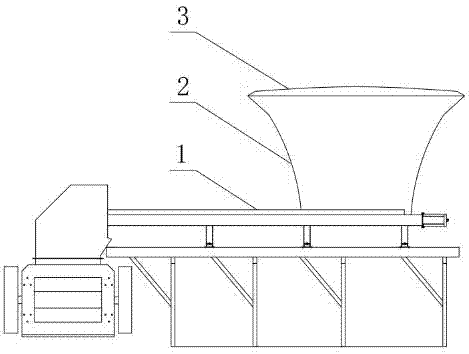

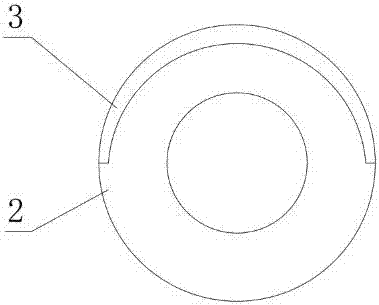

Roller crusher

The invention provides a roller crusher, which is used to prevent wet ore from adhering to a feeding hopper during feeding. It includes a feed hopper, the feed hopper is composed of at least three side plates, one, two or more of the side plates corresponding to the feed side of the feed hopper are arc-shaped plates. This roll crusher has the advantage of preventing wet material from sticking to the feed hopper.

Owner:JIANGSU DELONG NICKEL IND CO LTD

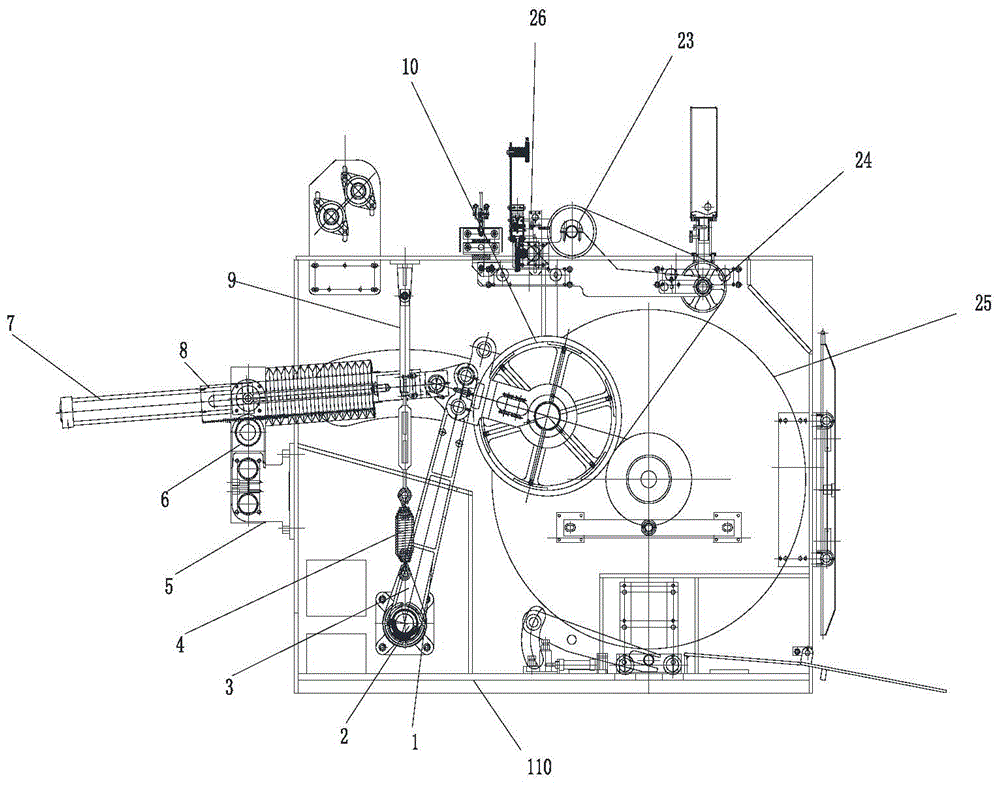

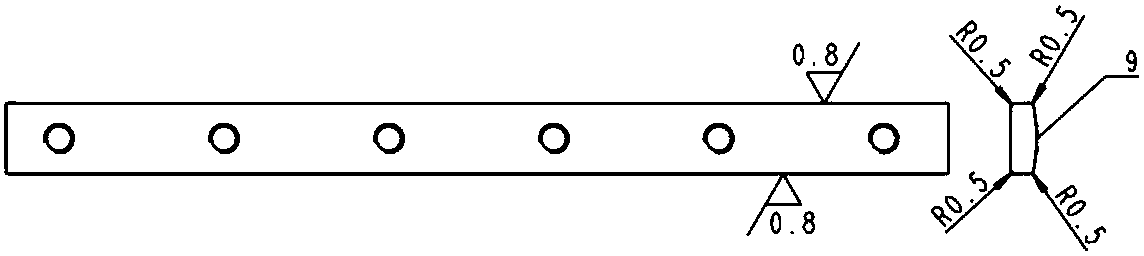

Roll-to-roll continuous electroplating conductive device

ActiveCN112095130BAvoid scratchesClose contactCurrent conducting devicesEngineeringMechanical engineering

Owner:崇辉半导体(深圳)有限公司

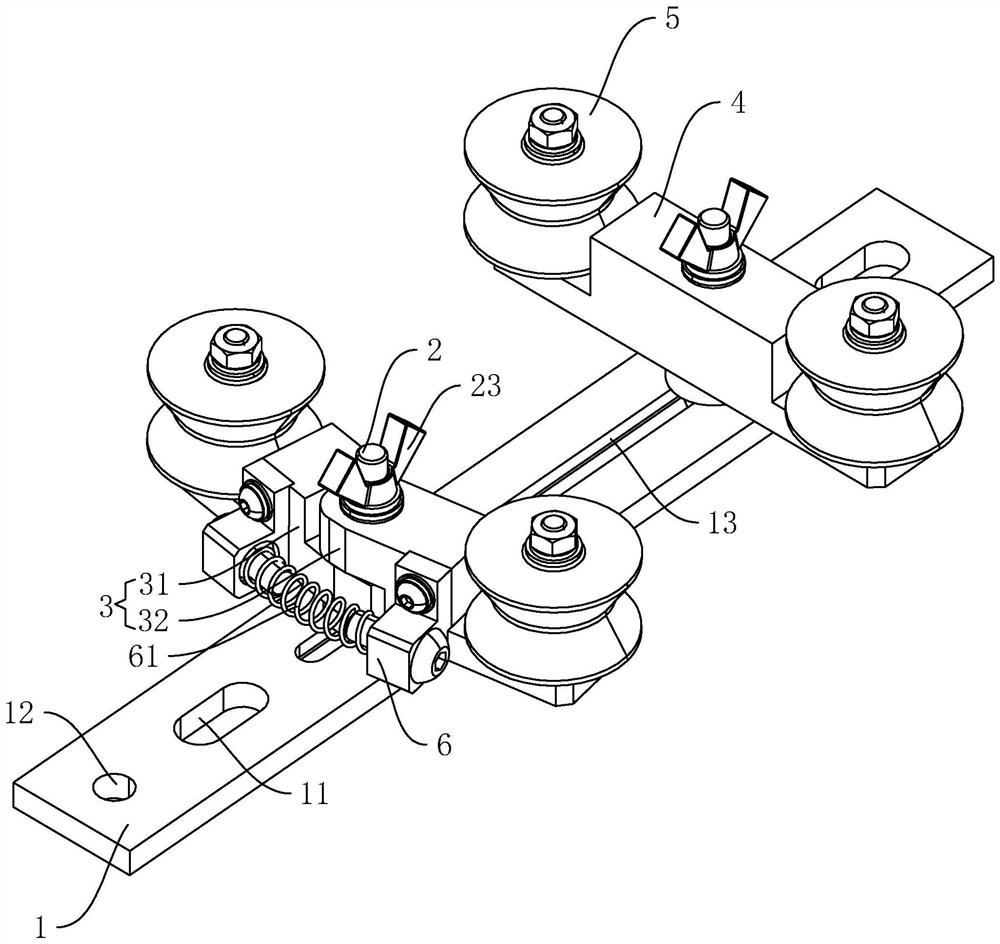

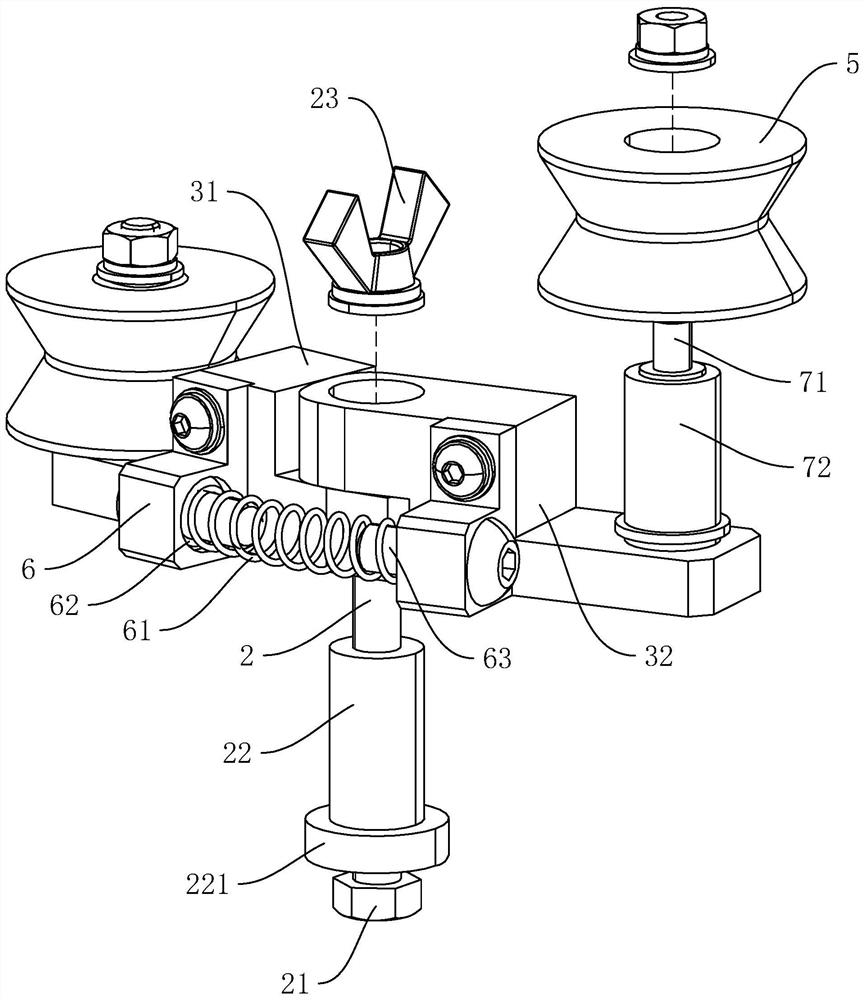

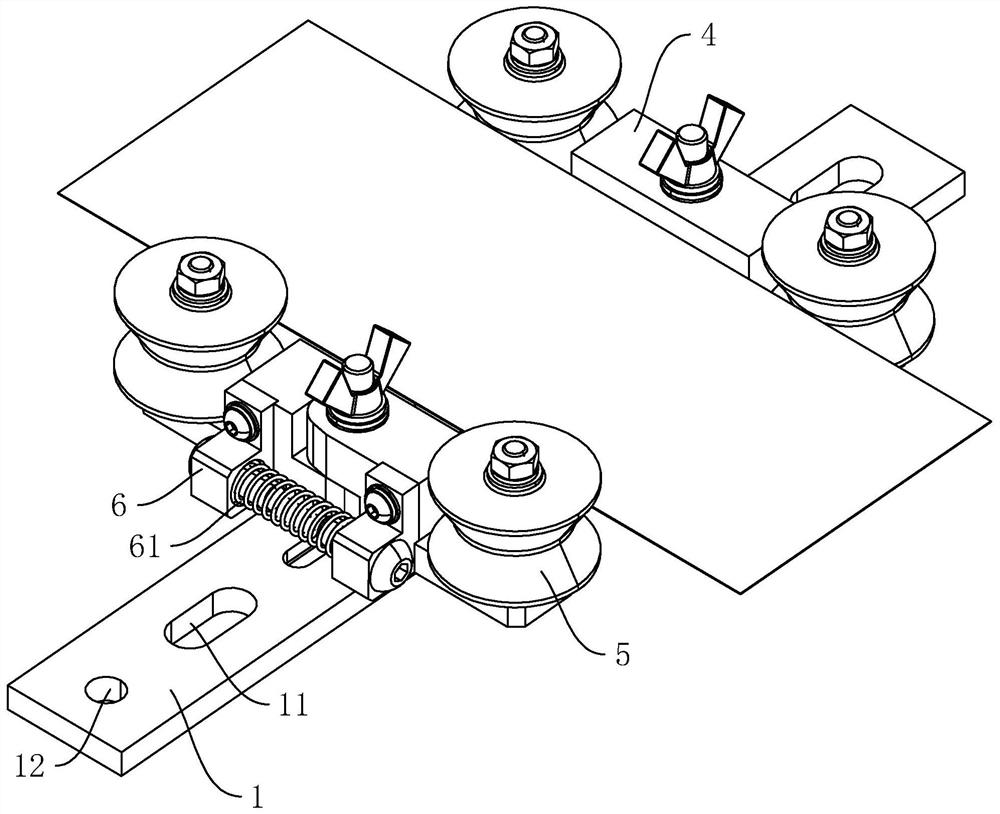

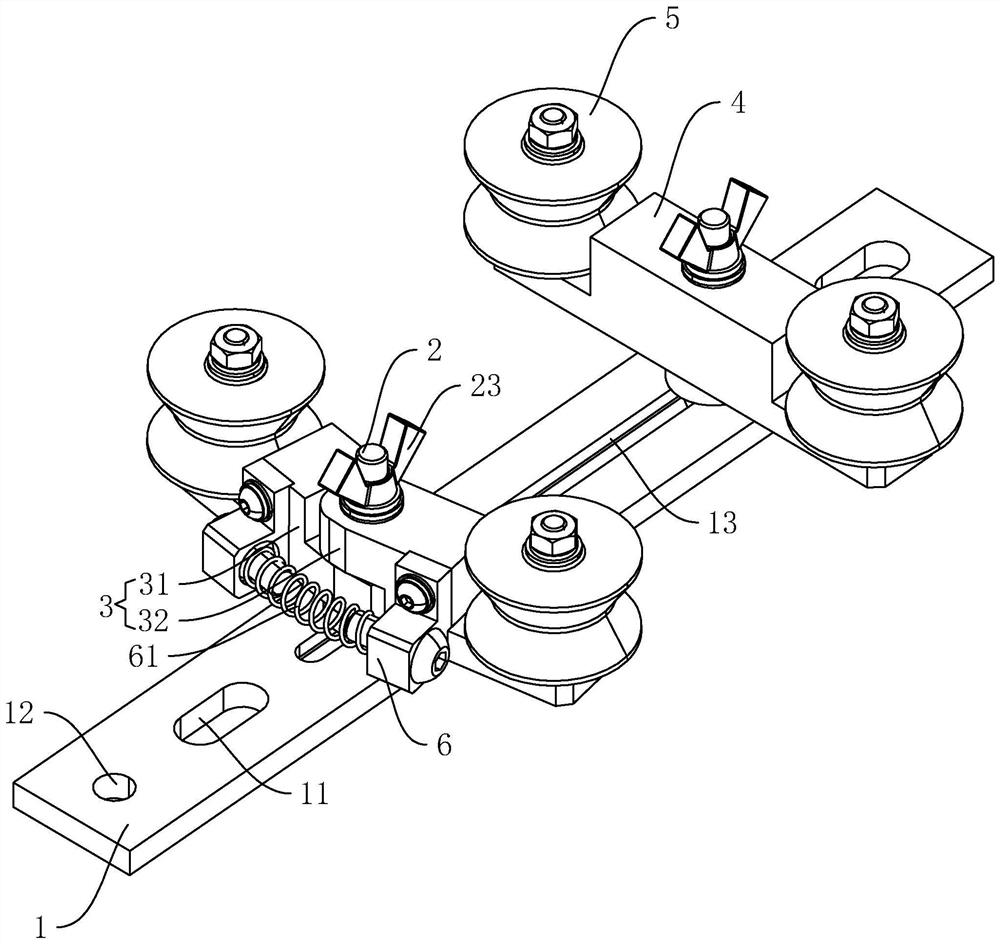

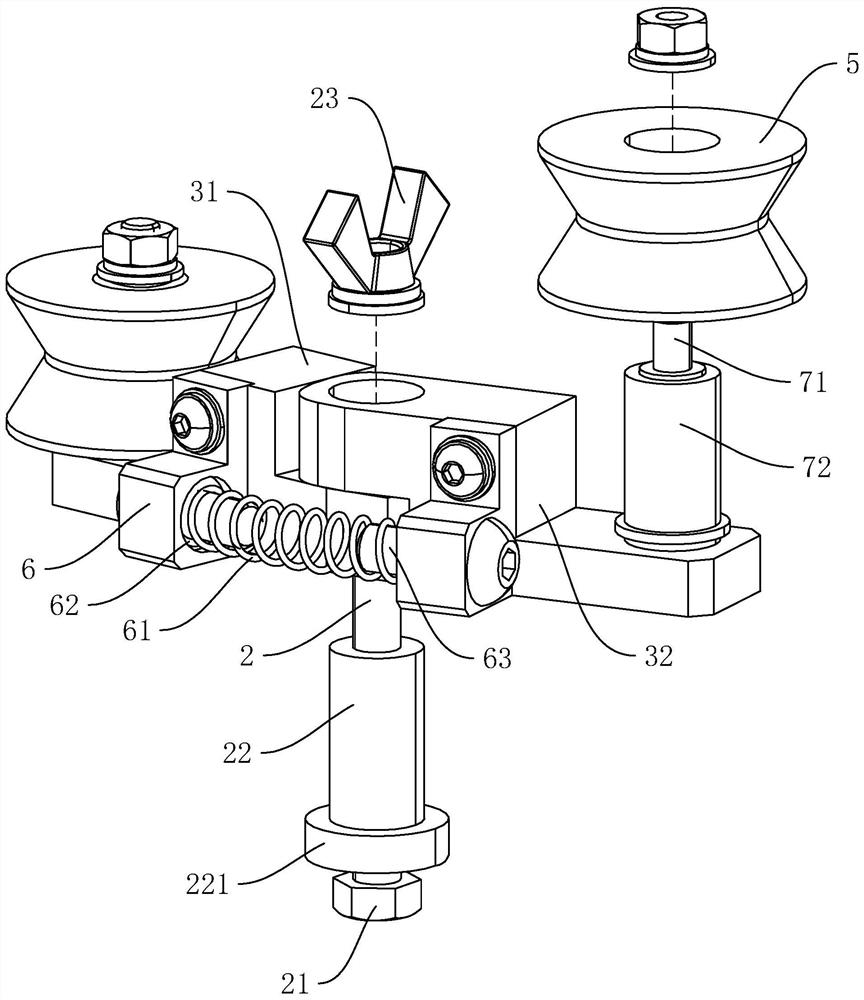

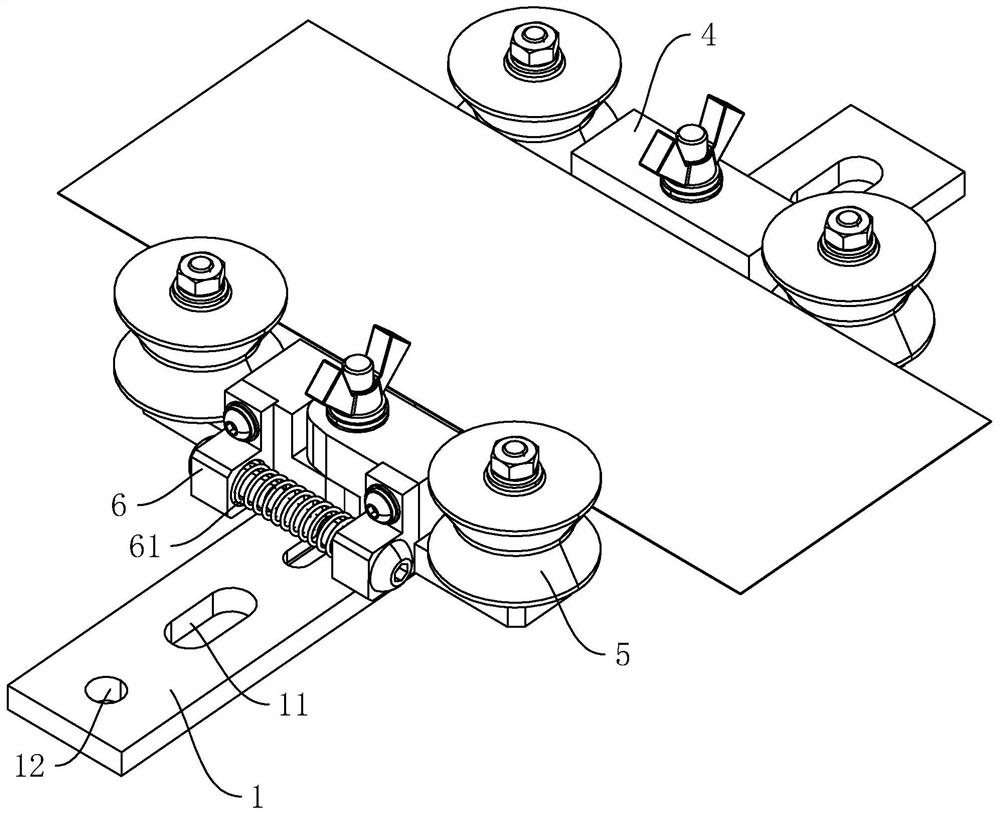

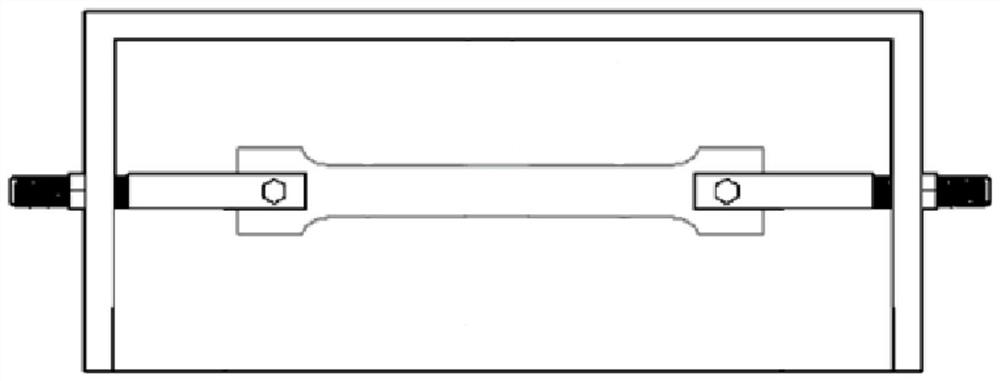

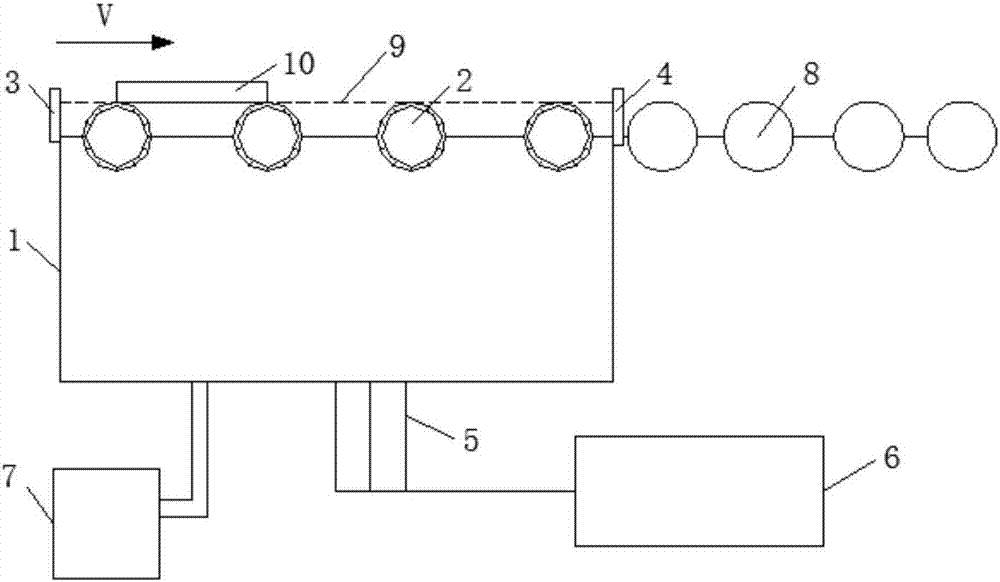

Roll-to-roll type continuous electroplating conductive device

ActiveCN112095130AAvoid scratchesClose contactCurrent conducting devicesEngineeringMechanical engineering

The invention relates to the field of electroplating conductive devices, in particular to a roll-to-roll type continuous electroplating conductive device. The problem that the quality of a plating layer is easily influenced by deviation of an electroplating sheet in the electroplating process is solved. The conductive device comprises a mounting bottom plate, two rotating shafts vertically arranged on the mounting bottom plate, a first mounting base and a second mounting base, wherein the two rotating shafts are rotationally sleeved with the first mounting base and the second mounting base correspondingly, and conductive wheels are horizontally and rotationally arranged at the two ends of the first mounting base and the two ends of the second mounting base correspondingly. The first mounting base comprises a first mounting block and a second mounting block, the first mounting block and the second mounting block are both rotationally connected with the rotating shaft, deviation rectifying blocks are arranged on the sides, away from the second mounting base, of the first mounting block and the second mounting block correspondingly, and a deviation rectifying spring is connected between the two deviation rectifying blocks. When an electroplating sheet deviates, the conductive wheels can rotate and keep close connection with the electroplating sheet, and the automatic deviation rectifying effect is achieved.

Owner:崇辉半导体(深圳)有限公司

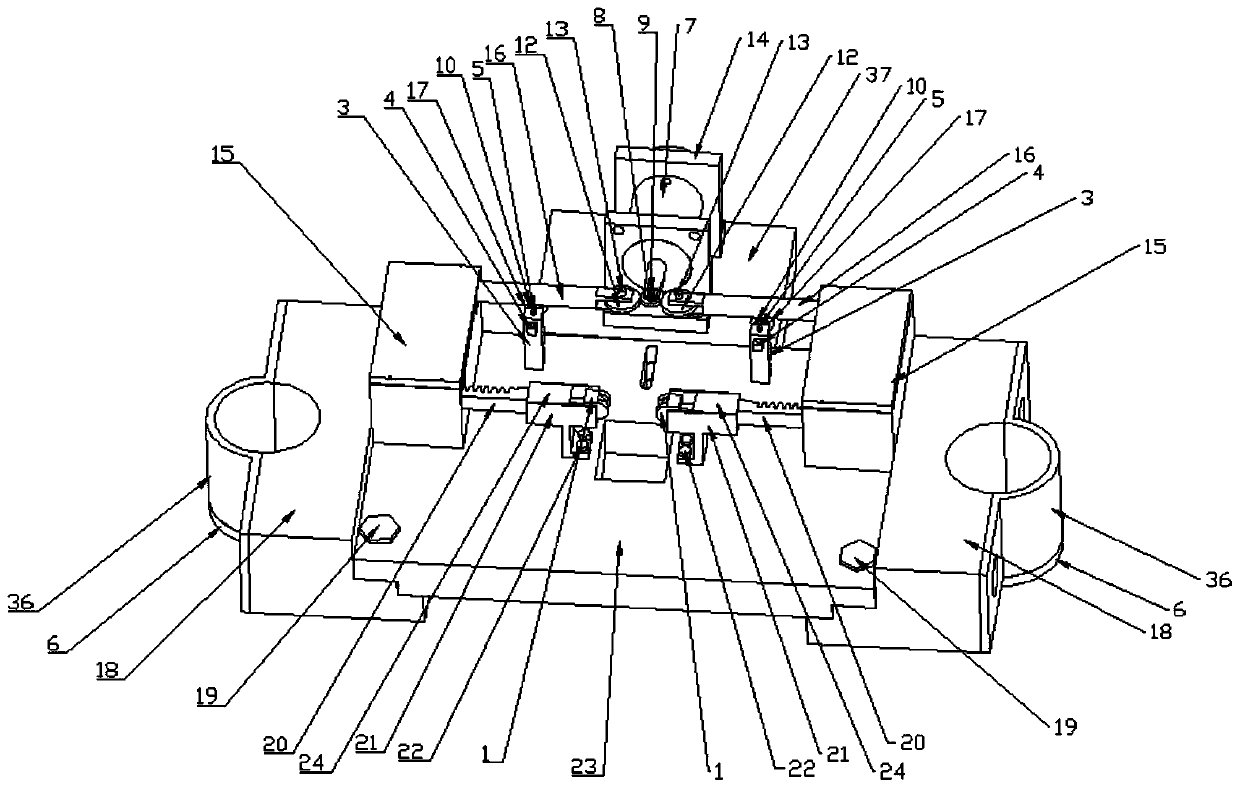

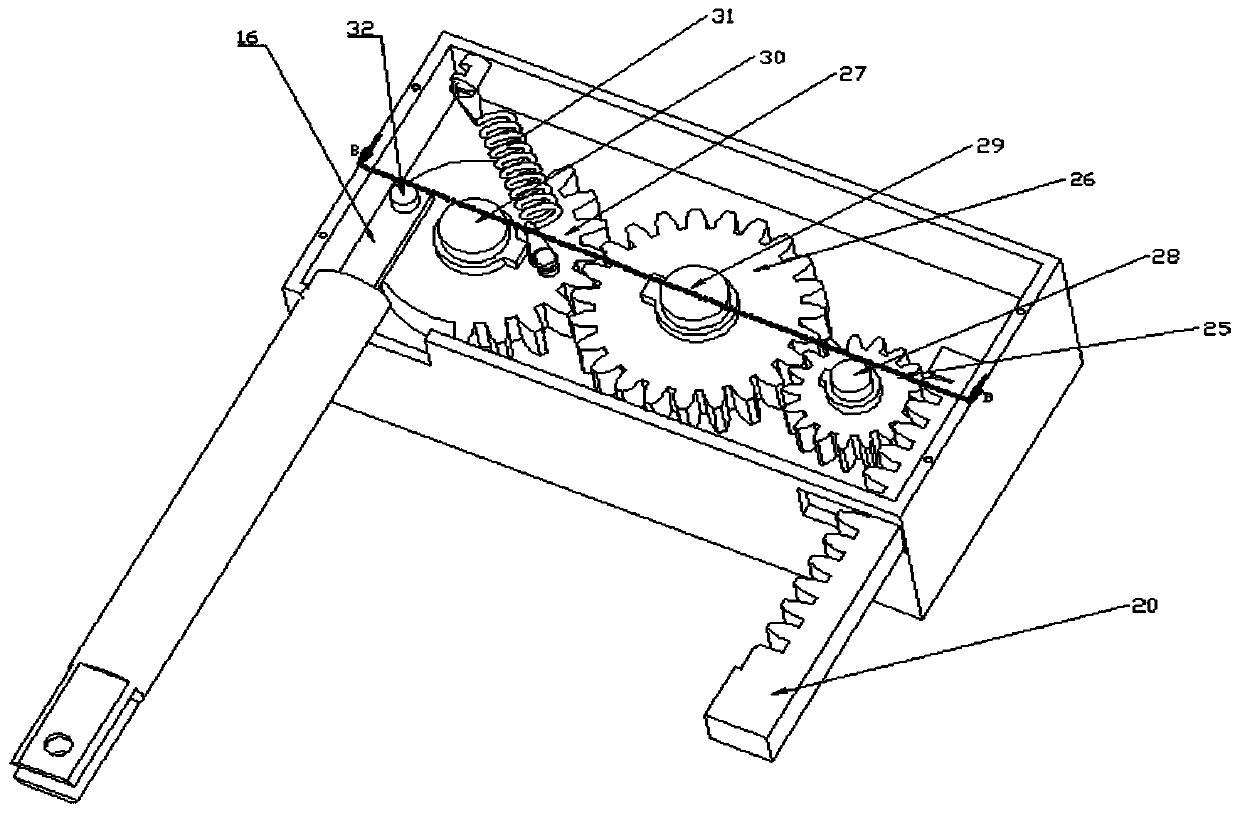

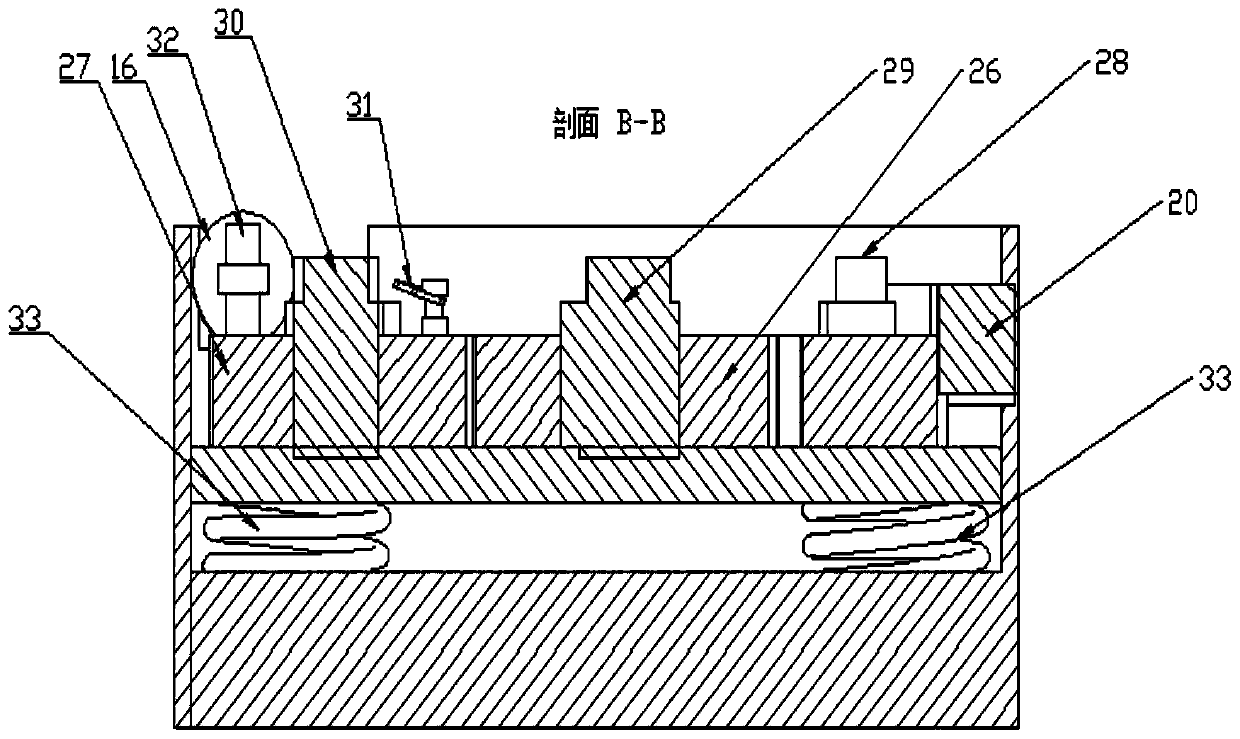

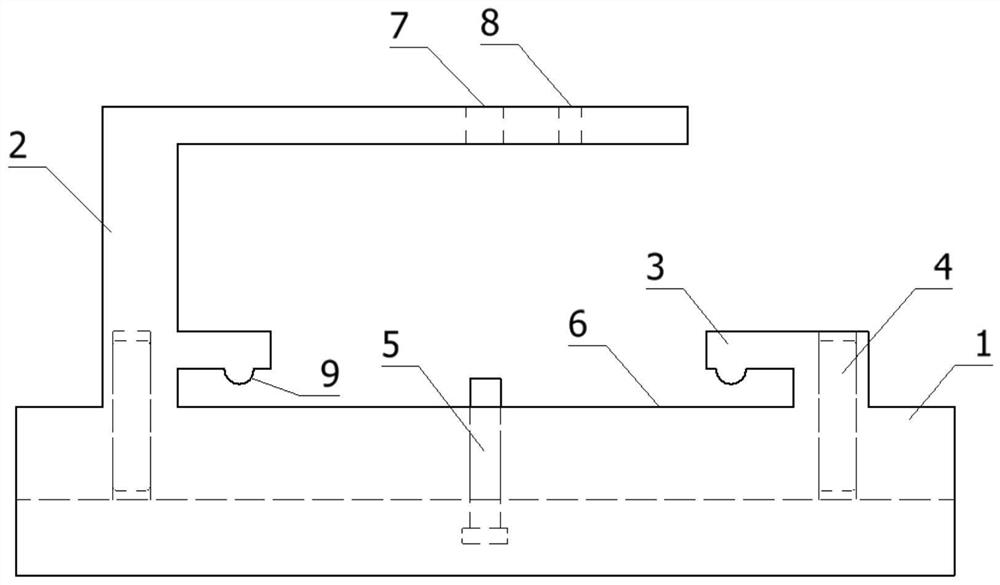

Normal loading device for fretting fatigue test

PendingCN109752258AChange contactLow costMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceT stressHydraulic cylinder

The invention discloses a normal loading device for a fretting fatigue test. The normal loading device comprises a transmission device, a power source device, a supporting device and a clamping device; the two sides of the power source device are connected with the transmission device and the clamping device respectively; the clamping device is provided with a test piece and is connected with a computer through a data line; an incomplete gear of the transmission device is hinged to a connecting rod; the incomplete gear is connected with a box body through a return spring; one side of a rack ismeshed with a pinion; the power source device comprises a hydraulic cylinder, a hydraulic cylinder support, a bearing, a first roller and a hydraulic cylinder base; an output shaft of the hydraulic cylinder is provided with the bearing and the first roller; the two sides of the first roller are in contact with a second roller at one end of the connecting rod; the supporting device comprises a base, a supporting table, an anti-skid damping pad and a supporting table rear cover; a fretting pad bracket of the clamping device is fastened on the base; and a pressure sensor is arranged in the fretting pad bracket, has the two ends in contact with the rack and a fretting pad connecting rod respectively, and is connected with the computer through a data line.

Owner:ZHEJIANG UNIV OF TECH

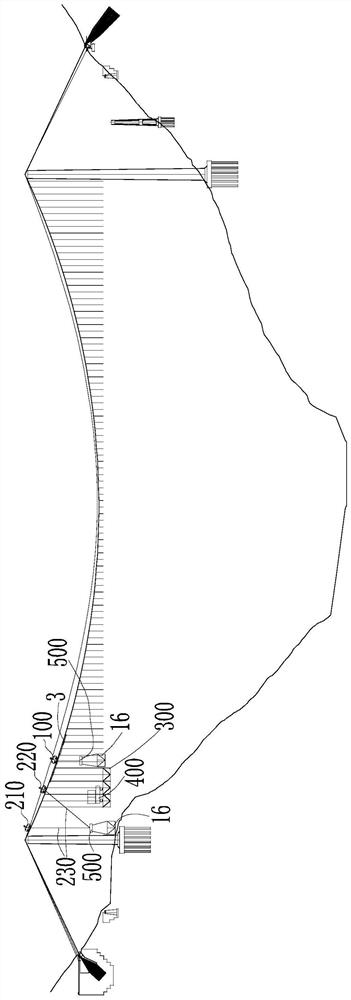

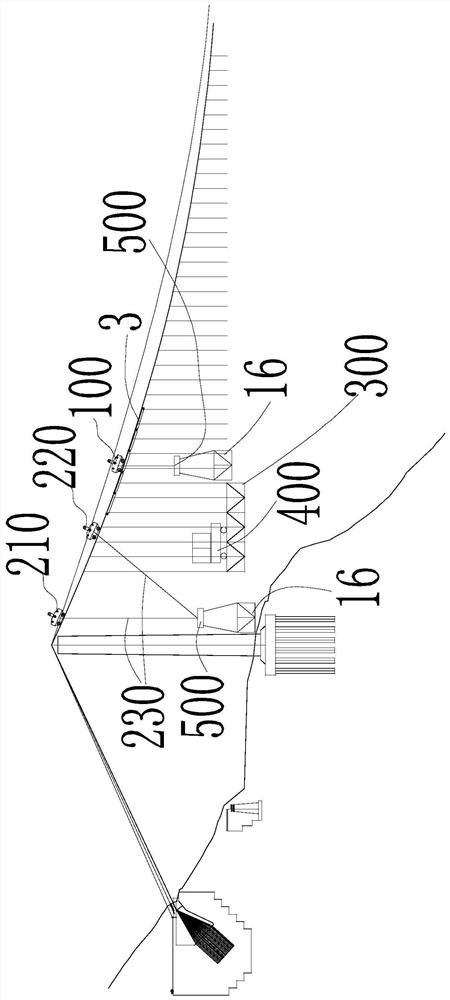

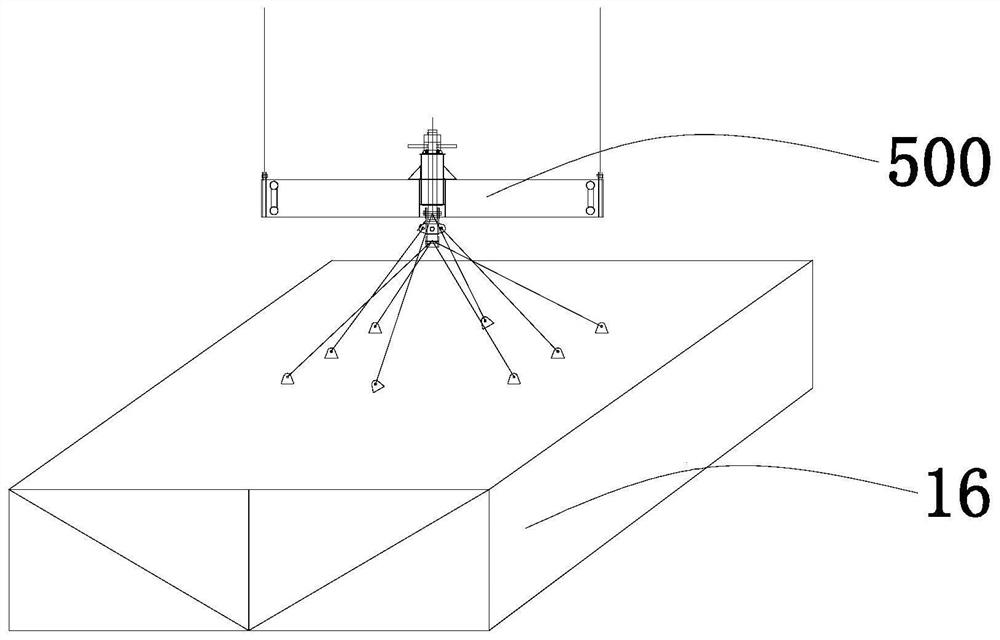

A cable-loaded crane device and installation method for installing suspension bridge stiffeners

ActiveCN110040638BShort lifting distanceAvoid potential hazardsBridge erection/assemblyCable carsArchitectural engineeringStructural engineering

The invention discloses a cable carrying crane device for installation of a stiff beam of a suspension bridge. The cable carrying crane device comprises a cable carrying crane for hoisting and a cablecarrying crane for carrying, wherein the cable carrying crane for hoisting and the cable carrying crane for carrying are installed on a main cable of the suspension bridge and arranged in a separatedmode. The cable carrying crane for hoisting is arranged on one side of a stiff beam section, and the stiff beam section is formed by multiple stiff beam segments in an assembly mode, and the cable carrying crane for hoisting is used for hoisting the stiff beam segments to the stiff beam section. The cable carrying crane for carrying can carry the load to move back and forth in the longitudinal direction of the main cable and is used for carrying the stiff beam segments on the stiff beam section to the other side of the stiff beam section so that the stiff beam segments and the stiff beam section can be assembled. The cable carrying crane for carrying comprises a special travelling rail mechanism which is fixedly connected with the main cable, and the cable carrying crane for carrying cantravel on the travelling rail mechanism in a load-carrying state. According to the cable carrying crane device, the double cable carrying cranes are adopted to cooperate so as to achieve installationof the stiff beam, the construction efficiency of the stiff beam can be improved, and the cable carrying crane device has the advantages of being safe and reliable, causing no damage to the main cableand the like.

Owner:HUNAN ZHONGNAN BRIDGE INSTALLATION ENG

Suitable for multi-channel corrosion electrolytic cell loading and supporting devices considering the influence of bending stress

ActiveCN111398155BMonitor temperature in real timeDissolved oxygen real-time monitoringWeather/light/corrosion resistanceEngineeringStructural engineering

The invention provides a multi-channel corrosion electrolytic cell loading and supporting device suitable for considering the influence of bending stress, comprising: a PVC base, a PVC upper part, a PVC end plate, a connecting bolt and a loading bolt; the PVC upper part and the PVC The end plate is fixed on the PVC base through a plurality of connecting bolts and welding; the PVC upper part is provided with two rows of holes: hole I and hole II; the upper surface of the PVC base has matching loading bolts The equidistant threaded holes; rotate the loading bolt through the bottom of the PVC base to bend the sample placed horizontally on the workbench, and the two ends of the sample are limited by the semicircle on the PVC end plate on both sides to realize loading . The present invention greatly increases the range of stress that can be loaded in the experiment by changing the loading method; and the multi-channel experimental device can also be modified on the existing basis to be suitable for more samples to be tested and measured at the same time, compared with the original Only a single sample can be tested, which greatly improves the test efficiency.

Owner:DALIAN UNIV OF TECH

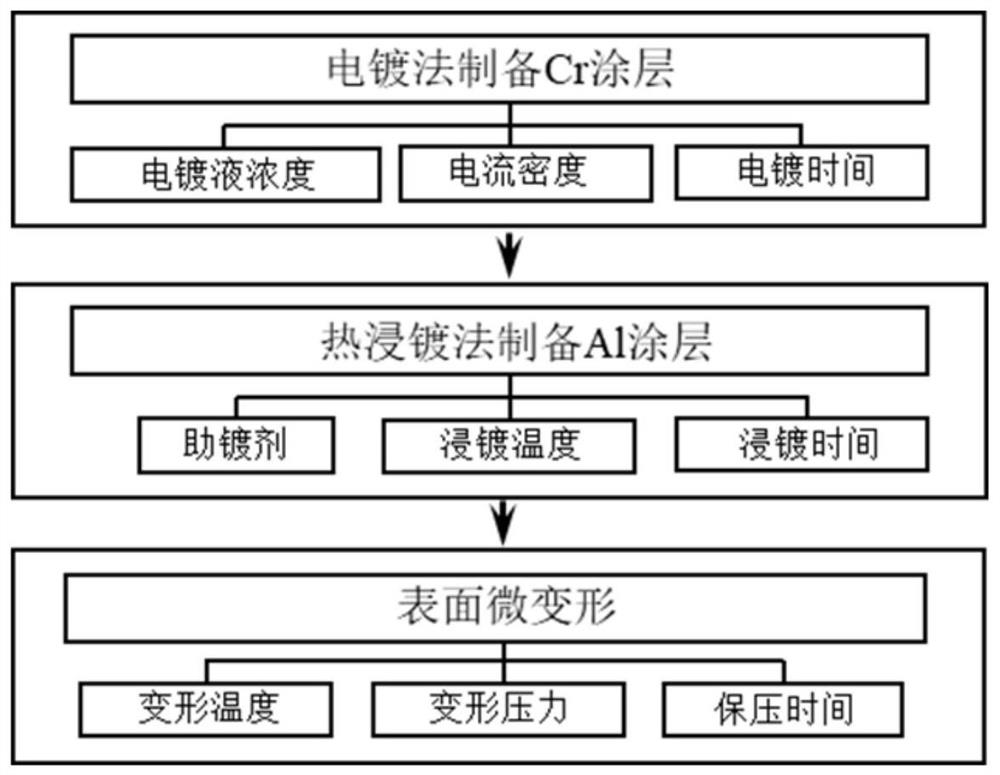

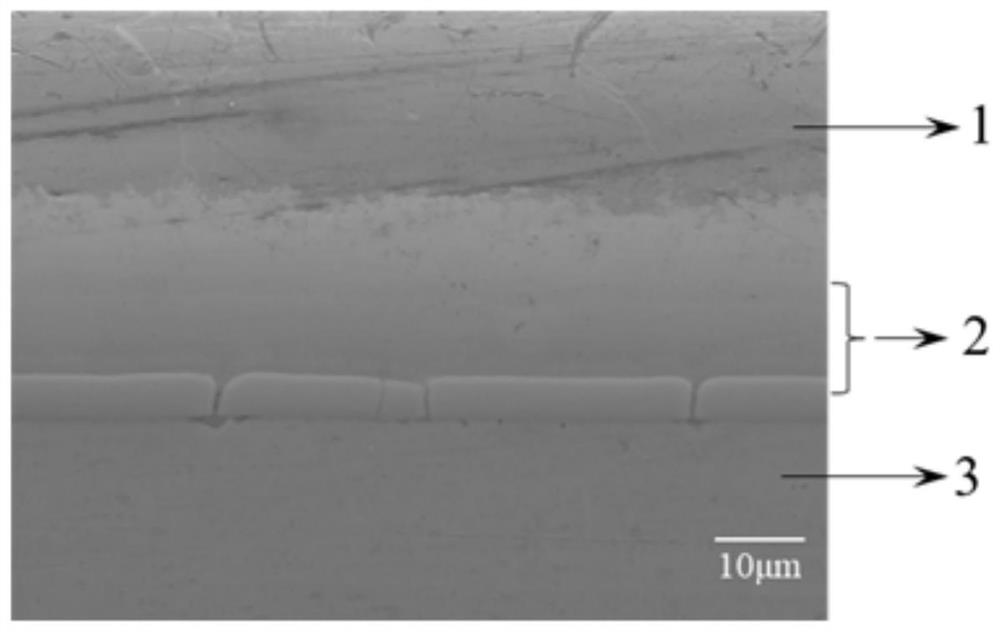

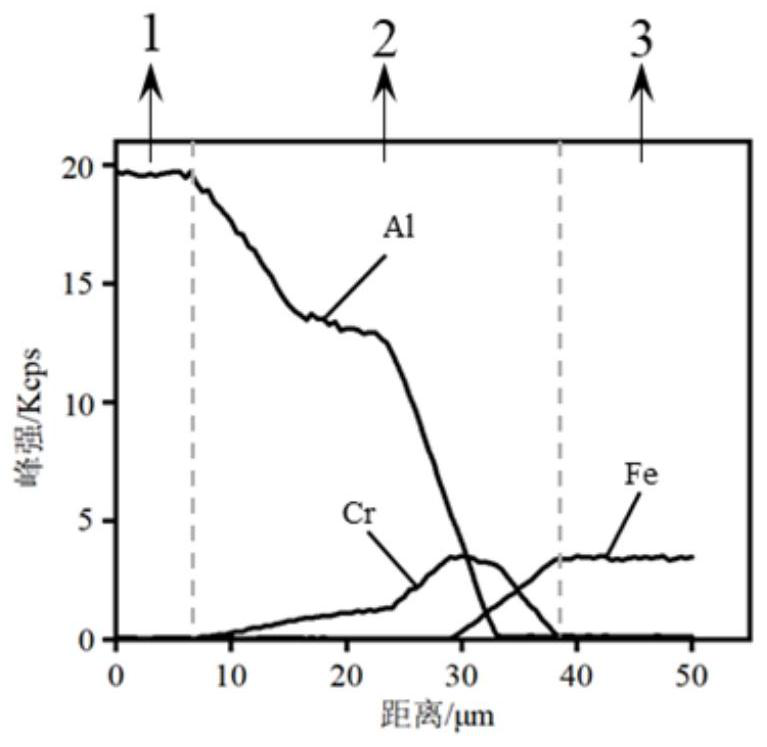

Al-cr coating preparation and surface micro-deformation method and al-cr coating surface micro-deformation device

ActiveCN110241428BImprove corrosion resistanceImprove economyHot-dipping/immersion processesCoated surfaceIntermetallic

The invention discloses an Al-Cr coating preparation method and a surface micro-deformation device and an Al-Cr coating surface micro-deformation device. The method firstly prepares a Cr coating on the surface of a steel plate by an electroplating method, and the prepared Cr coating can be used as a barrier layer , hinder the interdiffusion between Al / Fe elements, reduce the thickness of the Fe-Al intermetallic compound layer, and can also be used as a diffusion element to improve the corrosion resistance of the coating. Then, an Al coating is prepared on the surface of the Cr-coated steel sheet by a hot-dip aluminum plating method to obtain an Al-Cr coating. Finally, through the micro-deformation of the surface of the Al-Cr coated steel sheet, the compactness of the Al-Cr coating is enhanced, thereby further improving the corrosion resistance of the Al-Cr coated steel sheet.

Owner:SHAANXI UNIV OF SCI & TECH

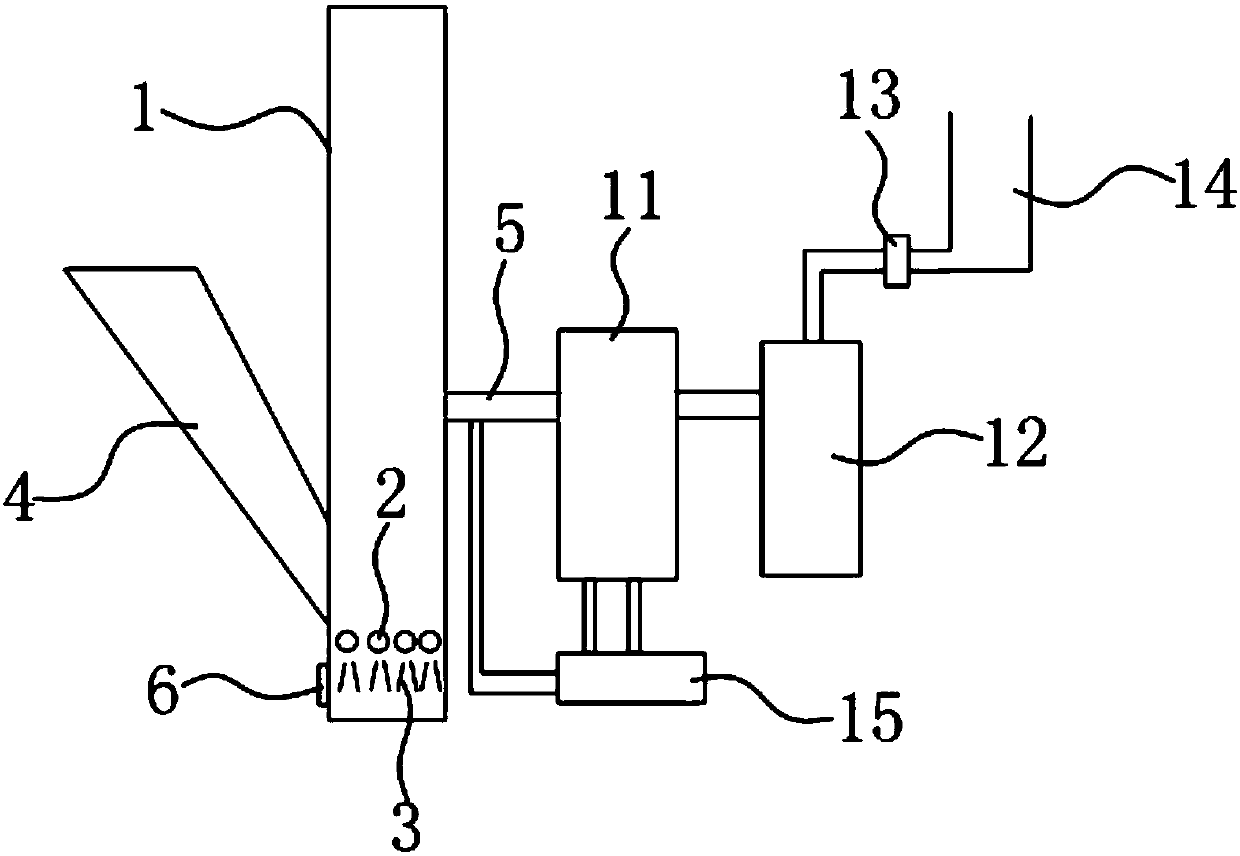

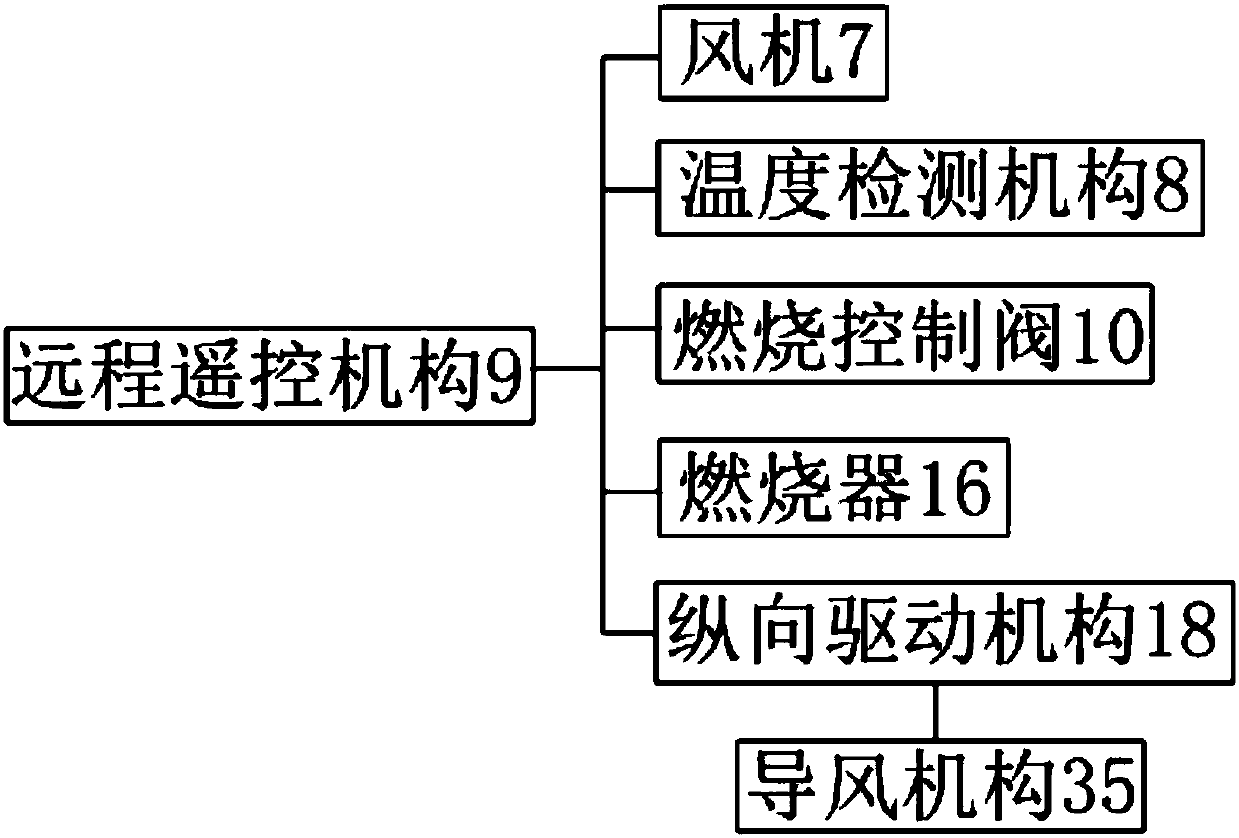

A garbage incinerator with remote control

ActiveCN106016296BImprove purification effectFully contactedIncinerator apparatusBaghouseRemote control

Owner:JIANGSU MARITIME INST

Flat yarn warping machine

ActiveCN104357993BPrevent fallingAvoid warping quality problemsWarping machinesOther manufacturing equipments/toolsYarnEngineering

A flat yarn warping machine comprises a stander (110) having a compression roller adjusting mechanism for adjusting both the position and the pressure of a compression roller (10), the flat yarn warping machine further comprises a group of edge yarn devices (24) arranged on the stander (110), and the edge yarn devices (24) are positioned above a warp beam flange (25) and above the end part of the compression roller (10). The edge yarn devices (24) comprise a mounting shaft (2441) fixed on the stander (110). An edge thread roller (2448) is provided on the mounting shaft (2441) positioned at one side of the stander (110). A roller mounting plate (2447) is provided on the mounting shaft (2441) positioned at one side of the edge thread roller (2448). A sliding shaft (2446) is provided on the roller mounting plate (2447). The other end of the sliding shaft (2446) is fixedly provided with a baffle plate (2443). A threaded shaft (2444) is arranged between the baffle plate (2443) and the roller mounting plate (2447). A sliding seat (2445) for guiding a flat yarn is arranged on the threaded shaft (2444), and the slide seat (2445) is also sleeved on the slide shaft (2446). An adjusting hand wheel (2442) is provided on the end part of the threaded shaft (2444). The flat yarn warping machine can keep the flat yarn from falling into the gap between the end part of the compression roller (10) and the warp beam flange (25), and thereby solving the problem of less uniformity of the warp beam flange surface.

Owner:NEWTRY COMPOSITE

Preparation method of nano ato powder

ActiveCN106986376BChange contactSmall particle size distribution rangeMaterial nanotechnologyTin oxidesTin dioxideDopant

The invention discloses a preparation method of nano ATO powder. The preparation method comprises the following steps of: weighing antimony chloride and stannic chloride in a molar ratio of 1:10, dissolving the two with absolute ethyl alcohol and adding ethylene glycol; equally dividing the mixed solution into three parts, and separately placing the three parts in a first reaction kettle, a second reaction kettle and a third reaction kettle; switching off three valves, introducing ammonia gas into a fourth reaction kettle till the pressure is 120KPa, introducing air into the first, second and third reaction kettles till the pressures are 300KPa, and then switching on the three valves; raising the temperature of the fourth reaction kettle to 40-50 DEG C and keeping the temperature for 1-1.5h, then raising the temperature to 60-70 DEG C and keeping the temperature for 30-40 minutes, taking out the mixed solution, filtering the same, washing and drying the obtained filter cake with absolute ethyl alcohol to obtain a precursor; and calcining the precursor. Antimony-doped nano stannic oxide powder obtained by the preparation method is small in grain size, the dopant is uniformly distributed, and the resistivity is low.

Owner:柳州呈奥科技有限公司

Slide slot type guide tooth limiting and guide device of electromechanical actuator

ActiveCN108019479AReduce efficiency lossImprove efficiencyGearingCombination bearingsRolling resistanceEngineering

The invention belongs to the technical field of interior structure design of electromechanical actuators, and particularly relates to a slide slot type guide tooth limiting and guide device of an electromechanical actuator. A base body of a guide tooth is fixedly mounted in a groove in the axial direction in one side of an inner hole of an actuator housing; an actuating rod is positioned inside the actuator housing, and one end of the actuating rod gets out of the actuator housing; a nut sleeves the outer wall of a lead screw, and is connected with the other end of the actuating rod; a guide tooth slot base body is pressed into the groove in the actuating rod and is fixed; a supporting ring is mounted on the actuating rod and is in contact with the actuator housing; and the guide tooth isin engaged connection with the guide tooth slot. The slide slot type guide tooth limiting and guide device changes surface-surface friction into line-line friction or line-surface friction, can acheive the effect as rolling friction within a short-time working occasion, and greatly reduces friction force and efficiency loss.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

SCHMID etching tank capable of reducing acid consumption, and use method thereof

PendingCN107195573AImprove etching effectAvoid the phenomenon of fragile maintenanceSemiconductor/solid-state device manufacturingEngineeringStructural engineering

The invention discloses an SCHMID etching tank capable of reducing acid consumption. The SCHMID etching tank comprises a tank body, a plurality of spiral back polishing rollers are horizontally arranged at the opening of the tank body, and a front baffle and a back baffle are movably arranged on outer side walls of two ends of the tank body; and a manual valve is arranged on a lower end of the tank body, the manual valve is connected with a TANK, and the tank body is further connected with a liquid level test box. The invention further discloses a use method of the SCHMID etching tank capable of reducing the acid consumption. The method comprises the following steps: S1: adjusting the heights of the front baffle and the back baffle; S2: setting the height of the liquid level through the liquid level test box; S3: opening the TANK, and injecting liquid in the tank body through the manual valve; and S4: adding a silicon wafer to the tank body from the front baffle for etching. By adoption of the SCHMID etching tank disclosed by the invention, the consumption of nitric acid is reduced by 80%, the consumption of hydrofluoric acid is reduced by 65%, the power consumption cost is greatly reduced, and due to the reduction of the power consumption, no exhaust pipe needs to be arranged; and moreover, the utilization rate of an SCHMID machine is greatly reduced, the equipment maintenance cost is reduced, and the SCHMID etching tank is very effective.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

A multi-layer film structure negative plate and its mixed solid-liquid electrolyte lithium battery

ActiveCN112151757BIncrease energy densityImprove cycle lifeCell electrodesSecondary cellsElectrical batteryNew energy

The invention belongs to the technical field of new energy lithium secondary batteries, and in particular relates to a multi-layer film structure negative plate and a mixed solid-liquid electrolyte lithium battery, which have high energy density, long cycle life, excellent rate performance and high safety performance. features. The negative electrode sheet includes a current collector and several negative electrode composite layers arranged on the current collector. The negative electrode composite layer includes a silicon layer, a lithium titanate layer and a graphite layer compounded in sequence, and the silicon layer is fixed on the current collector. The lithium storage battery includes a positive electrode sheet, the above-mentioned negative electrode sheet, a mixed solid-liquid electrolyte membrane, an outer packaging film, a positive electrode tab and a negative electrode tab; the mixed solid-liquid electrolyte membrane is arranged between the graphite layers of the positive electrode sheet and the negative electrode sheet; the outer packaging film Coated on the outside of the positive electrode and the negative electrode; one end of the positive electrode tab is connected to the positive electrode sheet, and the other end protrudes from the outer packaging film; one end of the negative electrode tab is connected to the negative electrode sheet, and the other end protrudes from the outer packaging film. outside of the wrapping film. The negative electrode sheet and the lithium storage battery of the present invention.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com