Modular socket

A modular and socket technology, applied in the direction of contact parts, electrical components, coupling devices, etc., can solve the problems of increasing cost investment, achieve the effect of reducing structural design and material input costs, achieving mass production, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

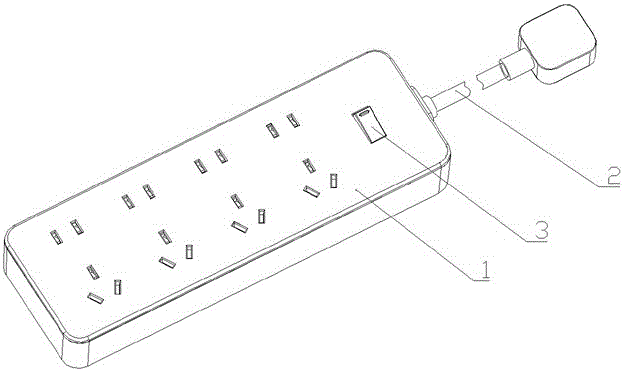

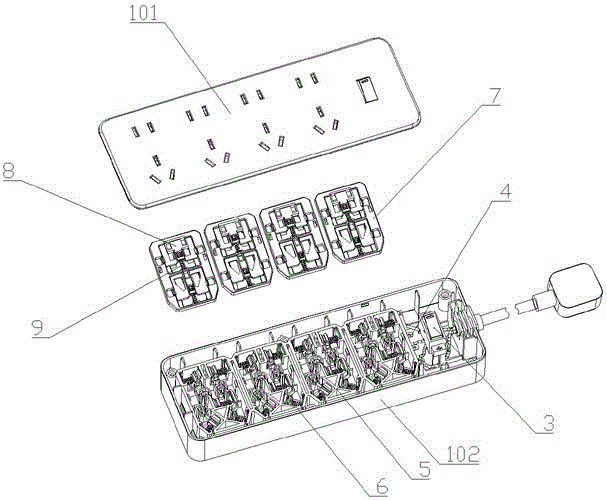

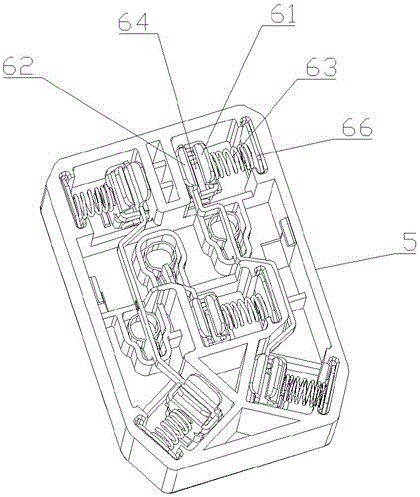

[0028] Such as Figure 1 to Figure 11 As shown, the present invention includes a housing 1, a plug connecting wire 2, a switch 3 and a conductive connecting piece 4, the plug connecting wire 2 is connected to the conductive connecting piece 4 through the switch 3, and the conductive connecting piece 4 includes a live wire Conductive sheet, neutral conductive sheet and ground conductive sheet. The housing 1 includes an upper cover 101 and a base 102 , the upper cover 101 is arranged above the base 102 and fits therewith. In the cavity formed by the base 102 and the upper cover 101 are provided a conductive module and a socket safety door structure above the conductive module, and a module installation position is provided on the base 102 . In this embodiment, the number of the module installation positions is set to four, of course, it can also be set to other numbers, such as one fixed socket fixed on the wall, which can be determined according to specific conditions. The so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com