Patents

Literature

48 results about "T stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

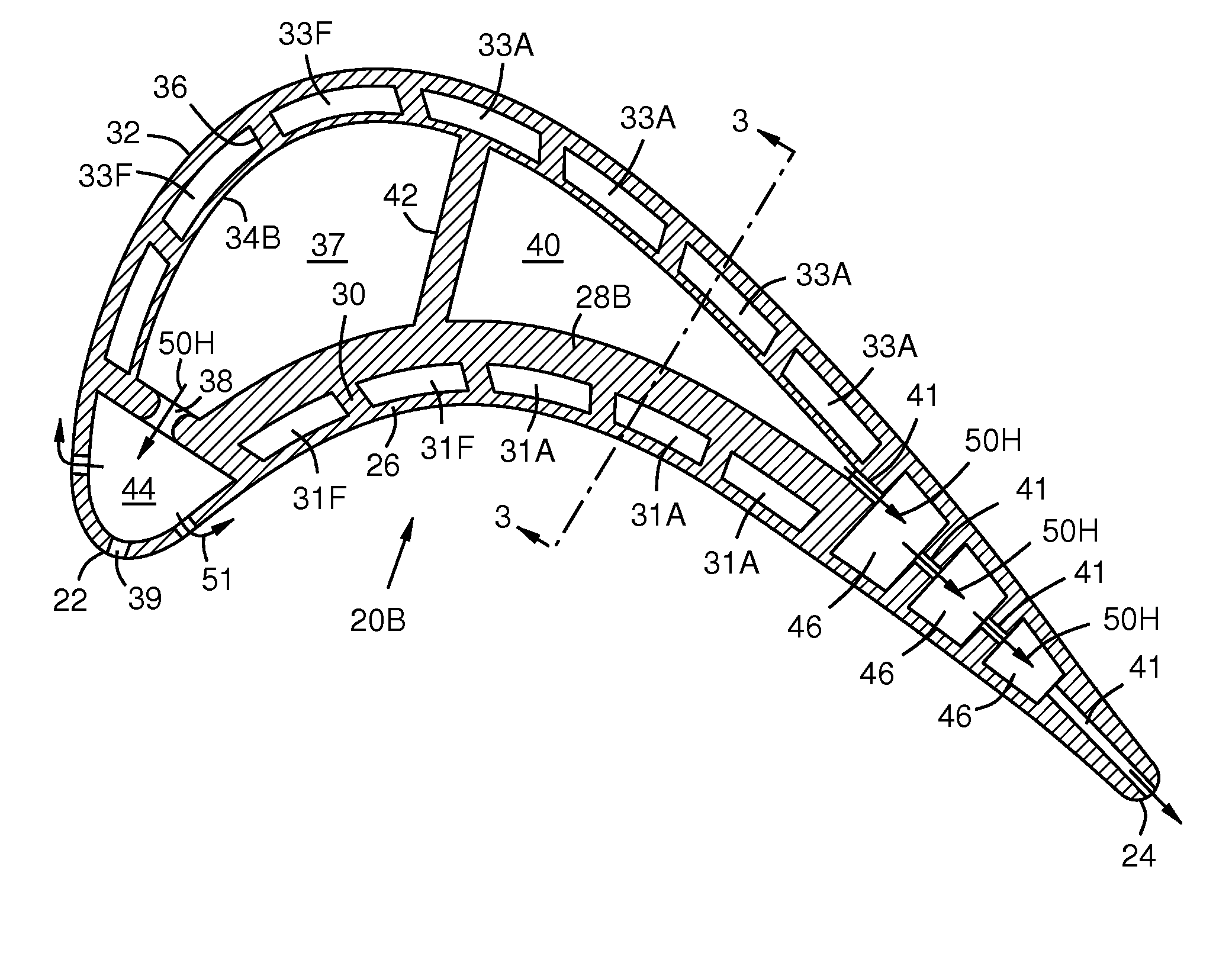

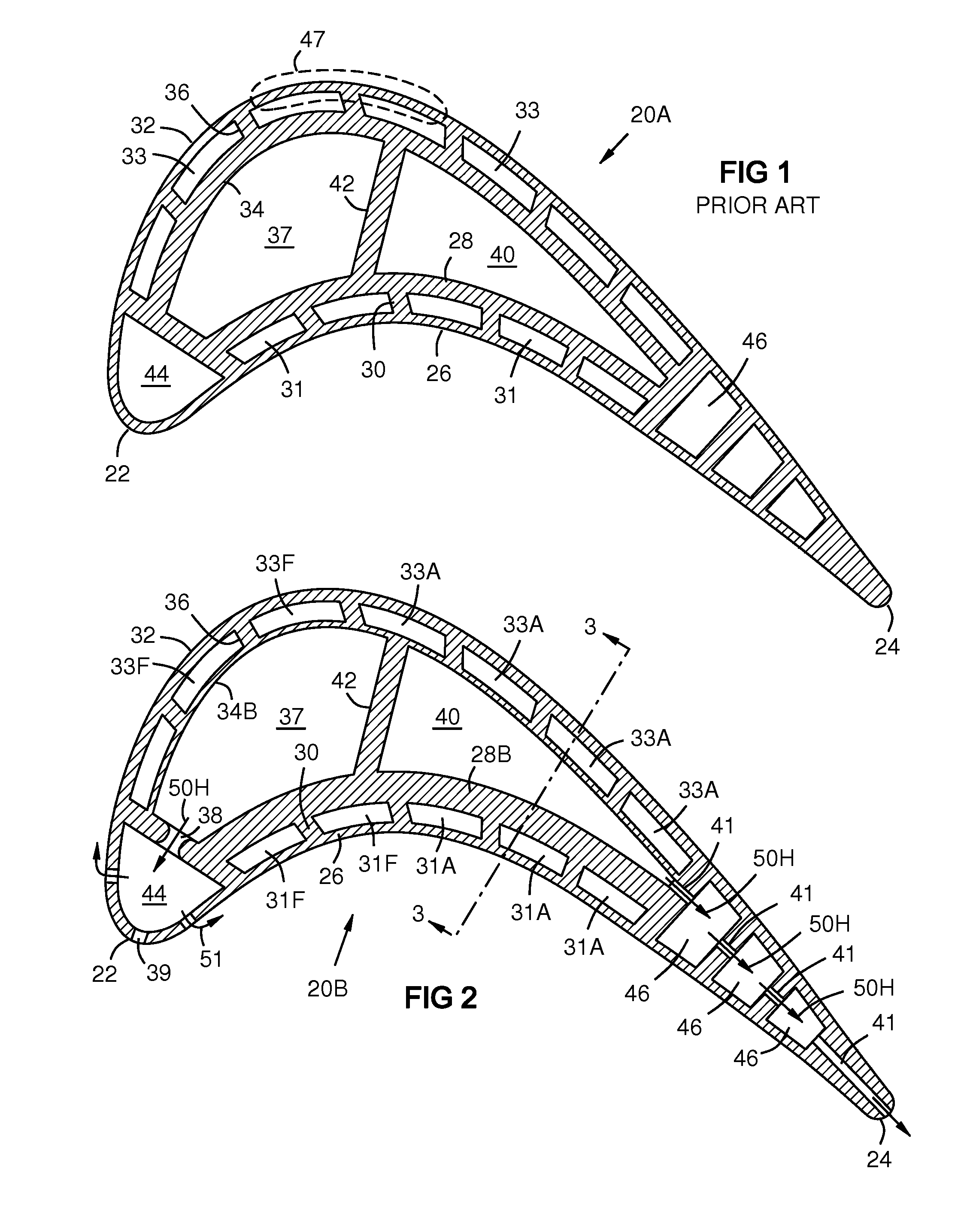

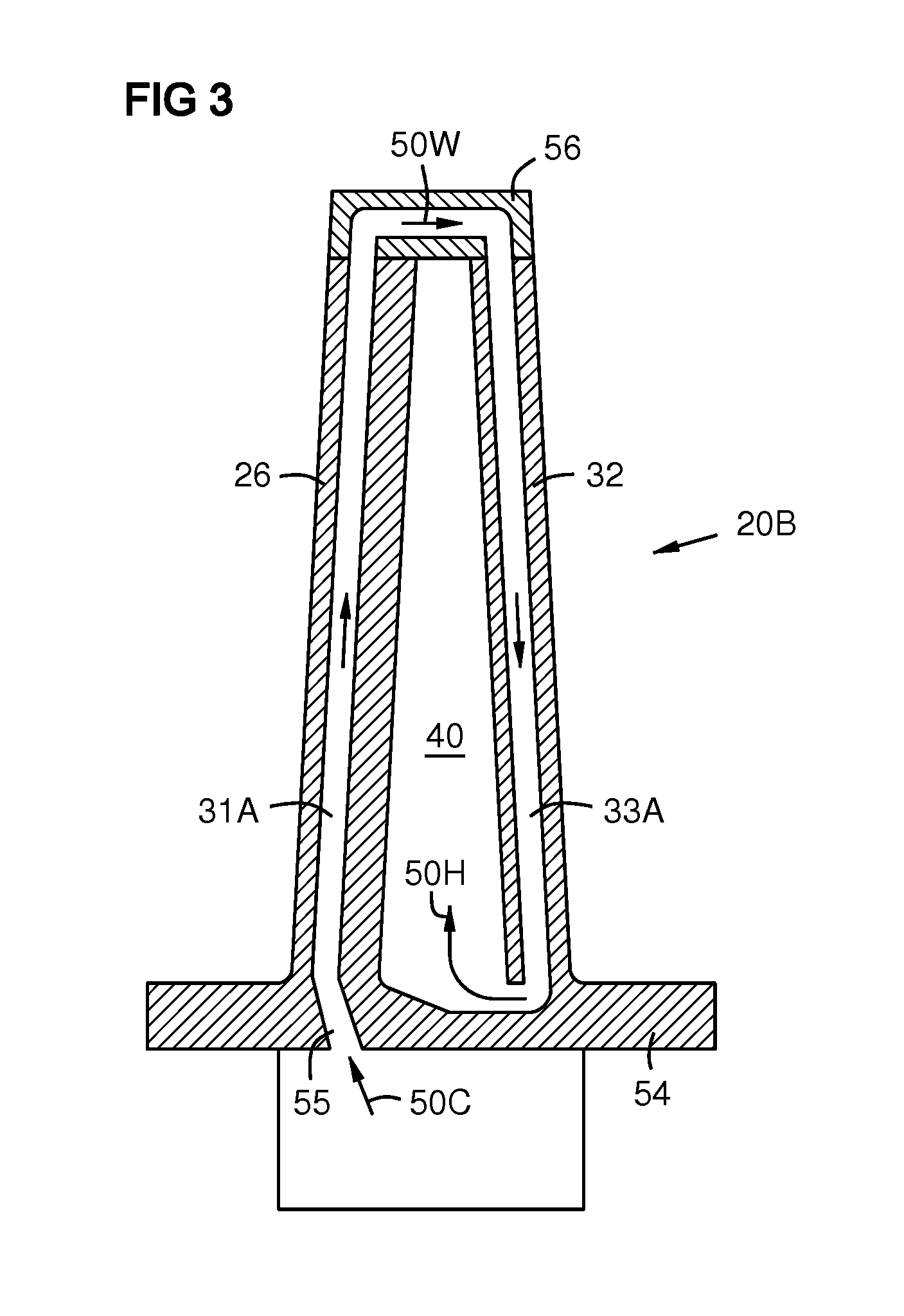

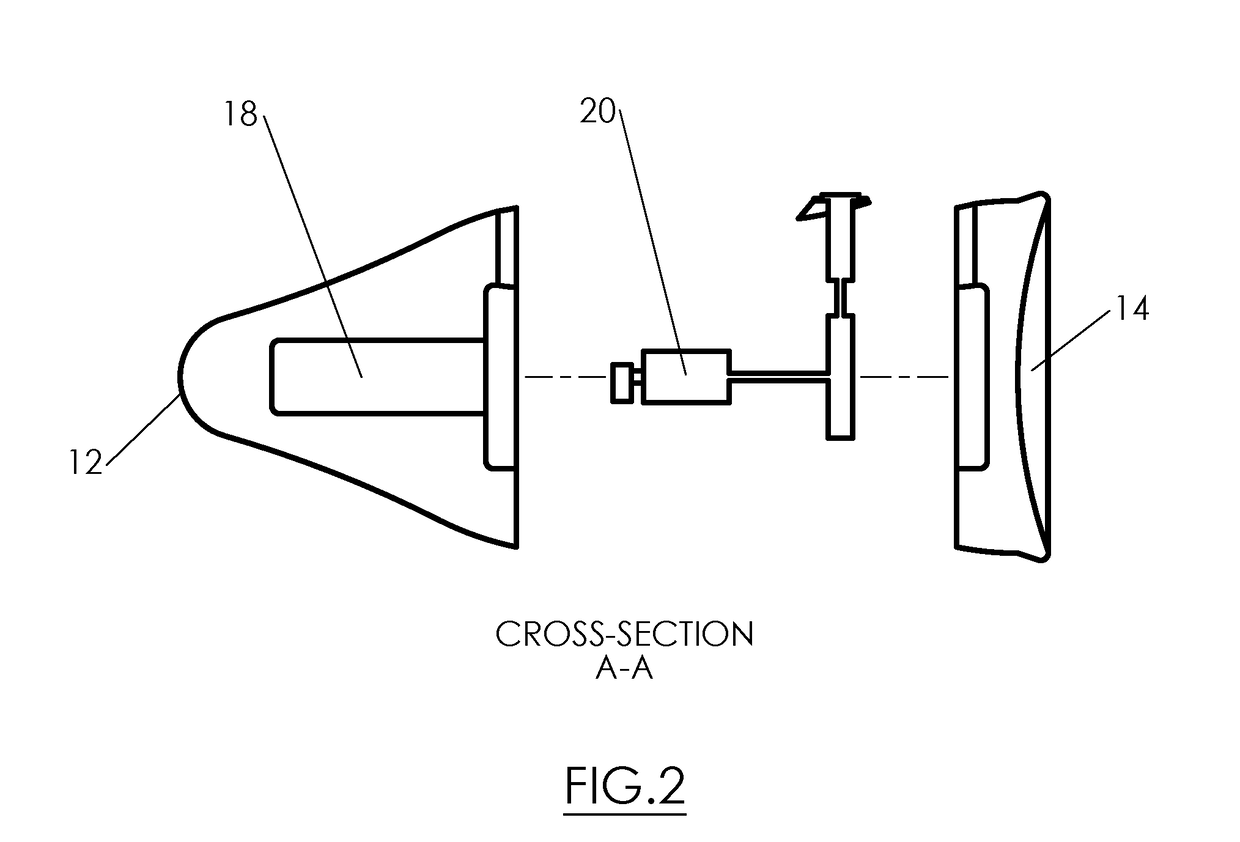

Four-wall turbine airfoil with thermal strain control for reduced cycle fatigue

A turbine airfoil (20B) with a thermal expansion control mechanism that increases the airfoil camber (60, 61) under operational heating. The airfoil has four-wall geometry, including pressure side outer and inner walls (26, 28B), and suction side outer and inner walls (32, 34B). It has near-wall cooling channels (31F, 31A, 33F, 33A) between the outer and inner walls. A cooling fluid flow pattern (50C, 50W, 50H) in the airfoil causes the pressure side inner wall (28B) to increase in curvature under operational heating. The pressure side inner wall (28B) is thicker than walls (26, 34B) that oppose it in camber deformation, so it dominates them in collaboration with the suction side outer wall (32), and the airfoil camber increases. This reduces and relocates a maximum stress area (47) from the suction side outer wall (32) to the suction side inner wall (34B, 72) and the pressure side outer wall (26).

Owner:SIEMENS ENERGY INC

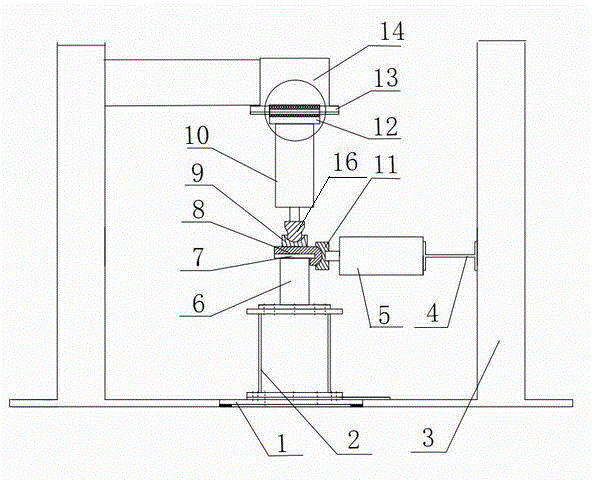

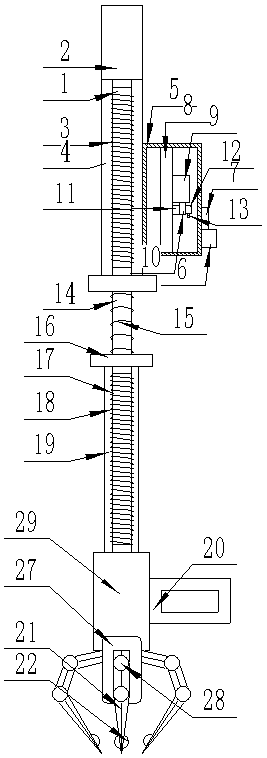

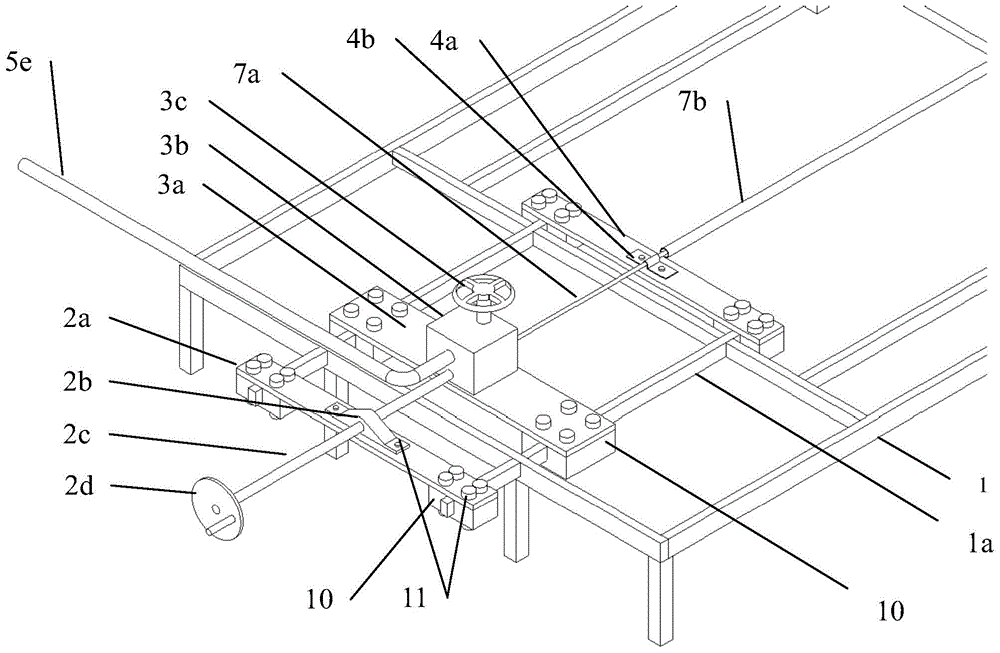

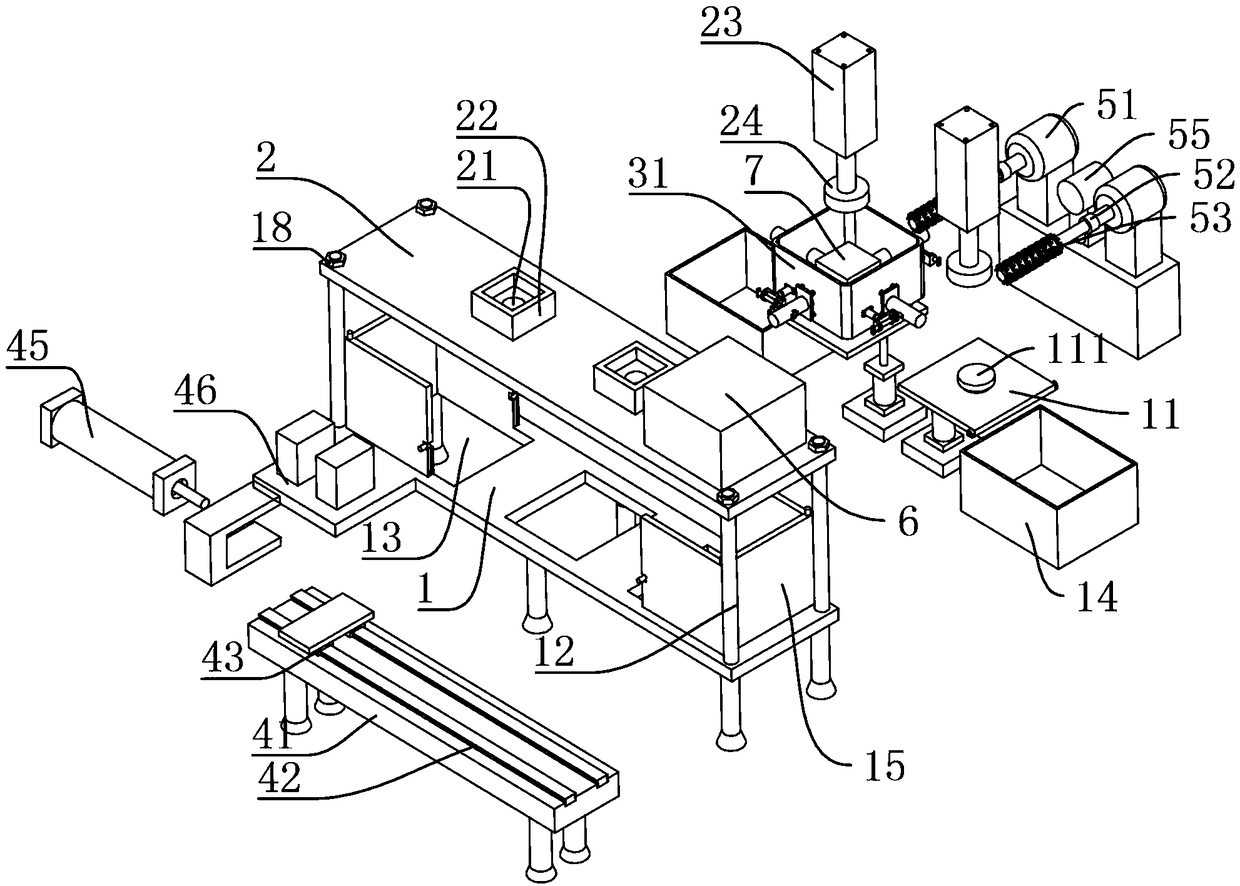

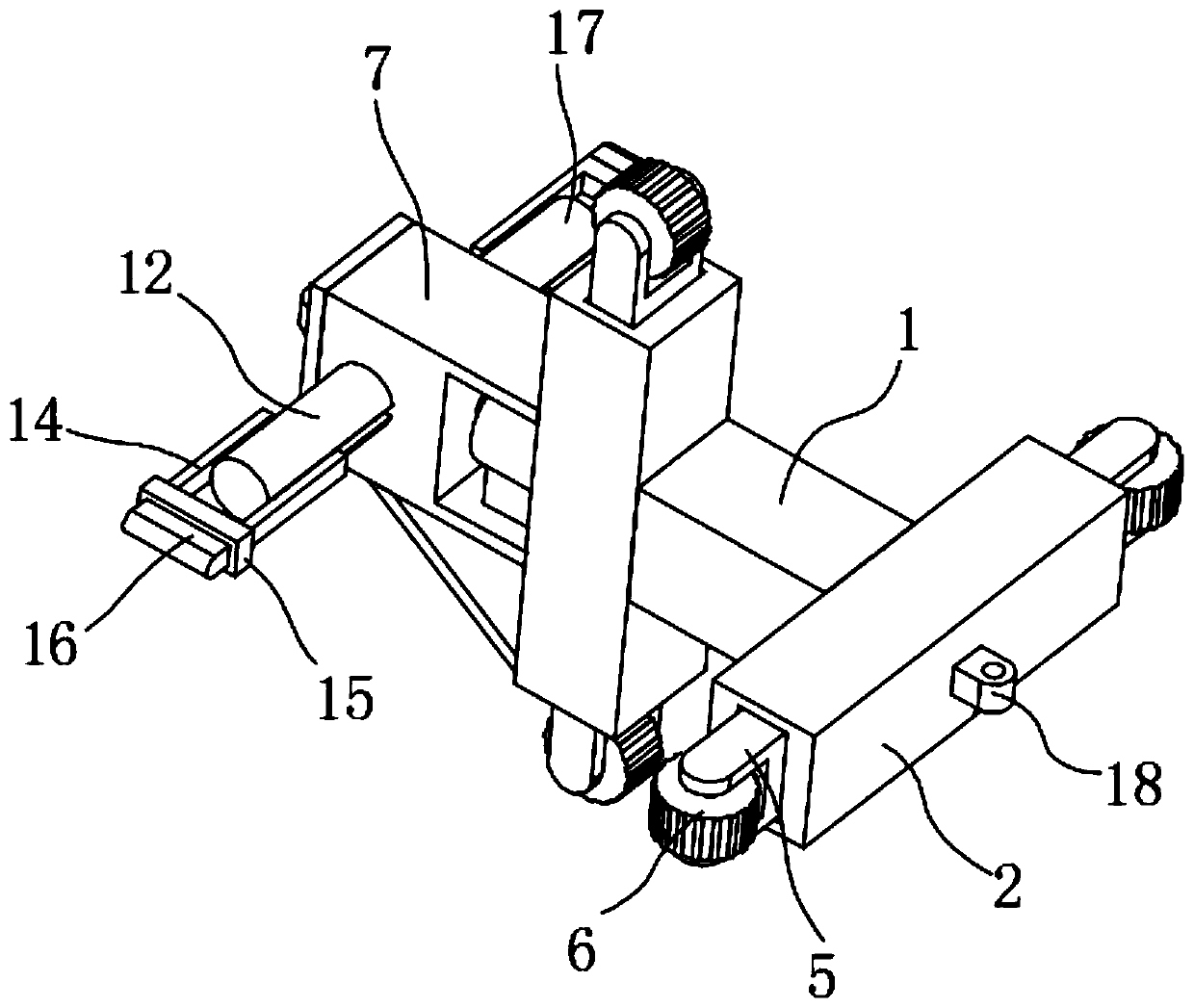

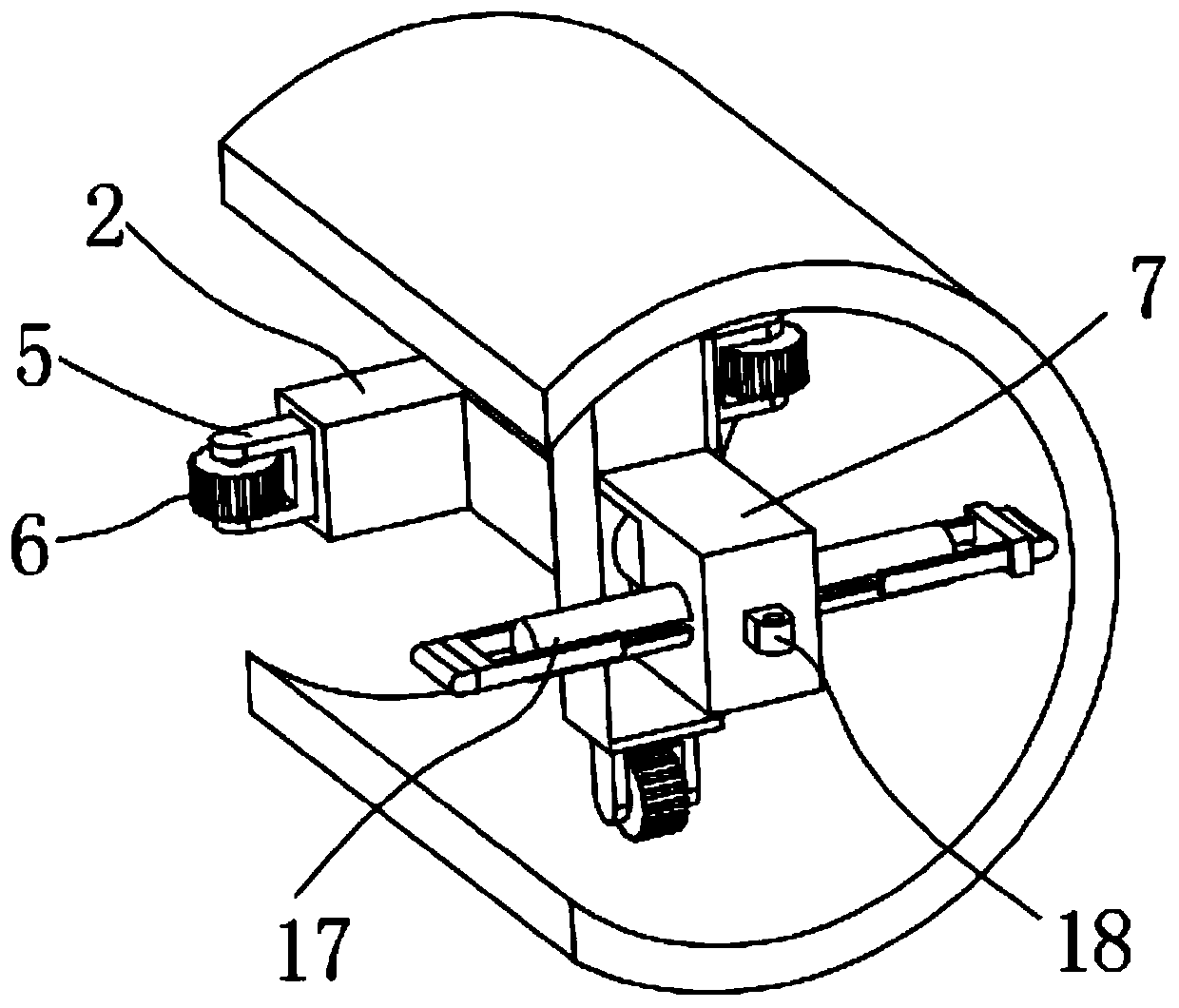

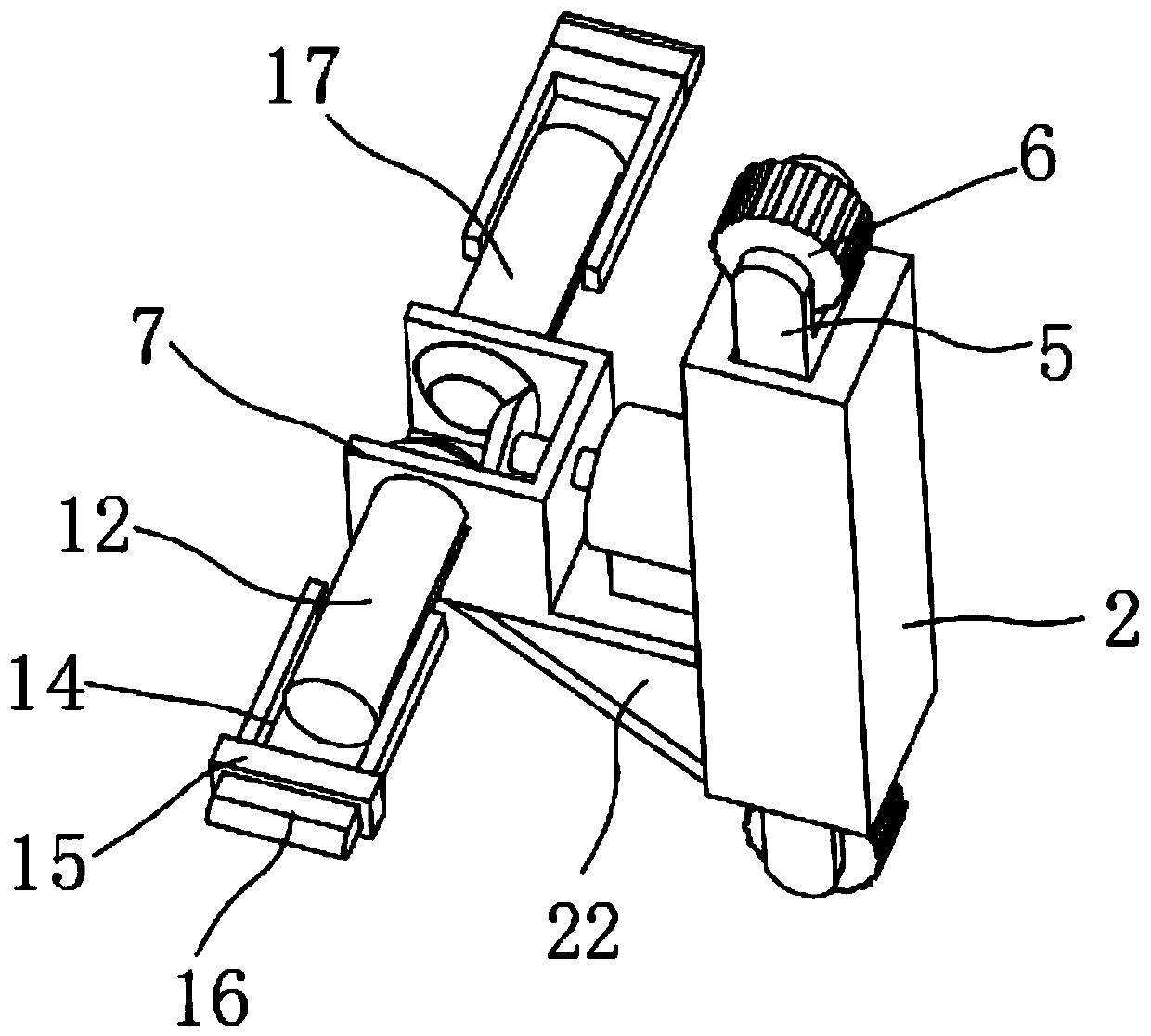

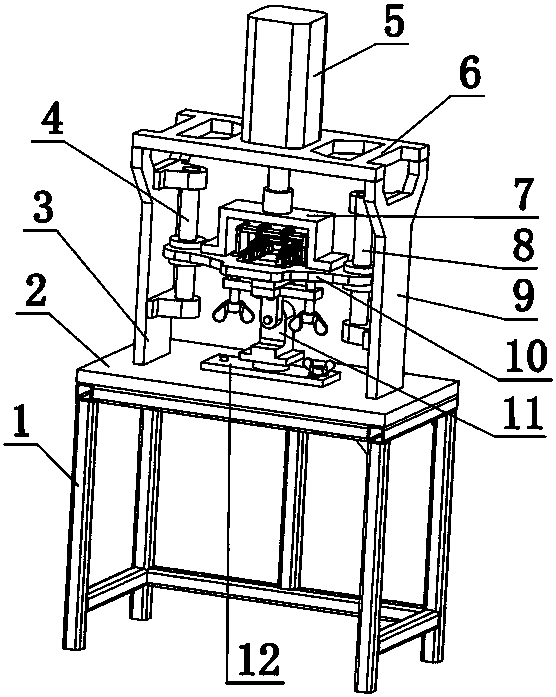

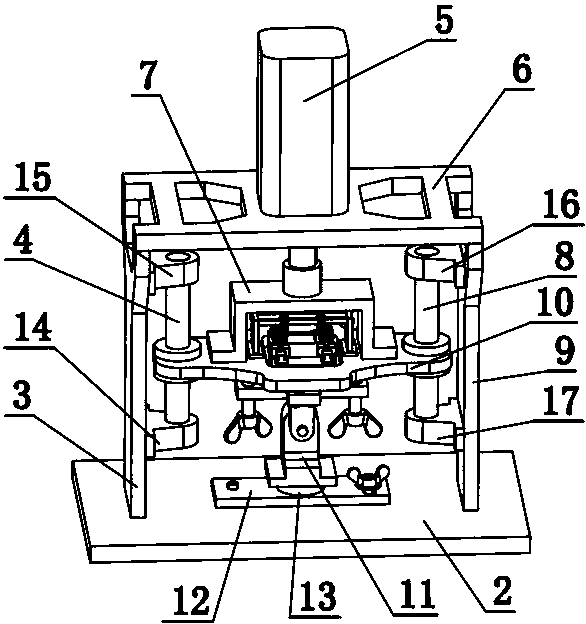

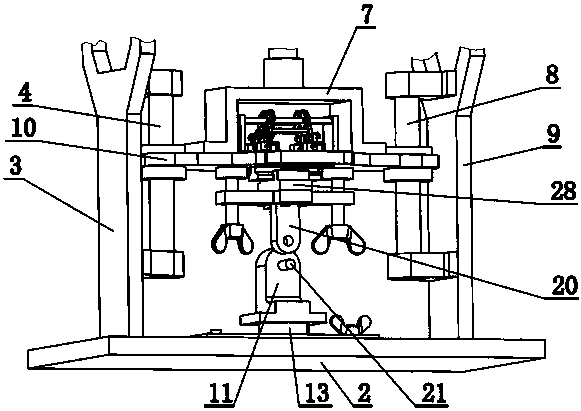

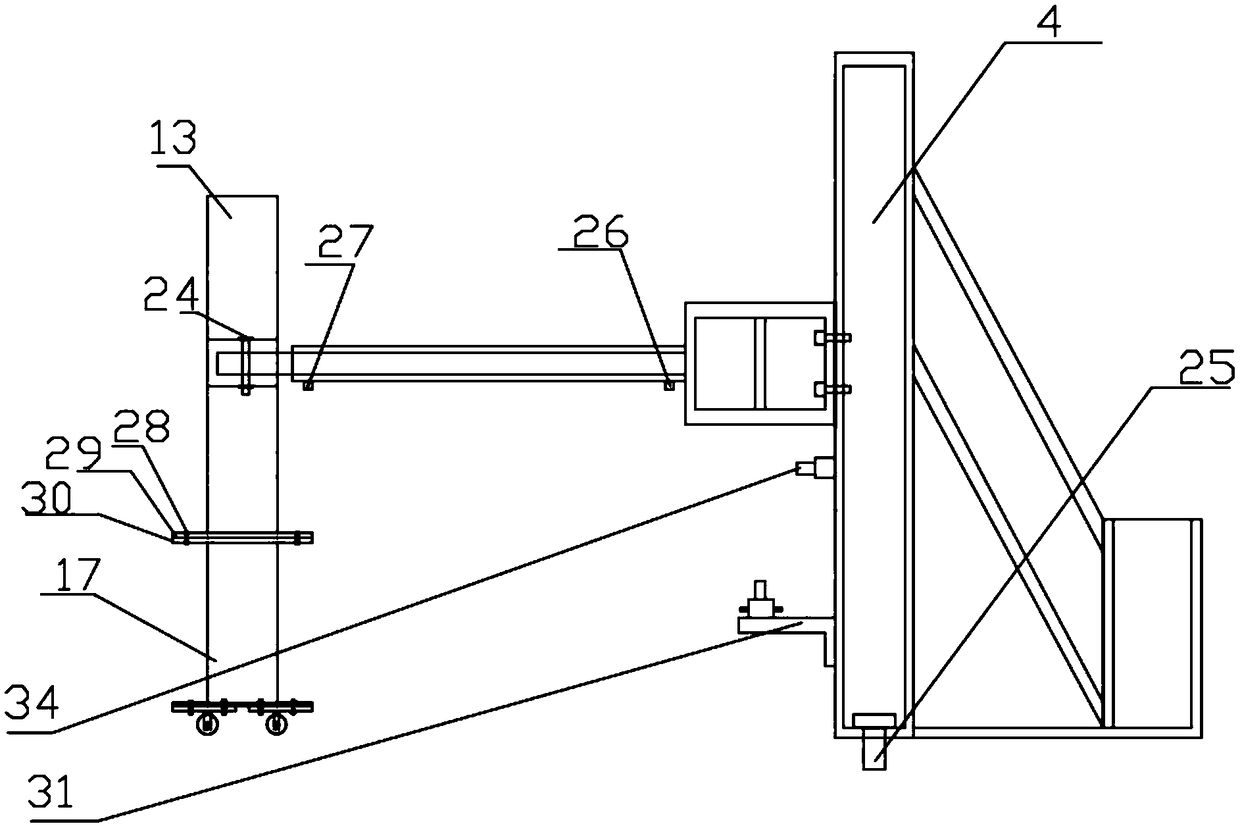

Device for testing loading of component compositely stressed by pressure, bending moment and shearing force

InactiveCN104089820AReduce frictional resistanceLower requirementMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesT stressAxial pressure

The invention discloses a device for testing loading of a component compositely stressed by pressure, bending moment and shearing force. The bottom end of a test piece is fixed on a base box; a horizontal jack is fixed on a reaction frame; a vertical jack is fixed on a support frame; the support frame is arranged in a sliding rail of a top beam of the reaction frame in a sleeving manner; a transverse loading arc hinge is arranged on a jacking shaft of the horizontal jack; a transverse loading plate is arranged on a cover plate of the test piece; a jacking shaft of the vertical jack is fixedly connected with a vertical loading ball hinge; the bottom surface of the vertical loading ball hinge is a spherical surface; a spherical groove is formed in a vertical loading ball base; the spherical groove is matched with the spherical surface of the bottom of the vertical loading ball hinge so as to form an arc hinge. By virtue of the device for testing the loading of the component, loading of various components in the presence of pressure, bending moment and shearing force can be achieved; the arc hinge formed by the transverse loading plate and the transverse loading hinge can be used for applying horizontal shearing force; the ball hinge formed by the vertical loading ball hinge and the vertical loading ball base can be used for applying axial pressure. The device with the structure ensures that the overall horizontal shearing force is born by the test piece; the overall device is relatively simple in structure and reliable to use.

Owner:EAST CHINA JIAOTONG UNIVERSITY

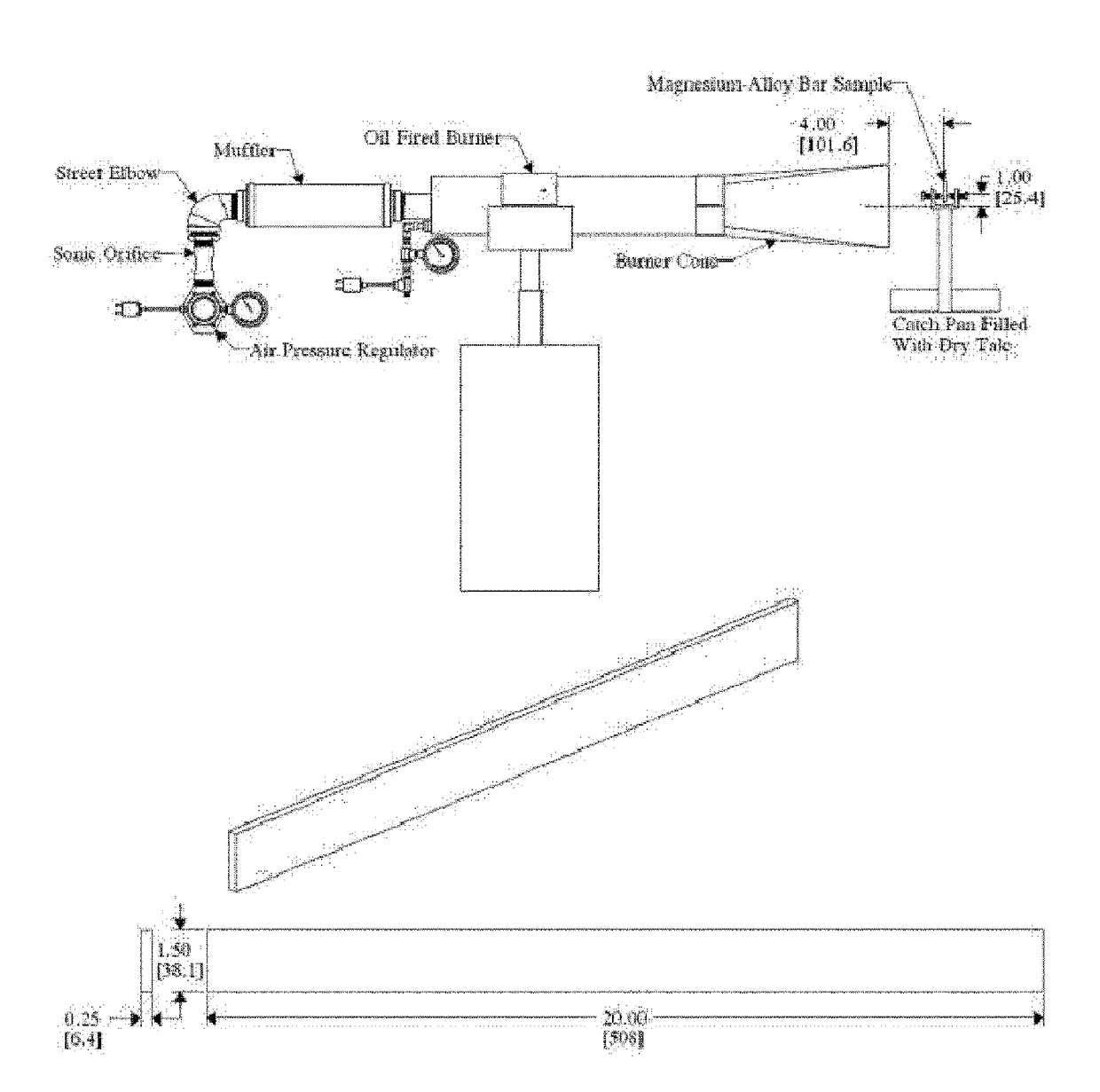

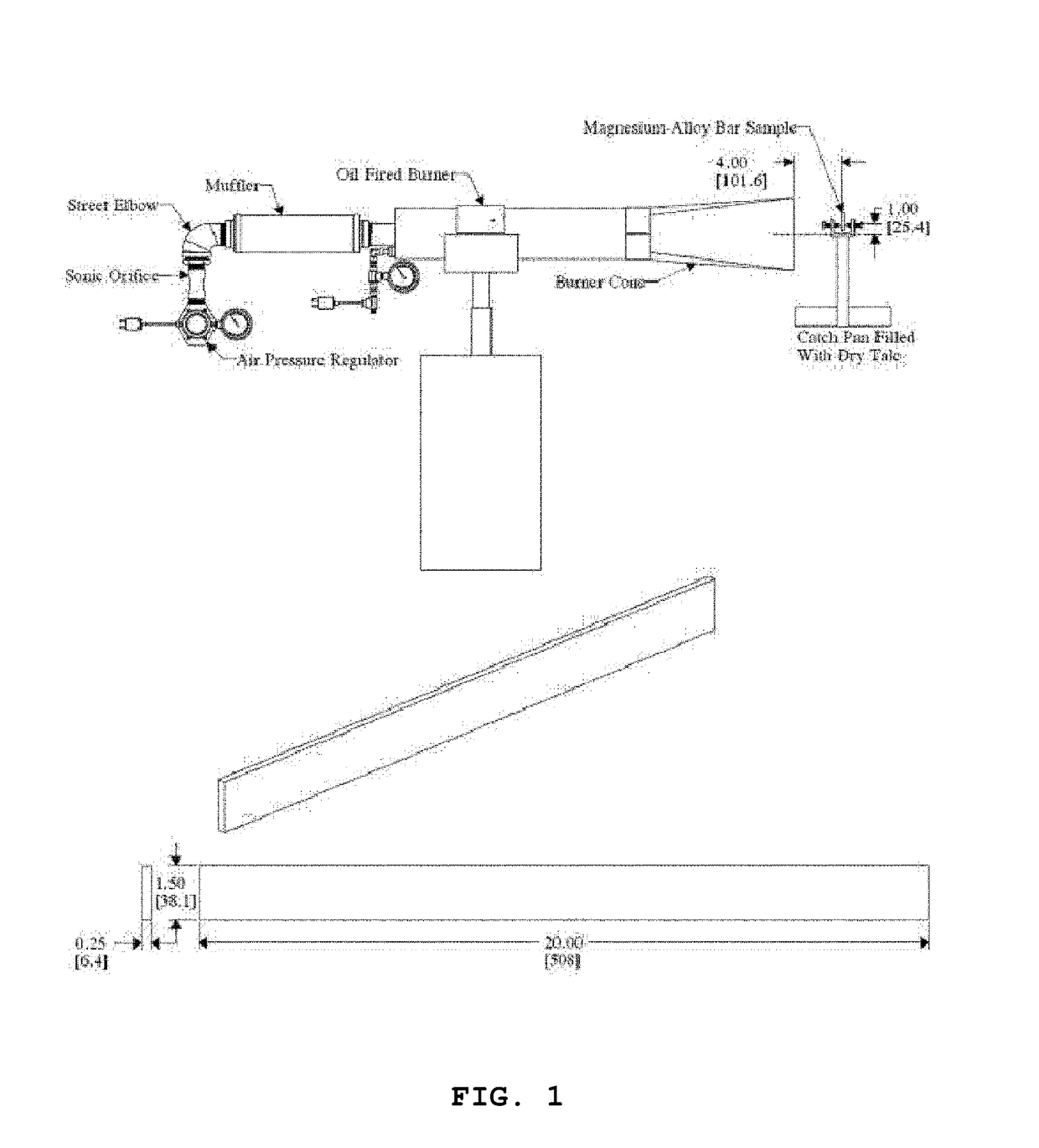

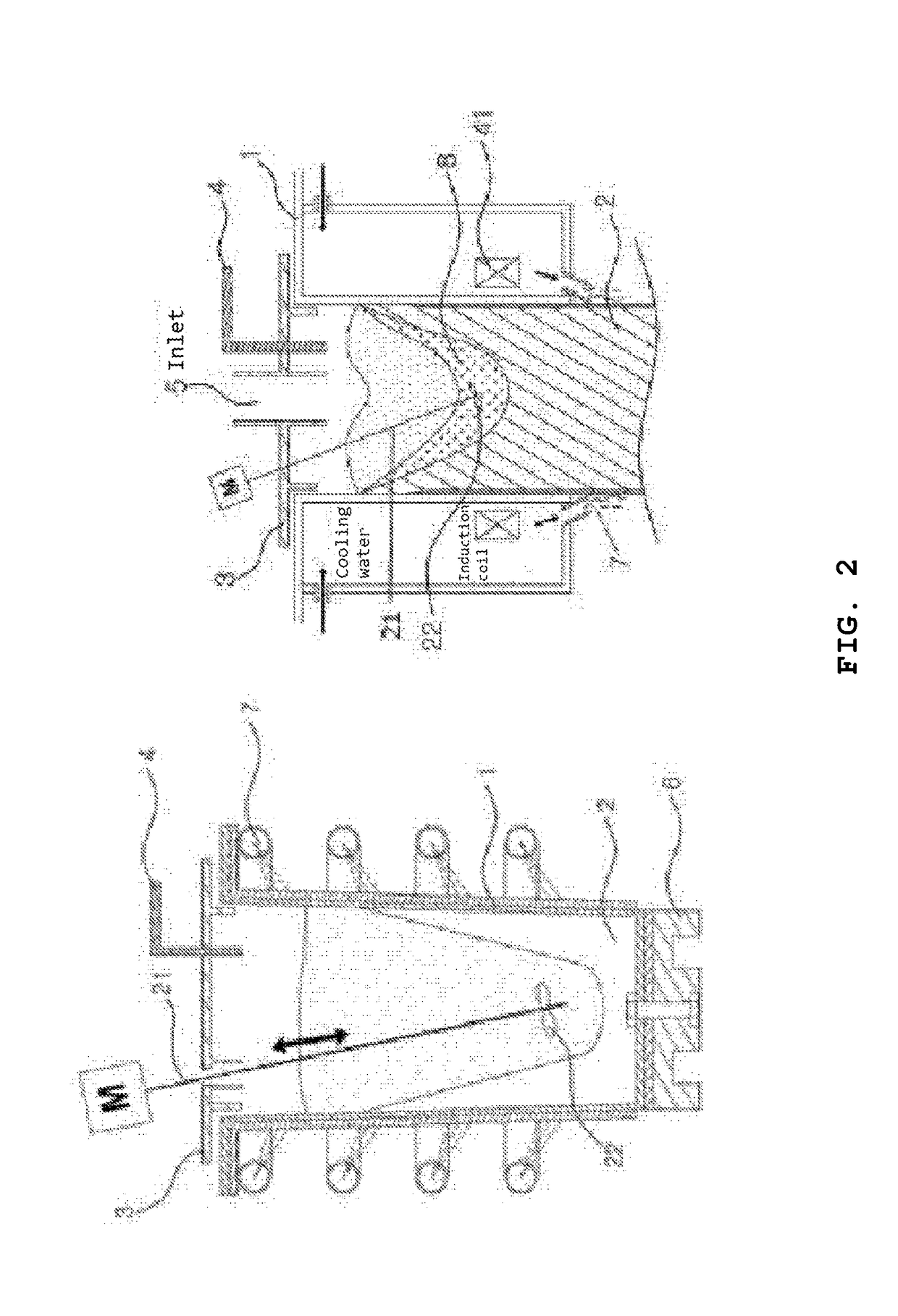

Plastic deformation magnesium alloy having excellent thermal conductivity and flame retardancy, and preparation method

Disclosed is a magnesium alloy that has high thermal conductivity and flame retardancy and facilitates plastic working, wherein magnesium is added with 0.5 to 5 wt % of zinc (Zn) and 0.3 to 2.0 wt % of at least one of yttrium (Y) and mischmetal, with, as necessary, 1.0 wt % or less of at least one selected from among calcium (Ca), silicon (Si), manganese (Mn) and tin (Sn), the total amount of alloy elements being 2.5 to 6 wt %. A method of manufacturing the same is also provided, including preparing a magnesium-zinc alloy melt in a melting furnace, adding high-melting-point elements in the form of a master alloy and melting them, and performing mechanical stirring during cooling of a cast material in a continuous casting mold containing the magnesium alloy melt, thus producing a magnesium alloy cast material having low segregation, after which a chill is removed from the cast material or diffusion annealing is performed, followed by molding through a tempering process such as rolling, extrusion or forging. This magnesium alloy is improved in ductility by the action of alloy elements for inhibiting the formation of lamella precipitates due to a low-melting-point eutectic phase in a magnesium matrix structure, can be extruded even at a pressure of 1,000 kgf / cm2 or less due to the increased plasticity thereof, and can exhibit thermal conductivity of 100 W / m·K or more and flame retardancy satisfying the requirements for aircraft materials and is thus suitable for use in fields requiring fire safety, thereby realizing wide application thereof as a heat sink or a structural material for portable appliances, vehicles and aircraft components and contributing to weight reduction.

Owner:G I TECH

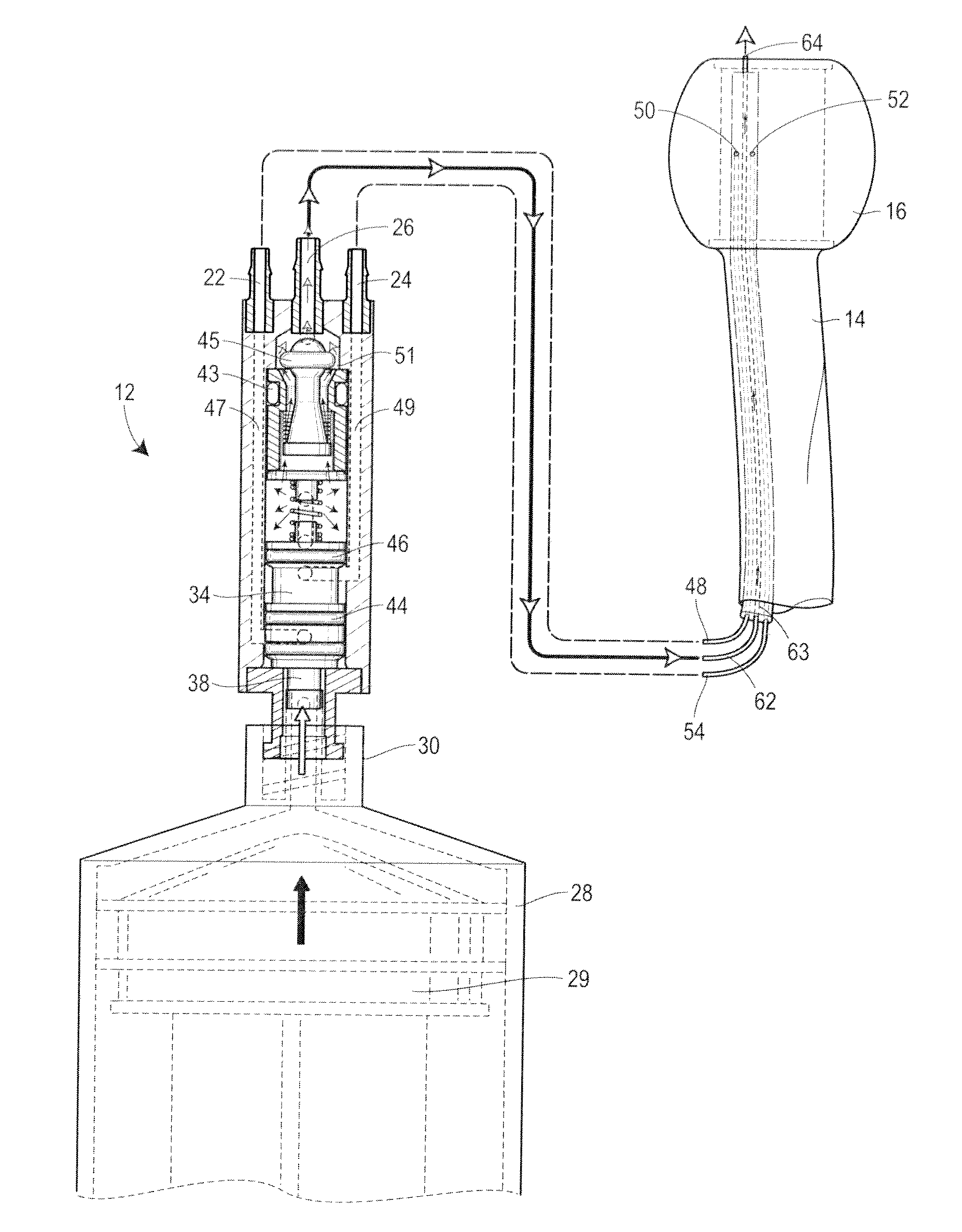

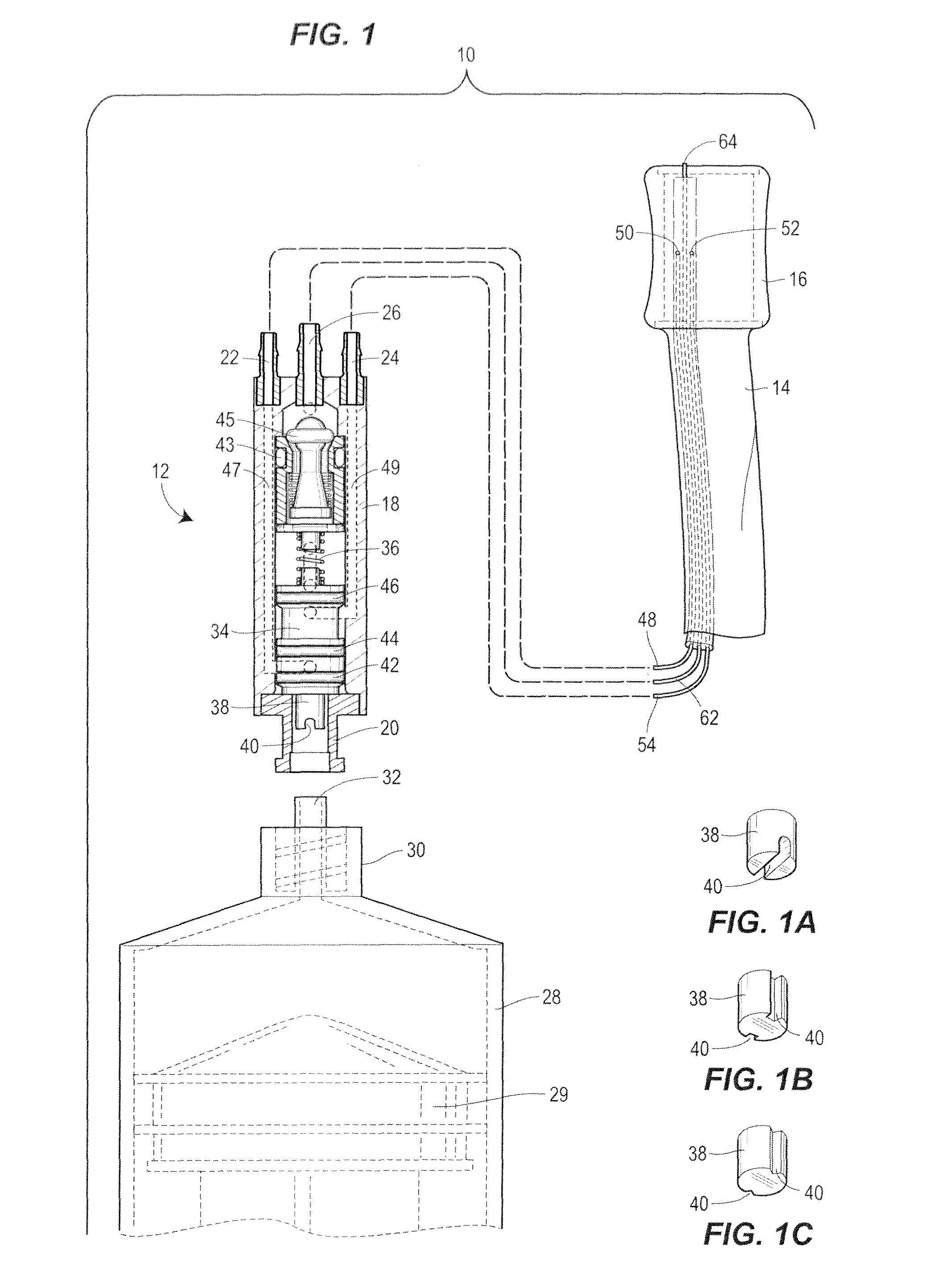

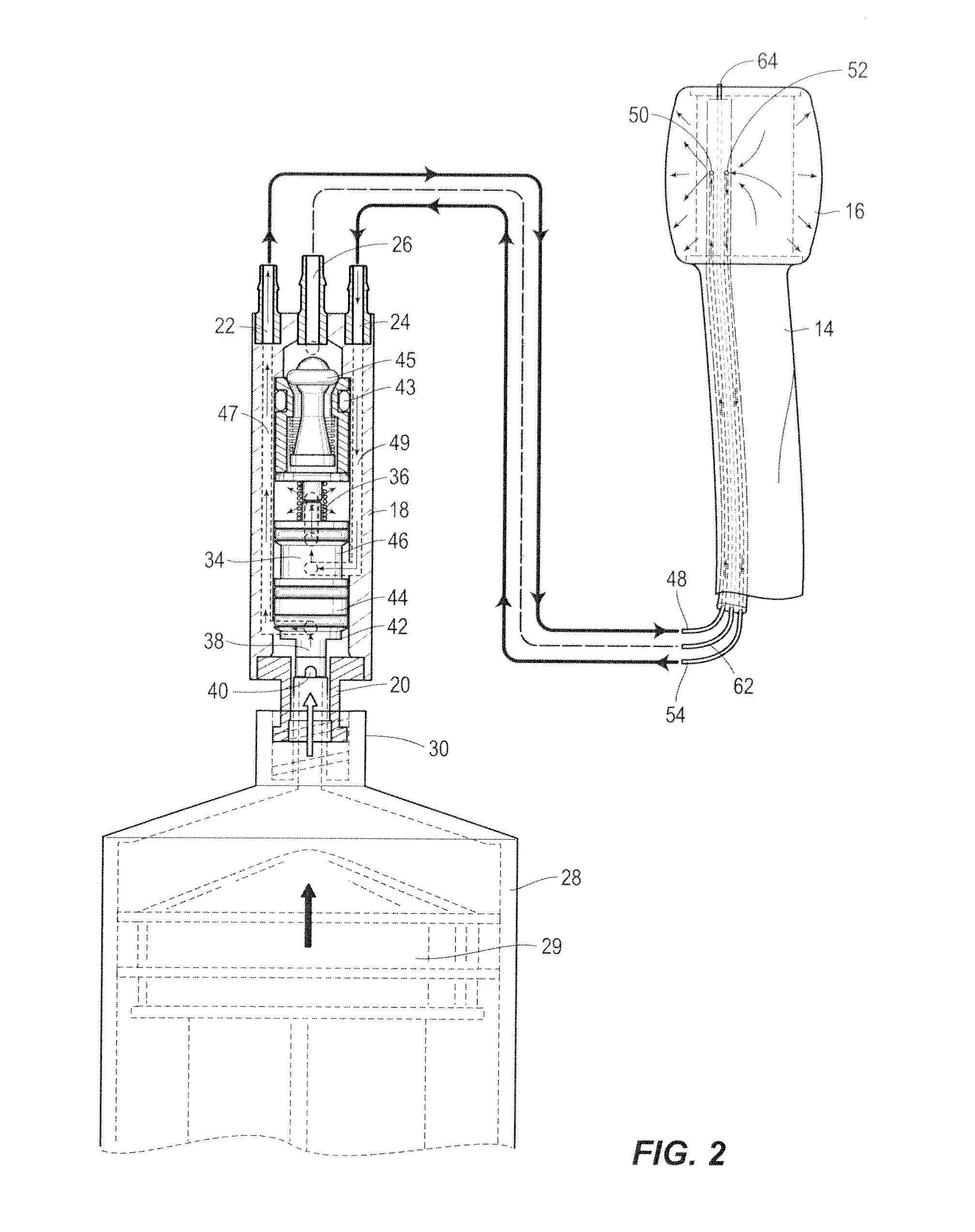

Inflation cuff with transient-resistant over-pressure preventor

A catheter system (10) with a valve assembly (12) that expels excess inflation fluid when a cuff or balloon (16) of the catheter system is overinflated. The valve assembly includes a luer-activated spool (34) biased toward a sealed condition, a precision relief / check valve (56) biased toward a scaled condition, a primary valve body outlet (22), a valve body feedback inlet (24), and a secondary valve body outlet (26). An inflation lumen (48) is in fluid communication with the primary valve body outlet and an interior of the cuff or balloon. A feedback lumen (54) is in fluid communication with the interior of the cuff or balloon and the valve body feedback inlet. When feedback fluid builds up pressure in excess of the restoring force of the relief spring, the relief / check valve opens, unsealing an expulsion pathway and relieving excess fluid from the cuff or balloon.

Owner:HOLLISTER INCORPORAED

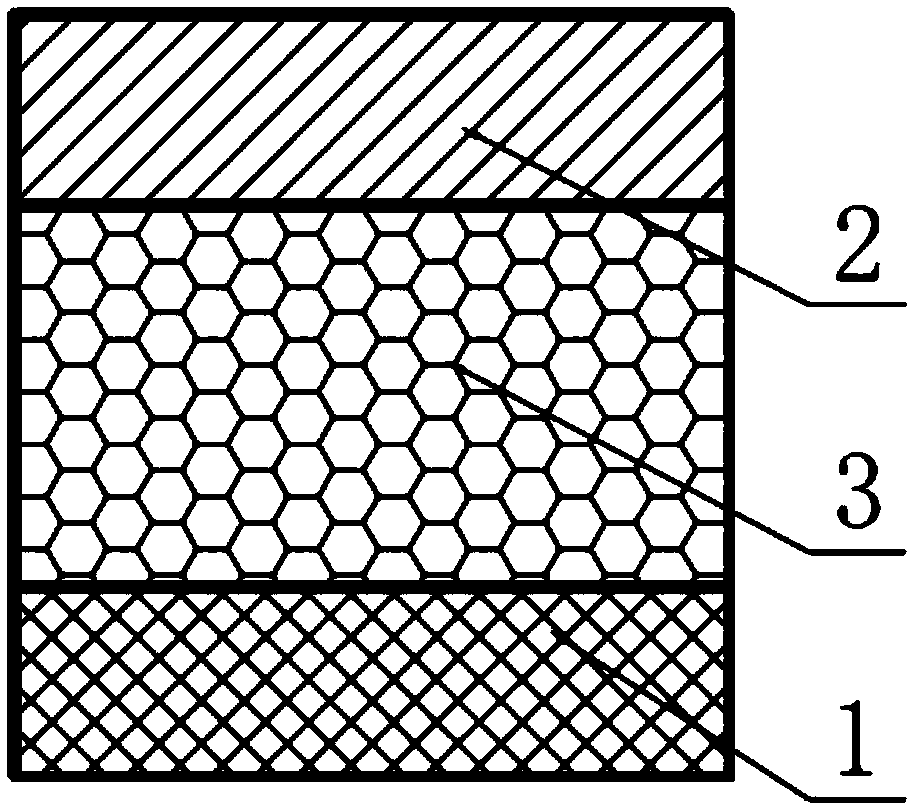

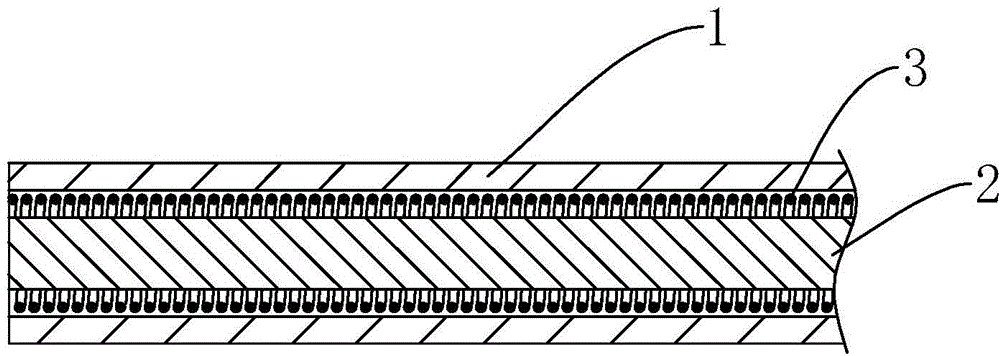

Bending insensitive pressure sensor

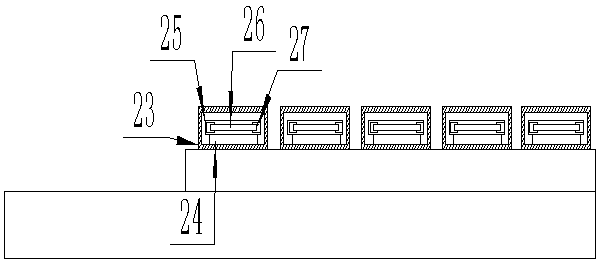

InactiveCN109211443AImprove elastic deformation abilityNo significant tensile strain occursForce measurement using piezo-electric devicesFiberT stress

The invention discloses a bending insensitive pressure sensor, and belongs to the field of micro-sensors. The bending insensitive pressure sensor comprises a flexible substrate (1), a gold-plated filmlayer (2) and a nanoporous structure layer (3), wherein the flexible substrate (1) is coated with the gold-plated film layer (2); the nanoporous structure layer (3) is arranged between the flexible substrate (1) and the gold-plated film layer (2); the flexible substrate (1) is made of polyethylene terephthalate; the nanoporous structure layer (3) is a porous material layer made of nanofibers withdiameters of 500 to 800 nanometers and a mixed conductive nanomaterial; the mixed conductive nanomaterial is located inside a nanofiber substrate, and is 1 to 2 percent by mass; the mixed conductivenanomaterial is made of carbon nanotubes (31) with diameters of 10 to 50 nanometers and graphene (32) with a thickness of 10 to 50 nanometers. The bending insensitive pressure sensor is suitable for flexible surface detection, has relatively low comprehensive elastic modulus, and does not generate additional pressure when measuring surface bending.

Owner:CHANGZHOU UNIV

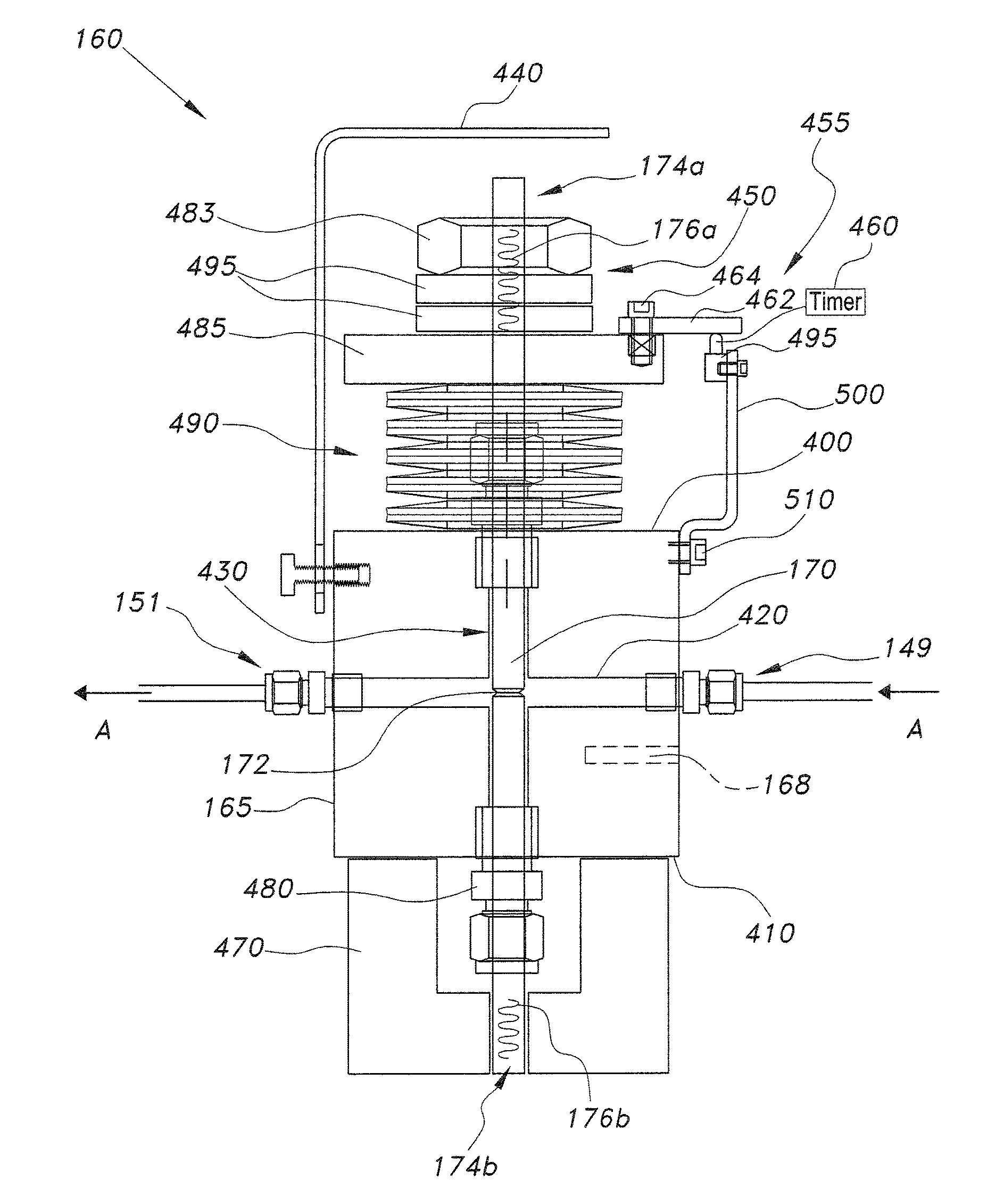

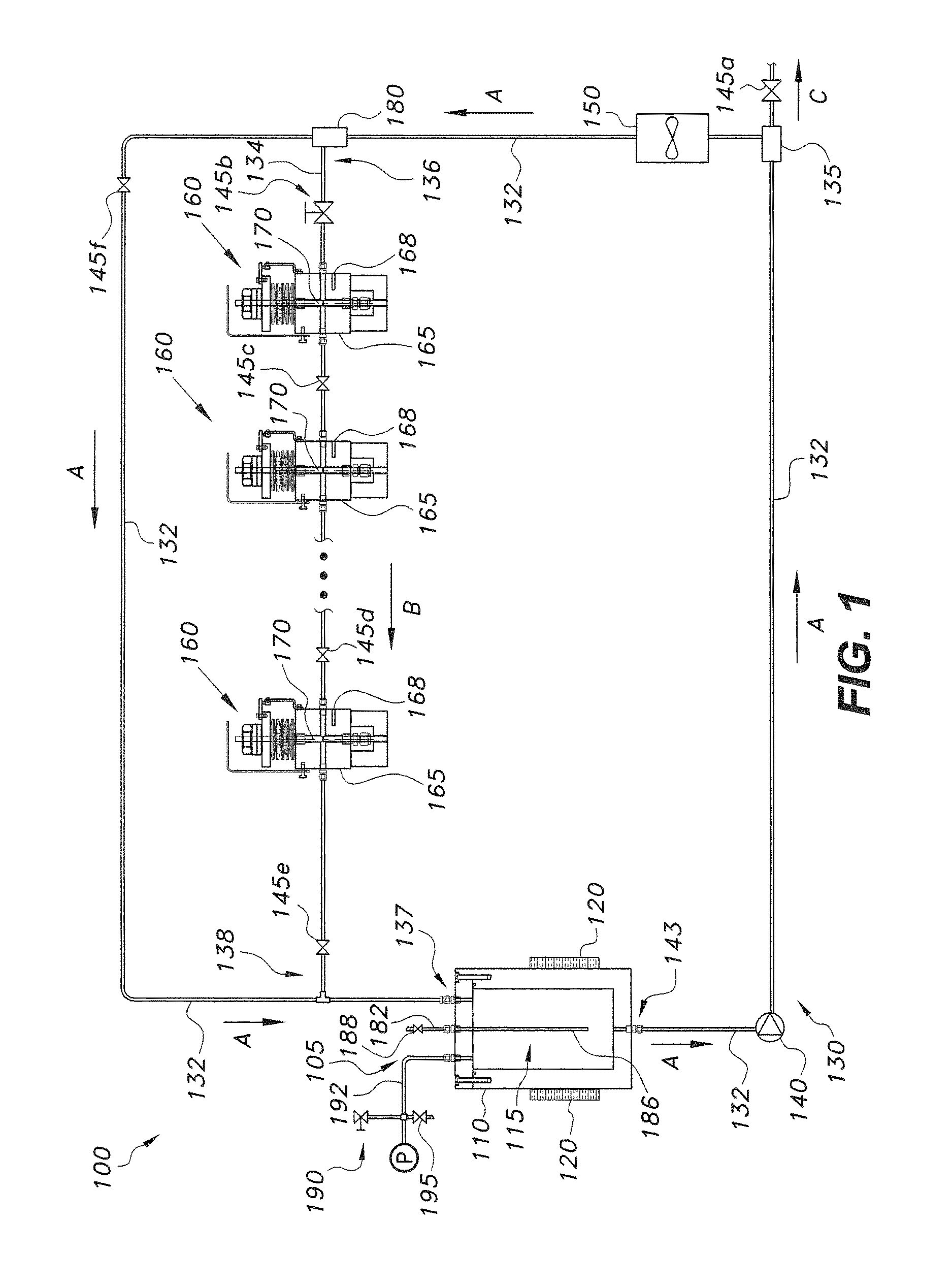

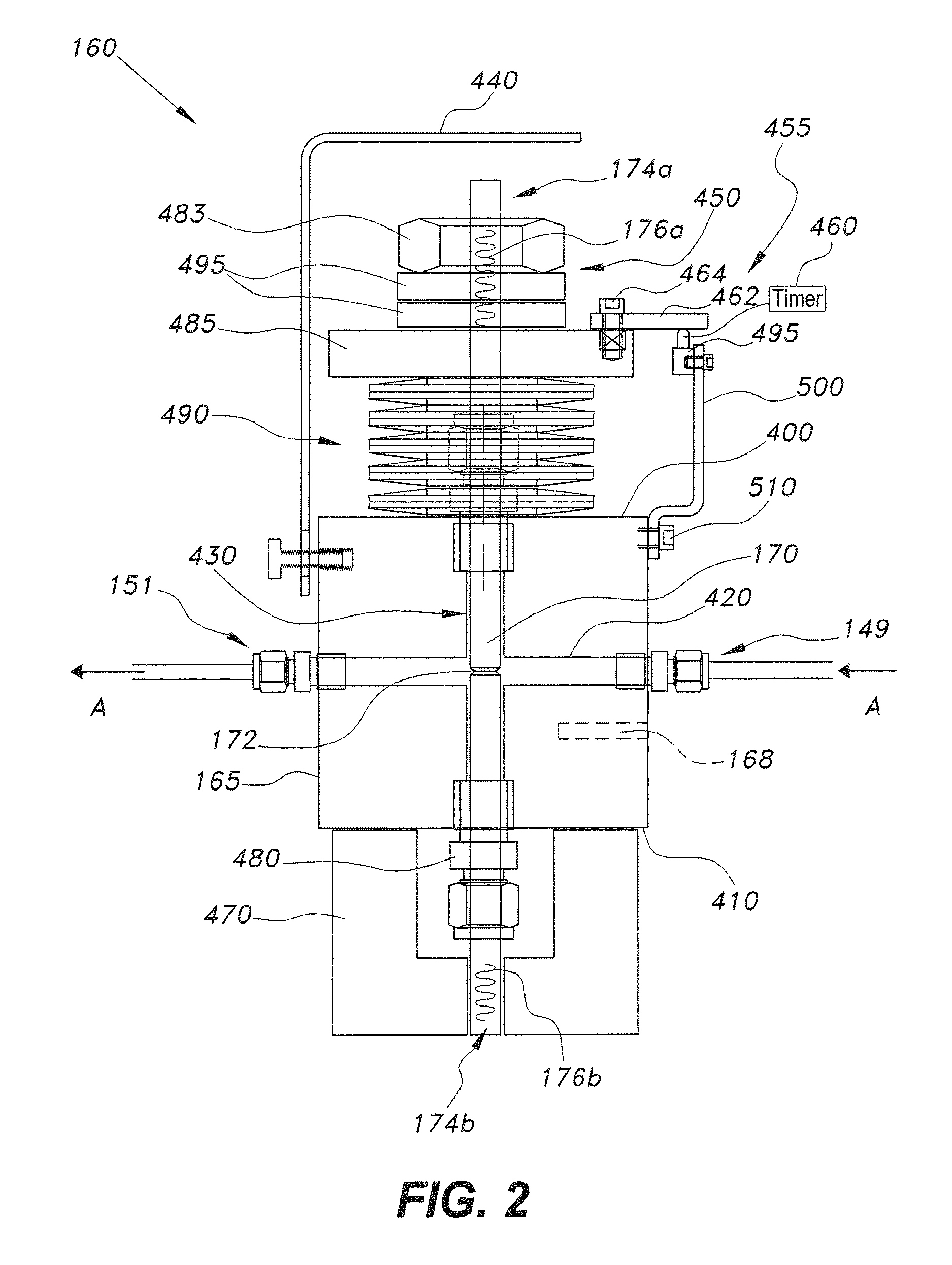

System for testing stress corrosion cracking

ActiveUS9541485B1Readily apparentWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesT stressEngineering

The system for testing stress corrosion cracking (SCC) includes an autoclave having at least one heating element selectively actuated to heat the interior portion of the autoclave, the autoclave being configured for receiving a liquid and / or gas and for forming a corrosive fluid. The system also includes a circulation assembly having a flow line and a test section line. A plurality of test sections is positioned in series along the test section line and configured for receiving the corrosive fluid via the test section line once the required temperature is reached to expose the specimens directly to the corrosive fluid, the fluid flowing through a section of the flow line parallel to the test section line until the required temperature is reached. The circulation assembly includes a circulating pump, a flowmeter positioned along the flow line, and a pressure assembly mounted on the autoclave.

Owner:KUWAIT INST FOR SCI RES

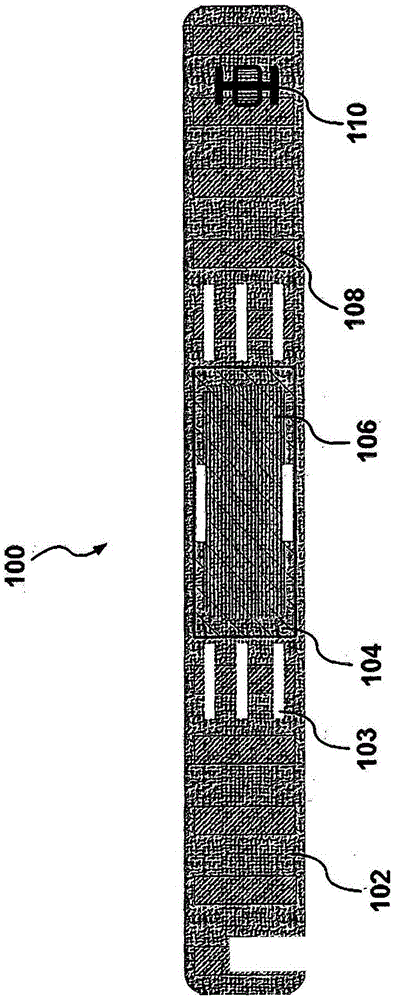

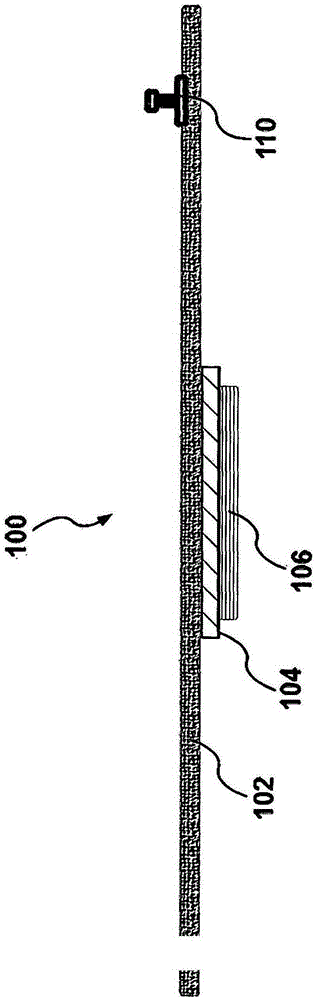

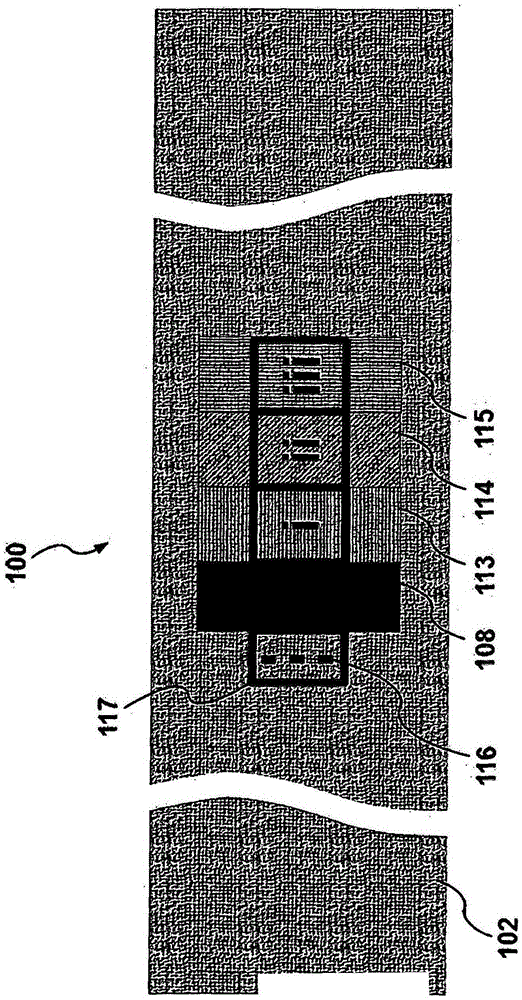

Multi-function emergency bandage

A unique multi-functional emergency bandage is introduced, wherein bleeding is stopped by: (1) optimizing mechanical properties and preventing ischemia and / or necrosis while applying enough pressure to help stop bleeding, and (2) incorporating inorganic anti-bleeding nano-structures (embedded within a gauze and / or microbial cellulose) with almost infinite life-time. Additionally, pathogen passage through the bandage is prohibited (via an intermediate filter layer). Together with the overall anti- microbial character of the bandage, the unique multi-functional bandage offers all these vital features within a single design. The unique bandage can be applied by using a single hand and bandaging direction can be changed using a unique binding apparatus. Visual aids, such as printed rectangles, on the final fabric provides the user with an indication of how to control the amount of stretch, as vertical rectangles would turn into horizontal rectangles when stretched too much, whereas rectangles turn to squares around the optimum region of the stress-strain curve.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Omni-directional rotating rebar drawing stress mechanism

The invention discloses a force-bearing mechanism for steel bar drawing with omnidirectional rotation, which includes a handle, and a ceramic pressure sensing mechanism is arranged inside each rectangular protrusion, and the intelligent MCU microcomputer control chip is respectively connected with touch sensing keys, red and green Indicator light, switch control board, 3V auxiliary power supply, power supply and drive controller are electrically connected. The invention has the advantages of simple structure and strong practicability.

Owner:张卓琳

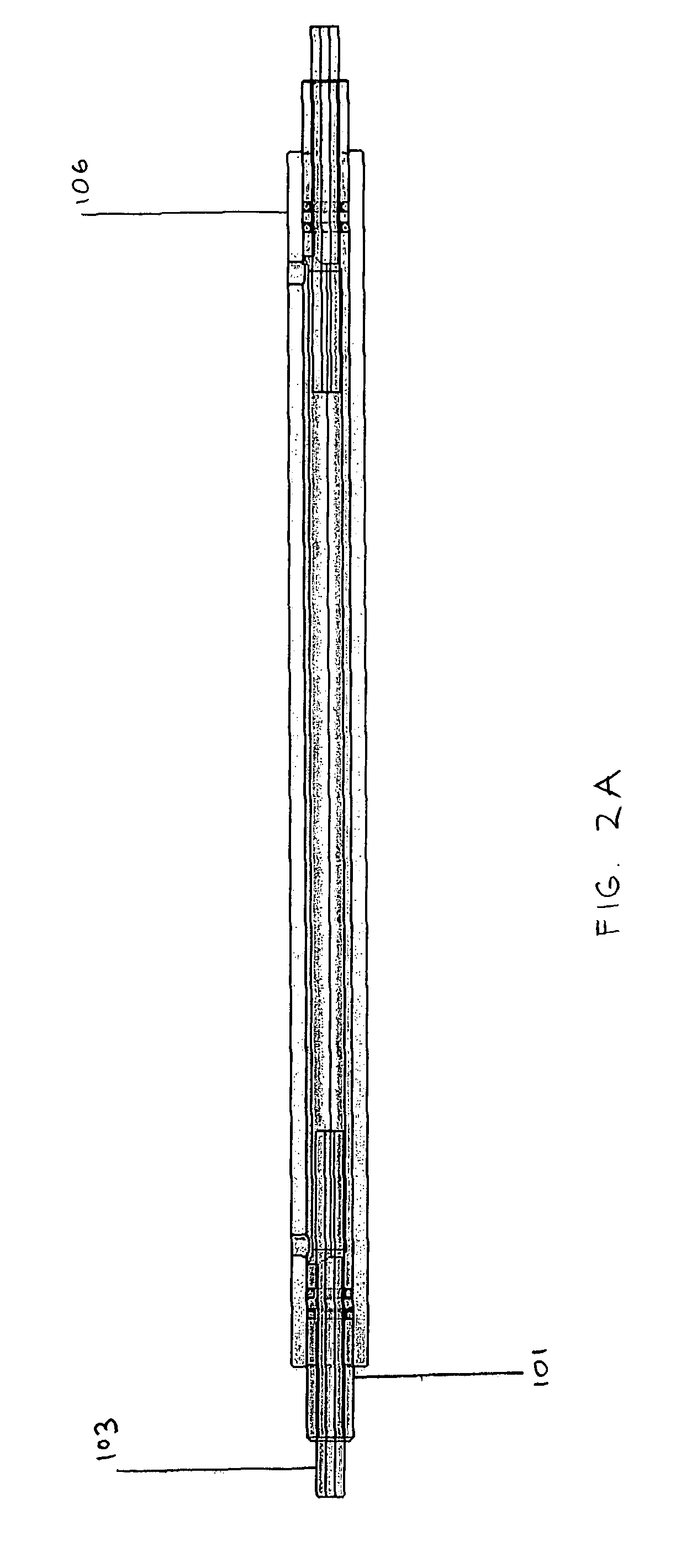

Surface strain detecting device and surface strain sensor thereof

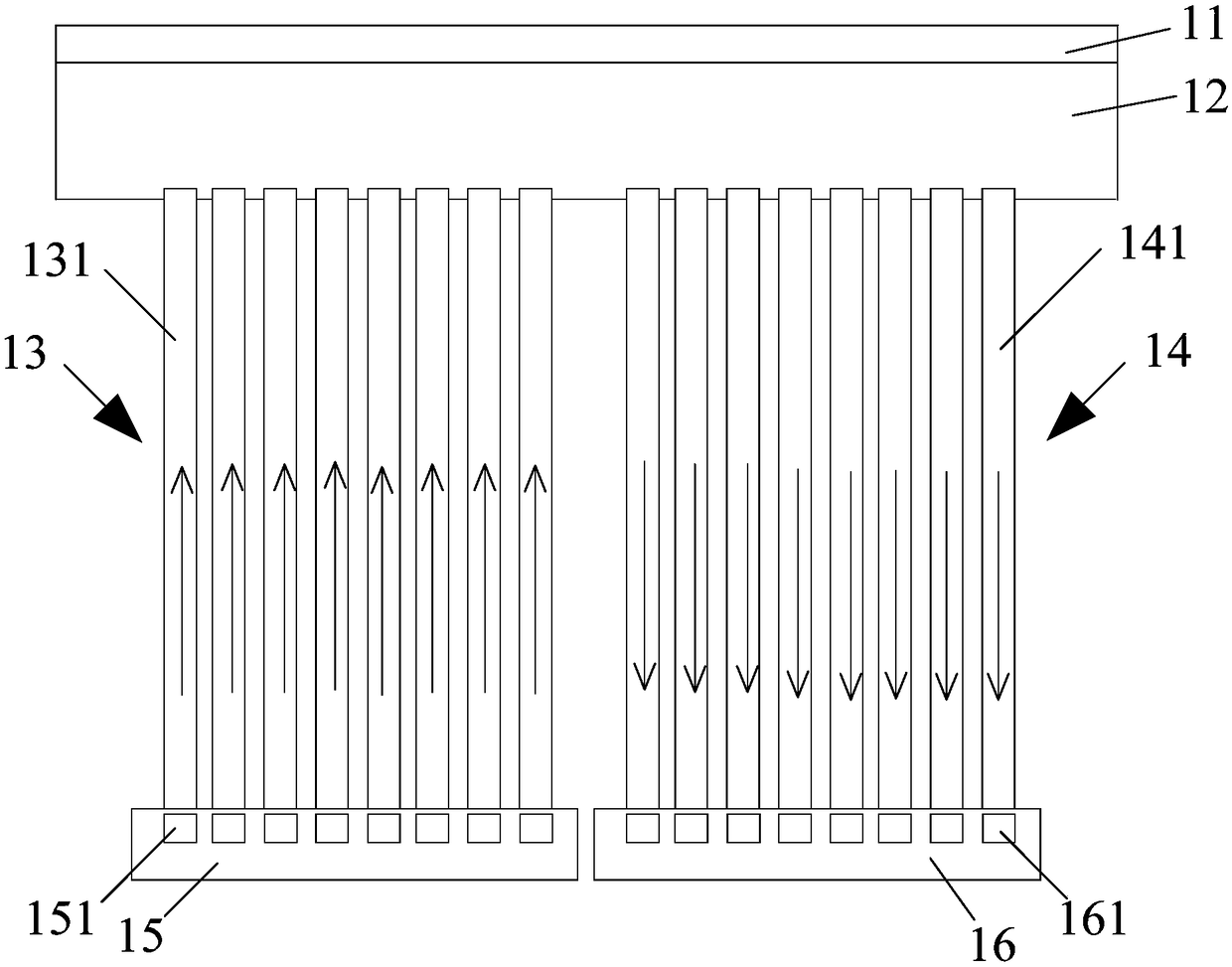

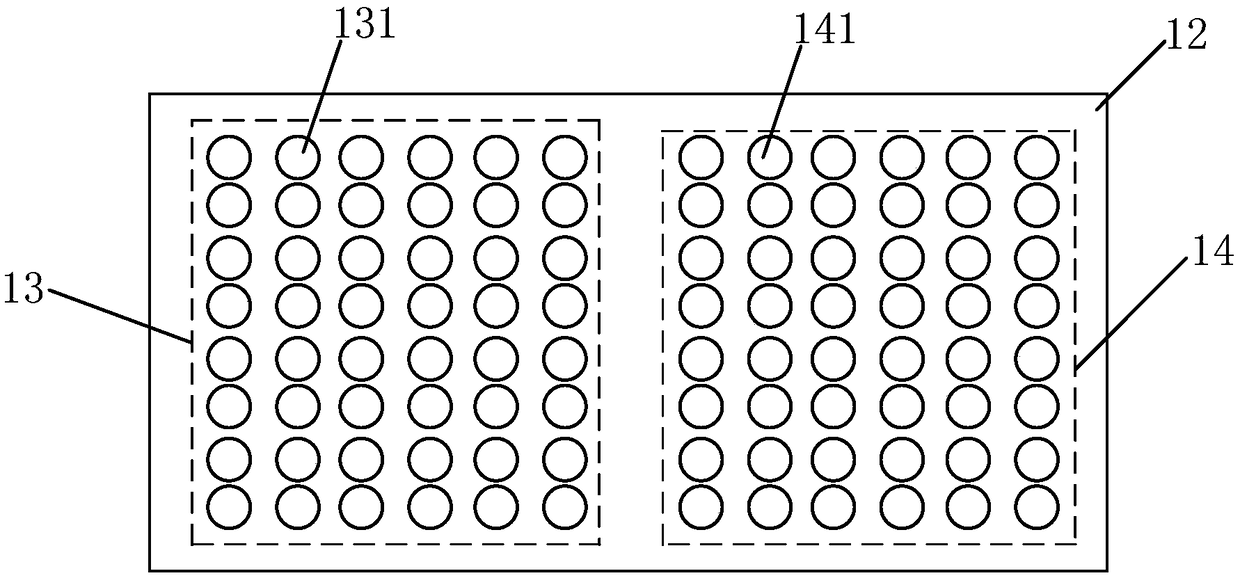

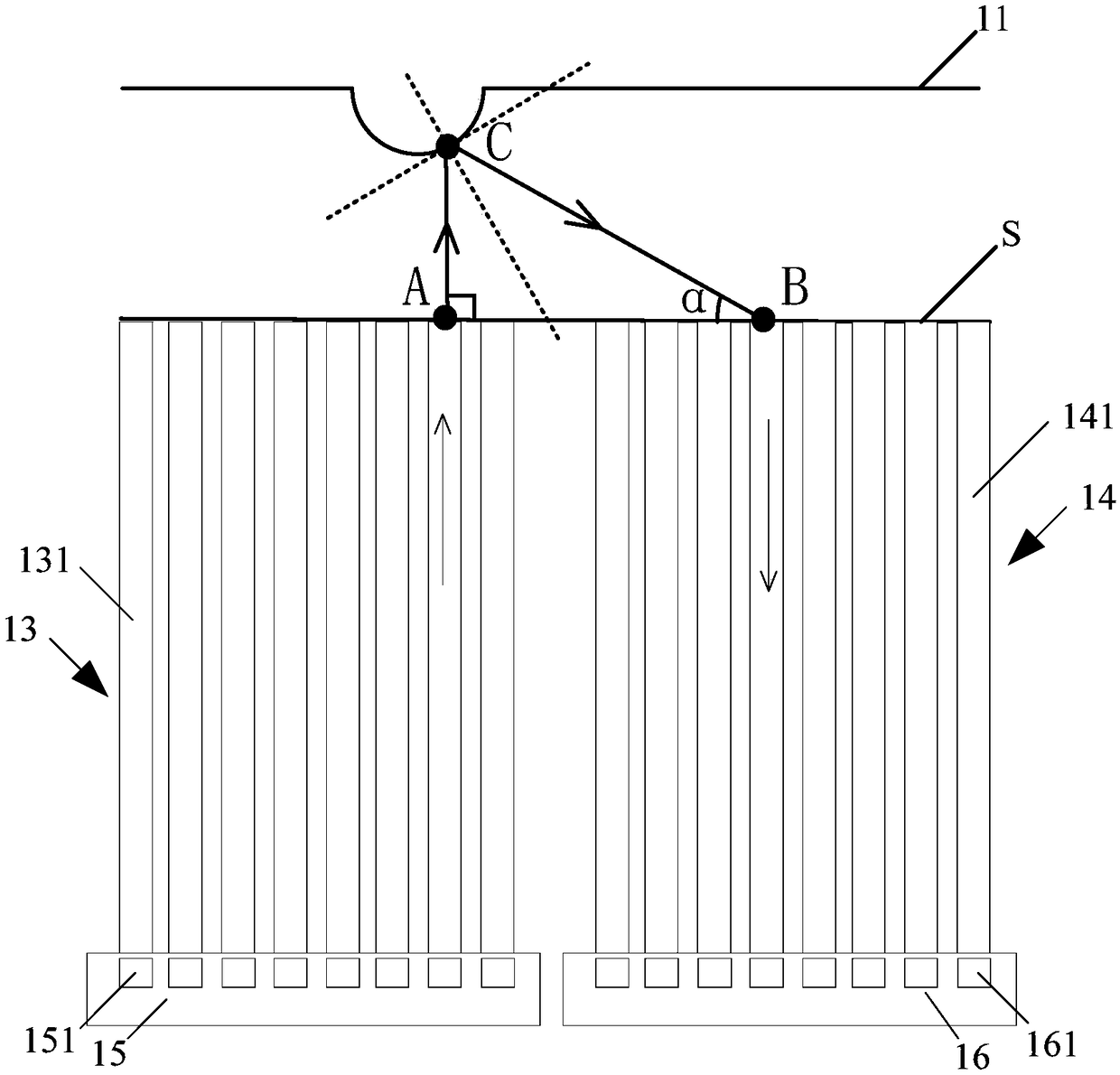

ActiveCN109414200AAvoid outside interferenceHigh precisionCatheterDiagnostic recording/measuringT stressFiber

The invention discloses a surface strain sensor, comprising: a light reflecting film (11) for deforming according to a pressure change of a surface to be tested; a transparent connecting layer (12) disposed on the light reflecting film (11);a first fiber array (13) and the second fiber array (14), each including a plurality of fibers (131, 141), wherein the first ends of the plurality of optical fibers (131, 141) are connected to a transparent connecting layer (12), and the plurality of connecting positions of the plurality of optical fibers (131, 141) and the transparent connecting layer (12)are in a matrix distribution on the transparent connecting layer (12); a light emitter array (15) including a plurality of light emitters (151) which are connected in one-to-one correspondence with the second ends of the plurality of fibers (131) in the first fiber array (13); an optical receiver array (16) including a plurality of optical receivers (161), which are connected in one-to-one correspondence with the second ends of the plurality of optical fibers (141) in the second optical fiber array (141). The surface strain sensor can improve the accuracy of surface strain detection and avoidexternal interference.

Owner:深圳市大富智慧健康科技有限公司

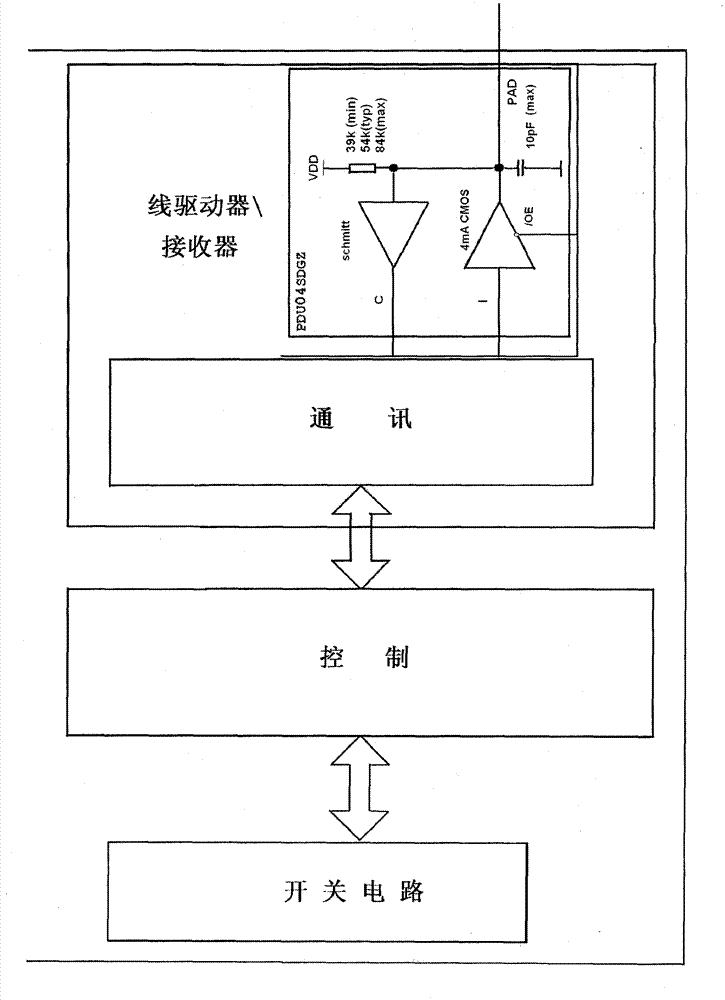

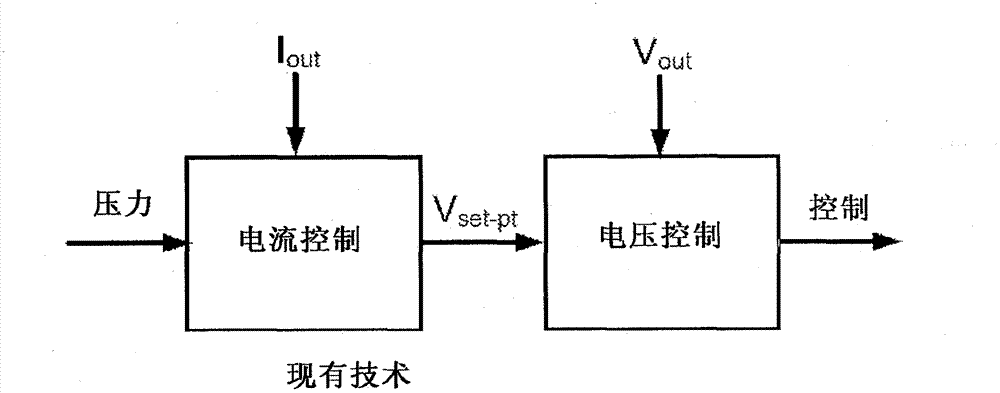

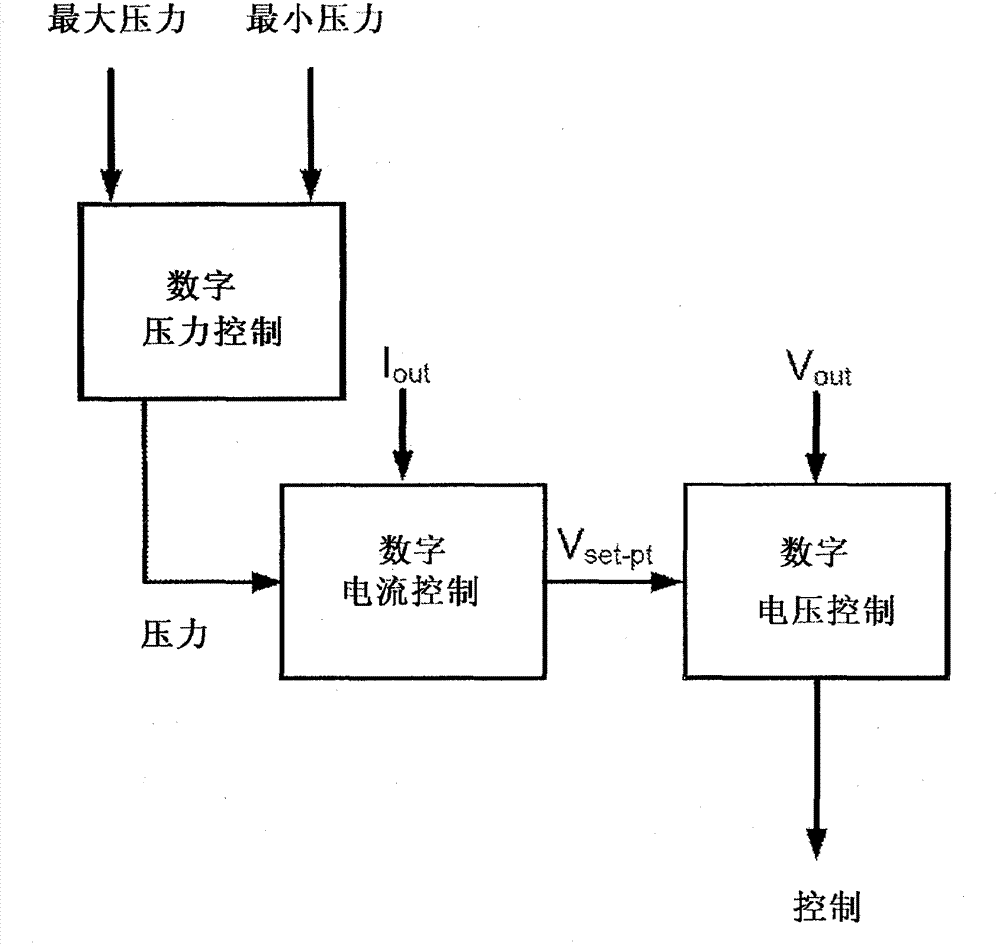

A digital stress share method

The invention discloses a PWM controller for controlling a phase in a multiphase environment. The PWM controller includes a control circuit for generating a control signal for a switch circuit to provide an output voltage, the control circuit providing the control signal so that the switch circuit runs with a voltage level, and a communication circuit configured to receive maximum and minimum voltage values, wherein the control circuit is adapted to adjust the voltage level towards an average value of the maximum and minimum voltage values.

Owner:ROHM CO LTD

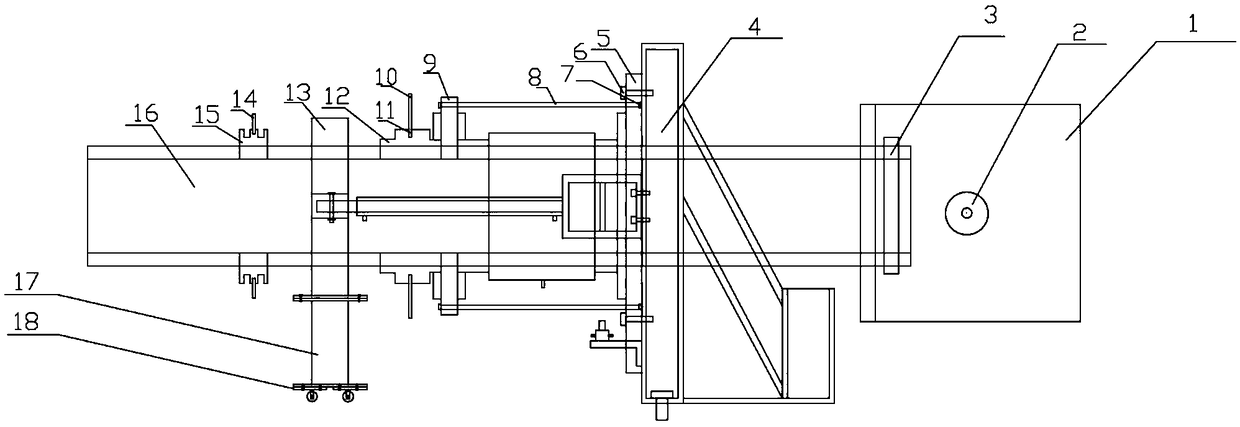

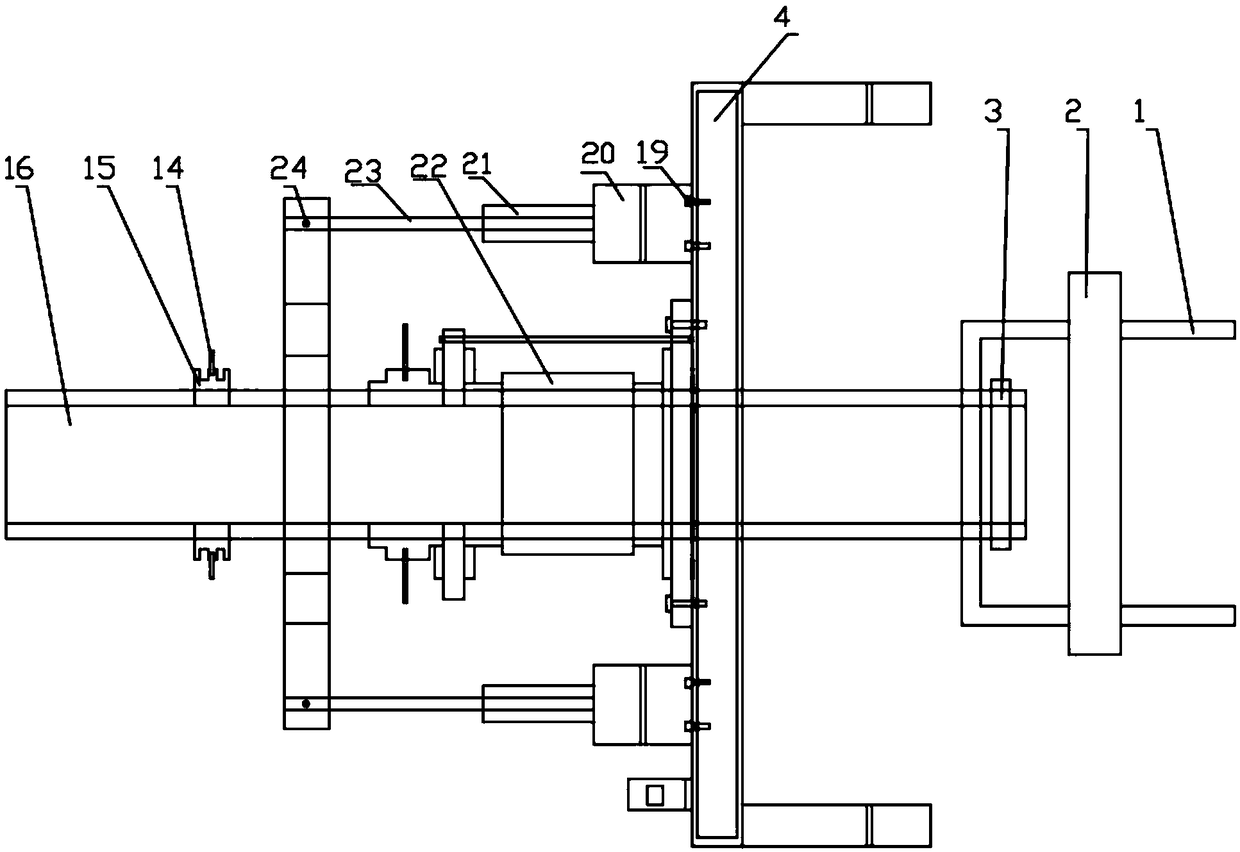

Wear-resistant and shock-resistant agricultural material conveying device

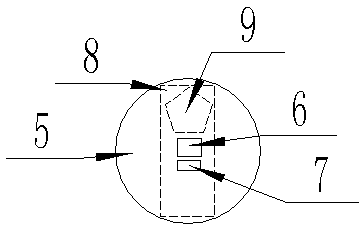

InactiveCN105453767AEnsure physical separationInhibit outputFertiliser distributersSeed depositing seeder partsT stressWear resistant

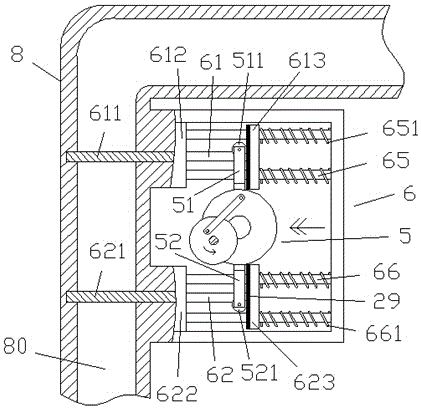

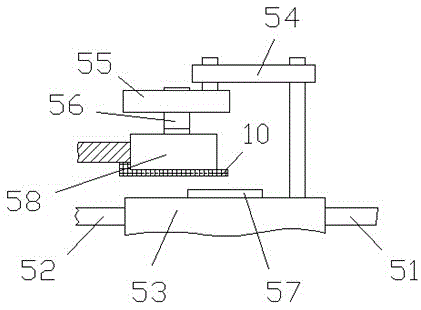

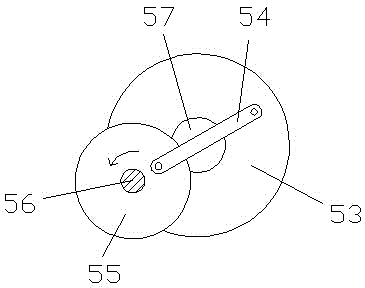

A wear-resistant and shock-resistant agricultural material conveying device comprises a material supply pipeline (8) fixed to a machine frame, and a supply control part (6) fixedly connected with the material supply pipeline (8). The material supply pipeline (8) receives materials discharged by exerting supply pressure from a material supply bin. The supply control part (6) comprises an upper cut-off plate (611) and a lower cut-off plate (621) which can stretch into an internal passageway (80) of the material supply pipeline (8) in a telescopic mode so as to cut off the internal passageway (80). The upper cut-off plate (611) is fixedly connected with an upper drive protruding plate (613) through an upper cut-off plate connection part (61), wherein the upper drive protruding plate (613) is borne on two upper guide columns (65) in a slidable mode.

Owner:CIXI ZHIJIANG MECHANICAL TECH CO LTD

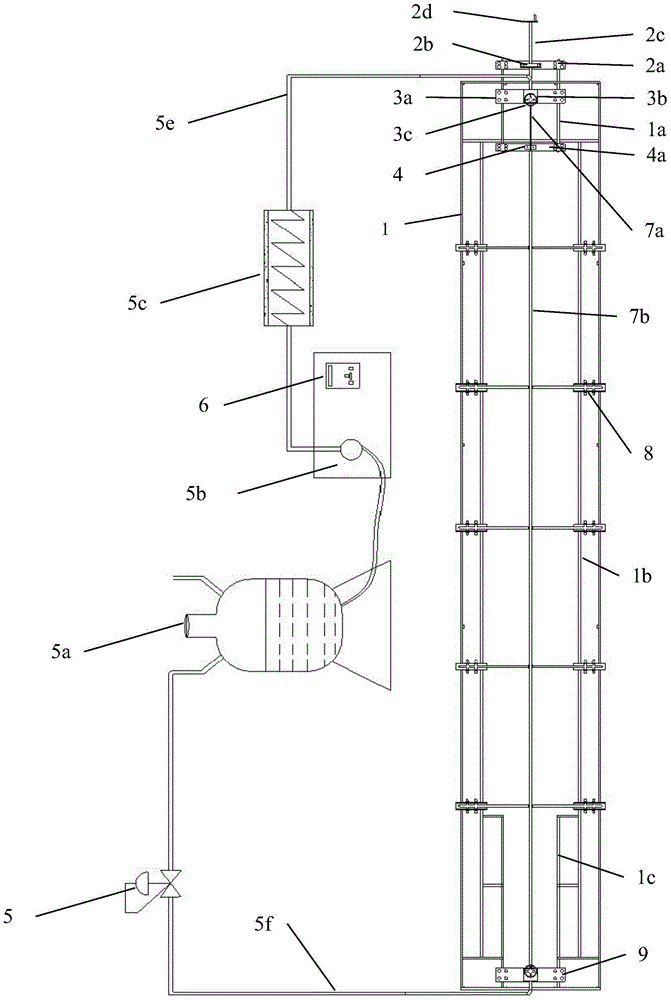

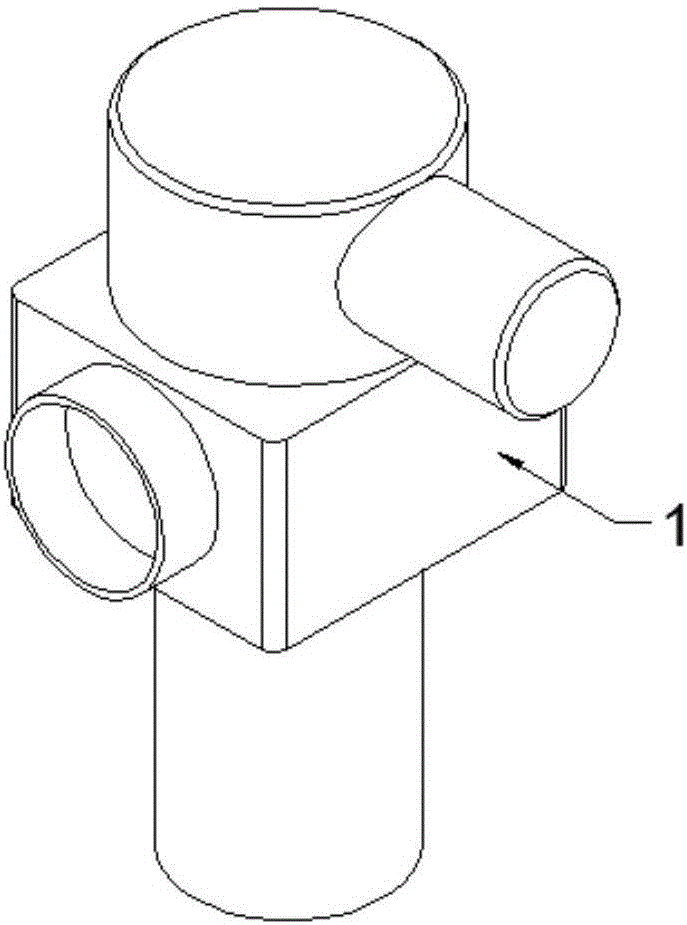

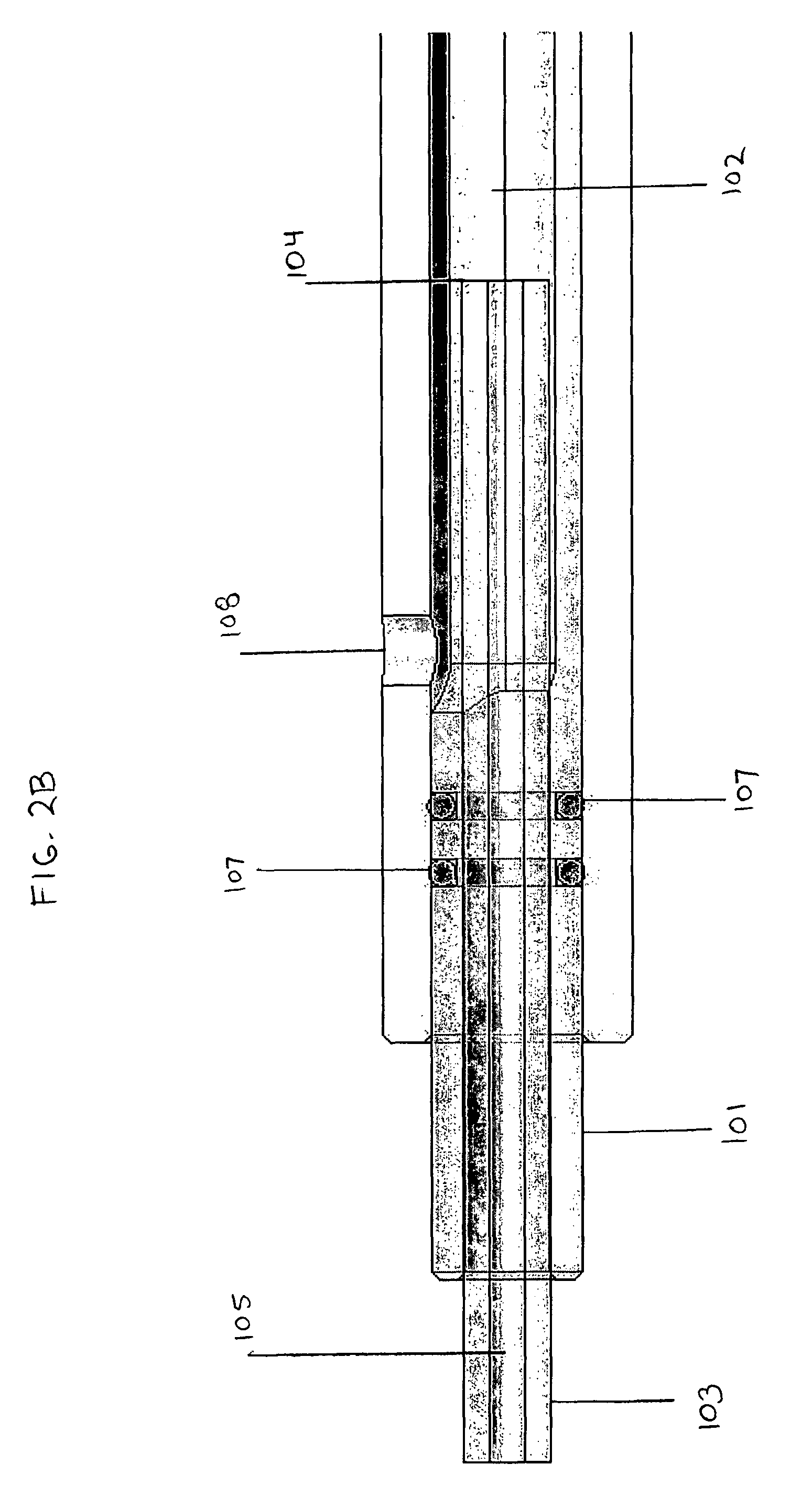

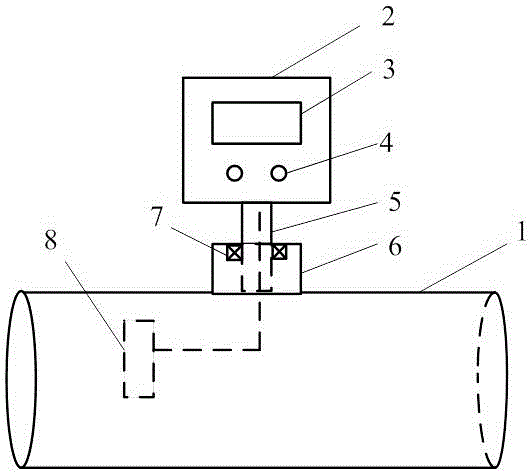

Multifunctional loading pipeline overall buckling experiment system

InactiveCN104316412AAchieve temperatureMaterial strength using tensile/compressive forcesT stressExhaust valve

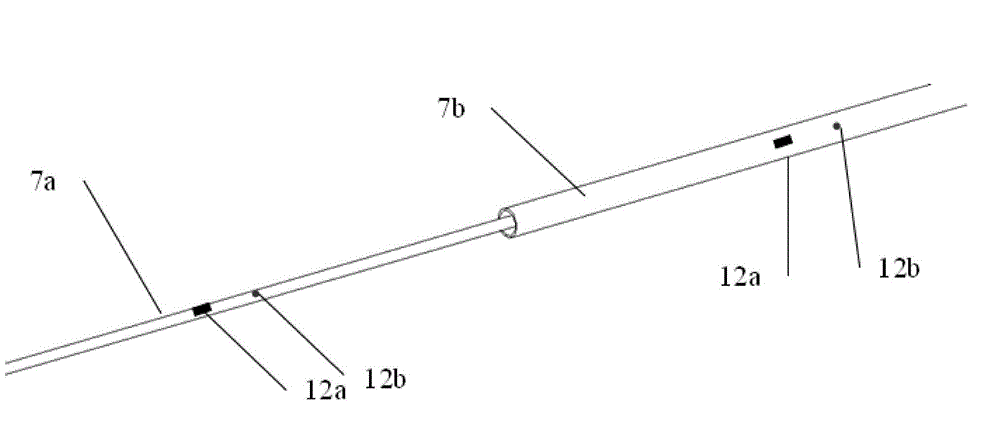

The invention relates to a multifunctional loading pipeline overall buckling experiment system. The system includes a self-balance reaction frame (1), a mechanical loading device (2), a multifunctional loading block (3), a pipeline guiding block (4), liquid circulating device (5) and a controller (6). The liquid circulating device (5) comprises a raw material tank (5a), a feed pump (5b), a preheater (5c) and a backpressure valve (5d). The liquid in the raw material tank (5a) is pumped into a pipe (7) through a feed pump (5b) and a circulation pipeline; the preheater (5c) and the backpressure valve (5d) are arranged in the circulation pipeline; the controller (6) is used to control the feed pump (5b) and preheater (5c); exhaust valves (9c) are arranged on the connection positions of the multifunctional loading block (3) and a fixed block (9b) with the rear end of the pipe (7). The invention can realize pipeline temperature, pressure and force loading, and can compare the differences of the loading modes.

Owner:TIANJIN UNIV

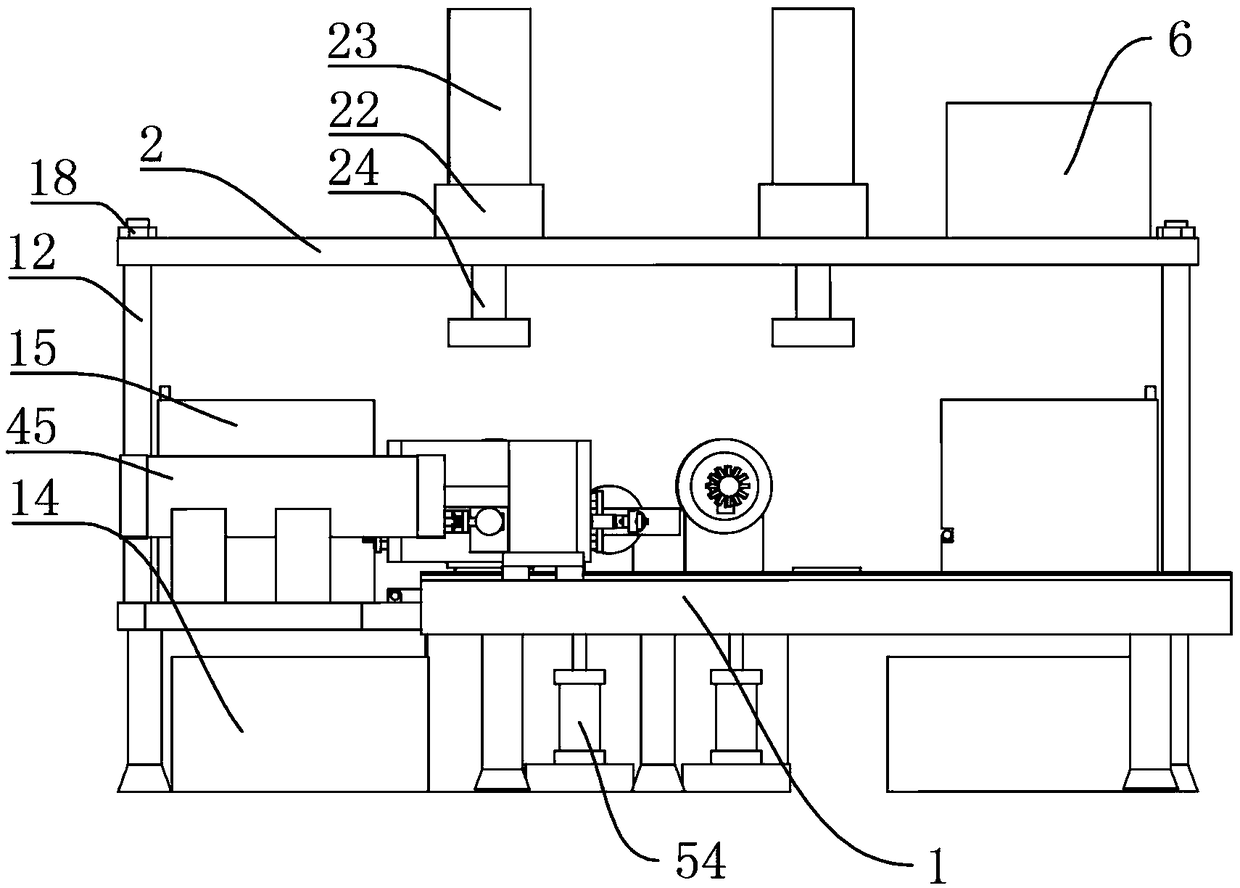

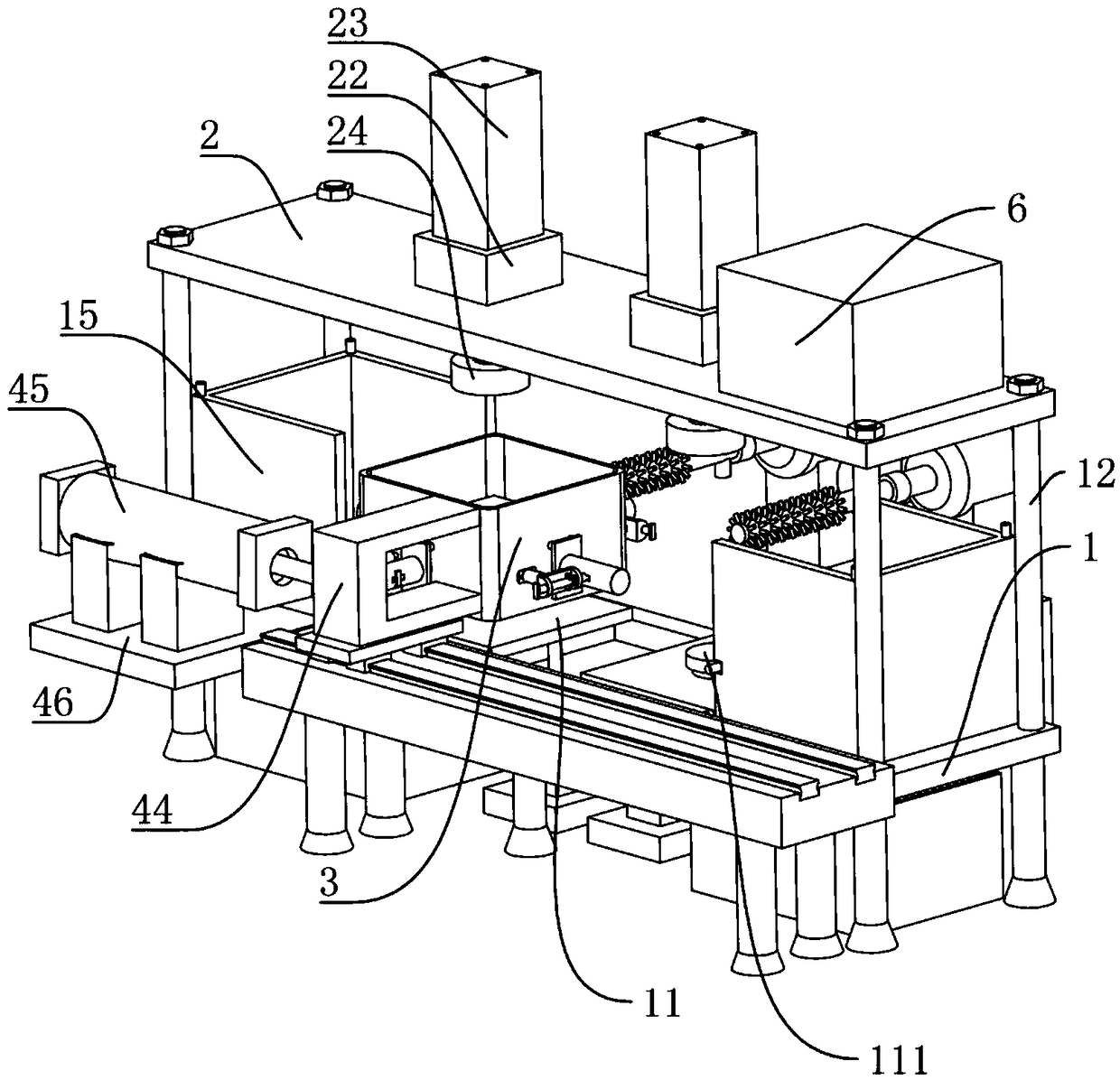

Pressure tester

PendingCN109342228AAvoid cloggingEasy to cleanMaterial strength using repeated/pulsating forcesT stressTest efficiency

The invention discloses a pressure tester which comprises a pedestal, wherein struts are symmetrically arranged at two ends of the pedestal, the struts are used for supporting a top seat and fixing the top seat to the upper end of the pedestal, two bases are transversely arranged side by side on the upper end face of the pedestal, a test bed is fixedly connected to each base, first through holes corresponding to the two test beds are formed in the top seat, hydraulic cylinders are mounted on the top seat through mounting seats, a lower pressure block is concentrically arranged on one end, closed to the test beds, of a piston rod of each hydraulic cylinder, positioning devices for positioning a test piece are arranged at the upper ends of the test beds, a push device connected to a box is arranged on one side of the pedestal, and a cleaning mechanism is arranged on the other side of the pedestal. By adopting the pressure tester, test pieces of different sizes can be positioned; the cleaning device has a relatively good cleaning effect, and the two test beds are arranged to switch between test and cleaning, so that the cleaning effect is relatively good and the test efficiency is relatively high.

Owner:绍兴市匠人软件科技有限公司

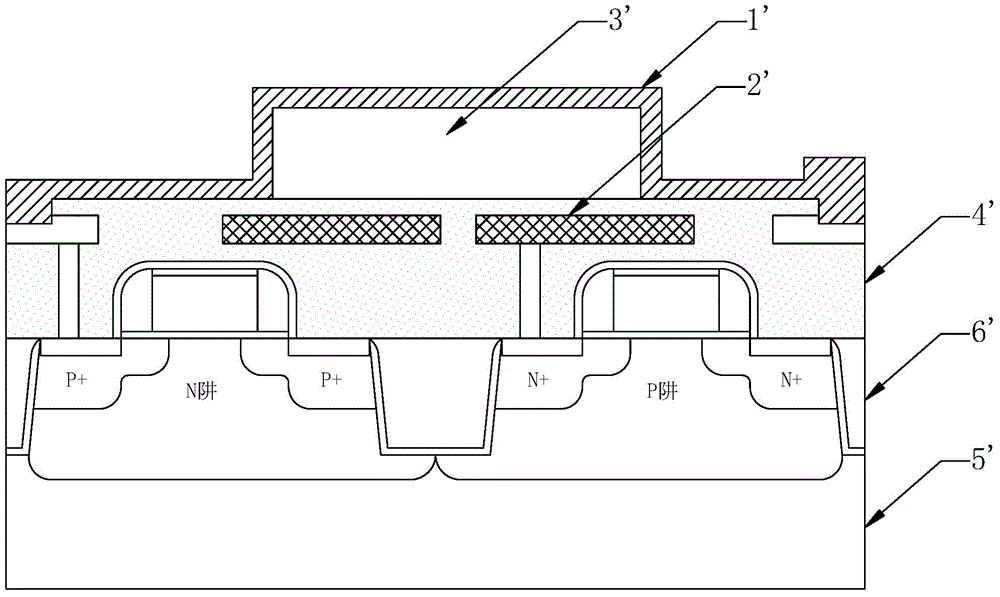

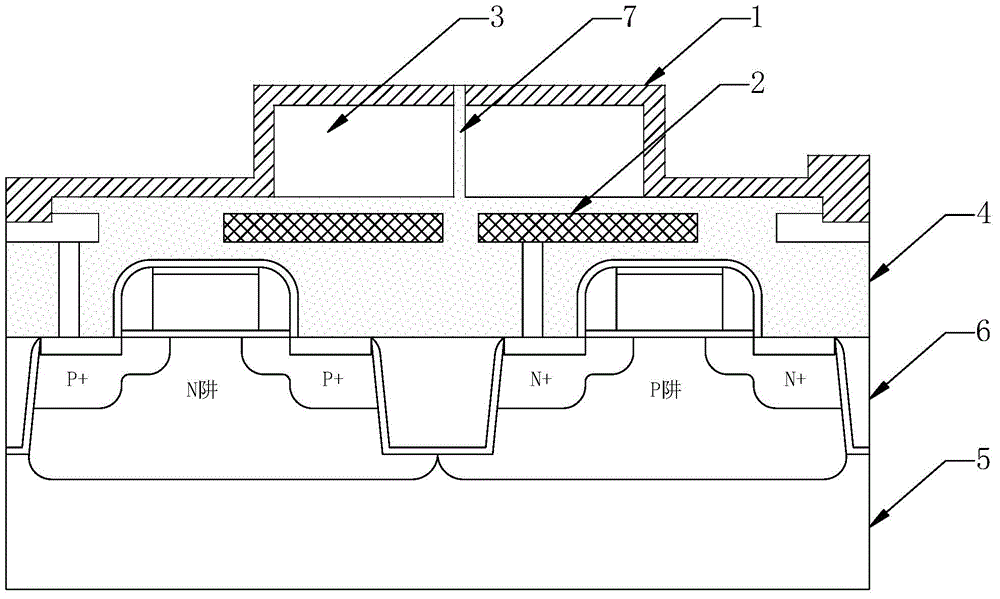

MEMS pressure sensor and manufacturing method

ActiveCN104949776AImprove efficiencyIncreased sensitivityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesT stressMems pressure sensor

The invention provides an MEMS pressure sensor and a manufacturing method. The MEMS pressure sensor is formed on a substrate structure, and at least comprises an oxide layer, a lower pole plate, an upper pole plate and a suppressing pile, wherein the lower pole plate is positioned in the oxide layer, the upper pole plate is positioned on the upper surface of the oxide layer, a cavity is formed between the upper pole plate and the oxide layer and positioned above the lower pole plate, and the suppressing pile is positioned in the cavity and connected with the upper pole plate and the oxide layer. The suppressing pile suppresses arching of the upper pole plate to the distance between the highest arching place of the upper pole plate and the lower pole plate. A suppressing pile is added between the upper and lower pole plates to shorten the distance between the highest arching place of the upper pole plate and the lower pole plate. The induction efficiency and sensitivity of the MEMS pressure sensor are improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Device for detecting repair compressive strength of CIPP pipeline and detection method thereof

ActiveCN109813599ARealize detectionPlay a supporting roleMaterial strength using tensile/compressive forcesT stressEngineering

The invention discloses a device for detecting repair compressive strength of a CIPP pipeline. The device comprises a connecting block, wherein a supporting box is fixed on the connecting block; a baffle is fixed in the supporting box; springs are arranged on both sides of the baffle; a sliding block is arranged at one end of the springs; a roller wheel is rotatably arranged at the end of the sliding block; an installation box is fixed at one end of the supporting box; a servo motor is fixed in the installation box; a first bevel gear is fixed on an output shaft of the servo motor; a second bevel gear is in transmission connection with the first bevel gear; a first screw rod is in transmission connection with the second bevel gear; a first transmission nut is in transmission connection with the first screw rod; a first connection frame is in transmission connection with the first transmission nut; a first top block is fixed at the end of the first connecting frame; a pressure sensor isarranged between the first top block and the first connecting frame; a supporting mechanism is arranged at one end of the installation box. By adopting the structure, the detection of the compressivestrength is realized, the structure is simple, and the operation is easy.

Owner:上海潜业市政工程有限公司

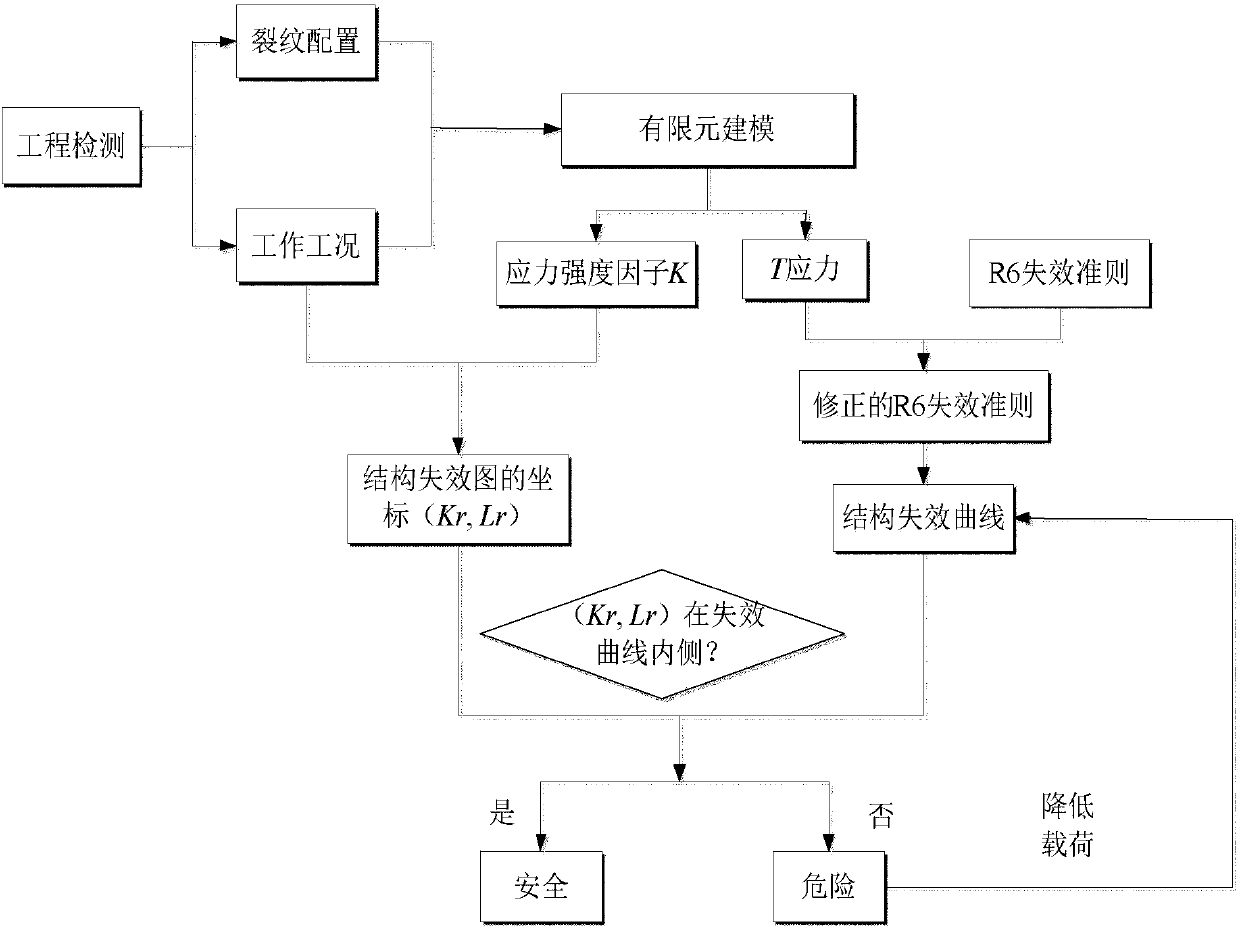

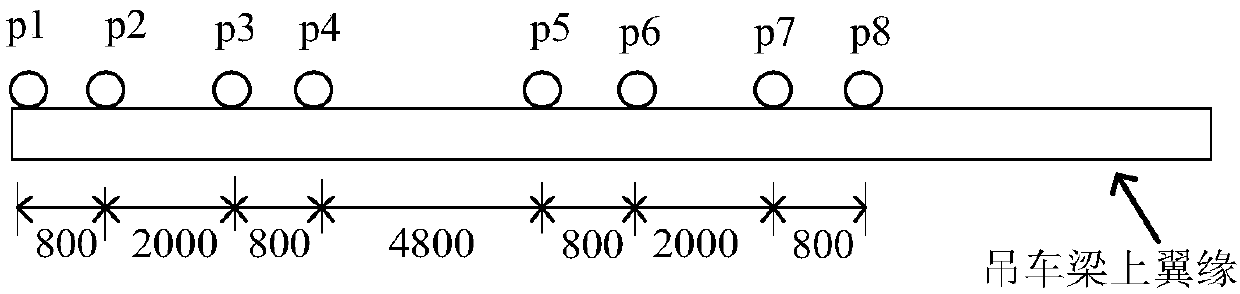

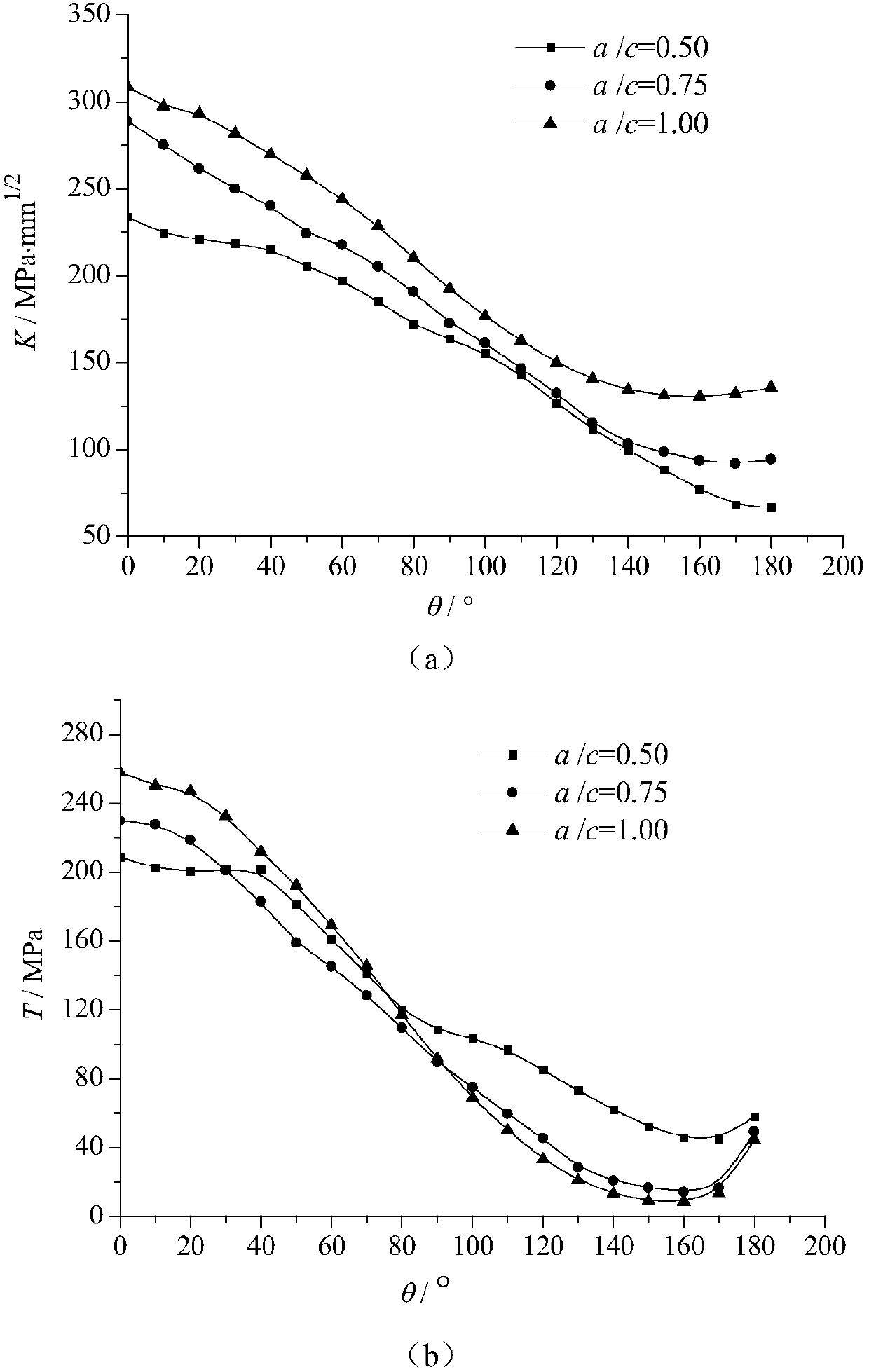

Steel crane beam structure integrity evaluation method considering constraint effect

ActiveCN108051161AIncrease safety reserveEnsure safe productionElasticity measurementT stressElement model

The invention discloses a steel crane beam structure integrity evaluation method considering the constraint effect. The method comprises steps that a steel crane beam in the service period is tested,and a geometric parameter of a crack in the steel crane beam, a track eccentric distance E0 and the crane wheel pressure Py0 in an actual working load are acquired; secondly, a three-dimensional finite element model of the steel crane beam with the crack is established, and a stress intensity factor K of the crack front of the steel crane beam and a constraint effect characterization parameter T stress are extracted from the model; influence of the T stress on structure integrity is considered, and R6 failure criteria are collected; and lastly, the corrected R6 failure criteria are utilized todetermined the structure integrity condition of the steel crane beam. The method is advantaged in that influence of the constraint effect of the crack front on structure integrity of the crane beam is considered, the T stress is the characterization parameter, the method can be utilized for evaluating safety production of the cracked steel crane beam in service, the safety reserve of the overallstructure can be enhanced, and safety production of the steel crane beam with the defect can be better guaranteed.

Owner:SOUTHEAST UNIV

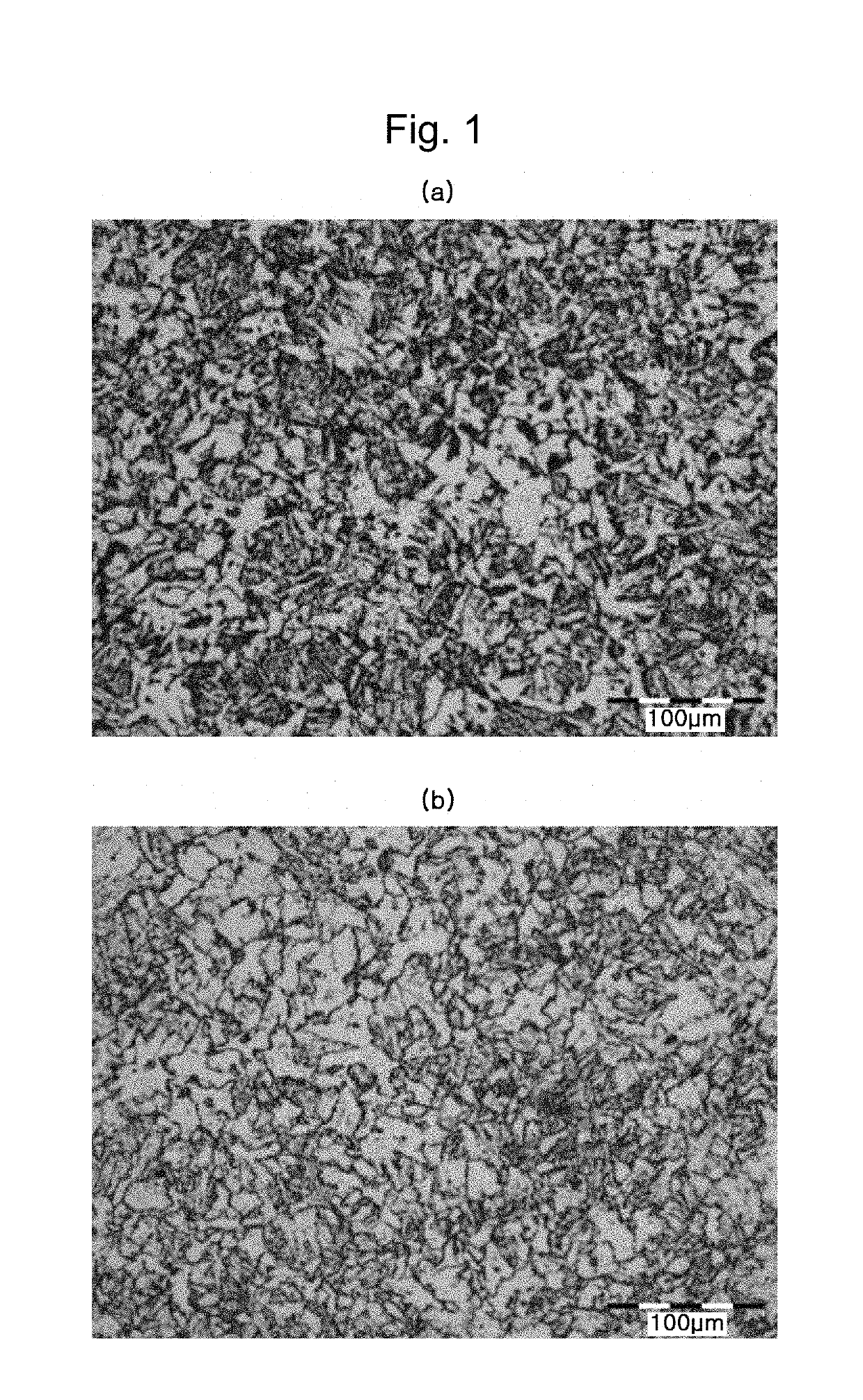

High-strength steel plate for pressure vessel having excellent toughness after post weld heat treatment and manufacturing method thereof

ActiveUS20190100818A1Improve mechanical propertiesInhibition strengthFurnace typesWelding/soldering/cutting articlesNiobiumManganese

Provided is a high-strength steel plate for a pressure vessel having excellent low temperature toughness after a post weld heat treatment (PWHT). The high-strength steel plate for a pressure vessel includes: by wt %, 0.02-0.15% of carbon (C), 0.05-0.50% of silicon (Si), 1.0-2.0% of manganese (Mn), 0.005-0.1% of aluminum (Al), 0.015% or less of phosphorus (P), 0.0015% or less of sulfur (S), 0.01-0.03% of niobium (Nb), 0.01-0.03% of vanadium (V), 0.01-0.03% of titanium (Ti), 0.005% or less of chromium (Cr), 0.005% or less of molybdenum (Mo), 0.02-0.50% of copper (Cu), 0.05-0.60% of nickel (Ni), 0.0002-0.0010% of boron (B), 0.0035-0.0065% of nitrogen (N), and a balance of iron (Fe) and other inevitable impurities. A microstructure of the high-strength steel plate includes a complex structure of ferrite having an area fraction of 35-40% and a balance of bainite, and the bainite has a packet size of 15 μm or less.

Owner:POHANG IRON & STEEL CO LTD

Radial shearing limit experiment device for axis parts

ActiveCN108548731AAccurate measurement of radial shear strengthGuaranteed sliding fit accuracyMaterial strength using steady shearing forcesT stressHydraulic cylinder

The invention discloses a radial shearing limit experiment device for axis parts. The radial shearing limit experiment device comprises a hydraulic cylinder, an upper fixed plate (6), a lifting plateand a control system, wherein a left right vertical plate and a right side vertical plate are respectively fixed on the left and right sides of a lower fixed plate, guiding mechanisms which are provided with lifting plates and move along the up-down direction are arranged on the left right vertical plate and the right side vertical plate, the upper fixed plate is fixed at the upper ends of the left right vertical plate and the right side vertical plate, and the hydraulic cylinder is fixed on the upper fixed plate; a connecting frame is fixed by a piston rod of the hydraulic cylinder, the lifting plate is fixed by the connecting frame, a left side guide rail flexible supporting device and a right side guide rail flexible supporting device are arranged on the lifting plate, a loading guide rail is fixed by the left side guide rail flexible supporting device and a right side guide rail flexible supporting device, a loading sliding block is mounted on the loading guide rail, an upper shearing seat is fixed on the loading sliding block, a butterfly bolt is screwed to the upper shearing seat, and an upper pin hole is formed in the upper shearing seat; and a lower pin hole is formed in alower shearing seat, the lower shearing seat is fixed on a swing plate through a pressure sensor, and the fixed position of the swing plate on the lower fixed plate can be adjusted. By utilizing the left side guide rail flexible supporting device and the right side guide rail flexible supporting device, the load can be completely borne by the butterfly bolt.

Owner:ANYANG INST OF TECH

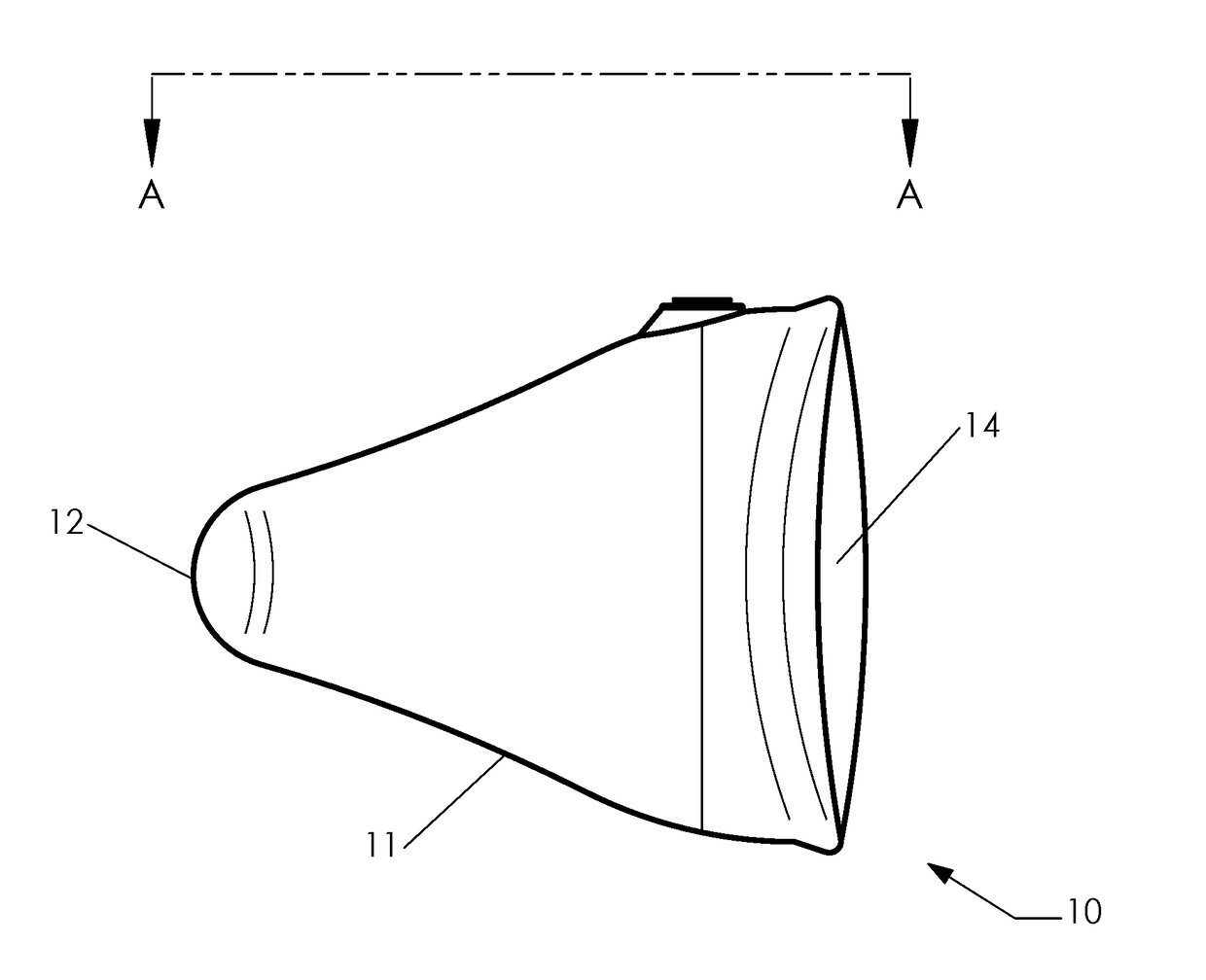

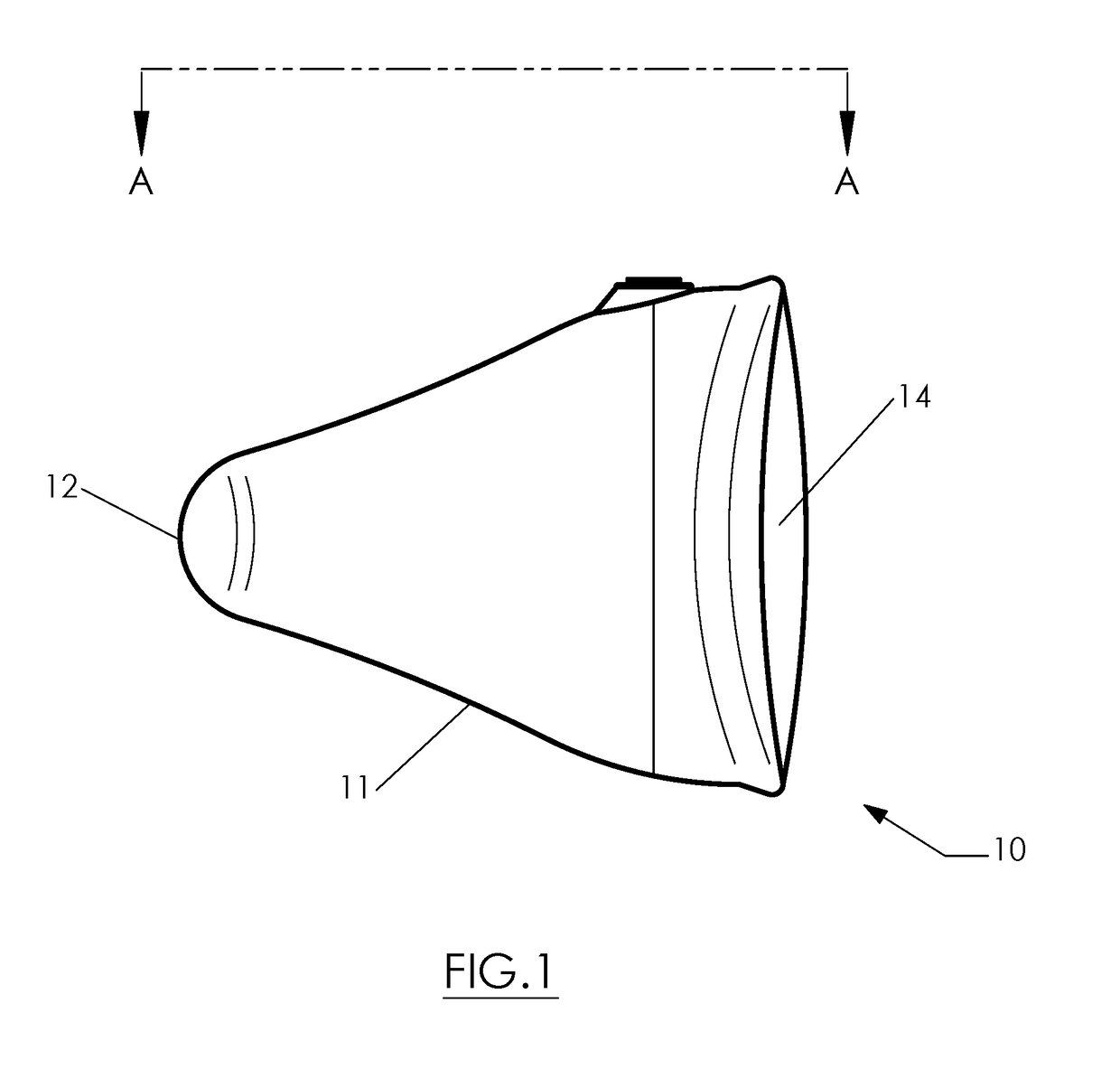

Stress Cone

InactiveUS20170087051A1Devices for pressing relfex pointsVibration massageT stressCompressible material

A stress cone (10) for massaging tight back muscles of a human body, the stress cone being a conical shaped body (11) with a rounded tip (12) at one end and an opposed concave base (14) at an opposed end. The stress cone (10) is typically made of solid rubber or other rigid but slightly compressible materials, and in some embodiments features a hollow core (18) for housing a vibrating motor (20). In use, the stress cone (10) is affixed to a wall via the concave base (14), and a user positions an identified pressure point of his or her body against the tip (12) and applies body pressure to the tip. The user can move side to side or up and down against the stress cone, massaging the muscles located at the pressure point to loosen them.

Owner:DEEM DONALD OSCAR

Overpressure-resisting pressure instrument

InactiveCN106225987AImprove protectionImprove overpressure resistanceFluid pressure measurementT stressEngineering

The invention provides an overpressure-resisting pressure instrument which comprises an instrument main body, wherein a protecting shell made from stainless steel is detachably connected on the outer side of the instrument main body; the instrument main body comprises an instrument plate, an inner shell and a base in turn from top to bottom; a moveable pressure-resisting net is arranged at the upper end of the base; a sensor is arranged above the pressure-resisting net; the powder metallurgy is arranged above the sensor; the powder metallurgy is fixedly mounted on a powder metallurgy mounting body; the upper end of the powder metallurgy is fixedly connected with a copper tube through a damp bolt; a connecting loop sleeves the outer side of the copper tube; a terminal is arranged at the upper end of the connecting loop; under the shaking of the copper tube, the connecting loop is in contact with the terminal; the terminal also is connected with an intelligent meter for showing a measuring result. The overpressure-resisting pressure instrument has the beneficial effects that the instrument main body has two protecting wires in an overpressure measuring process due to the design of the protecting shell and the pressure-resisting net, so that the overpressure resistance of the instrument main body is promoted and the service life of the instrument main body is prolonged.

Owner:山东佰测传感科技股份有限公司

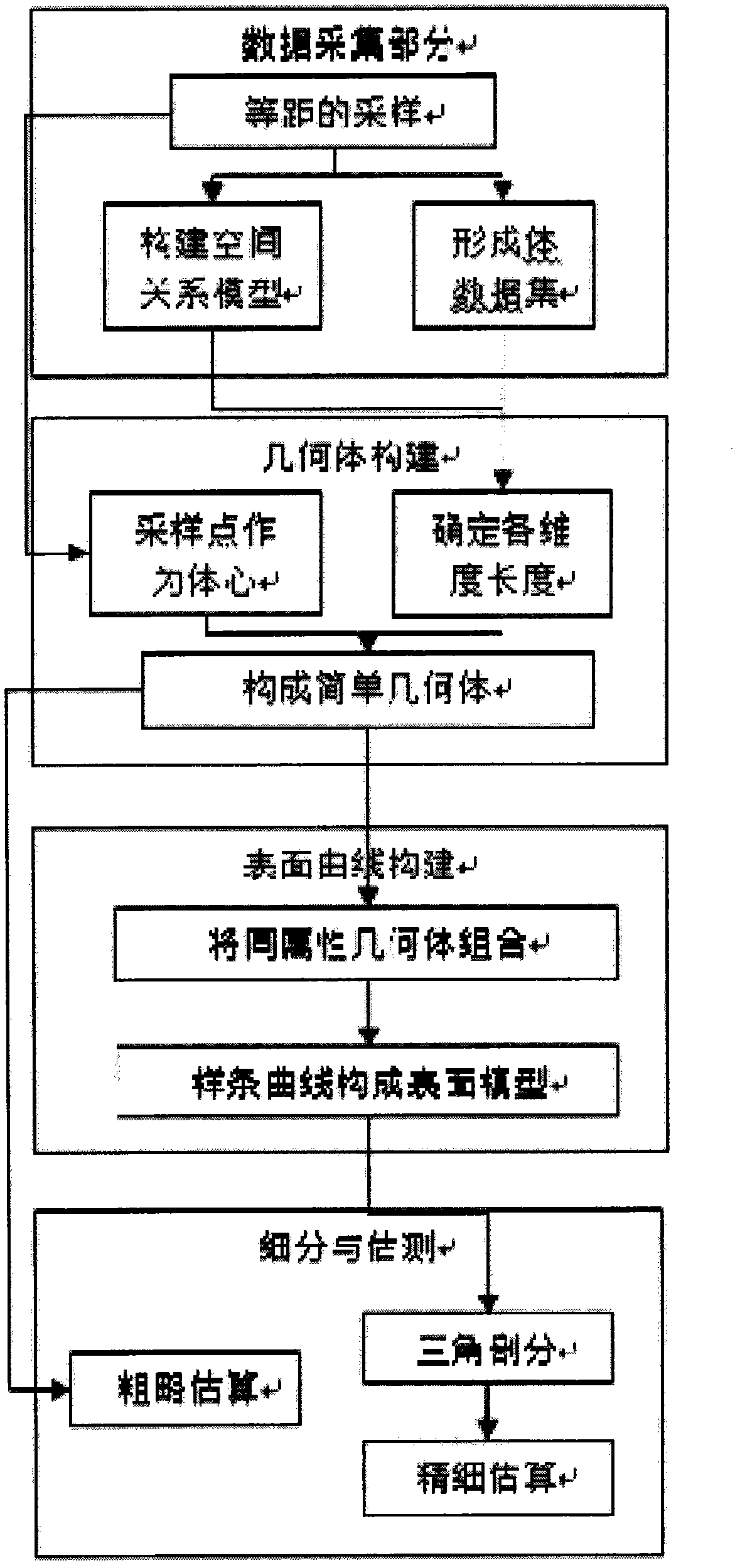

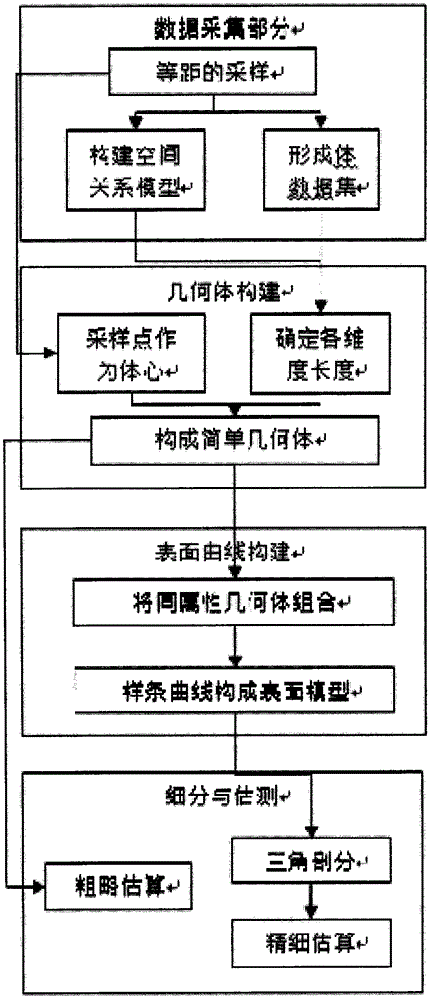

Self-traverse evolution-based three-dimensional mining stress-pressure analysis method

ActiveCN102880775ASolve and avoid water damageSolve the goaf layoutSpecial data processing applications3D modellingT stressThree-dimensional space

The invention provides a self-traverse evolution-based three-dimensional mining stress-pressure analysis method which is used for endowing an attribute class and a body structure class to a ground exploration spatial point so as to enable the ground exploration spatial point to carry out self-traverse to search for spatial difference value points of the same type of attribute class to be filled as geologic bodies of the same type. The method comprises the following steps of: (1) data acquisition; (2), geometry obtaining; (3) spline curve processing; and (4) data measurement and calculation processing. According to the self-traverse evolution-based three-dimensional mining stress-pressure analysis method, the design and management problems of water disaster prevention, gob arrangement and exploration process are solved by simulating the occurrence of new crushed zones and the change on rock mass structures caused by the engineering external force relation during mining engineering process, and a user can also endow other traverse attribute classes defined by self to established geologic bodies according to demands. The method has wide use and can be applied to fields such as geology, hydrology, mining and the like needing three-dimensional spatial analysis and resource management.

Owner:BEIJING TDTK TECH DEV

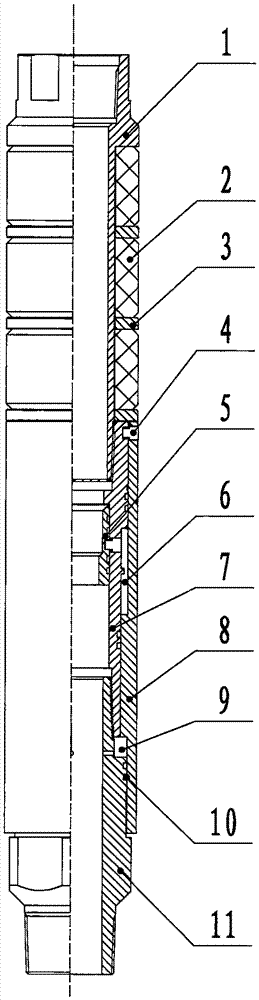

Hydrostatic pressure sealing type crack packer

The invention discloses a hydrostatic pressure sealing type crack packer that comprises an upper joint, a glue cylinder, a separating ring, a pin, a tee sliding sleeve, an air chamber, a slide block center pipe, a power sliding sleeve, a hydraulic chamber, a sealing ring and a lower clutch. The packer can be used more simply; when the pin is broken by pressing and sealing is realized, the packer can be used to maintain the sealing state without supercharging by a ground apparatus; the sealing or even hydrostatic pressure sealing is realized by differential pressure between the air chamber and the hydraulic chamber. The differential pressure sealing structure of the packer has no restriction to over-current area of a matching sand jet, and maximum flow that sandblast amount equal to drift diameter of a tubing string can be realized without sand jet throttling to provide differential pressure. In this way, the packer provides a possibility for large sandblast displacement for the sand jet, and the sandblast efficiency can be improved. The packer can be decompressed conveniently; similar to a throwing sand jet throwing a corresponding releasing ball, the pin is cut off; the air chamber isn't sealed; and the glue cylinder loses extruding effect and rebounds to recover.

Owner:盐城市畅海精密机械有限公司

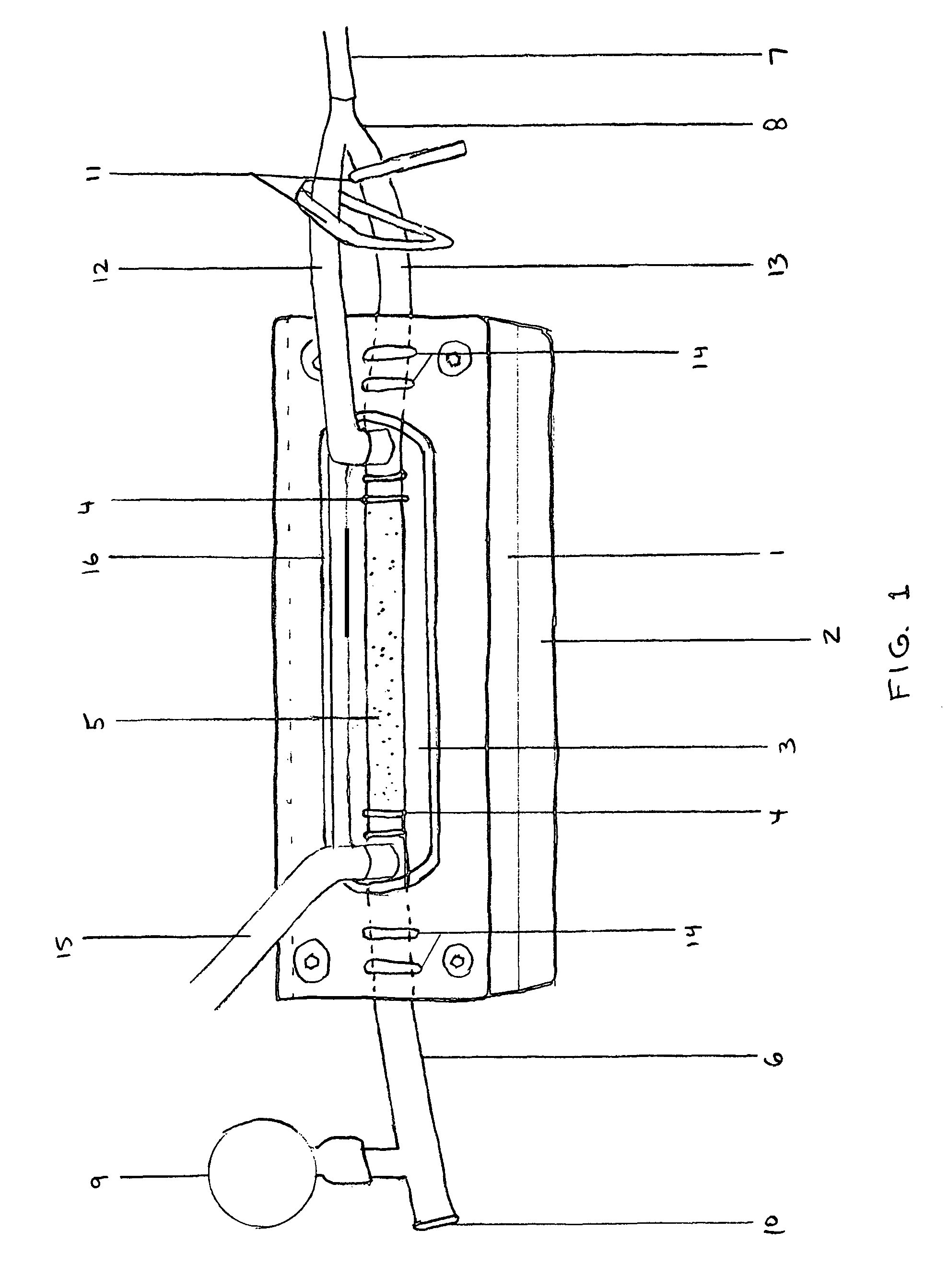

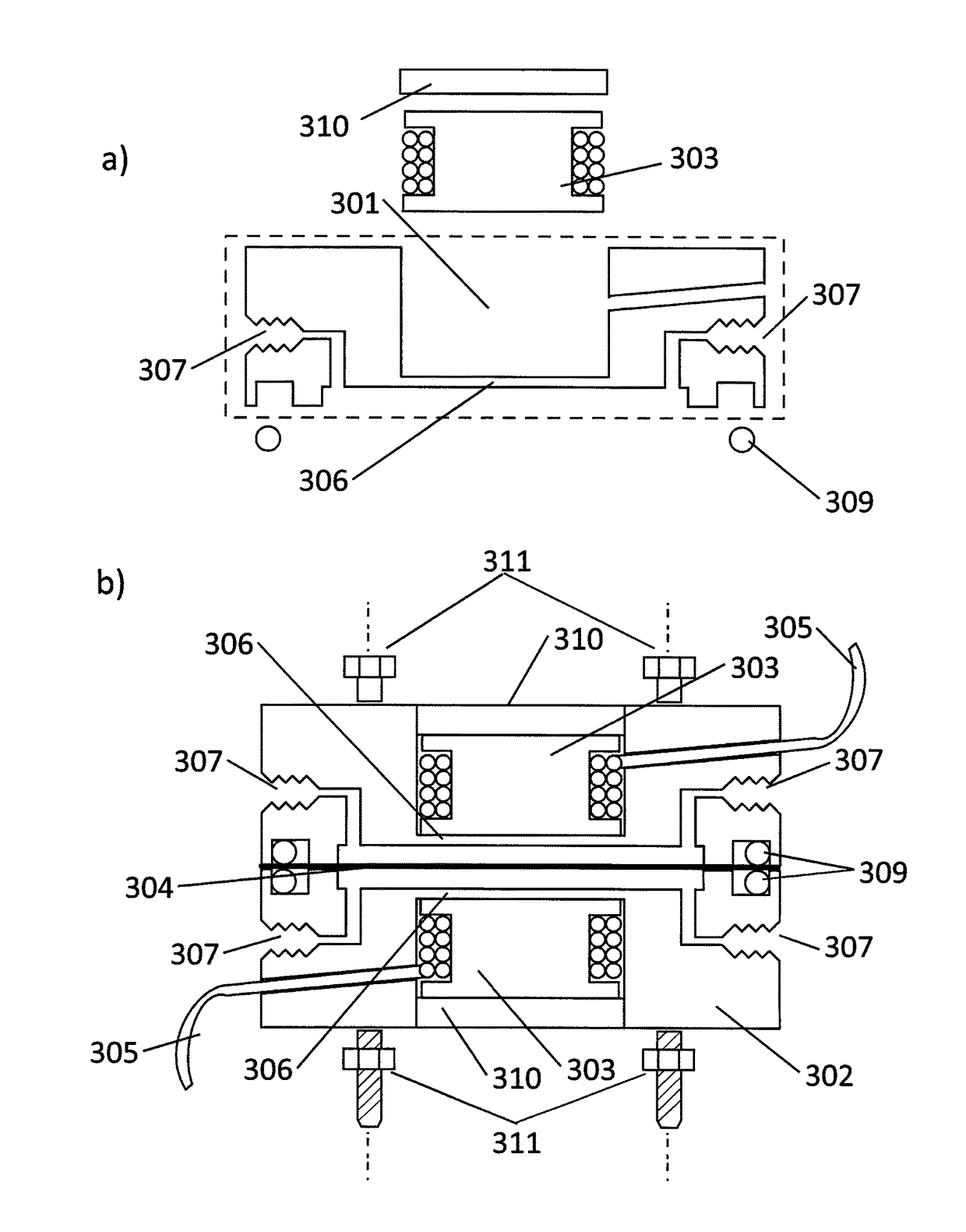

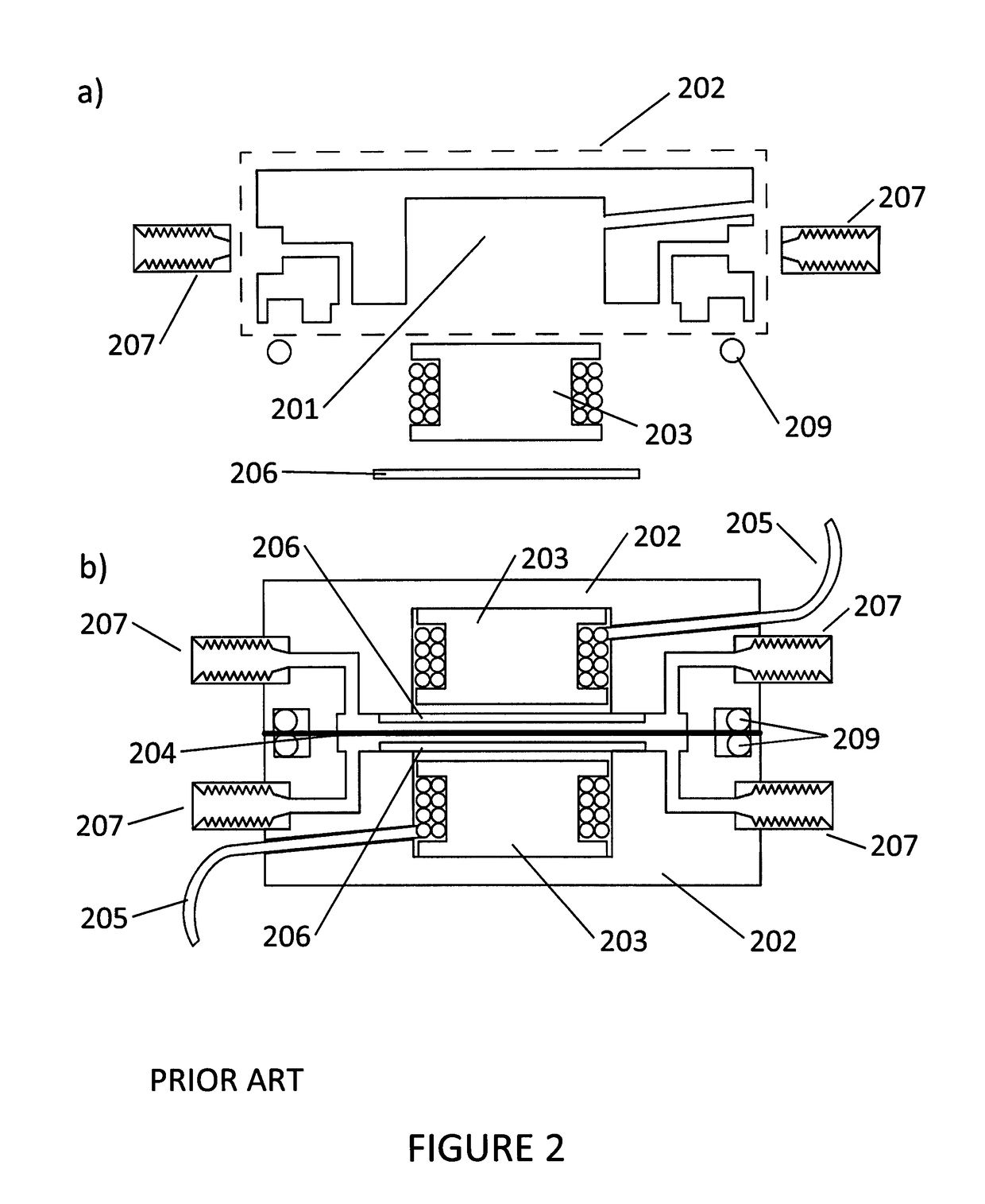

Cell sodding method and apparatus

ActiveUS8202725B2Easy to controlRapid and uniform adhesionArtificial cell constructsVertebrate cellsT stressInsertion stent

Tissue engineering methods and biochamber apparatus are provided for making tissue grafts for implantation into a patient. The methods include applying a sustained low magnitude pressure gradient transmurally across a permeable scaffold material using a media containing cells, preferably microvascular epithelial cells, to be deposited on the scaffold for the production of tissue grafts, preferably vascular grafts, to promote accelerated adhesion and maturation of cells on the scaffold material. Biochambers for preparing tubular tissue grafts are provided which contain connectors for holding a graft substrate, proximal and distal tubing for connection to an optional perfusion system, and structure for switching between transmural flow of a cell suspension across the graft substrate and translumenal flow through the lumen of the graft.

Owner:KOLIGO THERAPEUTICS INC

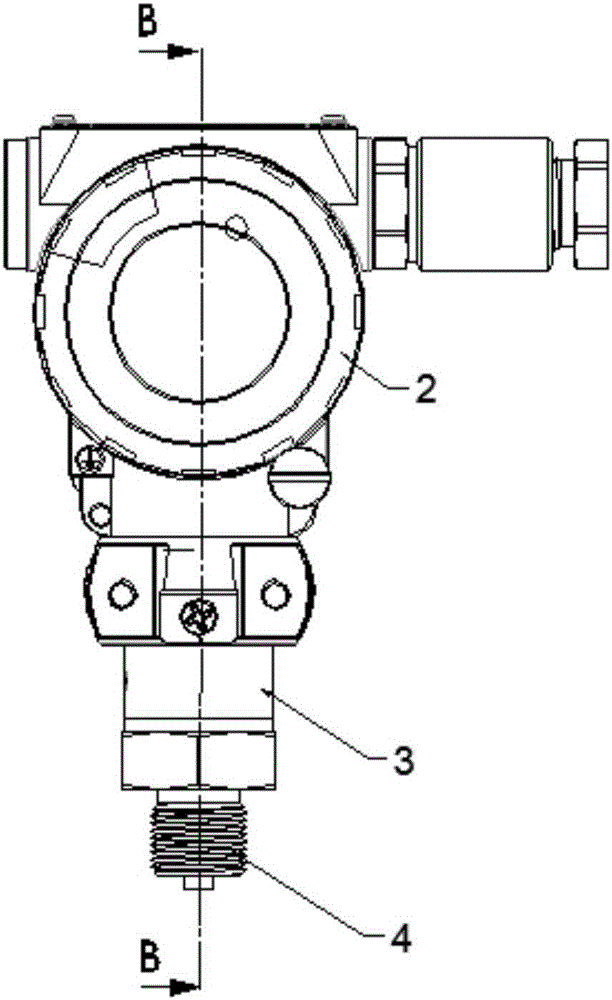

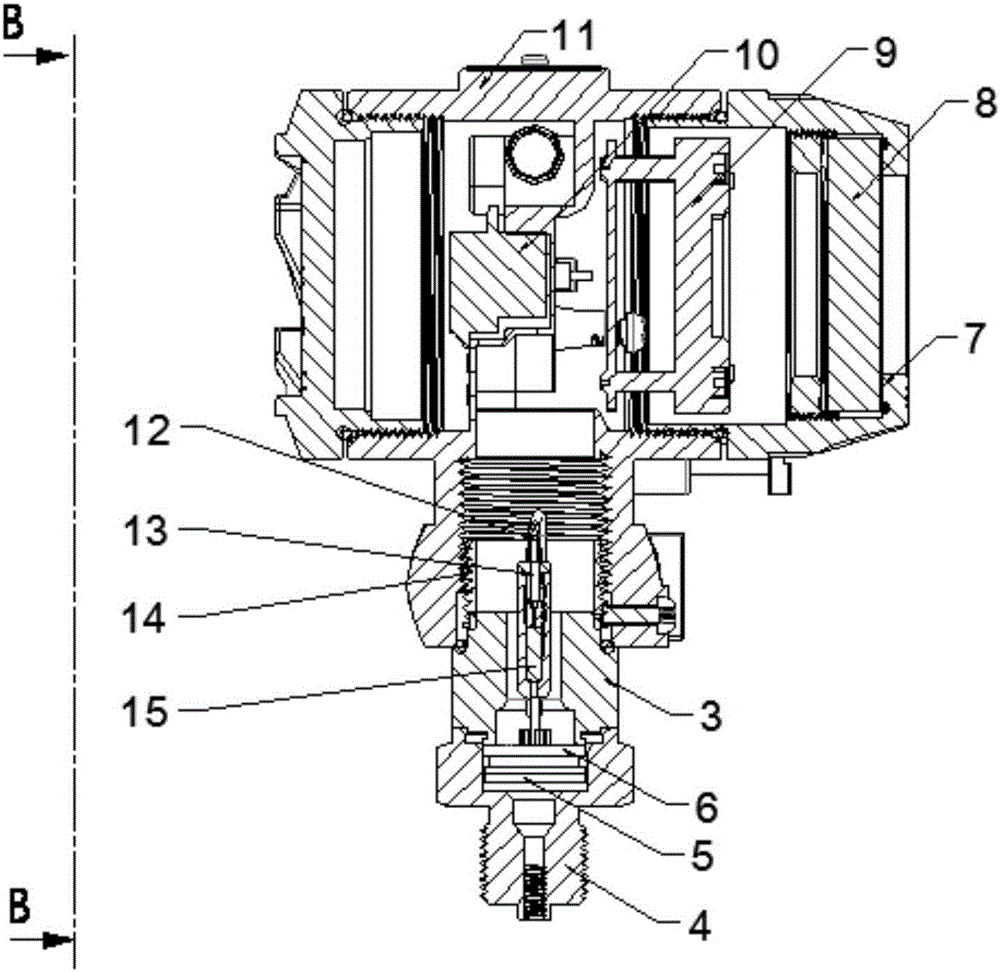

Corrosion resistant pressure transducer

InactiveUS9638546B2Improve concentrationHigh measurement sensitivityFluid pressure measurement using inductance variationConverting sensor output electrically/magneticallyWetted areaEngineering

A pressure transducer is disclosed wherein no wetted areas have been welded. A cavity is milled into the back of each of the blocks of a material which will make up the body of the transducer. Pickup coils are placed into these cavities and are held in place generally with epoxy cement. With the coils mounted within the sensor body, the surface which will be exposed to the sample or reference fluids is comprised of a single, solid material with no welding joints. Further, as the sensor block half is made of a single, solid material, fluid fitting connections may be machined directly into the body. The pickup coil placed within the improved sensor body may be wound on an open frame of nickel superalloy (NiSA). Another embodiment involves coating or encapsulating the sensing membrane within a soft, non-magnetic material protecting it from corrosion.

Owner:WYATT TECH

Stress transmitter

InactiveCN105910747AEasy to viewEasy to useFluid pressure measurement using elastically-deformable gaugesT stressEeg data

The invention discloses a stress transmitter which comprises a detection tube, a control device, a position limiting device, and a spring sheet contact type voltage sensor. The detection tube is horizontally arranged with two openings at two ends. The position limiting device is fixedly clamped onto the external part of the detection tube. The position limiting device, through a bearing, is connected in a rotation manner at one end of the bearing shaft. The other end of the bearing shaft is fixedly connected to the control device which comprises a control module, a power supply module, a display screen, and an adjusting button. The display screen, the adjusting button and the control module are connected through conductive wires. The spring sheet contact type voltage sensor is fixedly arranged in the detection tube and is connected to the control device through conductive wires. The voltage signals detected by the spring sheet contact type voltage sensor are transmitted to the control module through conductive wires, and are displayed on the display screen for people to conveniently check. With the adjusting button, currently available detection data can be stored; and previous detection concerned data that are stored can also be conveniently accessed. With a bearing, the entire control device can be rotated so as to facilitate the process of data check by a user according to their specific requirements.

Owner:JIANGSU HUAXIA INSTR

Anti-fatigue preparation

InactiveCN107582752ARelieve stressImprove learning effectAntinoxious agentsPlant ingredientsT stressGrape seed

The invention belongs to the technical field of health products, and discloses an anti-fatigue preparation, which is used for solving the problems of students such as the fatigue and absent mindedness. The anti-fatigue preparation is prepared from the following raw materials in parts by weight: 5 to 12 parts of largehead atractylodes rhizome, 5 to 20 parts of radix paeoniae alba, 3 to 9 parts of rhizoma chuanxiong, 5 to 10 parts of honey-fried liquorice root, 2 to 4 parts of apricot leaf extract, 3 to 4 parts of radix astragali, 6 to 8 parts of grape seeds, 4 to 6 parts of red dates, and 1 to2 parts of poria cocos. By virtue of scientific concerted application, the anti-fatigue preparation has a good effect on adjusting the body fatigue, power lack and the like, can relieve the pressure of the students and can improve the learning capability of the students.

Owner:华蓥市杜家坪小学

Compressive resistant pigtail conduit

The invention discloses a compressive resistant pigtail conduit. The compressive resistant pigtail conduit comprises a conduit tube body; the internal wall of the conduit tube body is provided with a spring-shaped supporting ring; the spring-shaped supporting ring is made of rigid materials; the conduit tube body is made of shape memory plastic materials. The spring-shaped supporting ring can provide certain supporting force for the tube wall of the conduit tube body, then the conduit tube body can keep a communication state under lateral press, the conduit is effectively prevented from being squeezed to be narrowed down and blocked, and the safety of the conduit is improved.

Owner:PLS MINIMALLY INVASIVE INTERVENTIONAL MEDICAL

Tensile force stroke compensating device

ActiveCN108730263ACompact structureReasonable structureMaterial strength using tensile/compressive forcesFluid-pressure actuatorsT stressPressure sensor

A tensile force stroke compensating device comprises an anti-tensile frame, wherein the middle part passes through a tensile screw; the head part of the tensile screw is connected with a puller through thread; the puller is fixed with a locking nut and a first pin shaft; the end face of the anti-tensile frame is provided with supporting flanges through first fixing bolts, flange supports are arranged at the interval between the supporting flanges, the flange supports are arranged outside the tensile screw, a plurality of screws are connected between the supporting flanges and the flange supports, and the screws are fixed with nuts; one side of the flange supports abut against a pressure sensor, and the other side of the flange supports are used as a stop block of a thread stop ring, the thread stop ring sleeves outside the tensile screw, a handle screw hole is arranged on the thread stop ring, a manual handle is arranged in the handle screw hole, an end stop ring is also arranged on the outer ring of the tensile screw rod, a rotating handle is arranged on the end stop ring; the device also comprises a running mechanism, wherein trolley supporting legs are arranged on the running mechanism; and a hydraulic telescopic mechanism is arranged between the trolley supporting legs and the anti-tensile frame. The working is reliable.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

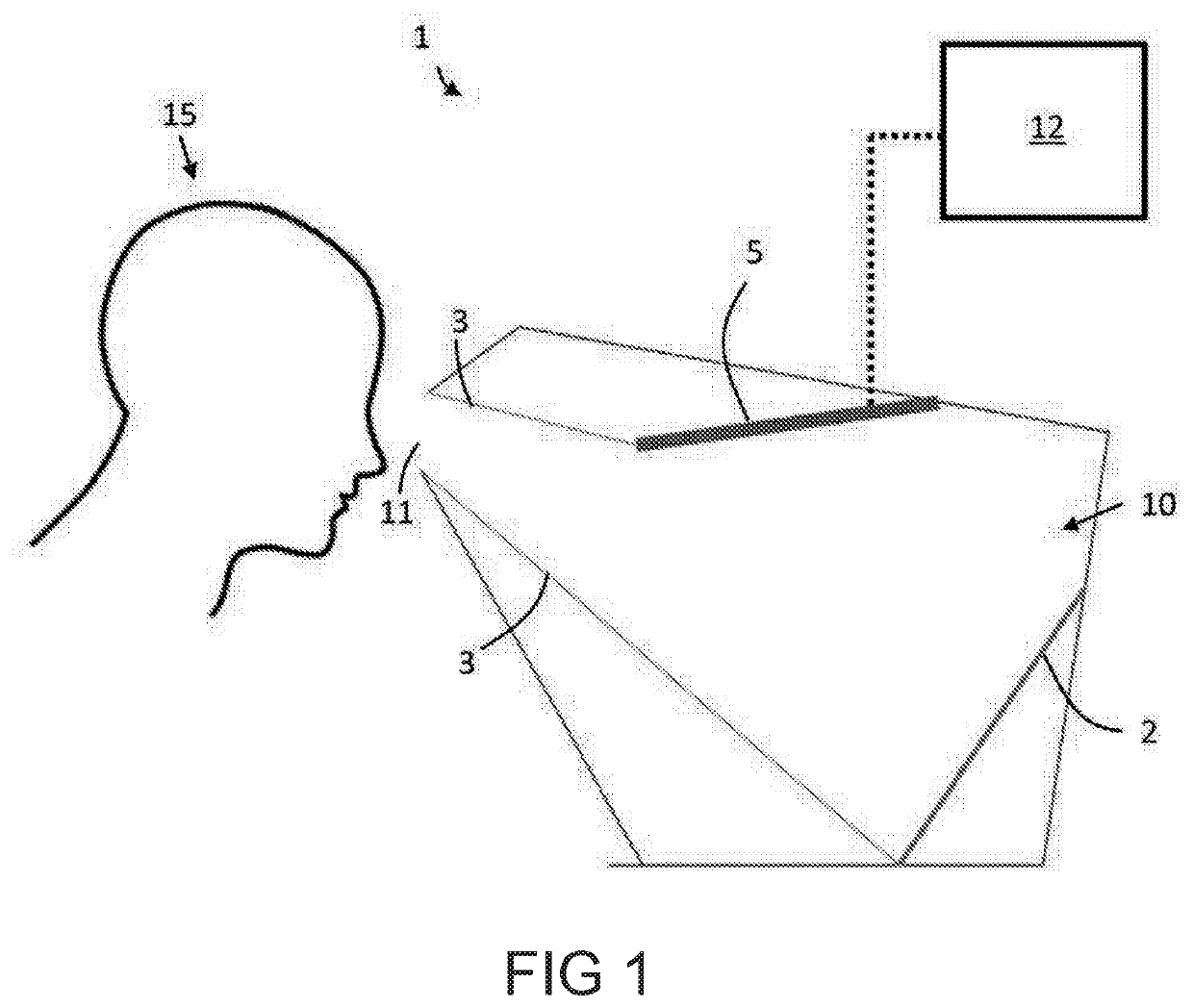

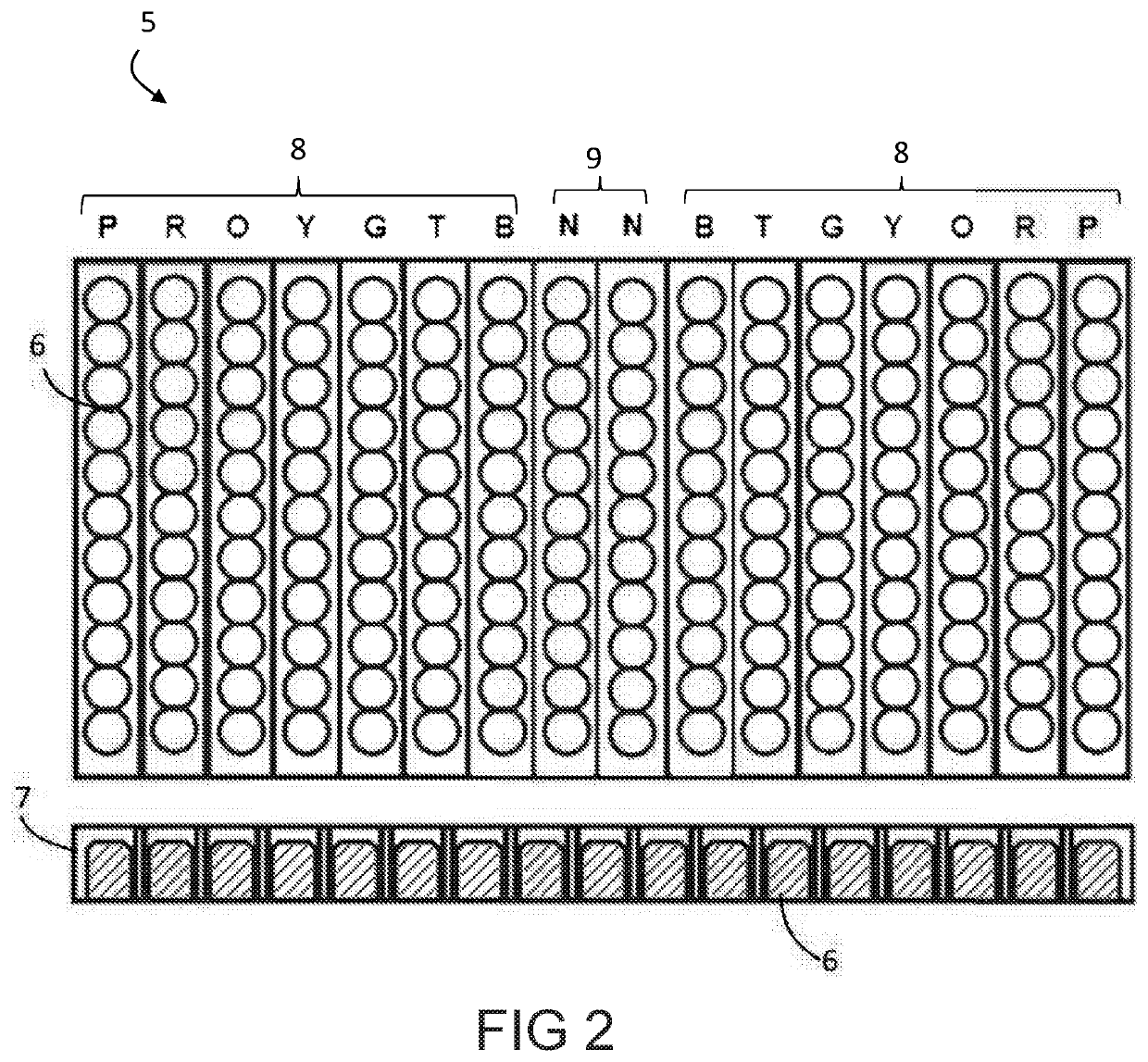

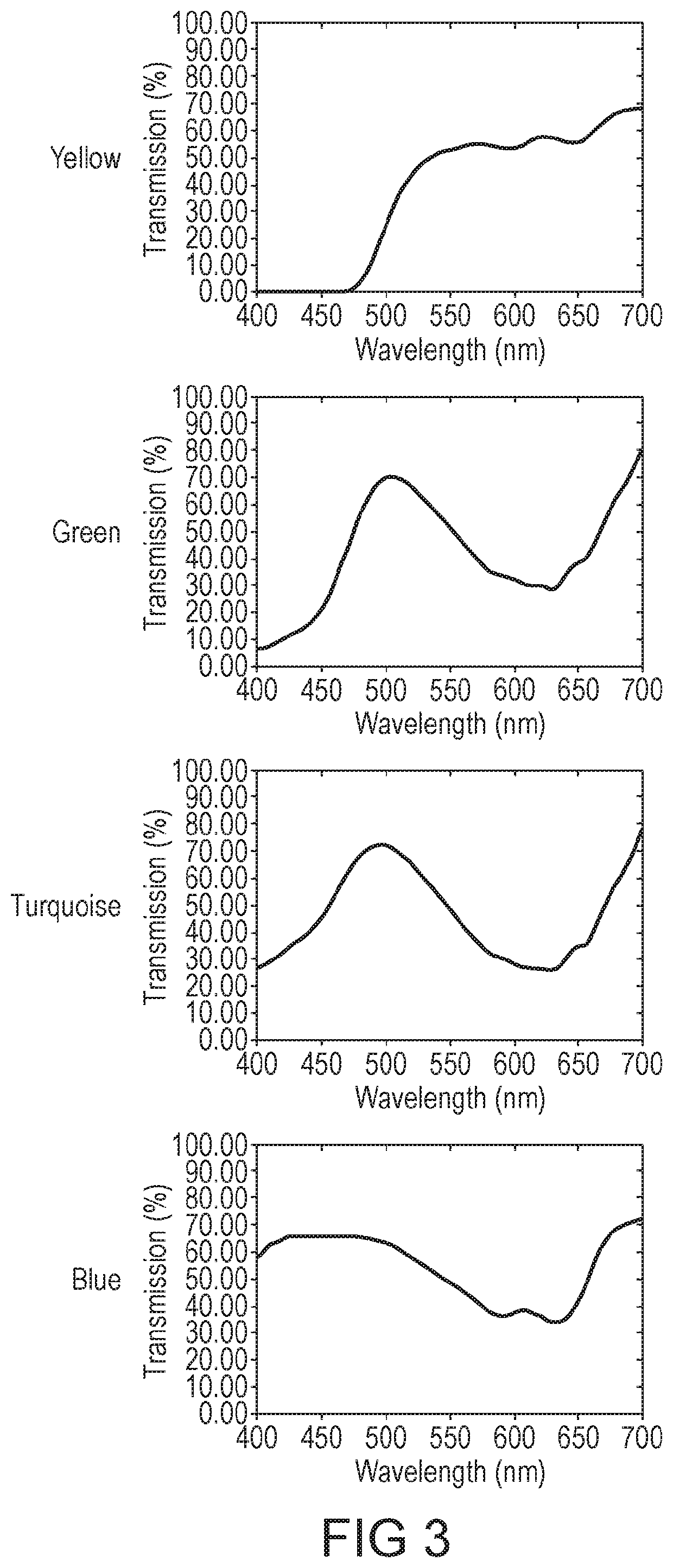

Visual stress assessment device

ActiveUS10499805B2Improve equipment reliabilityIncreases the ease and the potential accuracy with which the device can be usedEye diagnosticsT stressHue

A visual stress assessment device is provided comprising a plurality of coloured light sources, each adapted to produce light of a predetermined hue, and a white light source. The white light source and the coloured light sources each comprise a plurality of light emitting diodes. A chamber is provided having an interior comprising a viewable region configured to provide a sample for inducing visual stress, wherein said viewable region is arranged to be illuminated by the white light source and the coloured light sources. A controller is configured to selectively operate the white light source and coloured light sources such that only one or both of a first of the coloured light sources and a second of the coloured light sources are operated simultaneously with the white light source, whereby their respective emitted light is observable in the viewable region by a user at a predetermined hue and saturation.

Owner:UNIV OF ESSEX ENTERPRISES

Three-dimensional mining stress analysis method based on self-traversal evolution

ActiveCN102880775BWide range of usesSpecial data processing applications3D modellingPresent methodMeasurement point

The present invention provides a three-dimensional mining stress analysis based on self-traversal evolution by assigning attribute classes and body structure classes to geodesic exploration space points, allowing them to self-traverse to find spatial difference points of the same attribute class to fill in similar geological bodies The method includes the following steps: (1) data collection; (2) geometry construction; (3) spline curve processing; (4) data calculation processing. The three-dimensional mining stress analysis method based on self-traversal evolution of the present invention can make good use of the engineering external force relationship in the mining engineering process to simulate the generation of new broken zones and changes in coal and rock mass structures to solve the problem of avoiding water damage and goafs. For the design management of layout and mining technology, users can also assign other traversal attribute classes defined by themselves to the established geological bodies according to their needs. The method has a wide range of applications and can be applied to fields requiring three-dimensional space analysis and resource management, such as geology, hydrology, and mineral resources.

Owner:BEIJING TDTK TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com