Tensile force stroke compensating device

A stroke compensation and tension technology, which is applied in the field of tension stroke compensation devices, can solve the problems that the cylinder shrinkage sling does not reach the maximum bearing capacity and the deformation is large, and achieves the effects of compact structure, convenient operation and good work flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

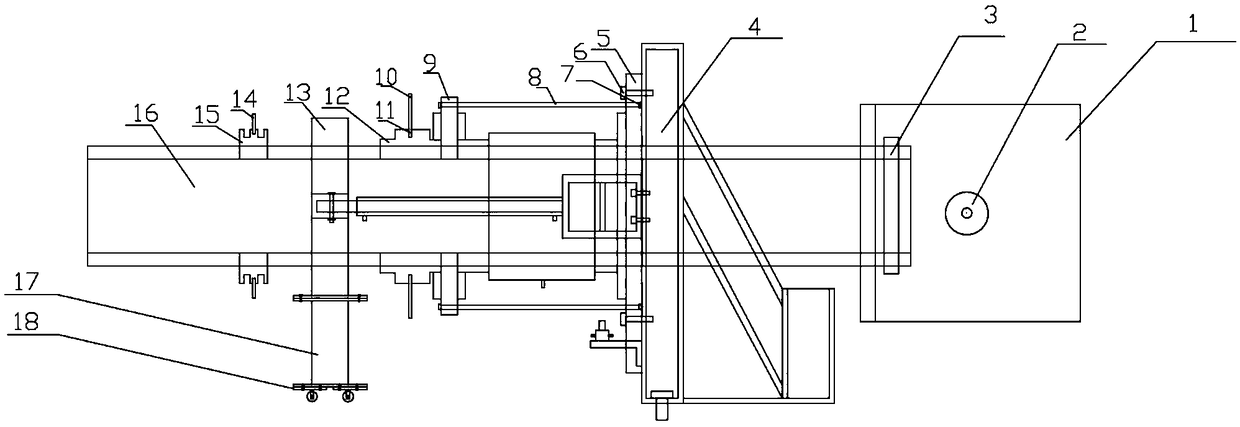

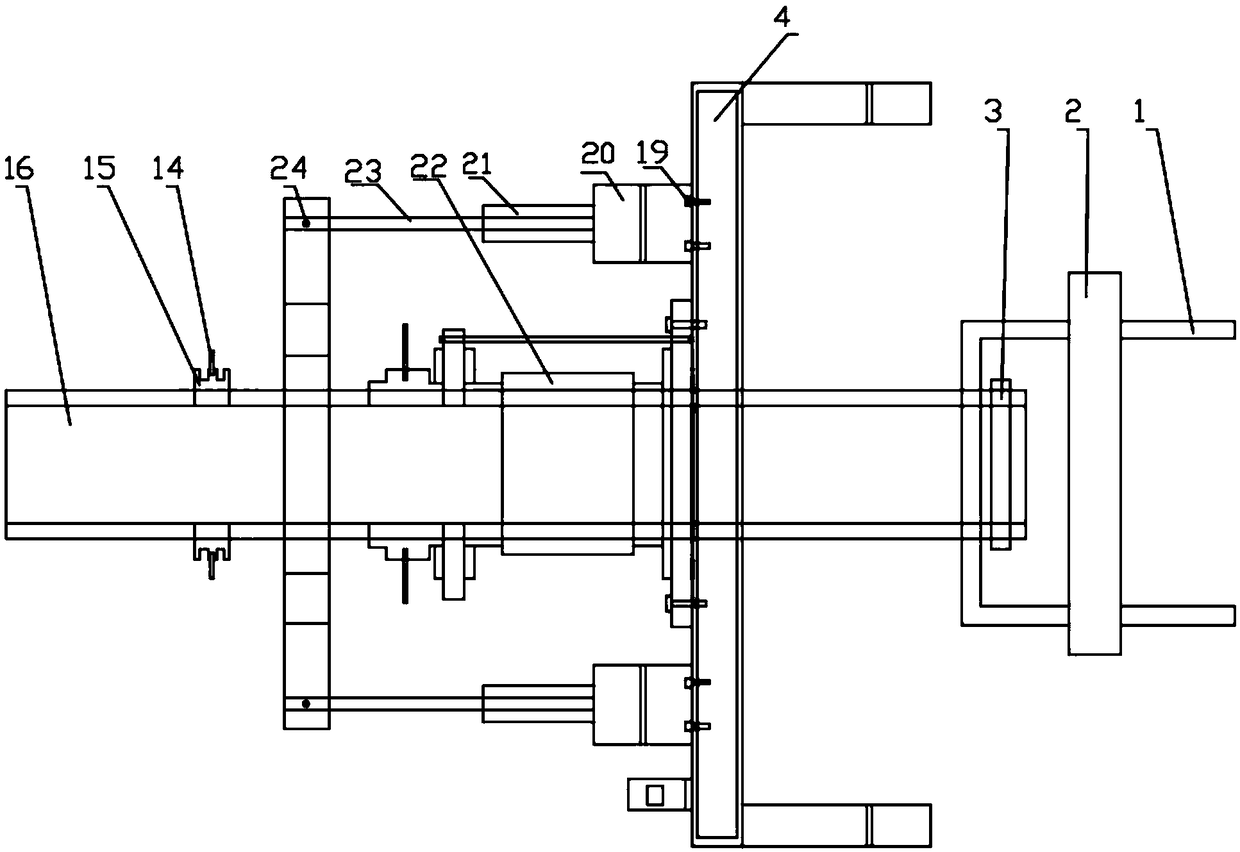

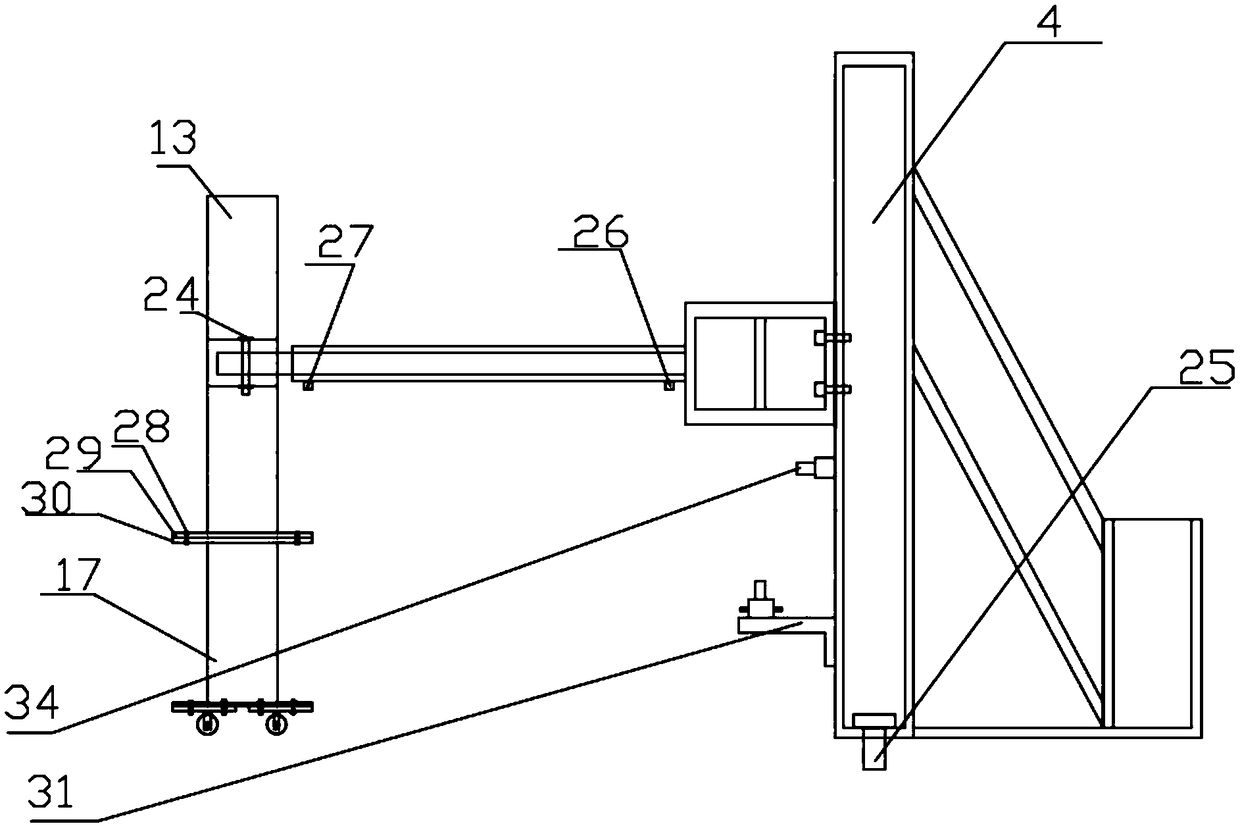

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0032] Such as Figure 1-Figure 5 As shown, the tension stroke compensation device of this embodiment includes a tension frame 4, the middle part of the tension frame 4 passes through the tension screw 16, the head of the tension screw 16 is threaded to the slider 1, and the slider 1 is passed through the lock nut 3 and the first pin shaft 2 are fixed; the end face of the tensile frame 4 is equipped with a support flange 5 through the first fixing bolt 6, and a flange support 9 is arranged at an interval from the support flange 5, and the flange support 9 is installed on the tension screw 16 There are multiple screws 8 connected between the support flange 5 and the flange support 9, and the screws 8 are fixed by the nut 7; one side of the flange support 9 is close to the pressure sensor 22, and the other side is used as a thread retaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com