Hydrostatic pressure sealing type crack packer

A hydrostatic pressure and packer technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of high operation requirements, troublesome decompression, easy to set in advance, etc., to improve sandblasting. Efficient, easy to decompress, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

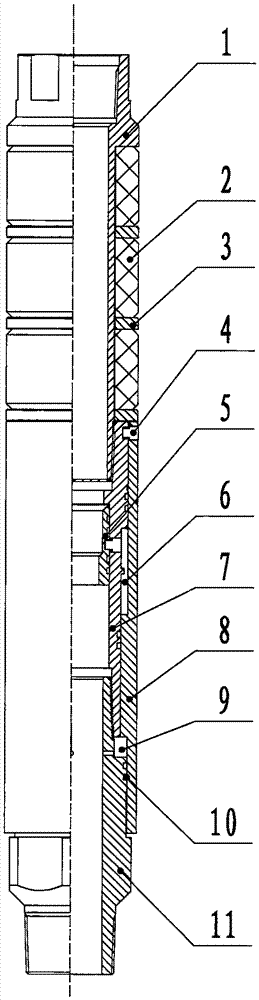

[0012] figure 1 Among them, the outer wall of the upper joint 1 is provided with three sets of rubber tubes 2 and spacer rings 3, and the lower part is connected with the central tube 7 of the slider. , the ball seat sliding sleeve 5 is fixedly connected with the slider central tube 7 through the pin 4, and two groups of sealing rings 10 are respectively arranged in the upper and lower sides of the ball seat sliding sleeve groove of the pin 4, and a power slider is provided outside the slider central tube 7. Sleeve 8, the upper end of the power sliding sleeve 8 is in contact with the spacer ring 3, and the lower end is placed on the boss of the lower joint 11. The power sliding sleeve 8 and the slider center tube 7 are fixedly connected by the pin 4, and the slider center tube 7 is provided with The lower joint 11, the lower joint 11 is provided with a water seepage slot, the hydraulic chamber 9 is surrounded by the lower joint 11, the slider center tube 7 and the power slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com