Device for testing loading of component compositely stressed by pressure, bending moment and shearing force

A loading test device and composite force-bearing component technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, etc., can Solve the problems of high requirements for reaction frame, unfavorable in-depth research and engineering application of bending and shearing components, complex structure, etc., and achieve the effect of low requirements, high recycling value and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

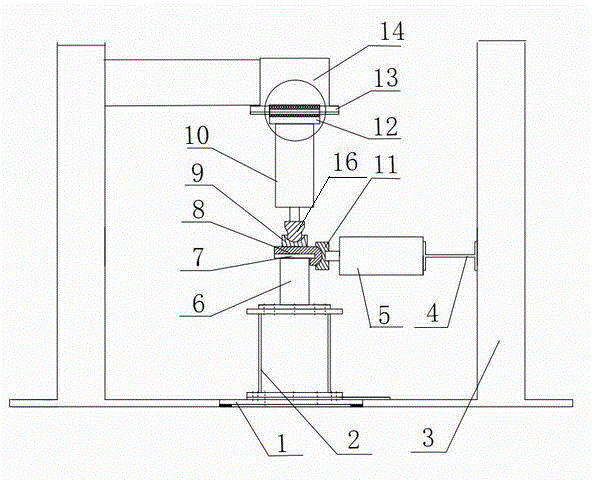

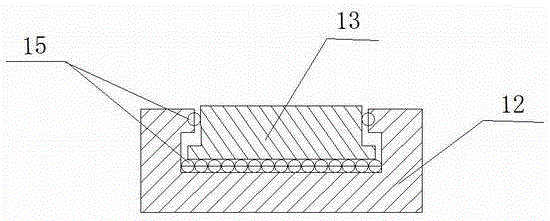

[0008] A loading test device for a compression-bending-shear composite stressed member, comprising a bottom fixed base 1, a base box 2, a reaction force frame 3, a horizontal jack 5, a vertical jack 10, and a top beam 14, and the bottom fixed base 1 is fixed on In the center of the bottom plate of the reaction force 3 frame, the base box 2 is installed on the bottom fixed base 1. It is characterized in that the bottom end of the test piece 6 is fixed on the base box 2 by bolts, and the horizontal jack 5 is installed on the I-shaped steel by bolts. 4, the I-shaped steel 4 is fixed on the side of the reaction force frame 3, the vertical jack 10 is fixed on the support frame 12, and the support frame 12 is sleeved in the slide rail 13 on the top beam 14 of the reaction force frame 3, and the support frame 12 and Balls 15 are installed between the slide rails 13; a horizontal loading arc hinge 11 is fixed on the top shaft of the horizontal jack 5, and a concave arc groove is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com