Steel crane beam structure integrity evaluation method considering constraint effect

A technology of structural integrity and constraint effect, which is applied in the structural integrity assessment of steel crane girders, and the field of structural integrity assessment of steel crane girders considering constraint effects, can solve the problem of consuming structural safety reserves, so as to ensure safe production and improve safety reserve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

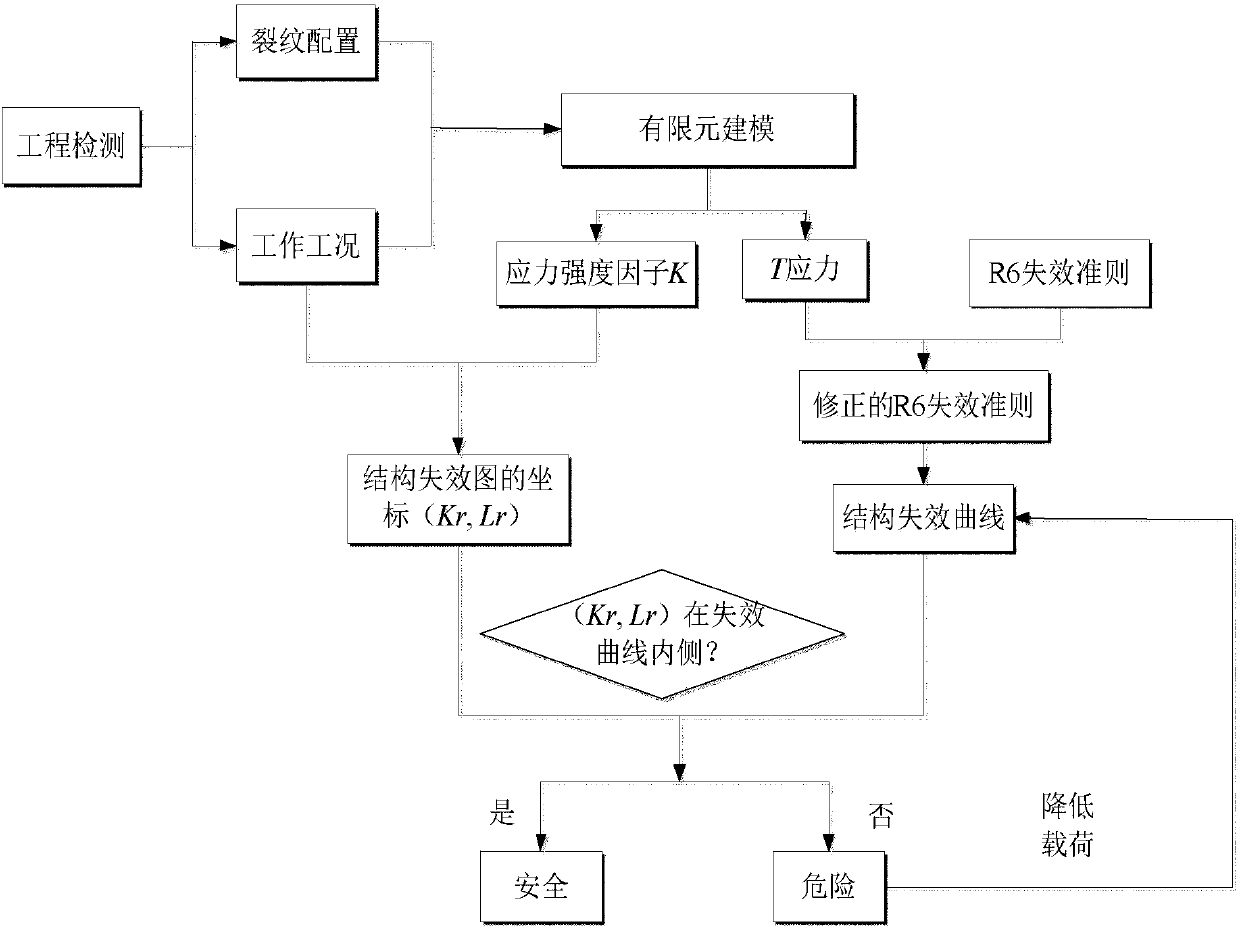

Method used

Image

Examples

Embodiment

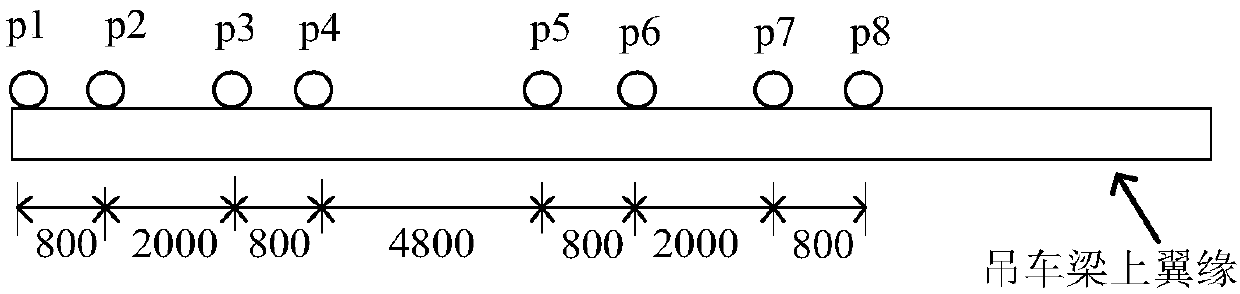

[0037] Taking the integrity assessment of the steel crane beam of a certain domestic industrial plant as an example, the evaluation method of the present invention is described in detail; the distribution of the crane wheels in the plant is as follows: figure 2 .

[0038] Step 1, detect the cracks that appear near the weld seam between the upper flange of the steel crane girder in the industrial plant and the web, fit the actual cracks with surface elliptical cracks, and obtain the geometric parameters of the cracks in the steel crane girder, including the actual position and size of the crack, (ie The major semi-axis length 2c and the minor semi-axis length 2a) of the crack, the track eccentricity e 0 , and the crane wheel pressure P under the actual working load y0 ;

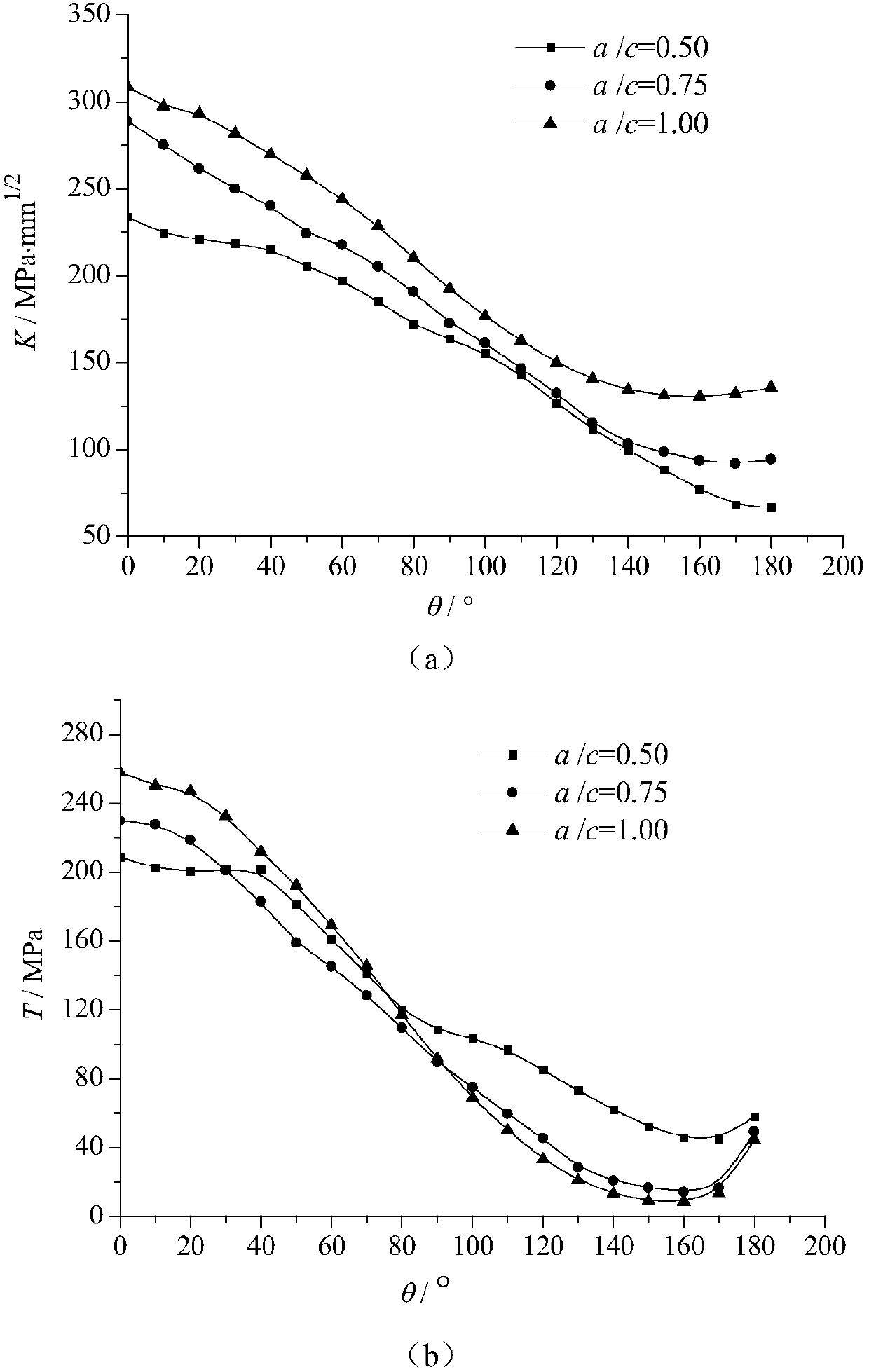

[0039] Step 2, establishing a three-dimensional finite element model of a steel crane beam containing cracks;

[0040] According to the detection data in step 1, when using the finite element software ABAQ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com