Construction process for triangular area of open-web rigid frame bridge

A technology of construction technology and triangular area, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high mutual influence of upper and lower chord loads, high construction costs, and high safety risks, so as to avoid the safety of construction operations. risk, optimize the stress of the system, and improve the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

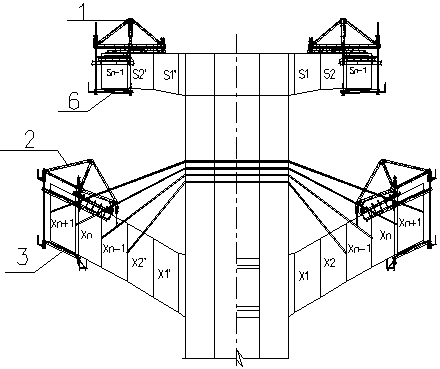

[0056] This embodiment provides a construction technique for the triangular area of an empty-bellied rigid frame bridge. Centering on the No. 0 beam section, hanging baskets are used to hang and cast the rest of the beam sections symmetrically to both sides. Each beam section includes upper chord beam section 19 and lower chord section The beam section 20, during the construction process, the lower string beam section 20 was constructed earlier than the upper string beam section 19 by two beam sections;

[0057] In the construction process of No. 1~n beam sections, support columns are not set for cantilever casting; when construction of No. The support is poured, and the buckle cables are tensioned after the 2~m beam sections of the lower chord are poured. Among them, n is the number of the beam section where the column is installed for the first time, and m is the number of the intersection beam section in the triangular area.

[0058] In the present invention, support colu...

Embodiment 2

[0060] On the basis of Embodiment 1, this embodiment provides a construction technique for the triangular area of a hollow rigid frame bridge, in which the cantilevered down-curved steel tendons 15 are laid on the web surface of the upper chord 1-n beam sections. Such as Figure 8 shown.

[0061] In the web section of the beam section No. 1~n (n is the number of the beam section where the support column 4 is installed for the first time) on the upper chord, the cantilevered down-curved steel tendons 15 are arranged, and the vertical beams 15 are provided in the cantilevered construction of the upper chord segment through the down-bent steel beams 15. The section with downbending steel beams 15 can realize balanced cantilever construction by itself, thereby optimizing the number of support columns, avoiding the safety risk of the construction operation of the support columns of the (n-1) sections, and improving safety Guarantee, save the construction period, and optimize the...

Embodiment 3

[0063] On the basis of Example 1, this example provides a construction technique for the triangular area of a hollow rigid frame bridge, and the construction process of beam sections 1 to n is as follows:

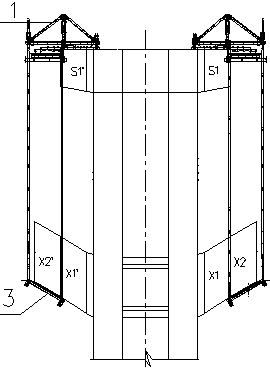

[0064] Step 1) The upper chord of the triangular area is equipped with the upper chord hanging basket 1, and the lower chord is equipped with the lower chord hanging basket 2. After assembling the upper chord hanging basket 1 on the No. The bottom basket 3 pours the No. 1 beam section of the lower chord, and then the hanging basket 1 of the upper chord travels to the No. 1 beam section of the upper chord, and then pours the No. 2 beam section of the lower chord; figure 1 shown;

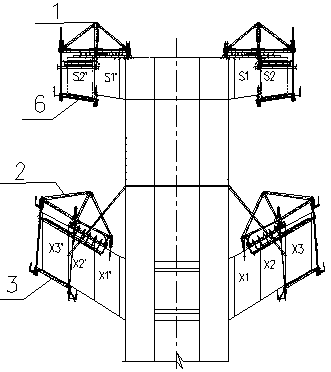

[0065] Step 2) Carry out the buckling and threading of the No. 2 beam section of the lower string, and then stretch the buckle cable of the No. 2 beam segment of the lower string, retain the bottom basket 3 of the hanging basket of the lower string, and pour the No. 3 beam section of the lower st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com