Patents

Literature

58results about How to "Avoid complicated procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for realizing selectivity metallization on glass surface by femto-second laser

The present invention discloses a method using the flying-second laser to realize the selective metal on the glass surface, which comprises the following steps: (1) a silver nitrate film is prepared on the glass base; (2) the method uses the flying-second laser focalized on the silver nitrate film to draw the design; (3) the method wipes off the silver nitrate film not being radiated; (4) the method adds the chemical copperizing liquid to make chemical copperizing. Compared with the traditional metal method, the present invention is with much simpler design, much faster preparation process and more controllable technical and so on. The method is with much greater application potential and practical value in the multi-functional chip experiment and the integration of the micro-component, in particular to the effective integration of the electricityl function and calorifics function.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Femtosecond laser direct writing preparation method of two-dimensional submicron butterfly-shaped metal microstructure

ActiveCN106735925AEffective control of shape characteristic parametersThe technical method is simpleLaser beam welding apparatusDelayed timeDirect writing

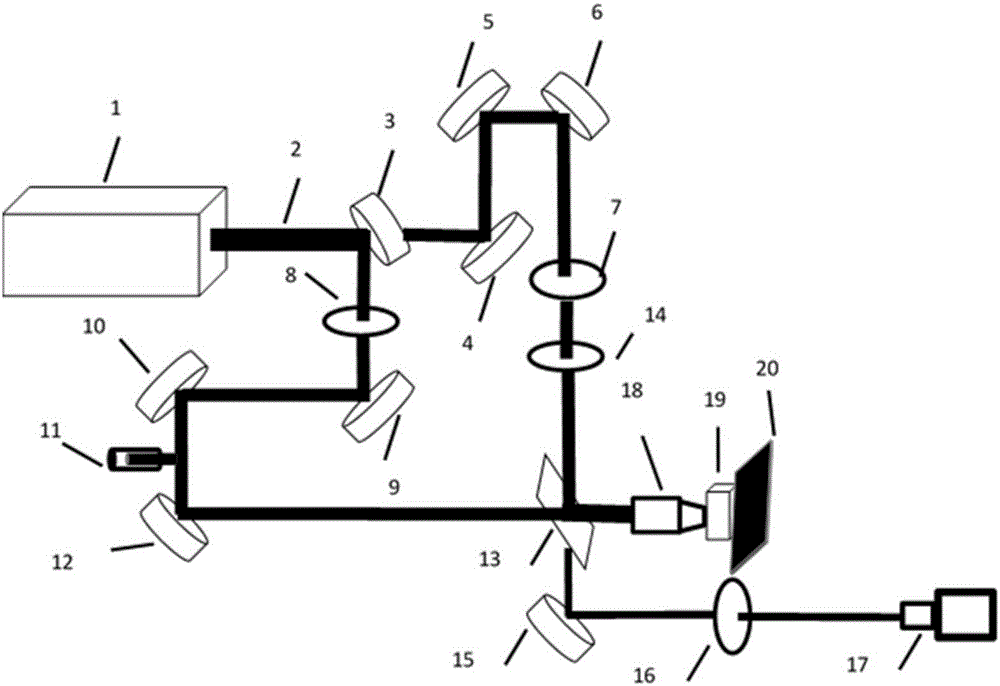

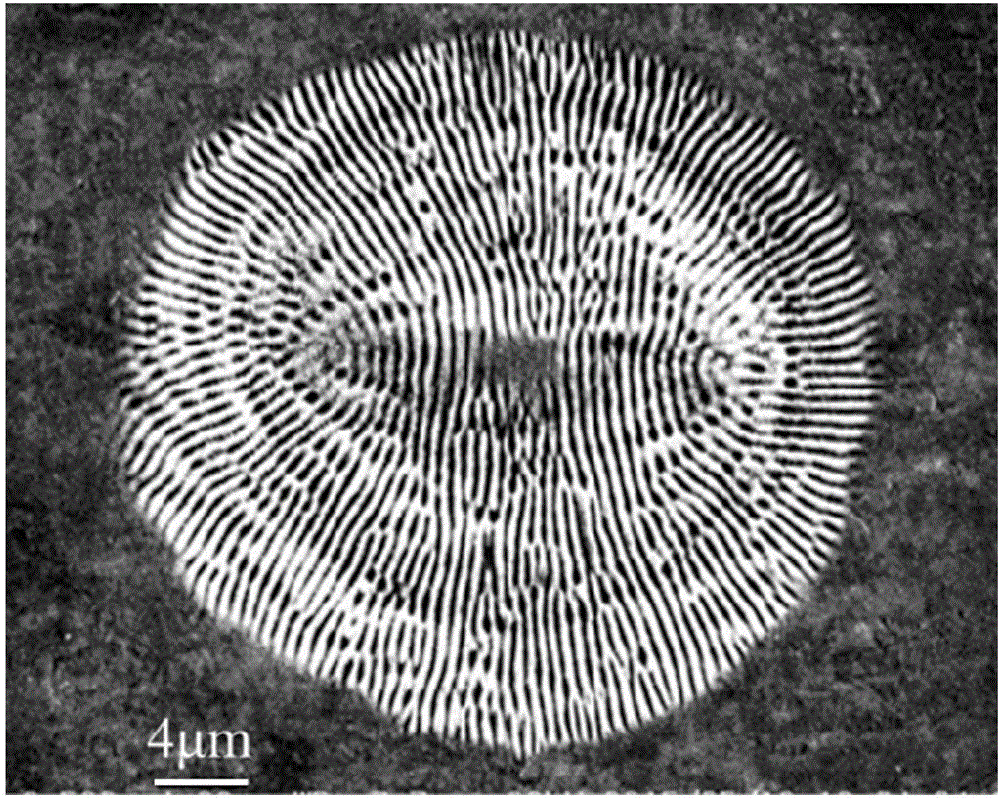

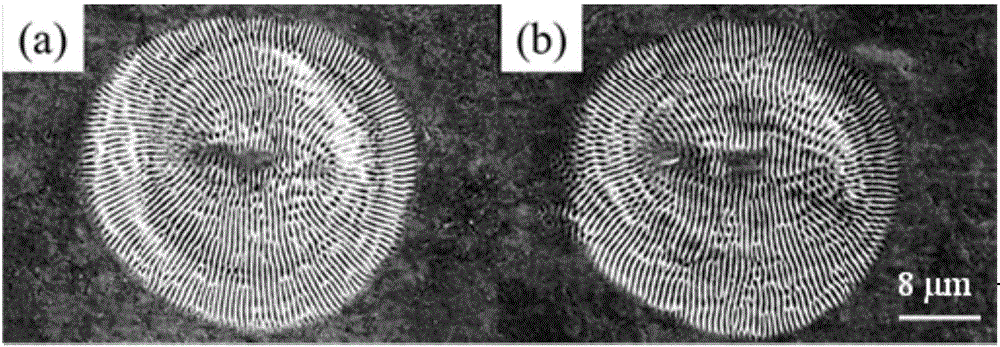

The invention discloses a femtosecond laser direct writing preparation method of a two-dimensional submicron butterfly-shaped metal microstructure. The technical scheme comprises the following steps: (1) a metal target sample material is polished and mounted; (2) linear polarization and angular polarization double-pulse femtosecond laser capable of changing the delay time is obtained; (3) the point focusing of the double-pulse femtosecond laser is performed; (4) the position of the metal target sample material is adjusted; (5) the focal position of an objective lens is determined; (6) the surface of the metal target sample material is adjusted; and (7) the two-dimensional submicron butterfly-shaped metal microstructure is prepared. The method forms two linear polarization and angular polarization double-pulse femtosecond laser for homochromatic collinear transmission and capable of changing the delay time through skillfully using a light splitting method of a micronanometer machining platform, and adopts the objective lens point focusing mode to conveniently and quickly perform direct writing on the metal surface to prepare the two-dimensional submicron butterfly-shaped metal microstructure with bent stripe direction.

Owner:SHANGQIU NORMAL UNIVERSITY

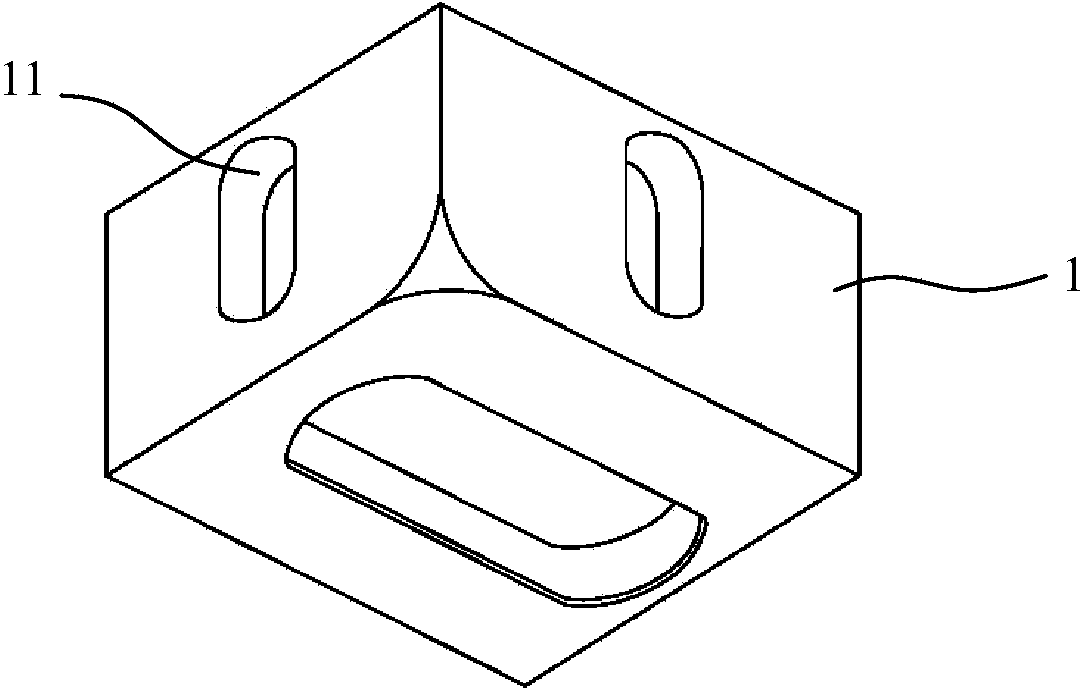

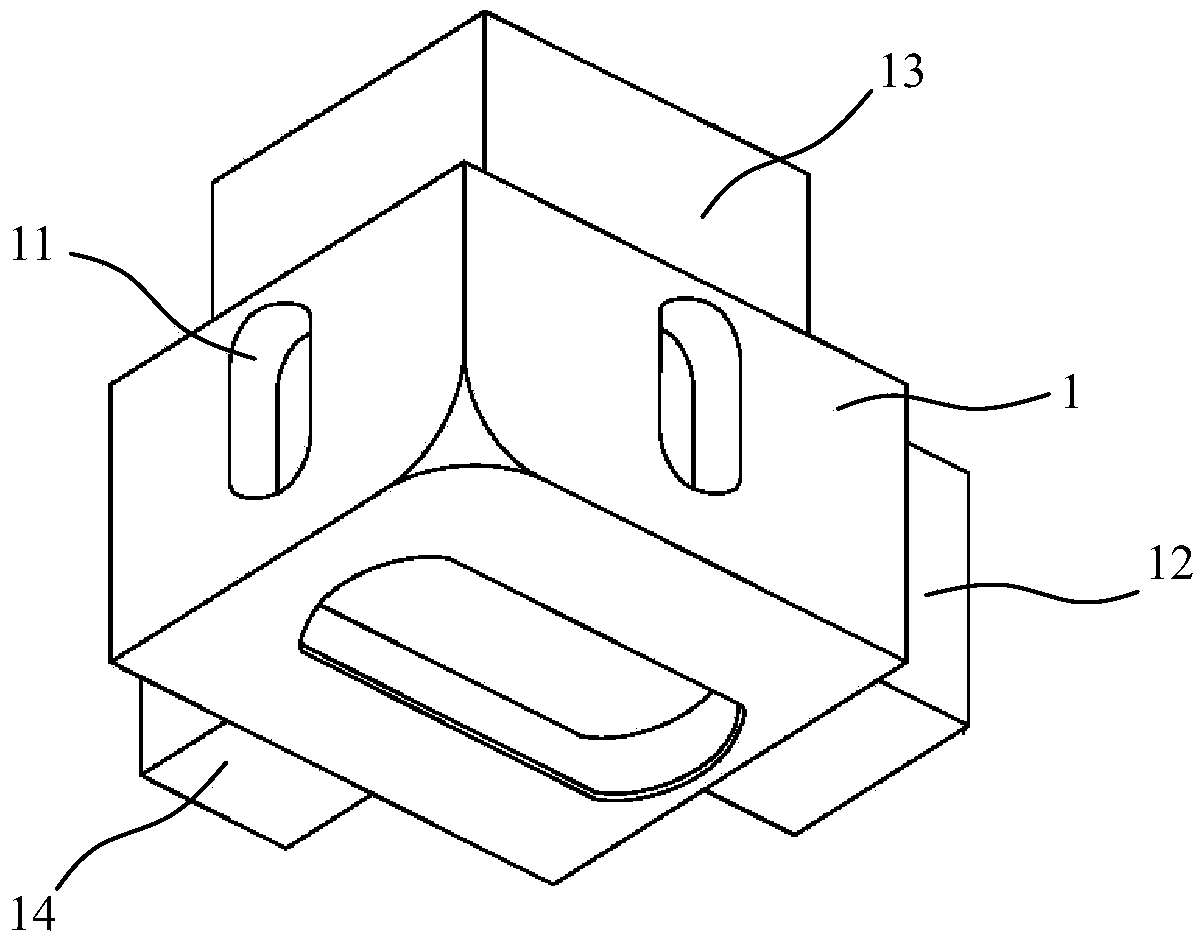

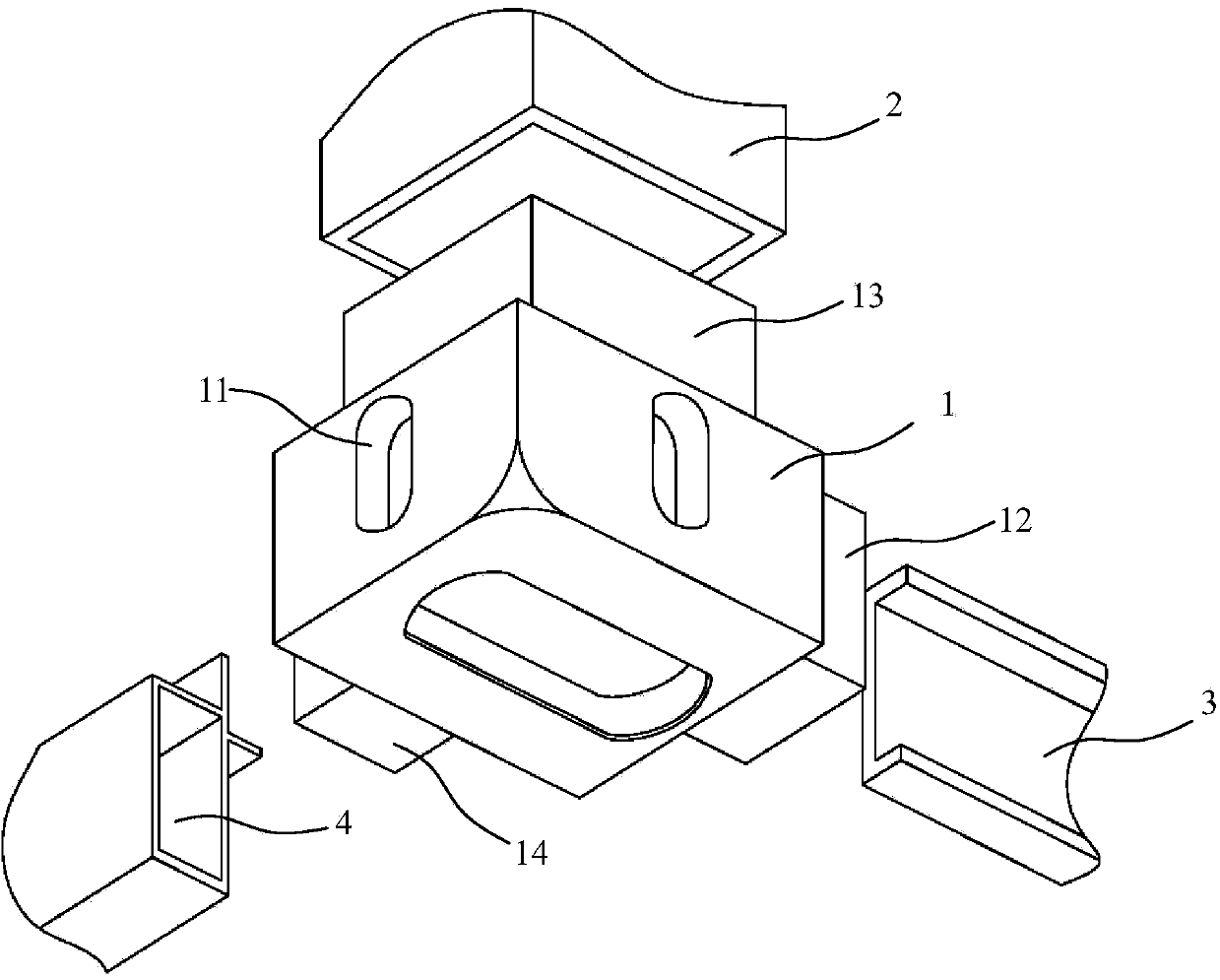

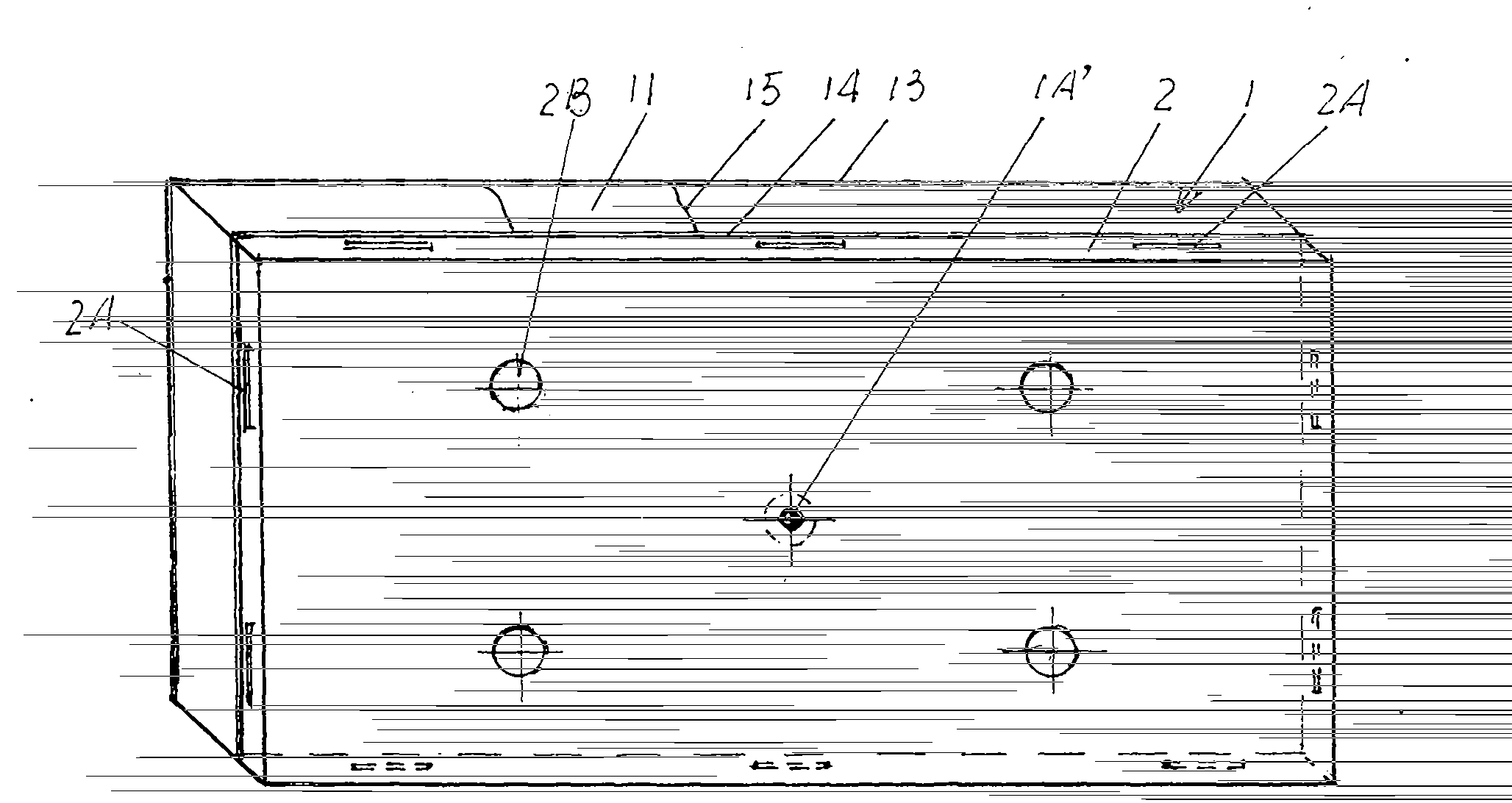

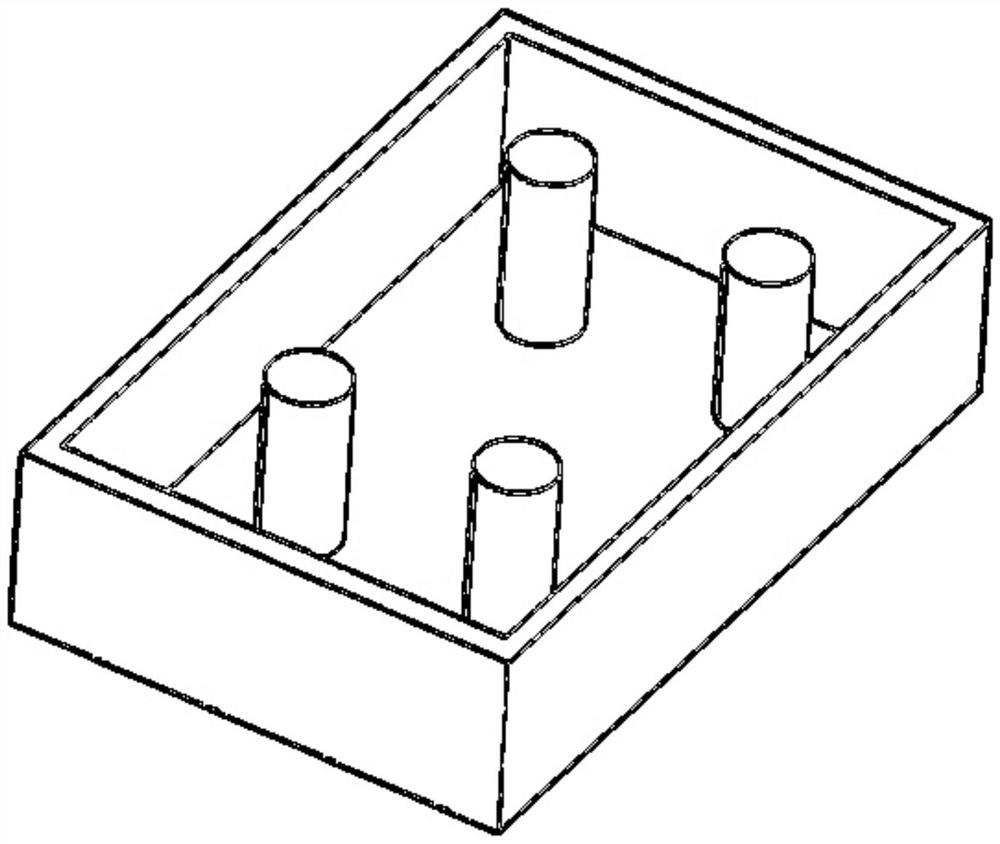

Corner fitting for container, container and container-type movable house

InactiveCN104176396ARapid productionReduce consumptionLarge containersBuilding constructionsTransportation energyAlloy

The invention discloses a corner fitting for a container, the container and a container-type movable house. A main body of the corner fitting for the container is cuboid-shaped; mounting through holes are formed in three outer end surfaces of the main body facing the outer side of the container, and the other three end surfaces of the main body can be fixedly connected with a side beam, an upright column and an end beam of the container respectively; a connecting boss is arranged on at least one end surface in the three end surfaces connected with the side beam, the upright column and the end beam of the container, can be connected with a matched beam column of the container in an insertion manner, and can be fixedly connected with the beam column of the container. According to the container and the container-type movable house with the corner fitting structure, a conventional welded structural part connecting mode can be replaced with a bond-riveted mode, the labor difficulty of a connecting process is reduced, the work efficiency is improved, and industrial pollution and energy consumption are reduced; meanwhile, a light aluminum alloy can be adopted as a base material of the container, and therefore the transportation energy consumption and the transportation cost are greatly reduced.

Owner:邵妮

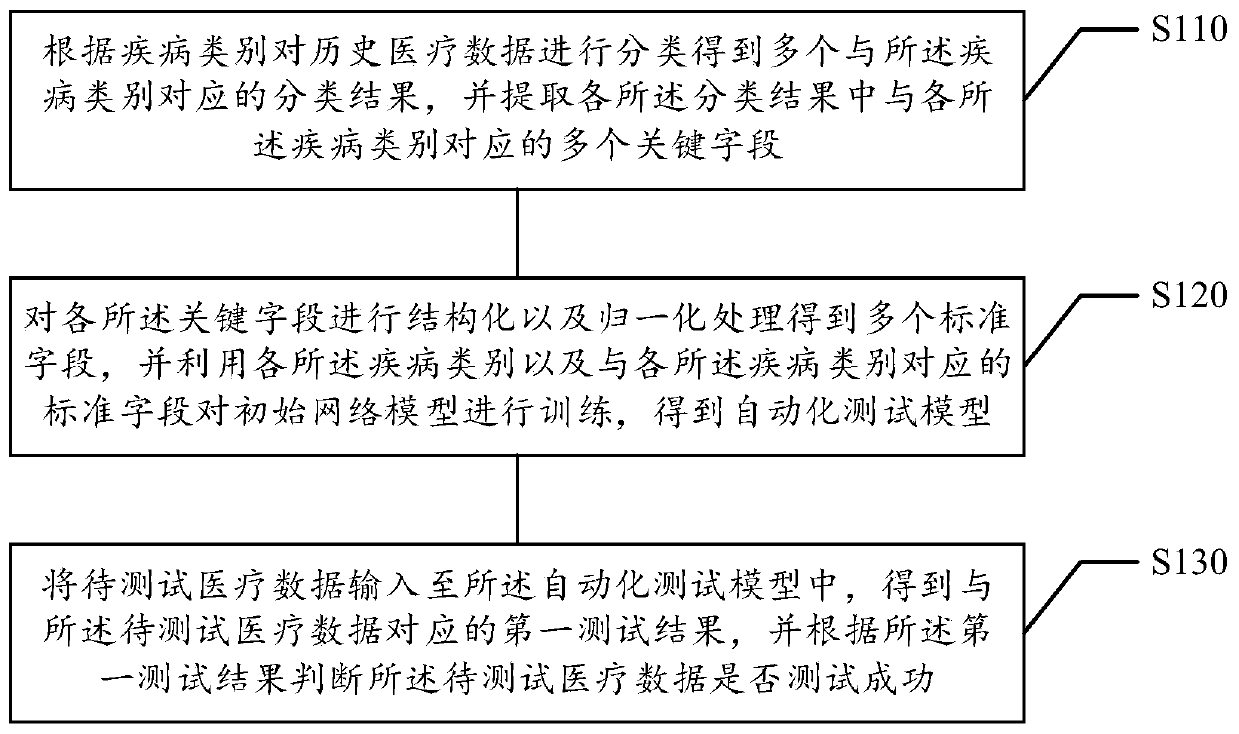

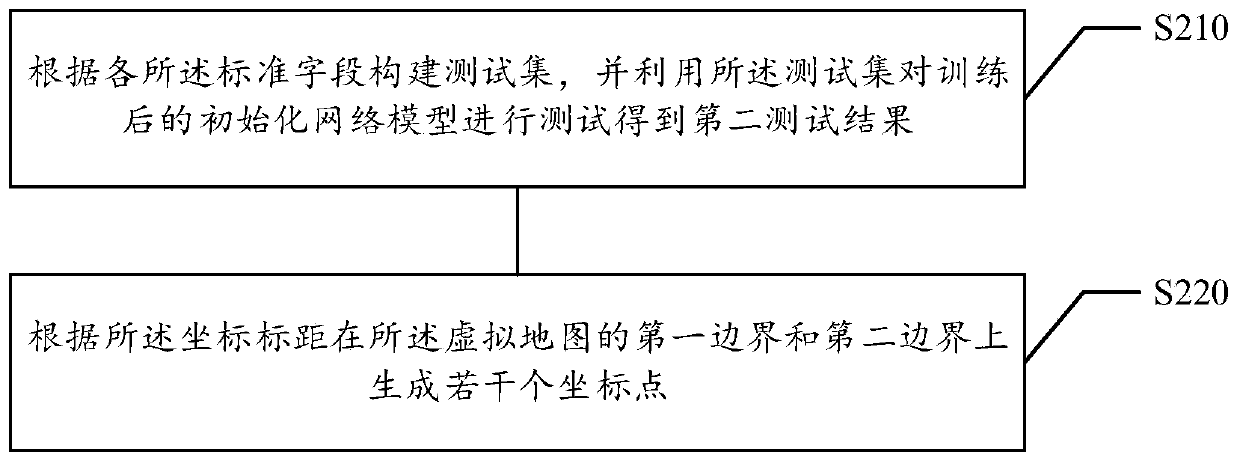

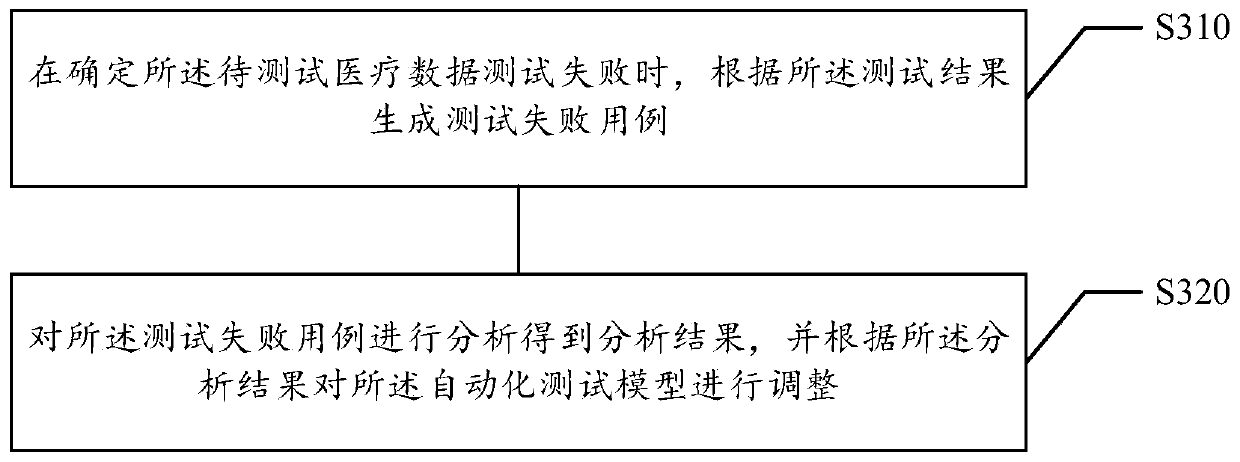

Automatic test method and device, computer readable storage medium and electronic equipment

ActiveCN111143226ALow resolution accuracyImprove accuracySoftware testing/debuggingICT adaptationEngineeringNetwork model

The embodiment of the invention relates to an automatic test method and device, a computer readable storage medium and electronic equipment. The method relates to the technical field of medical big data processing, and comprises the following steps: classifying historical medical data according to disease categories to obtain a plurality of classification results corresponding to the disease categories, and extracting a plurality of key fields corresponding to the disease categories in each classification result; structuring and normalizing the key fields to obtain a plurality of standard fields, and training an initial network model by utilizing the disease categories and the standard fields corresponding to the disease categories to obtain an automatic test model; and inputting to-be-tested medical data into the automatic test model to obtain a first test result corresponding to the to-be-tested medical data, and judging whether the to-be-tested medical data is successfully tested ornot according to the first test result. According to the embodiment of the invention, the accuracy of the first test result is improved.

Owner:YIDU CLOUD (BEIJING) TECH CO LTD

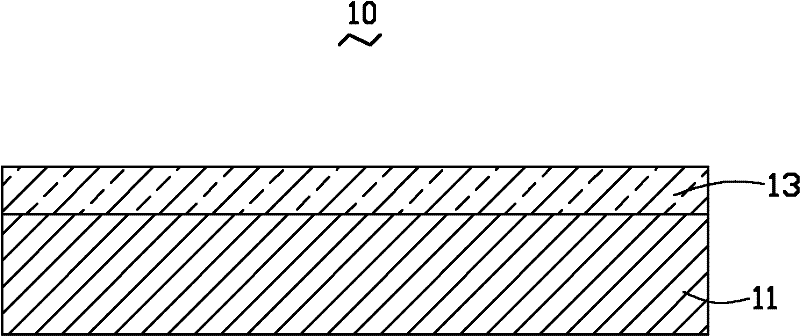

Plated piece and preparation method thereof

InactiveCN102477534AImprove wear resistanceExtended service lifeVacuum evaporation coatingSputtering coatingMicro nanoMastoid structure

The invention provides a plated piece and a preparation method thereof. The plated piece comprises a matrix and a fingerprint resisting layer formed on the surface of the matrix, the combination surface of the matrix with the fingerprint resisting layer has a roughness of 0.05-0.25mun, the fingerprint resisting layer is a nano-polytetrafluoroethylne layer, and a micro-nano mastoid structure is formed on the surface of the fingerprint resisting layer. The preparation method of the plated piece comprises the following steps: 1, providing the matrix; 2, roughening one surface of the matrix to make the surface have the roughness of 0.05-0.25mun; and 3, depositing the fingerprint resisting layer on the matrix-roughened surface with a plasma assisted deposition plating process.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

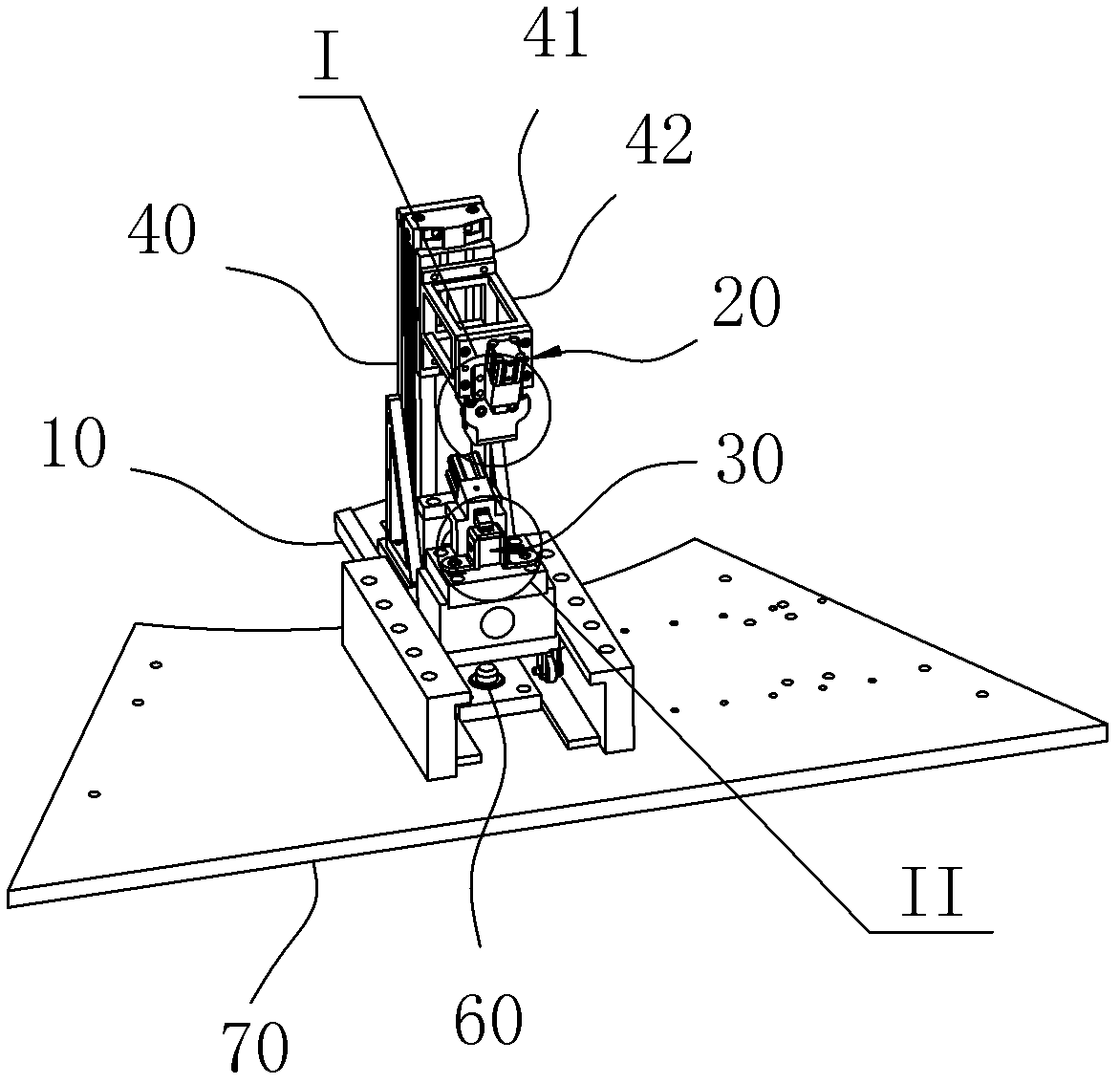

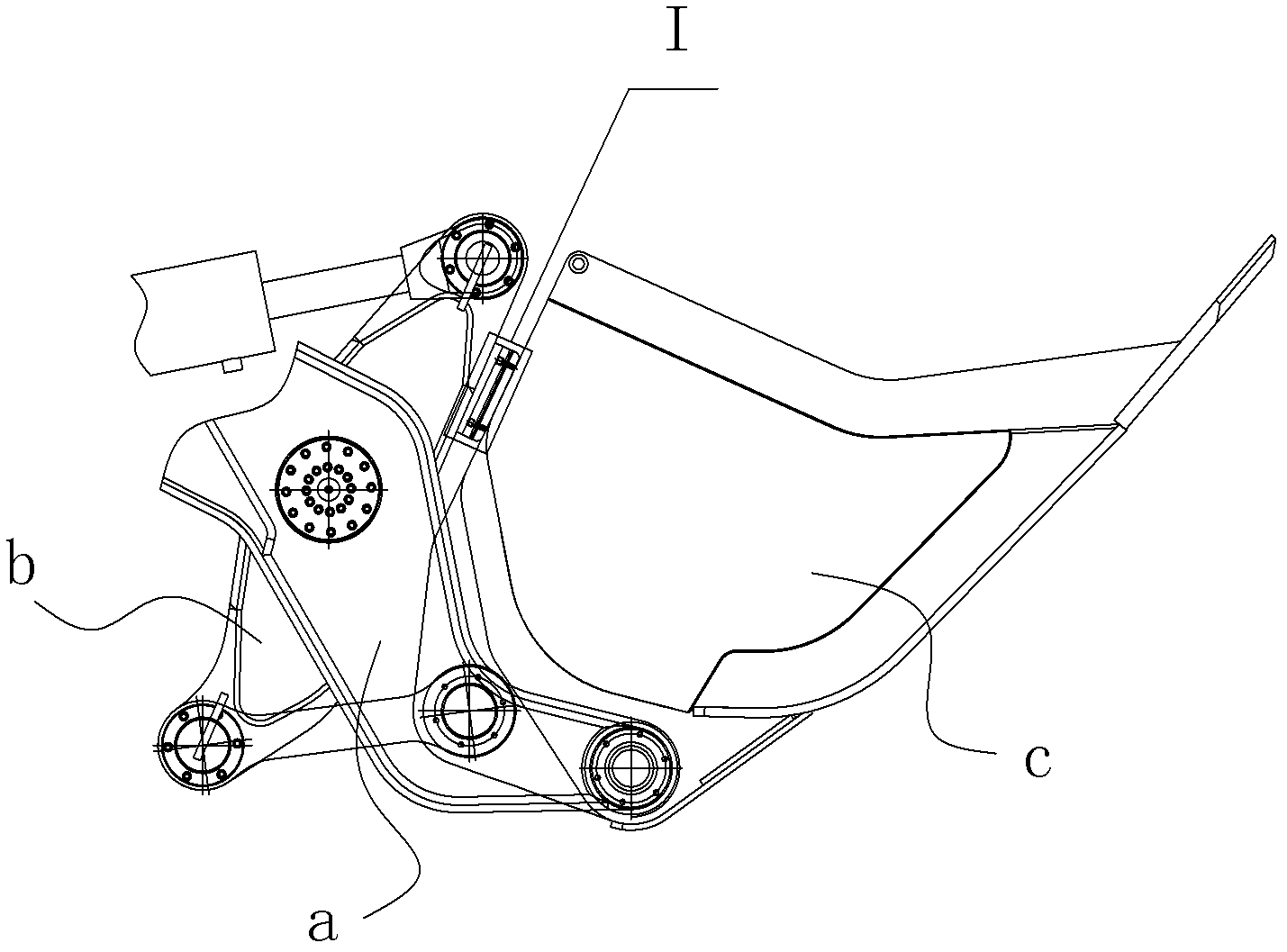

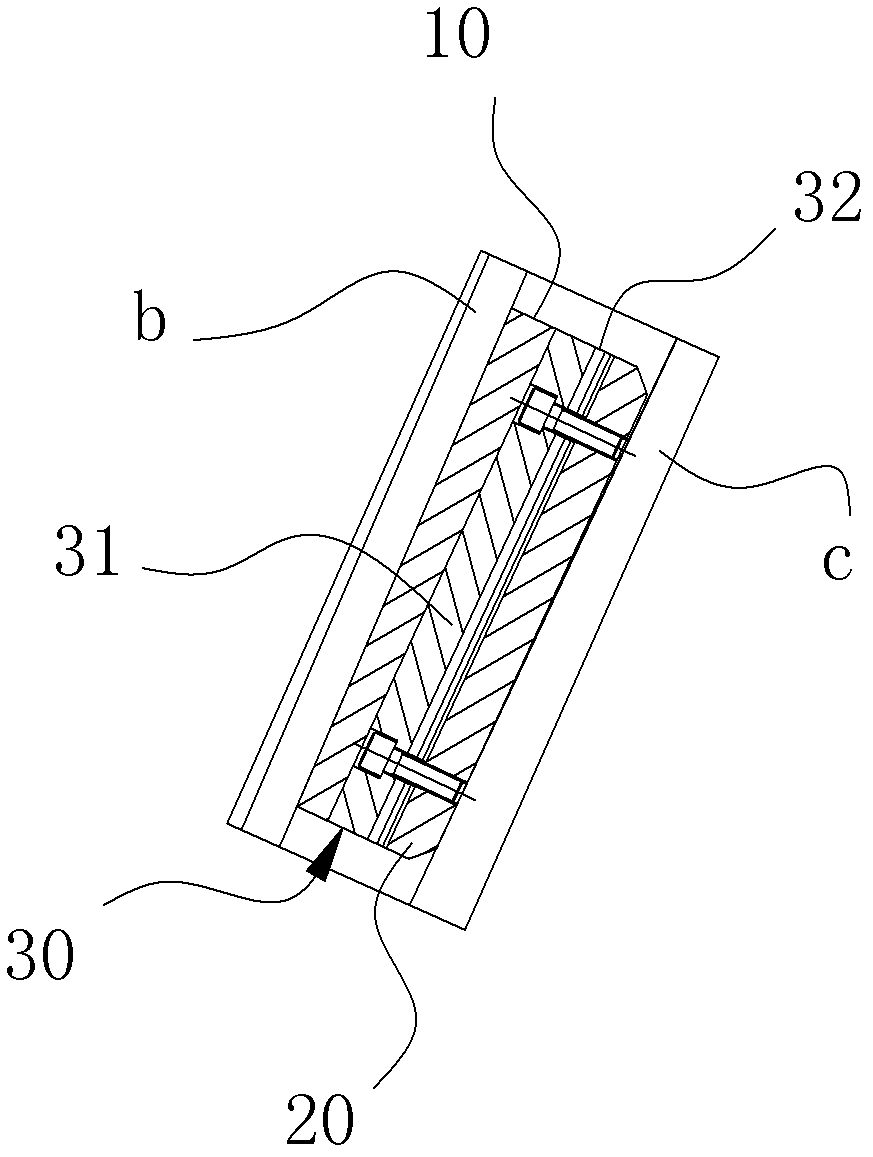

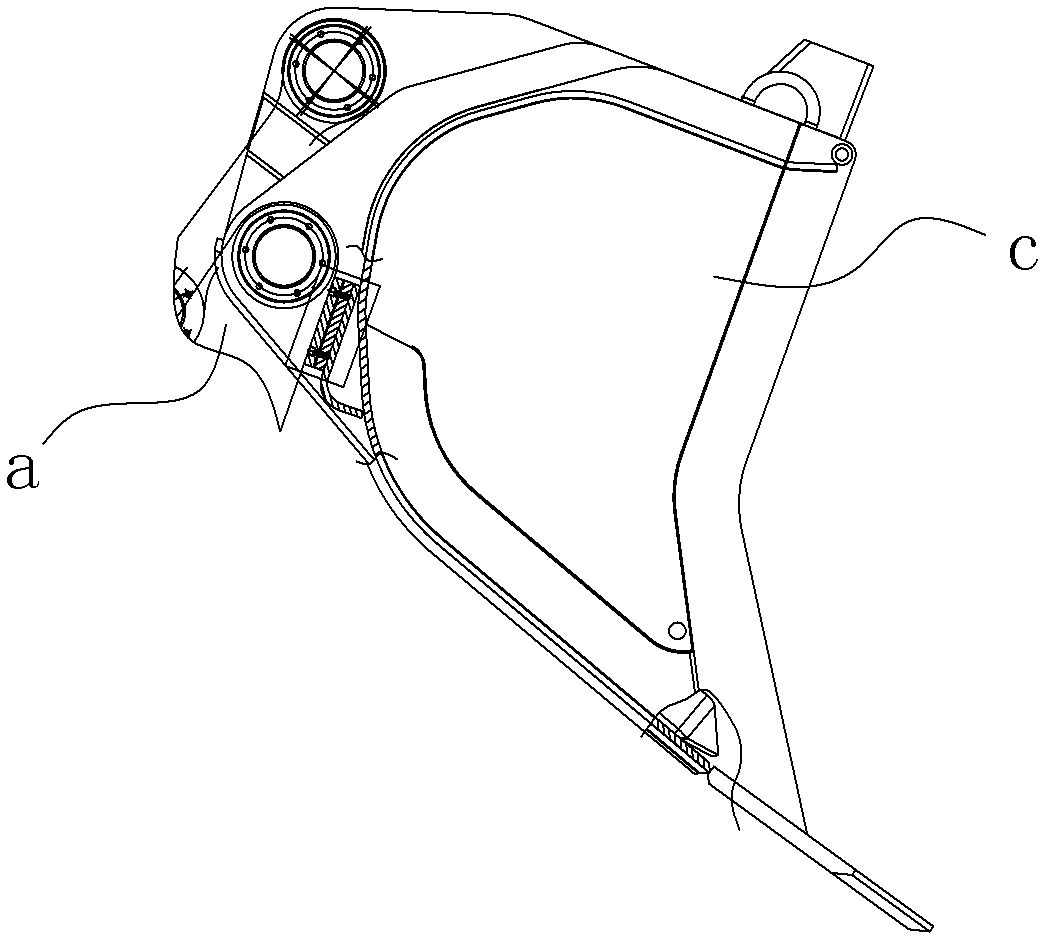

Automobile door hinge clamp

InactiveCN102248499ASatisfy positioningMeet assembly needsWork holdersEngineeringMechanical engineering

Owner:HEFEI XINGKE PETROCHEM EQUIP TECH

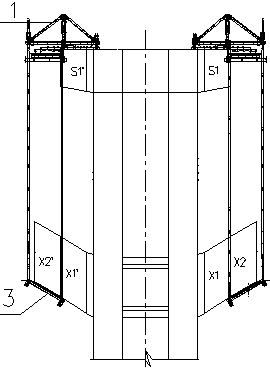

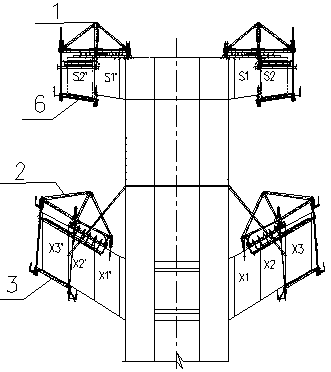

Construction process for triangular area of open-web rigid frame bridge

ActiveCN111335187AOptimize quantityAvoid Construction Work Safety RisksBridge erection/assemblyArchitectural engineeringHanging basket

The invention provides a construction process for a triangular area of an open-web rigid frame bridge. Suspension casting downward-bent steel bundles are arranged in the sections of webs of the firstto nth beam sections of the upper chord. Vertical force in upper chord section suspension casting construction is provided through the lower bent steel bundle; the sections provided with the downwardbent steel bundles can achieve balanced cantilever construction, the number of the supporting stand columns is further optimized, the construction operation safety risk of the supporting stand columnsof the (n-1) sections is avoided, the safety guarantee is improved, the construction period is shortened, and the complex system stress condition of a triangular area is optimized. Supporting stand columns are only arranged between n-m beam sections of the upper chord and the lower chord to support the n-m beam sections. The upper chord hanging basket does not cross the stand column; the mobile end is downwards embedded in the bottom fixed section, a fixed stand column is changed into a telescopic adjustable supporting stand column, the problems of conflict between a hanging basket bottom basket and the stand column, complex procedures of refitting the hanging basket bottom basket and the like are solved, cast-in-place concrete wet weight is completely borne by the hanging basket, the stress condition of a steel pipe stand column and a buckle cable is improved, and the overall safety reserve of the structure is improved.

Owner:上海远通路桥工程有限公司

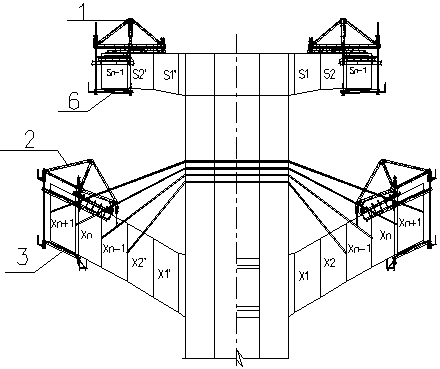

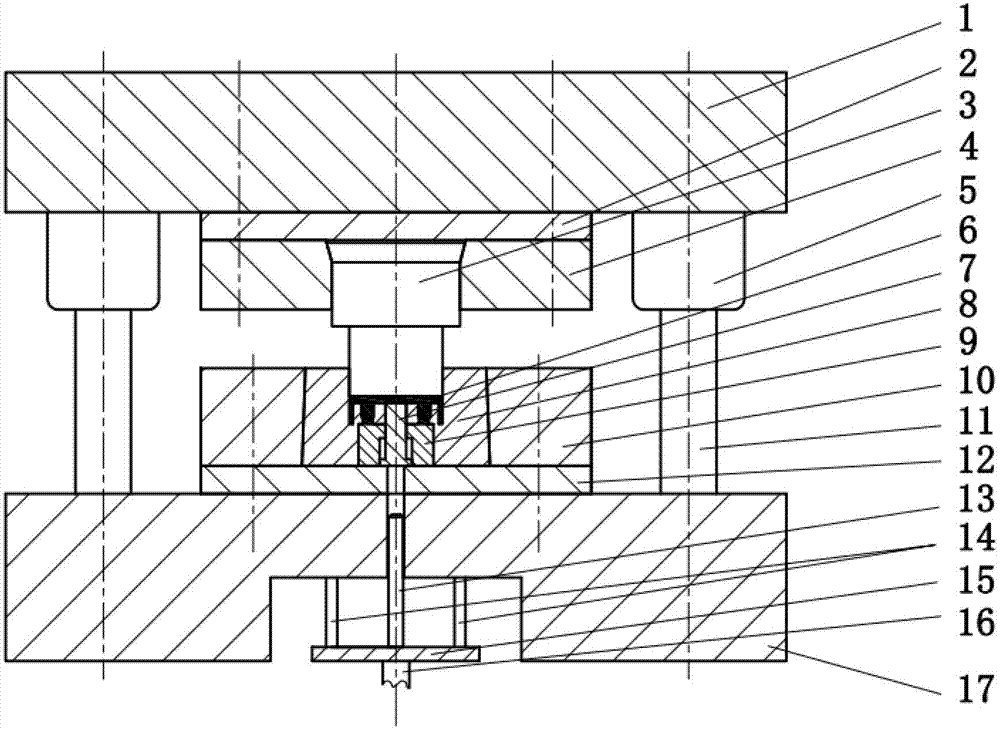

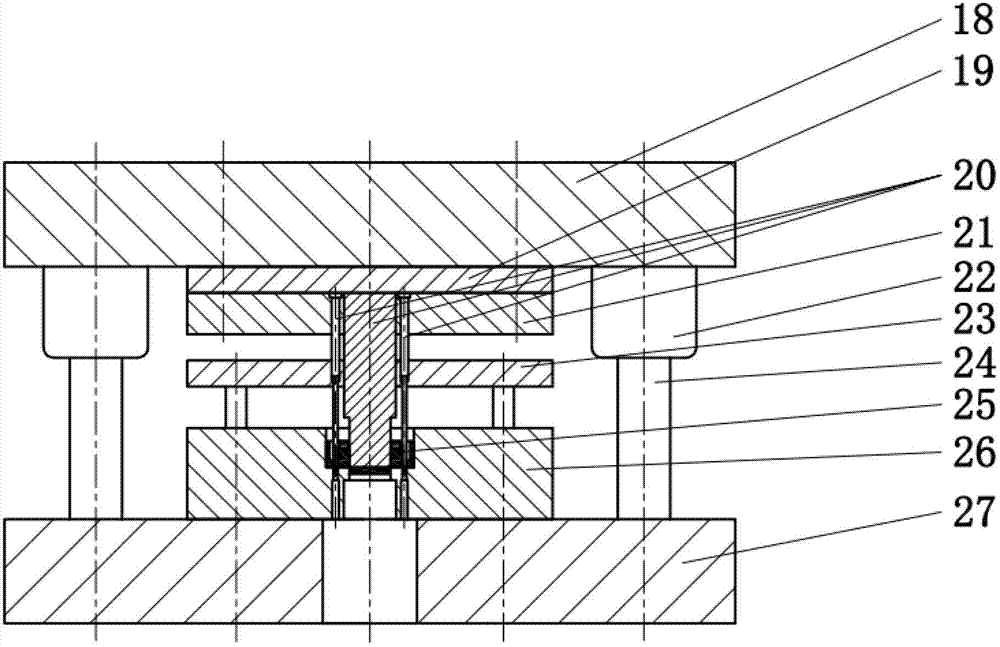

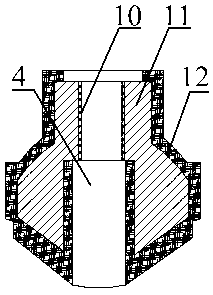

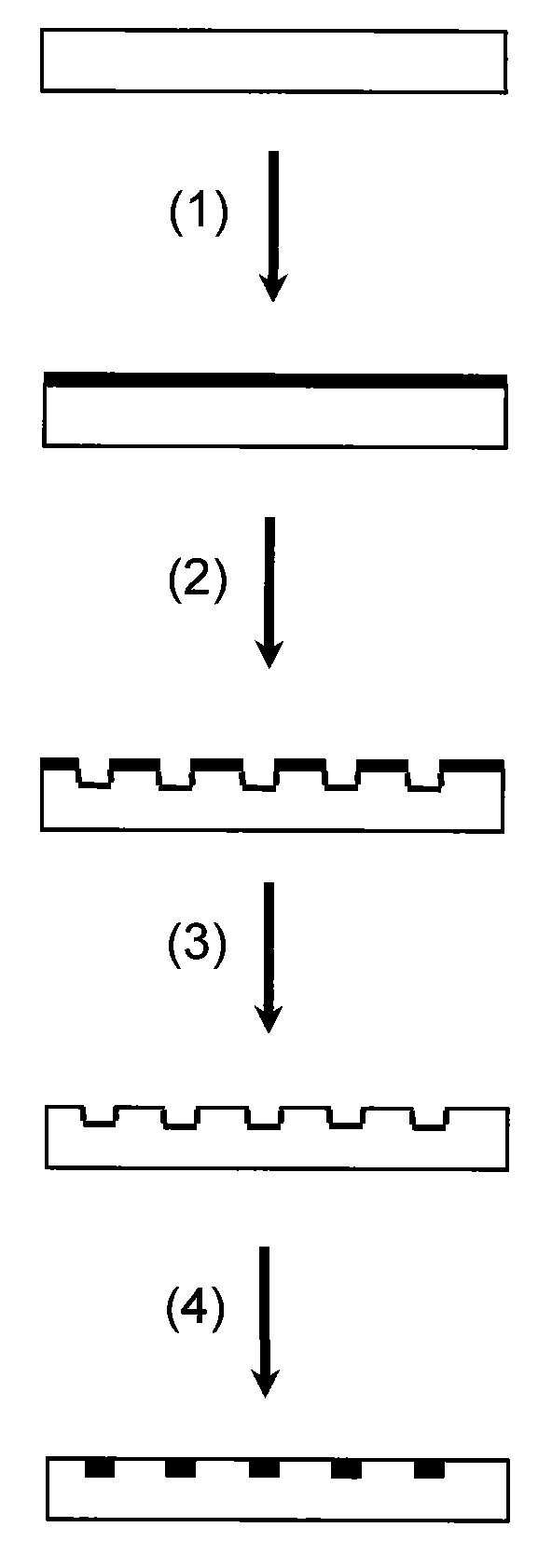

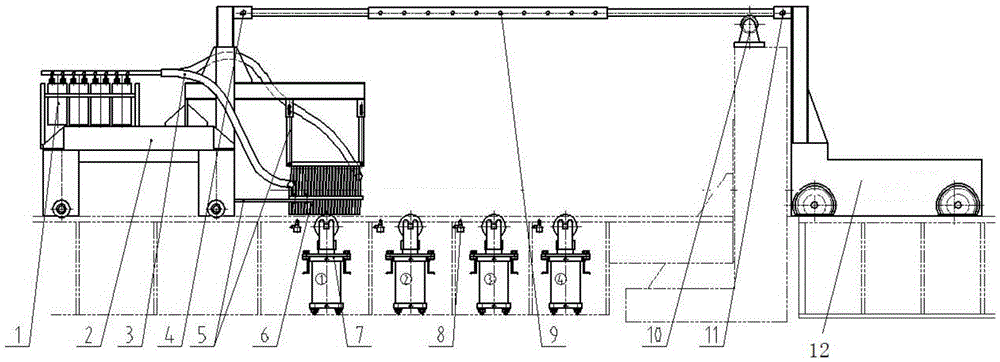

Warm extrusion forming process of stylus printing head base and forming mould thereof

InactiveCN102950165AReasonable and ingenious structural designAvoid complicated proceduresExtrusion diesNeedle typeEngineering

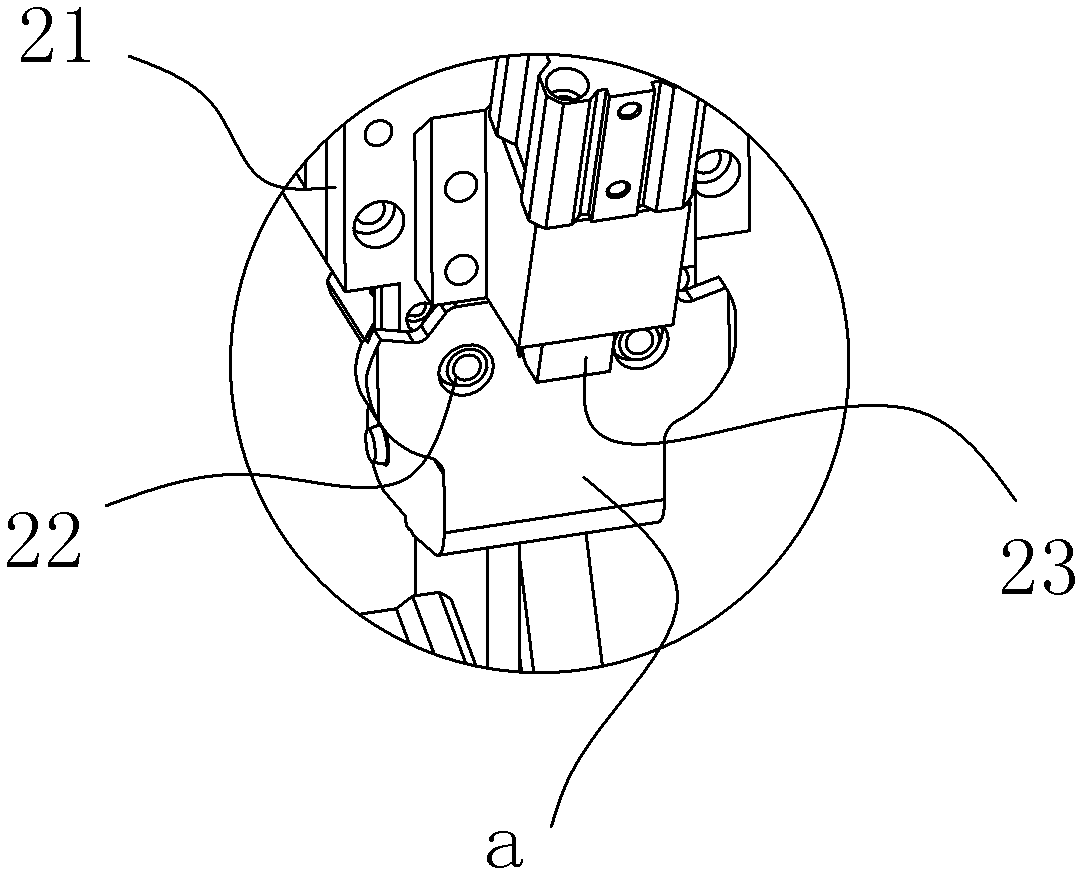

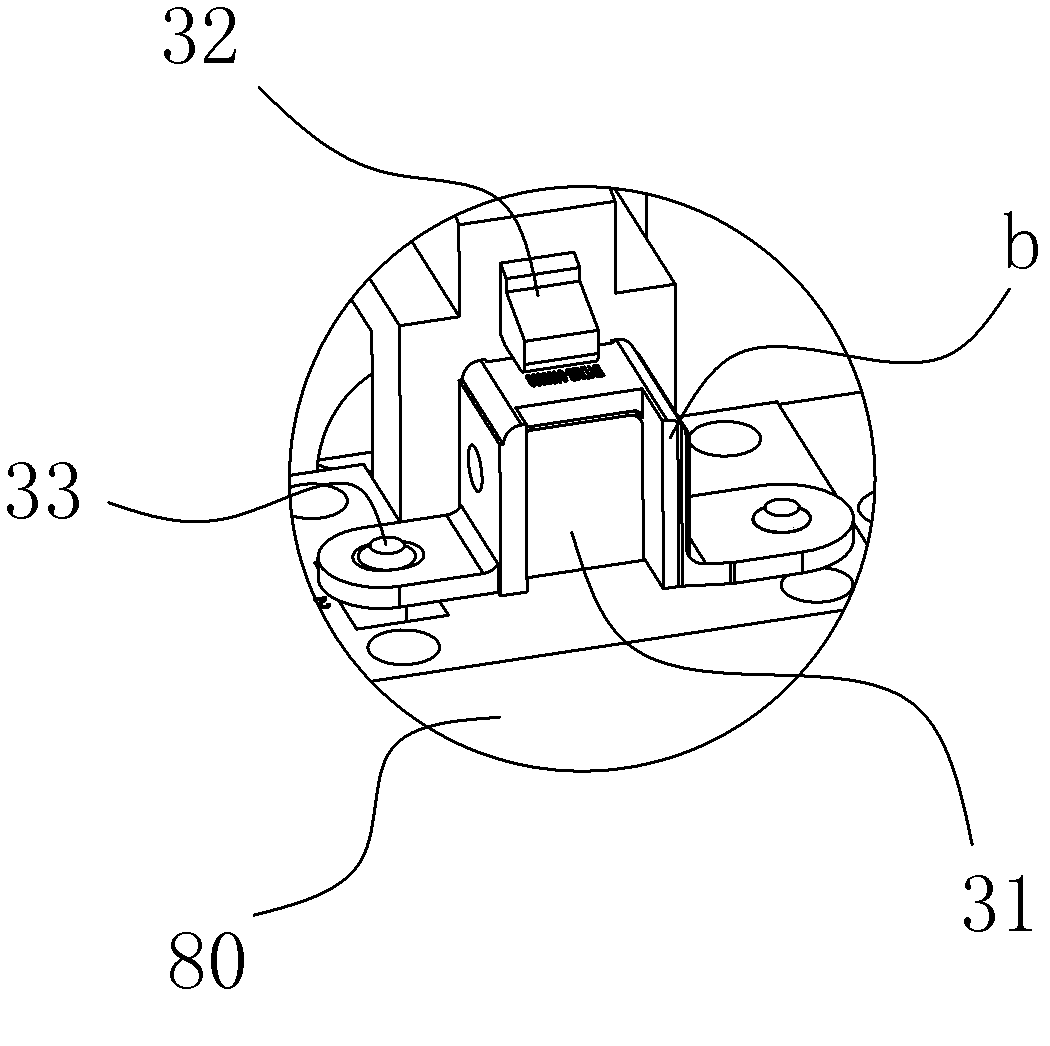

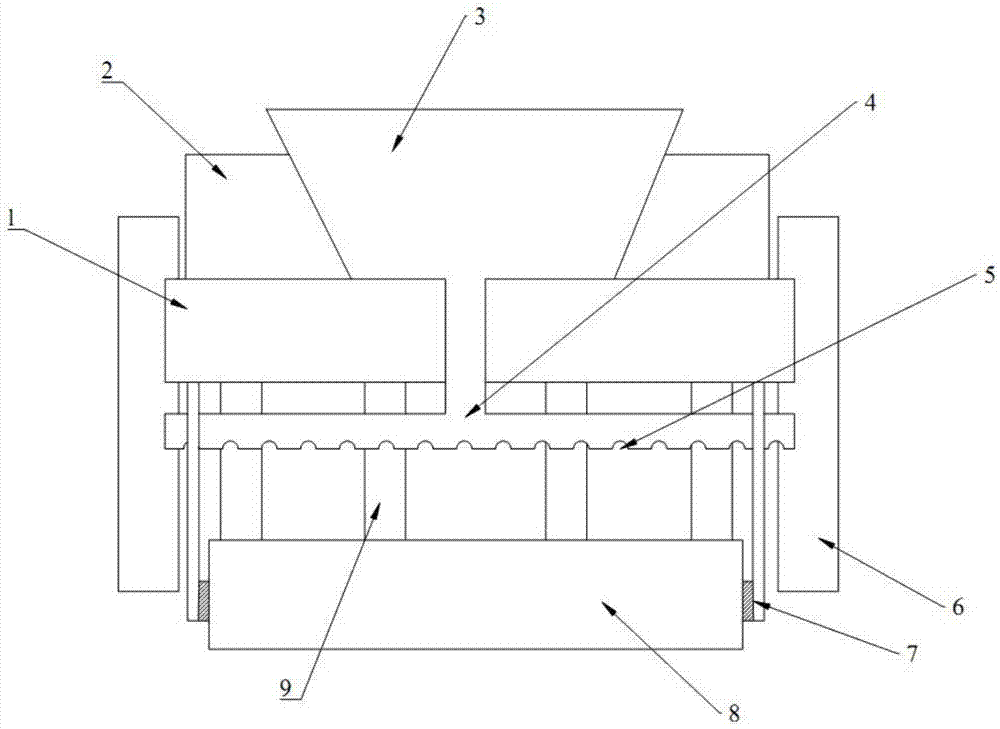

The invention provides a warm extrusion forming process of a needle-type printing head base and a forming mould thereof. The forming mould for the warm extrusion forming process comprises a warm extrusion mould and a blanking mould; the warm extrusion mould comprises an upper mould seat A, a lower mould seat A, a convex mould component A, a concave mould component, an ejection component, a guide column A and a guide sleeve A which is matched with the guide column A; and the blanking mould comprises an upper mould seat B, a lower mould seat B, a convex mould component B, a concave mould B, a stripper, a guide column B and a guide sleeve B which is matched with the guide column A. The warm extrusion forming process of the needle-type printing head base comprises the following steps that first the convex mould A and the concave mould A are matched and are preformed through the warm extrusion forming process so as to form a pre-formed piece which comprises an overall base structure consisting of an outer annular wall, a flange part and a small boss; and then one-time blanking is carried out in the blanking mould, and the stylus printing head base is obtained. The forming mould has the advantages of ingenious and reasonable structural design, simple process, convenience in operation, high production efficiency, good quality and low price.

Owner:SOUTH CHINA UNIV OF TECH

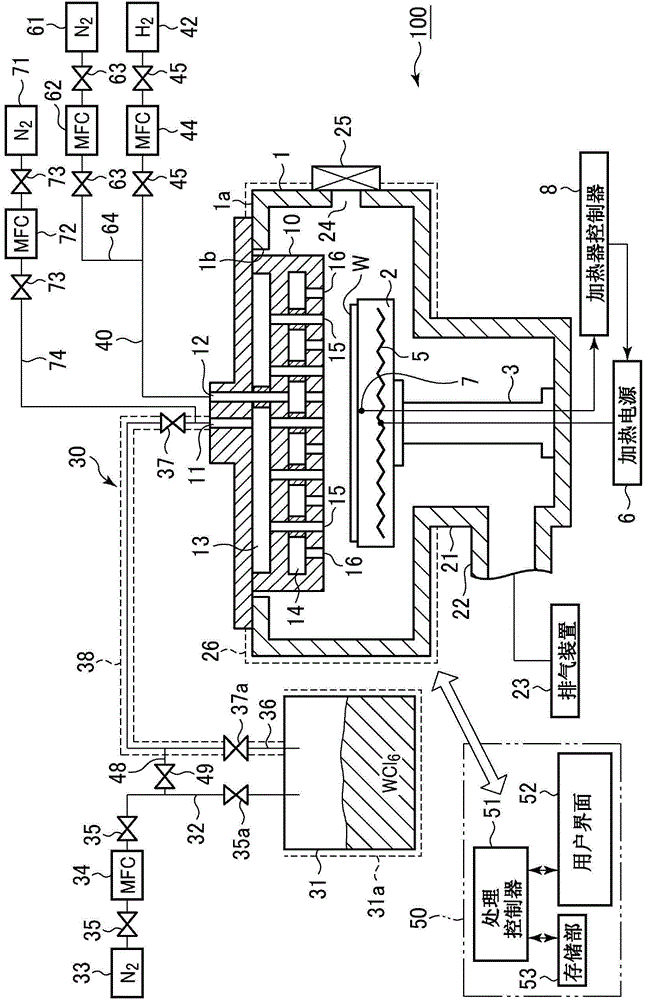

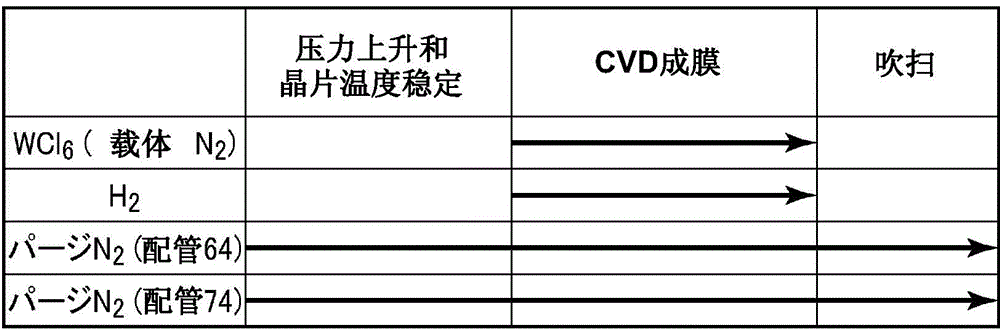

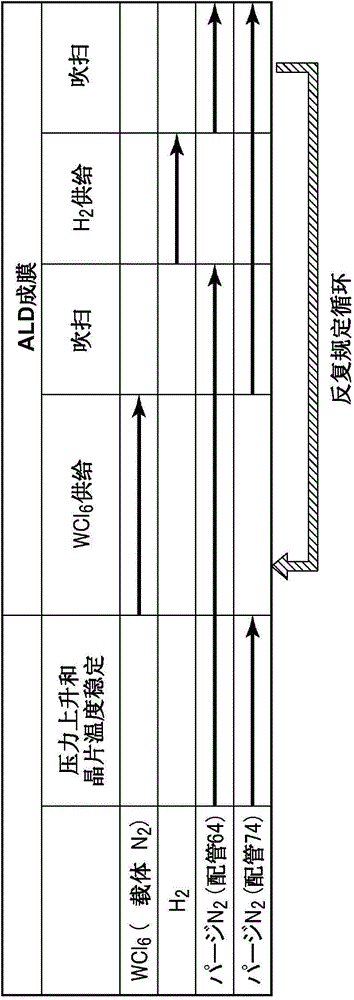

Tungsten film forming method and semiconductor device manufacturing method

ActiveCN104947064AIt is not easy to increase the resistance valueAvoid complicated proceduresSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSource materialChloride

A tungsten film forming method includes: supplying a tungsten chloride gas as a source material of tungsten and a reducing gas towards a substrate to be processed under a depressurized atmosphere to cause reaction between the tungsten chloride gas and the reducing gas while heating the substrate to be processed, such that a main tungsten film is directly formed on a surface of the substrate to be processed without forming an initial tungsten film for nucleus generation.

Owner:TOKYO ELECTRON LTD

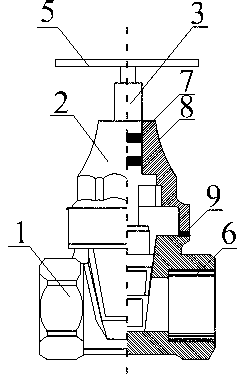

Anti-corrosive anti-pollution environment-friendly plastic brake valve with flexible seal and machining process thereof

The invention discloses an anti-corrosive anti-pollution environment-friendly plastic brake valve with flexible seal, and solves the defects that in the prior art, the manufacturing process of a flexible seal brake valve is complicated, the manufacturing cost is high, and secondary pollution is easily caused for fluids. The plastic brake valve comprises a valve body, a valve cover, a valve rod and a brake plate, wherein the valve body is in a three-way structure; the valve cover is arranged at the top end of the valve body, and is movably connected with the valve body; one end of the valve rod penetrates through the valve cover and stretches to the inside of the valve body, and the other end of the valve rod is provided with an adjusting hand wheel; the brake plate is arranged at one end of the valve rod; the brake plate is a composite plastic brake plate; the valve body and the valve cover are both made of modified polyphenylene oxide; and copper connectors are arranged at two connecting ends of the valve body. On the basis, the invention further discloses a machining process of the anti-corrosive anti-pollution environment-friendly plastic brake valve with flexible seal. The anti-corrosive anti-pollution environment-friendly plastic brake valve with flexible seal disclosed by the invention has a simple structure, and can be conveniently machined through injection molding; therefore, the brake valve is suitable to be widely promoted and applied.

Owner:陈建峰

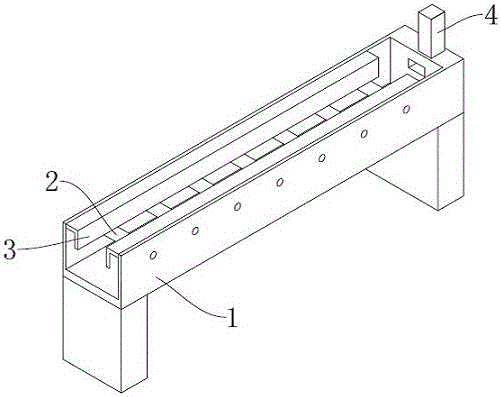

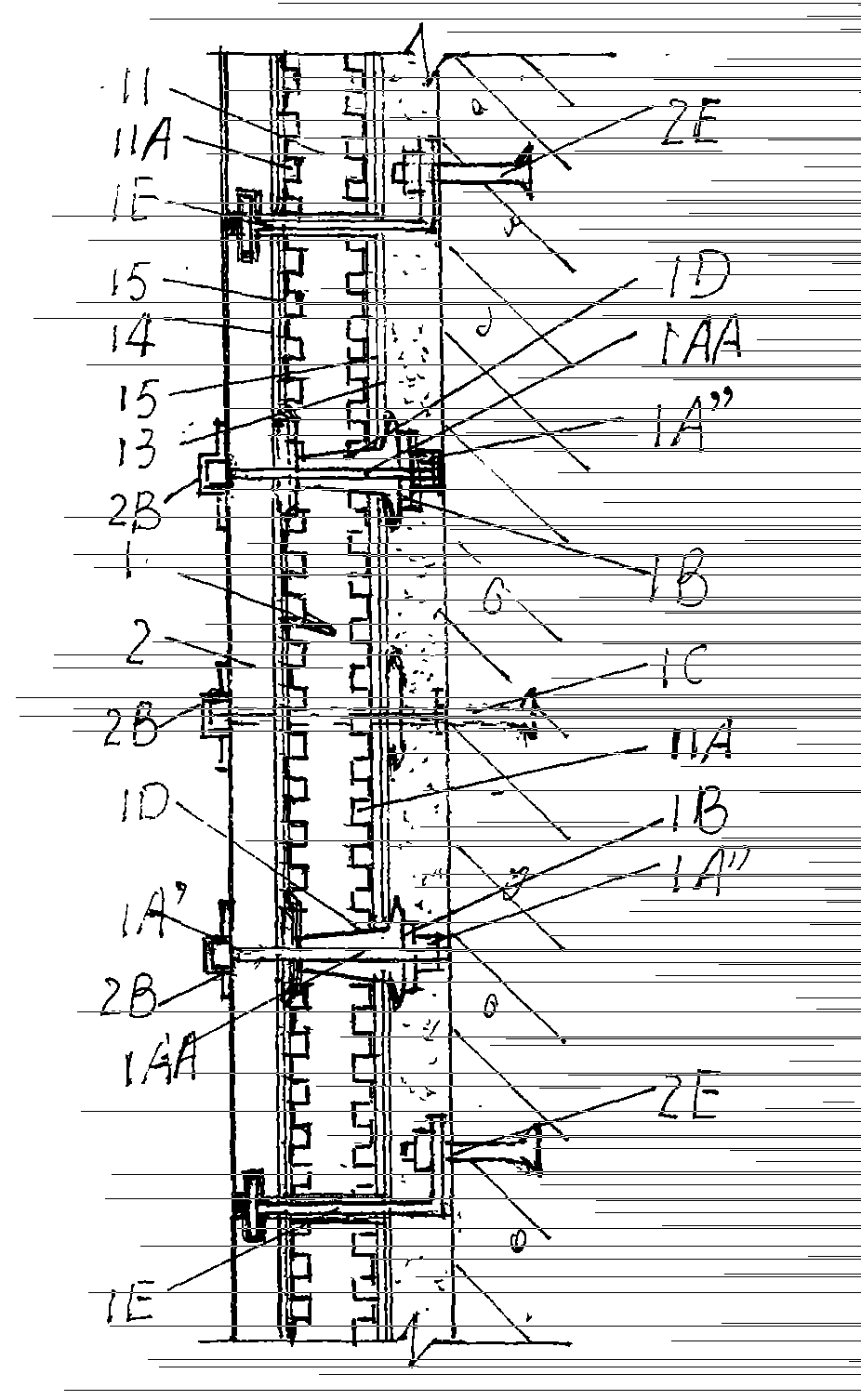

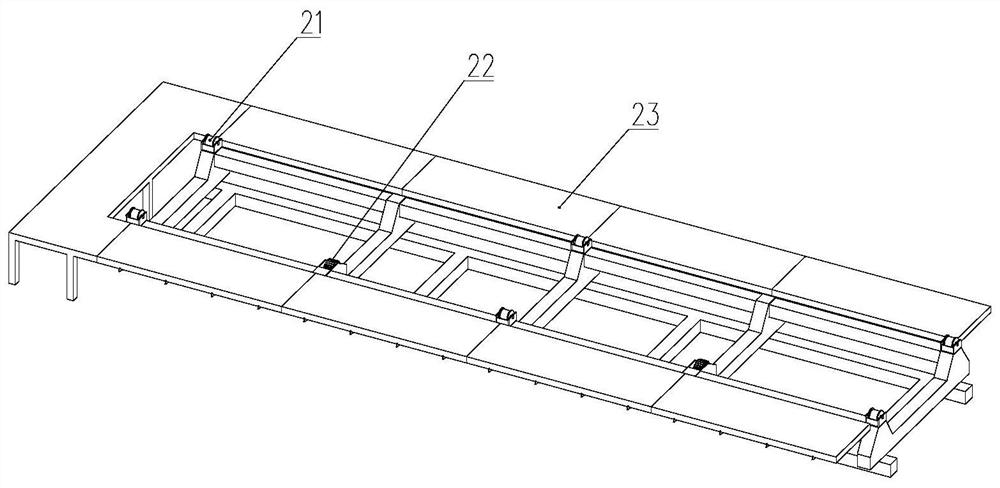

Fixed-length profile blanking device

InactiveCN105057805AEasy to operateAvoid complicated proceduresMeasurement/indication equipmentsMetal working apparatusEngineeringFixed length

The invention relates to a blanking device, in particular to a fixed-length profile blanking device. The fixed-length profile blanking device comprises a rack, wherein a transmission mechanism is arranged on the rack, and at least comprises two rolling shafts and a motor; the central axes of the rolling shafts are in the same plane; the centers of the rolling shafts are level; a transmission surface is formed by the rolling shafts; the motor is connected with at least one rolling shaft; a cutting device is arranged at an outlet of the transmission surface; a distance measuring mechanism is arranged on the rack, and comprises an encoder and a roller; and the roller is coaxially and rotationally connected with an input shaft of the encoder, and is fit with to-be-measured profiles. The fixed-length profile blanking device directly measures and cuts the profiles in different lengths; compared with the original fixed-length measuring tool or a measuring tape or other tools, an operator can operate more simply and easily; the problem that the original procedure is complicated is avoided; and the encoder is adopted for measurement, so that the precision can be higher compared with that by manual measurement.

Owner:CHONGQING WESTER ELEVATOR

Adjustable limiting device applied to underground scooptram

ActiveCN102535549AOverall installation flexibilityAvoid complicated proceduresMechanical machines/dredgersEngineeringElectrical and Electronics engineering

Owner:ANHUI TONGGUAN MACHINERY

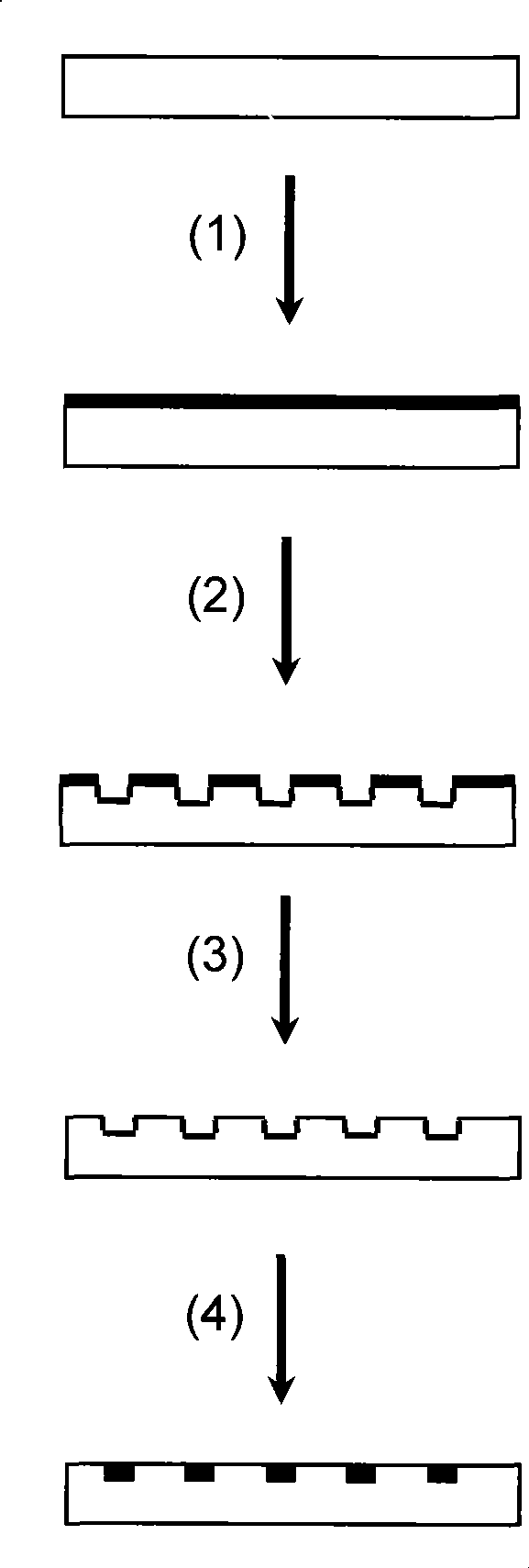

Method for realizing selectivity metallization on glass surface by femto-second laser

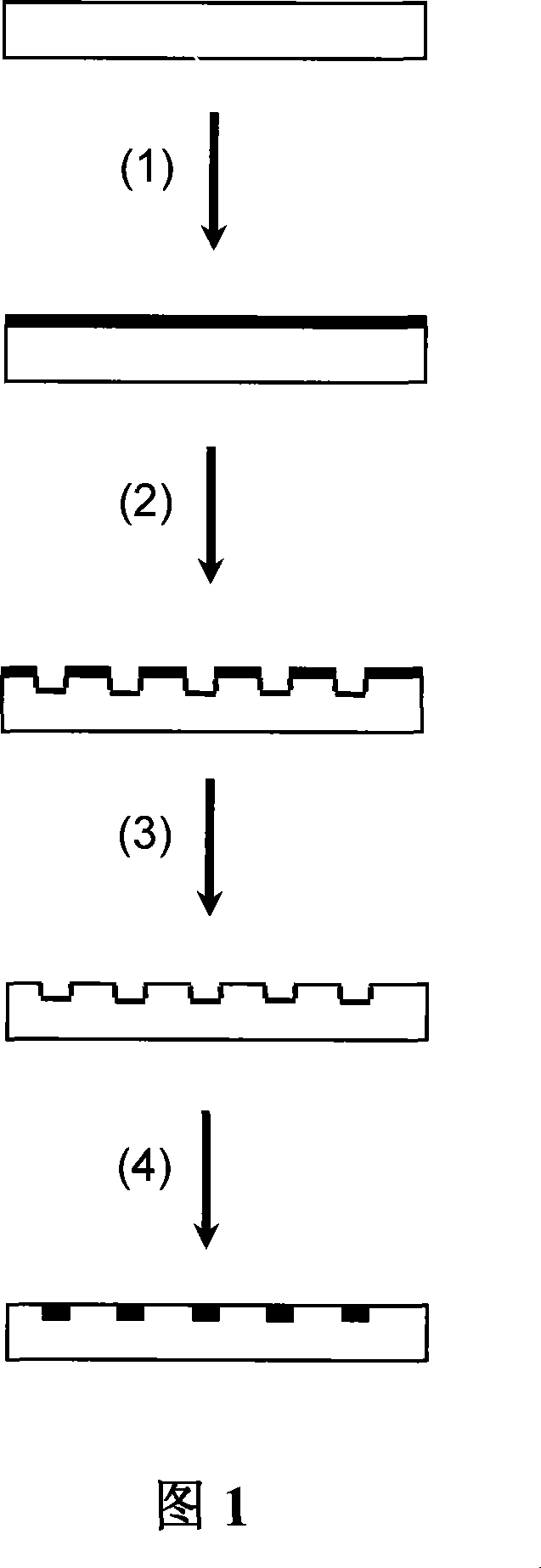

InactiveCN101121575BAchieve selective metallizationAvoid complicated proceduresCopper platingFemto second laser

The present invention discloses a method using the flying-second laser to realize the selective metal on the glass surface, which comprises the following steps: (1) a silver nitrate film is prepared on the glass base; (2) the method uses the flying-second laser focalized on the silver nitrate film to draw the design; (3) the method wipes off the silver nitrate film not being radiated; (4) the method adds the chemical copperizing liquid to make chemical copperizing. Compared with the traditional metal method, the present invention is with much simpler design, much faster preparation process and more controllable technical and so on. The method is with much greater application potential and practical value in the multi-functional chip experiment and the integration of the micro-component, in particular to the effective integration of the electricityl function and calorifics function.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

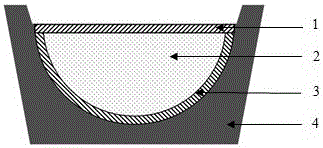

Molten-metal-cladding hot isostatic pressing preparation method for particle-reinforced metal-matrix composite

ActiveCN106735189AAchieve densificationIncrease heat transfer resistanceMetal matrix compositeEnergy consumption

The invention discloses a molten-metal-cladding hot isostatic pressing preparation method for a particle-reinforced metal-matrix composite, and aims at solving the problems that at present, when the particle-reinforce metal-matrix composite is prepared through the hot isostatic pressing process in the powder metallurgic method, a sheath good in leakproofness needs to be manufactured, procedures are complicated, generally, only blanks simple in shape can be prepared, the production efficiency is limited, strong light, smoke and the like can be generated in the welding process and environment friendliness is poor. The molten-metal-cladding hot isostatic pressing preparation method includes the four key steps of raw material mixing, cold isostatic pressing forming, assembling and hot isostatic pressing. As a new hot isostatic pressing method, the molten-metal-cladding hot isostatic pressing preparation method can effectively solve the problem that sheath sealing and welding need to be conducted in a traditional method, the production process is effectively simplified, the production efficiency is improved, and the bottleneck of the production efficiency is broken through. Meanwhile, the production energy consumption and cost can be effectively reduced while the material quality is ensured, and the molten-metal-cladding hot isostatic pressing preparation method is friendly to the environment, has high application value and is worthy of large-scale application and popularization.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

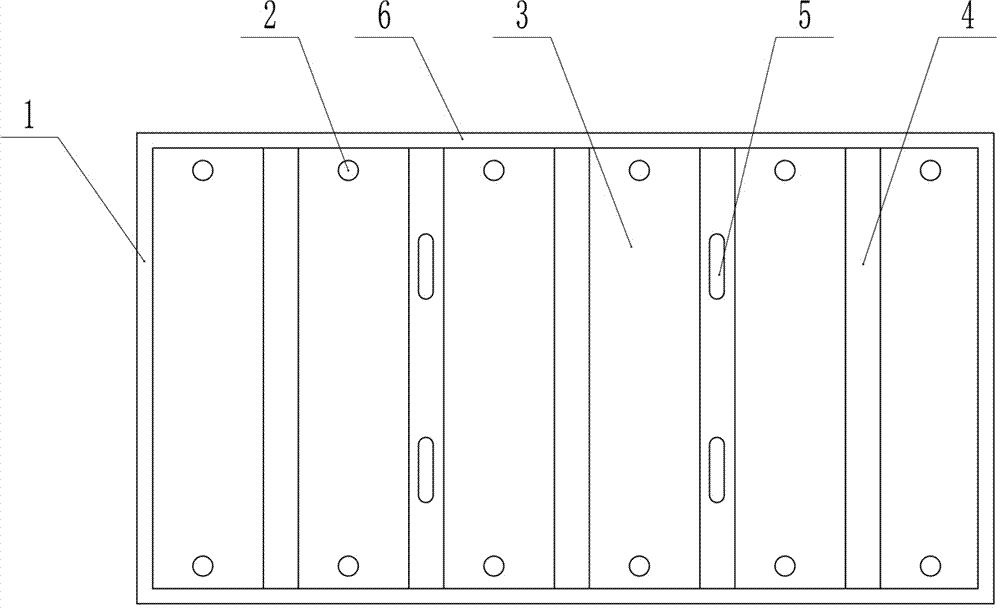

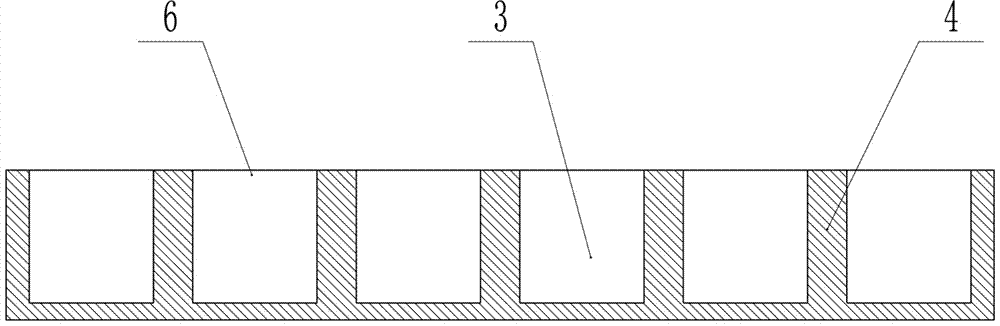

Multi-continuous-containing bread baking box and machining technique thereof

The invention provides a multi-continuous-containing bread baking box and a machining technique thereof. The multi-continuous-containing bread baking box comprises an integrally-formed multi-continuous-containing baking box main body, main body positioning holes, sealing plates and cover plate positioning holes. The multi-continuous-containing baking box main body comprises long groove-shaped mold cavities, a partition plate is arranged between every two adjacent long groove-shaped mold cavities, and the cover plate positioning holes are formed in the partition plates. The main body positioning holes are formed in the bottom surfaces of the long groove-shaped mold cavities, and the main body positioning holes in the long groove-shaped mold cavities are arranged at equal intervals. The sealing plates are fixed to the two ends of the multi-continuous-containing baking box main body. The multi-continuous-containing bread baking box has the advantages that the design is scientific, the number of joints is small, the structure is firm, and the service life is long. The machining technique of the multi-continuous-containing bread baking box comprises the following steps of (1) plate positioning; (2) laser cutting of the main body positioning holes and the cover plate positioning holes; (3) stretch forming; (4) re-performing of the step (3); (5) welding of the sealing plates; and (6) sand blasting, paint spraying and drying of the surface of a mold obtained after welding, and completing of manufacturing. The machining technique of the multi-continuous-containing bread baking box has the advantages that the design is scientific, the technological steps are simple, the labor intensity of workers is relieved, and forming steps are few.

Owner:河南赫斯特威自动化设备有限公司

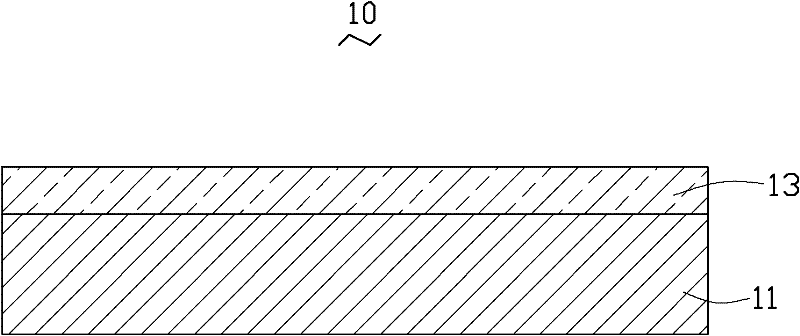

Coated part and manufacturing method thereof

InactiveCN102477532ASimple methodAvoid complicated proceduresVacuum evaporation coatingSputtering coatingSputteringTin dioxide

The invention provides a coated part and a manufacturing method of the coated part. The coated part comprises a basal body and an anti-fingerprint coating formed on the surface of the basal body, wherein the anti-fingerprint coating is a nano-sized tin dioxide coating and nano-sized protrusions are formed on the surface of the coating. The manufacturing method of the coated part comprises the following steps of: providing a basal body and forming an anti-fingerprint coating on the surface of the basal body by vacuum sputtering method, wherein the anti-fingerprint coating is a nano-sized tin dioxide coating and nano-sized protrusions are formed on the surface of the coating.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

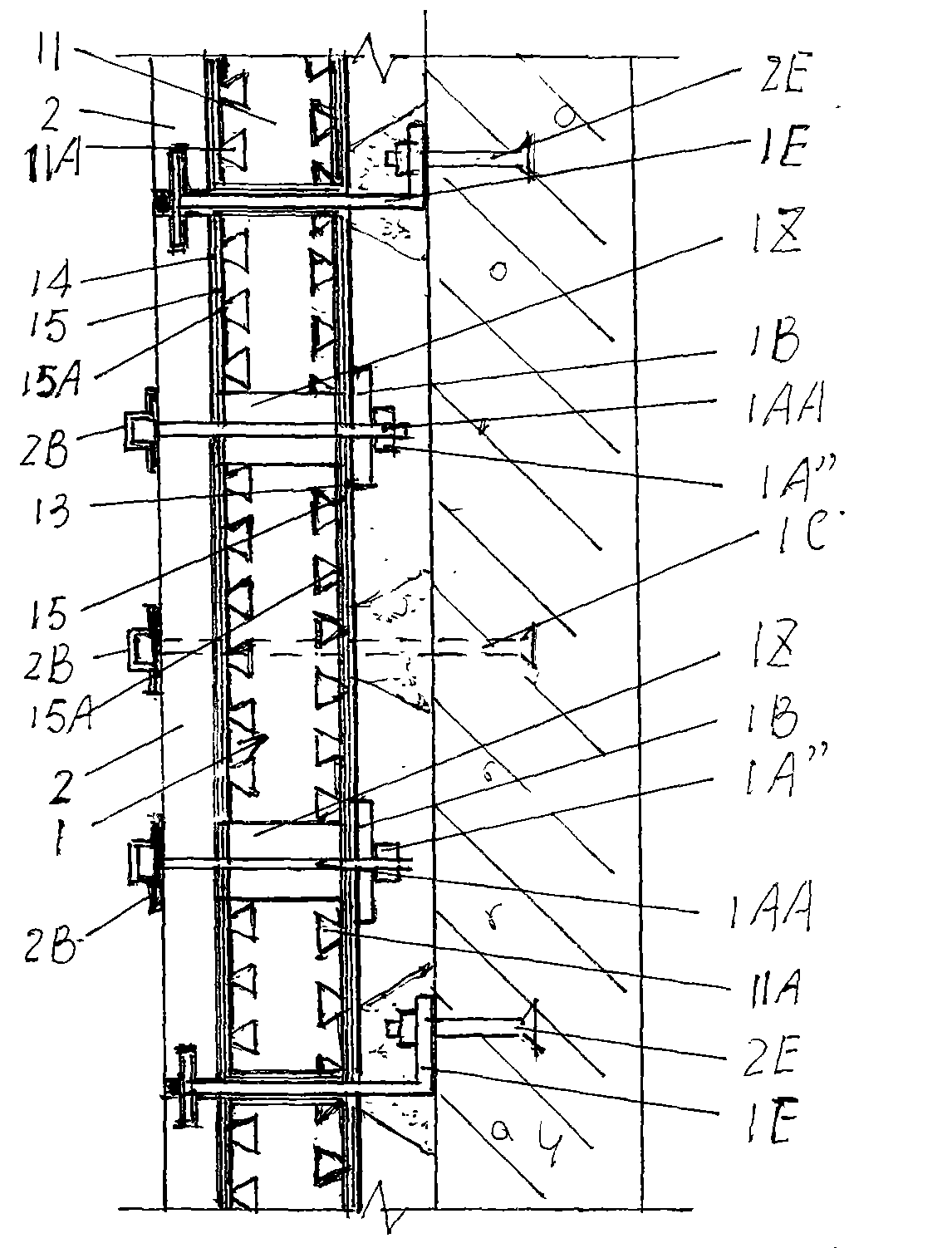

Drawing, expanding and follow-up heating device of cold-drawing unit

The invention discloses a drawing, expanding and follow-up heating device of a cold-drawing unit. One end of a water-cooled cable is connected with a high-voltage electric heating capacitor bank, and the other end is connected with an induction heating coil; one end of an insulation pull rod is fixed on a follow-up trolley, and the other end is connected with the induction heating coil; each lifting carrier roller consists of an air cylinder and a carrier roller rack; the extension length of each air cylinder is adjusted through an adjusting bolt; a traction rod is divided into three sections; pin shaft adjusting holes are drilled in the middle section at equal intervals; one end of the traction rod is connected with the follow-up trolley through a pin shaft I; the other end of the traction rod is connected with the drawing trolley through a pin shaft II; a traction rod carrier wheel is formed by assembling two bearing blocks and one carrier wheel; the lifting sequence of the lifting carrier rollers is controlled by travel switches; and the induction heating coil is formed by winding a copper tube on a stable frame which is fixed on an insulation bakelite plate through welded stainless steel bolts. According to the drawing, expanding and follow-up heating device, the heating speed and the drawing speed are synchronized; the heating speed for a workpiece is high; and the heating is uniform.

Owner:安徽宝泰特种材料有限公司

Vacuum fireproof thermal-insulating and decorating integrated wall board

InactiveCN103452262AExcellent thermal insulationAvoid the problem of hot and cold bridgesCovering/liningsThermal insulationEngineering

The invention relates to a vacuum fireproof thermal-insulating and decorating integrated wall board combined and fixed by a vacuum fireproof thermal-insulating board and a surface veneer through bolts. The vacuum fireproof thermal-insulating board is compounded by a blind core thermal-insulating layer or inorganic fireproof blind core thermal-insulating layer, a vacuum fireproof wrapping bag and inner and outer reflecting layers. The vacuum fireproof thermal-insulating layer is formed by steps of filling the blind core thermal-insulating layer into the vacuum fireproof wrapping bag, bonding the mouth of the bag, exhausting air in the vacuum fireproof wrapping bag and the blind core thermal-insulating layer to form a thermal-insulating vacuum layer, and bonding the reflecting layers to the inner side and the outer side of the vacuum fireproof wrapping bag; therefore, generation of cold and hot bridges at the board joints is avoided and thermal insulation and sound insulation effects are improved. The integrated wall board can be mounted by means of dry cladding, and can also be mounted by combination of wet combining and dry cladding, is easy to manufacture and convenient and stable in mounting, and has good fireproof thermal-insulating and decorating effects and low cost.

Owner:冯刚克

Multiple PCR reagent kit detecting breast cancer susceptibility gene mutation and preparation method thereof

ActiveCN101200766BQuick checkFast wayMicrobiological testing/measurementBreast cancer susceptibility genesBrca1 gene

The invention discloses a multiple PCR kit for detecting the eleventh exon mutation of breast cancer susceptibility gene and a preparation method thereof. The PCR amplification primers of the kit are composed of primers pair 1 which consist of SEQ ID NO:1 and SEQ ID NO:2 and primers pair 2 which consist of SEQ ID NO:3 and SEQ ID NO:4. The multiple PCR kit of the invention combines the SSCP technology with the DNA silver staining and can simultaneously screen the mutation conditions of the eleventh exon of BRCA1 gene and the eleventh exon of BRCA2 gene. The invention has the advantages of strong sensitivity, high accuracy, simple and convenient property, etc. and has important significance on the early detection and the forecast of the breast cancer.

Owner:BEIJING MOKOBIO LIFE SCI CO LTD

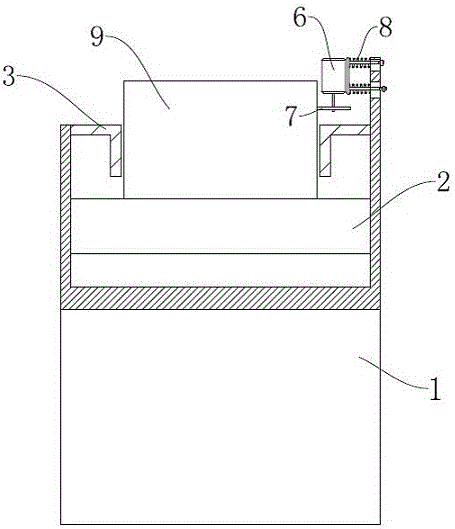

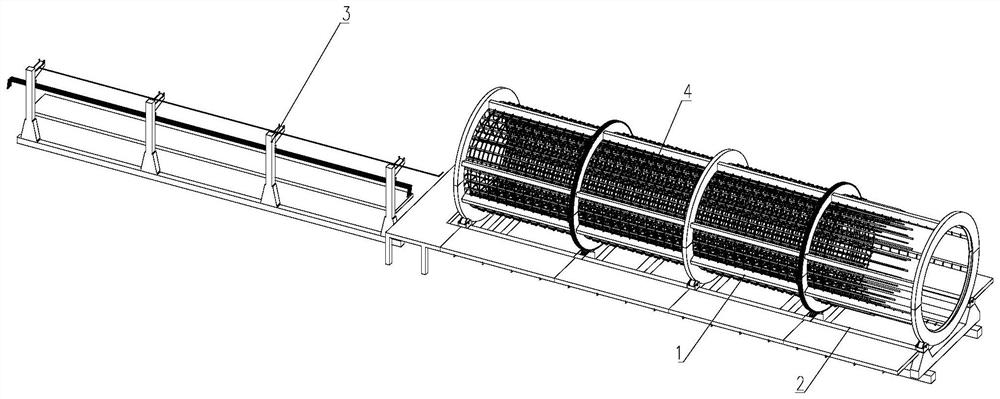

Rolling type cylindrical hollow pier reinforcement cage binding jig frame

PendingCN113732215ASimple structureEasy to manufactureWire networkBridge erection/assemblyGear wheelEngineering

The invention discloses a rolling type cylindrical hollow pier reinforcement cage binding jig frame which comprises a reinforcement cage limiting frame, a base, a vertical rib auxiliary penetrating and conveying mechanism and an electric control system. The reinforcement cage limiting frame is formed by splicing two semicircular limiting frame bodies, each limiting frame body comprises a plurality of annular toothed rails and a plurality of limiting longitudinal beams which are arranged in the circumferential direction and used for connecting the annular toothed rails into a whole in series, and a plurality of limiting grooves are formed in the limiting longitudinal beams; and a plurality of driving gears which are controlled by the electric control system to rotate are rotationally assembled on the base, and the driving gears are in one-to-one correspondence with the annular toothed rails and are in meshing transmission with the corresponding annular toothed rails. In the reinforcement cage binding process, the reinforcement cage limiting frame and a reinforcement cage can be driven by the driving gears to rotate by an angle of a vertical rib and are locked, the vertical rib does not need to be conveyed by 360 degrees in the circumferential direction around the reinforcement cage, the forming quality of the reinforcement cage is effectively assisted and controlled, and meanwhile, the convenience and safety of binding operation of the reinforcement cage are improved.

Owner:湖南五新智能科技股份有限公司

Granular active carbon regeneration method

InactiveCN110354830AImprove recycling rateAvoid complicated proceduresOther chemical processesCombustible gas purificationActivated carbonOrganic solvent

The invention discloses a granular active carbon regeneration method, which comprises: 1) cleaning, 2) acid washing, 3) drying, 4) pretreatment, 5) carbonization, 6) waste gas collecting, 7) activation, and 8) cooling. According to the present invention, before waste active carbon is carbonized and activated, the waste active carbon is washed with an organic solvent to remove small-particle organic impurities, and soaking is performed with a dilute hydrochloric acid solution to remove part of impurities, such that no impurity exists in the subsequent operation, the complicated subsequent process is avoided, and the process is simplified; the recycling rate of the obtained granular active carbon after the regeneration process of the present invention is increased compared with the regenerated active carbon in the prior art; and the heat can be reused through the heat exchanger so as to avoid the waste of energy and the environmental pollution.

Owner:南京安捷特环保科技有限公司

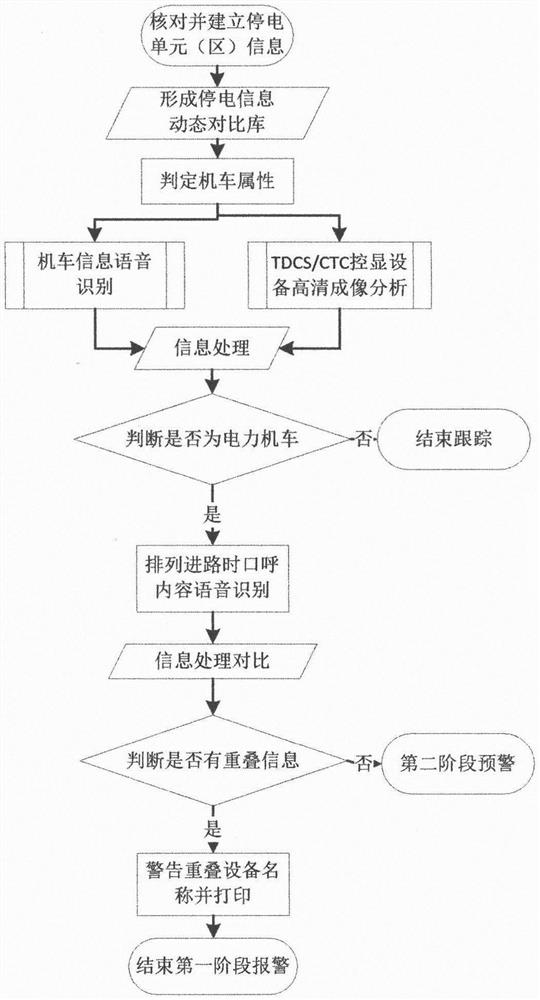

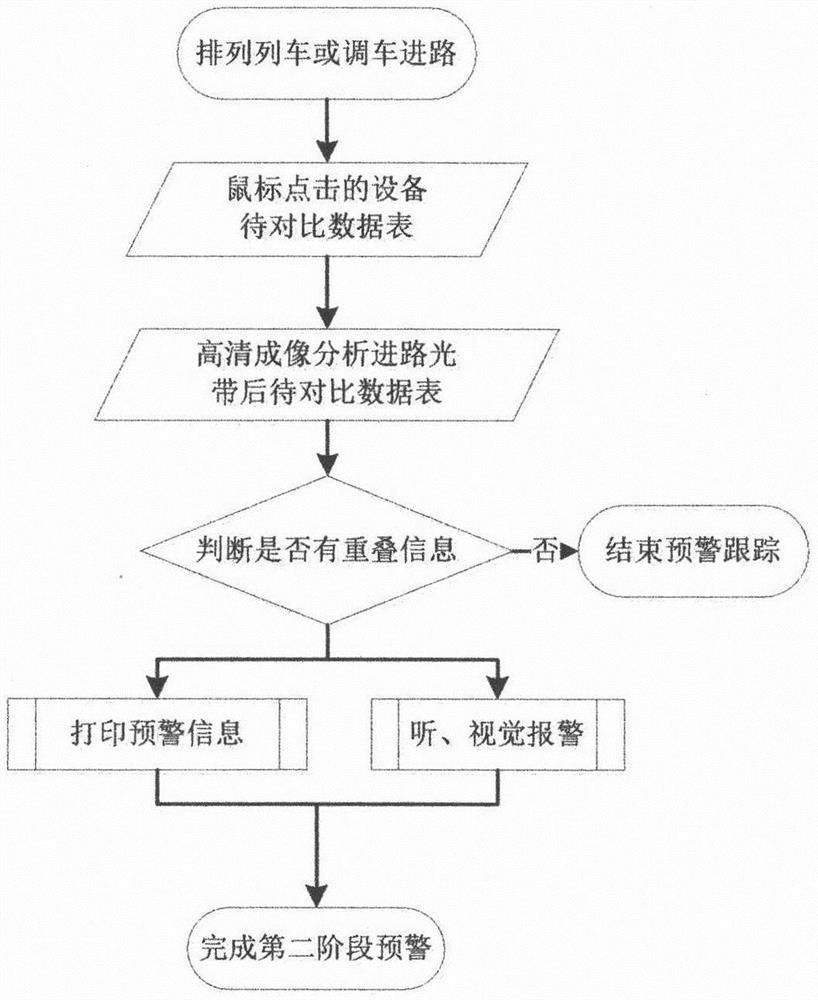

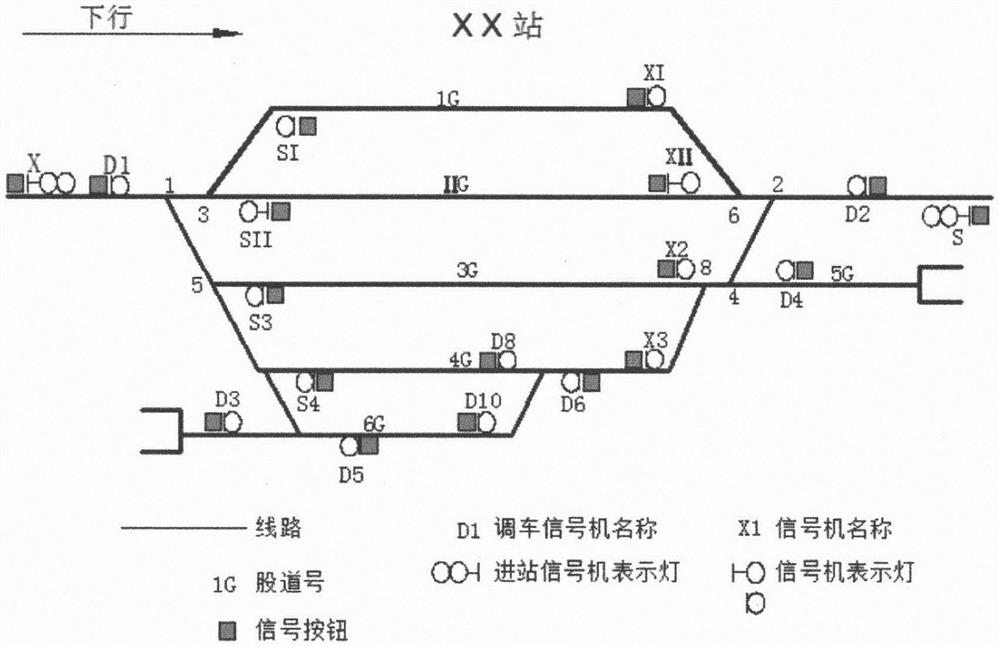

Safety control method for preventing electric locomotive from entering non-electric unit (area)

PendingCN112572540AAvoid complicated proceduresWays to achieve the purpose of early warningRailway signalling and safetySafety controlSpeech sound

The invention relates to the technical field of railway safety, and particularly discloses a safety control method for preventing an electric locomotive from entering a non-electric unit (area), whichcan be summarized into a three-element two-stage mode and comprises the following steps that: locomotive numbers and attributes obtained by handling train receiving and dispatching forecast voice recognition by an operator are obtained; the locomotive number and attributes are confirmed again by analyzing the locomotive color of TDCS / CTC control and display equipment through high-definition imaging, equipment names associated with voice recognition of the call content of the train route and the shunting route are acquired and compared with the information of a non-electric unit (area), and thus misoperation can be prevented; in the second stage, the equipment names corresponding to the screen mouse click coordinates can be obtained, the equipment names contained in the arranged access light bands on the computer interlocking interface are analyzed through high-definition imaging to be compared, wrong operation can be corrected, namely access operation is canceled, the whole process iseasy to operate, the cost is low, and the practicability is high. And errors and losses of personnel operation are greatly reduced.

Owner:NANJING INST OF RAILWAY TECH

Drug sowing apparatus

InactiveCN106912224AEffective controlAvoid the problem of respraying and complicated proceduresPlant protectionBroadcast seedersInsect diseaseDrive wheel

The invention discloses a drug sowing apparatus, belonging to the field of agricultural machinery. The drug sowing apparatus mainly overcomes the problem that seedlings sowed in fields are prone to attack by insect diseases since hill planters are mainly used in plantation of crops in the prior art. According to the invention, the frame of the drug sowing apparatus is of a rectangular structure; a sowing case is mounted on the front of the frame and is of a rectangular structure; a drug case is mounted behind the sowing case and is in the shape of a funnel; a drug liquid pipe penetrates the central part of the bottom of the drug case; the bottom of the drug liquid pipe is provided with a drug outlet; driving wheels are arranged out of two sides of the frame; the inner bottom end of the frame is provided with a pressing wheel via a rotating shaft; and a seed blanking pipe is communicated with the bottom end of the sowing case and is connected with the sowing case via welding. In use of the drug sowing apparatus, sowing and drug sprinkling are integrated into one, so insect diseases of roots are effectively prevented and treated, and the problem of complicated procedures successive sowing and drug sprinkling is overcome.

Owner:广州成航信息科技有限公司

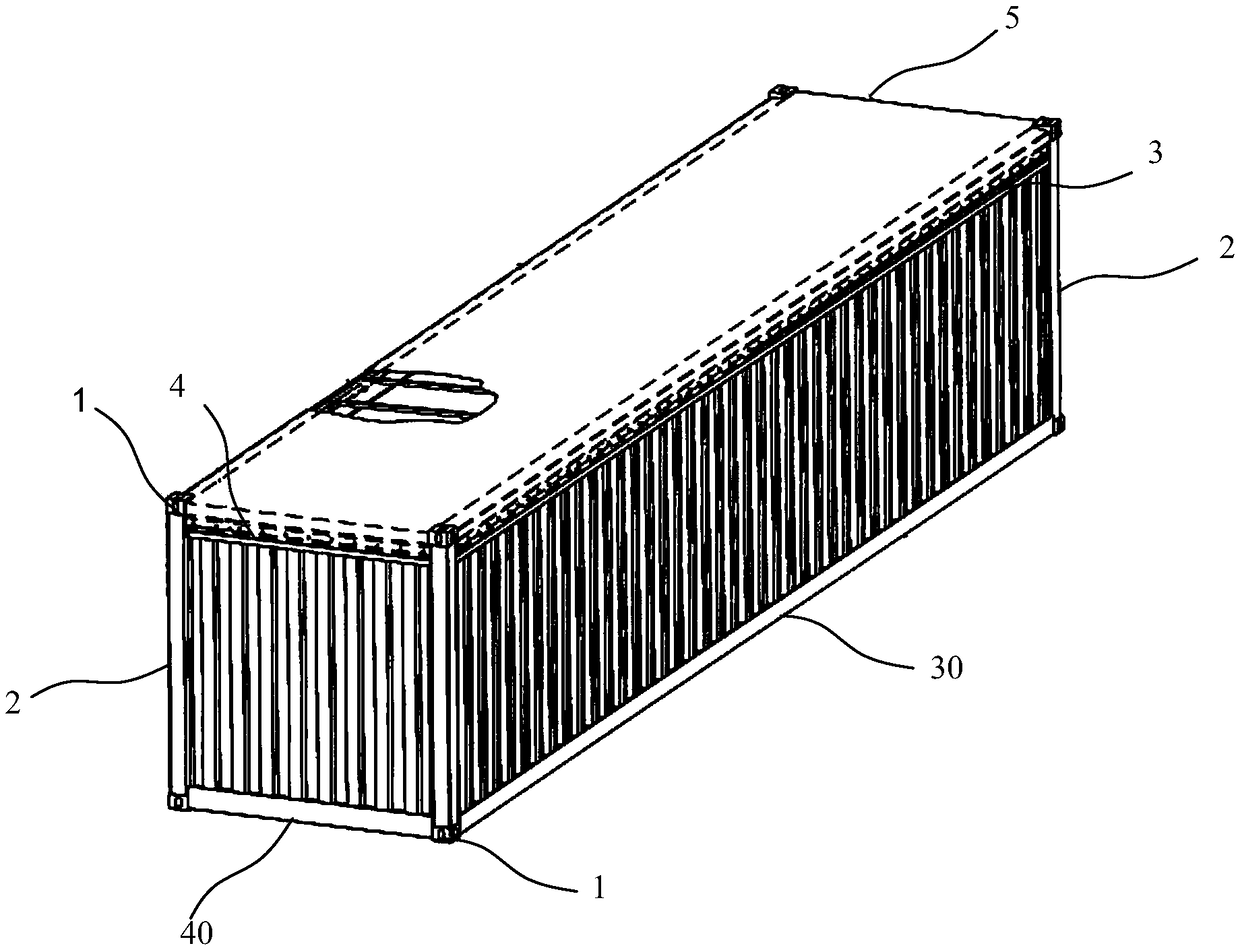

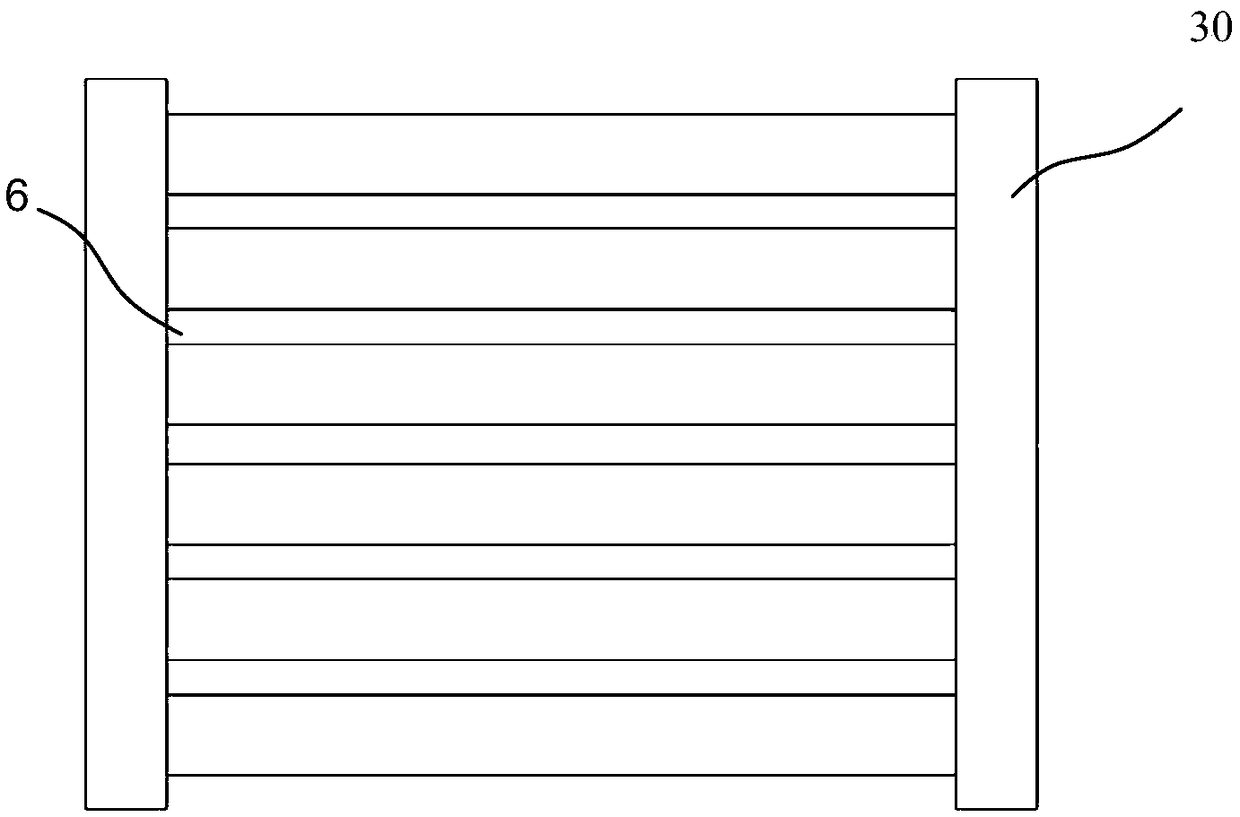

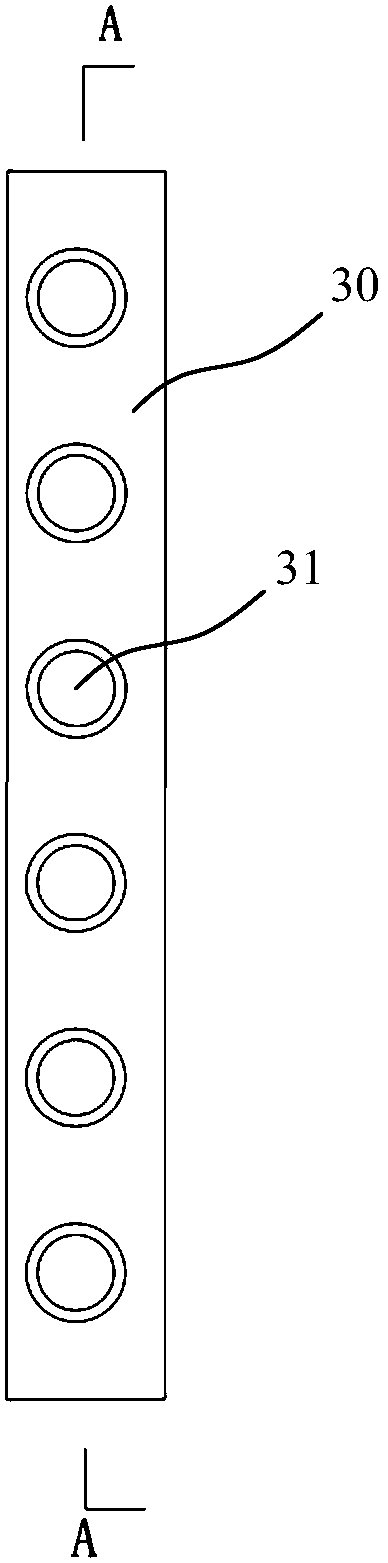

Bottom frame for container and container and container type mobile house thereof

InactiveCN108951871ARapid productionEfficient productionLarge containersBuilding constructionsEngineeringScrew thread

The invention discloses a bottom frame for a container and the container and a container type mobile house thereof. The bottom frame for the container includes a lower end beam, a lower door beam, twobottom side beams and multiple bottom cross beams. The lower end beam, the lower door beam, and the two bottom side beams are connected to form an outer frame of the bottom frame, the bottom cross beams are connected between the bottom side beams in a crossing mode. The bottom frame for the container is characterized in that the bottom cross beams are spirally connected with the bottom side beams, multiple first grooves or first protrusions are formed in the bottom side beams, internal threads are formed in the first grooves, and external threads are formed on the outer sides of the first protrusions; and external threads matched with the first grooves are formed on the end portions of the bottom cross beams, or cavities are formed in the end portions of the bottom cross beams, internal threads matched with the first protrusions are formed in the cavities. The bottom frame for the container improves the working efficiency of the container, greatly reduces industrial pollution, and reduces energy consumption.

Owner:邵妮

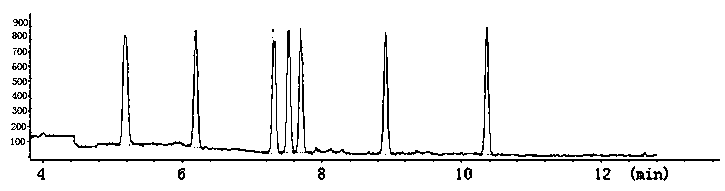

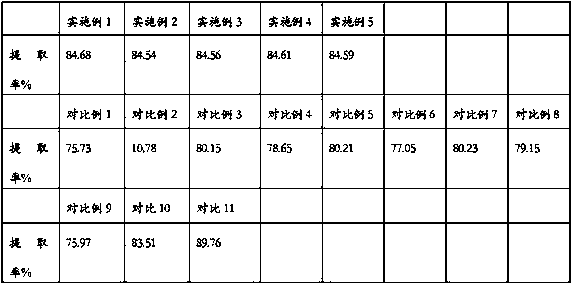

Extraction method of geranium oil

PendingCN110129124AHigh extraction rateSolve environmental problemsFatty-oils/fats productionYeastOrganic solvent

The invention belongs to the technical field of plant spice extraction, and particularly relates to an extraction method of geranium oil. The method comprises the following steps: (1) selecting stemsand leaves of Pelargonium roseum Ait. as raw materials; (2) smashing the stems and leaves into paste; (3) performing enzymolysis; (4) adding yeast powder for treatment; (5) performing high temperaturetreatment; (6) performing emulsification and homogenization; (7) performing ultrasonic treatment; (8) performing concentration; and (9) performing distillation. By adopting the method for extractingthe geranium oil, the extraction rate of the geranium oil is obviously increased, and the method adopts an enzymolysis mode with mild reaction conditions, thereby overcoming the environmental problemscaused by the traditional organic solvent extraction method and avoiding complicated procedures caused by subsequent recovery or treatment of an organic solvent.

Owner:QINGDAO UNIV OF SCI & TECH

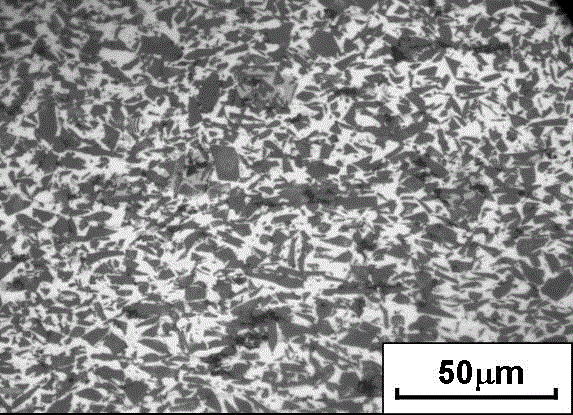

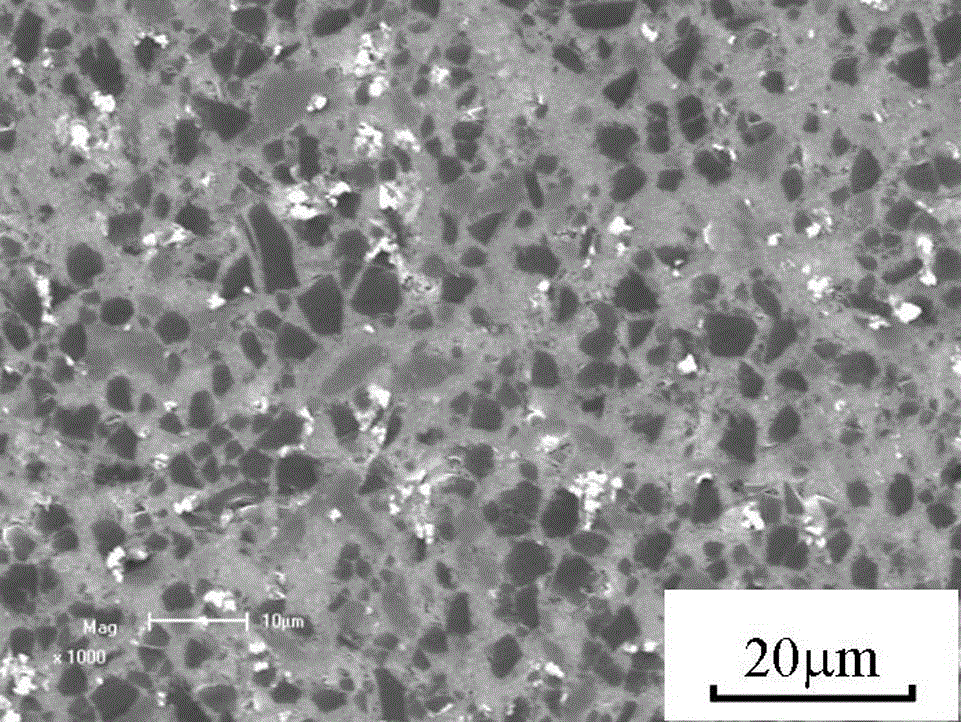

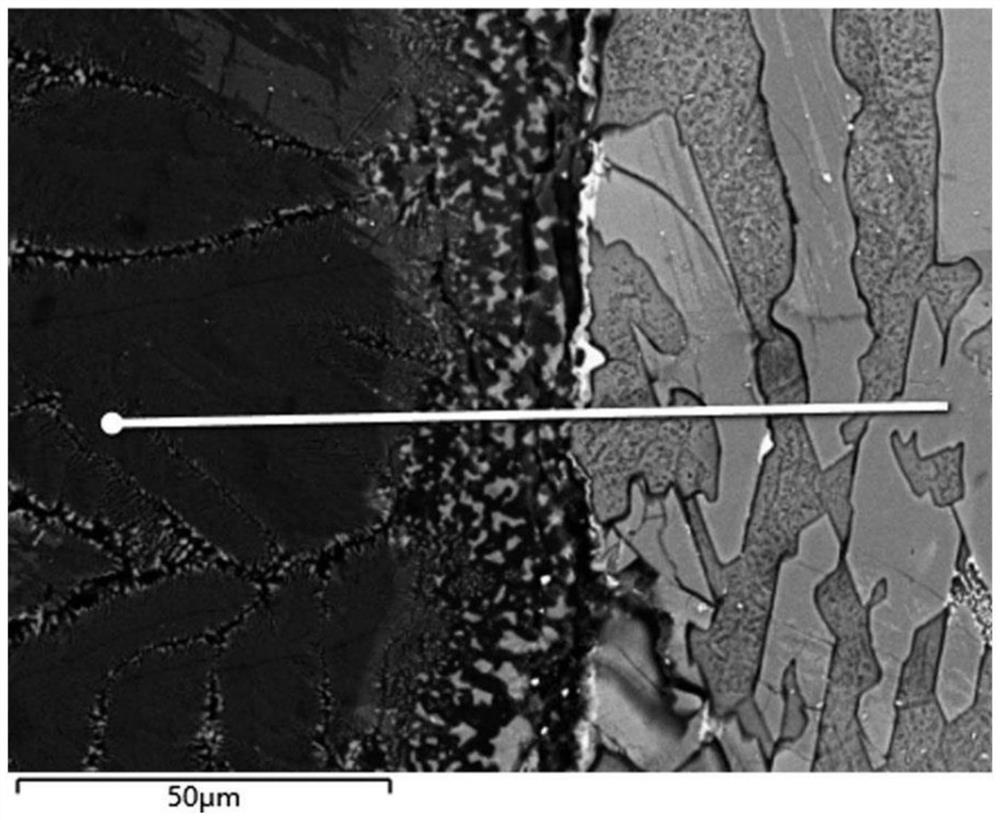

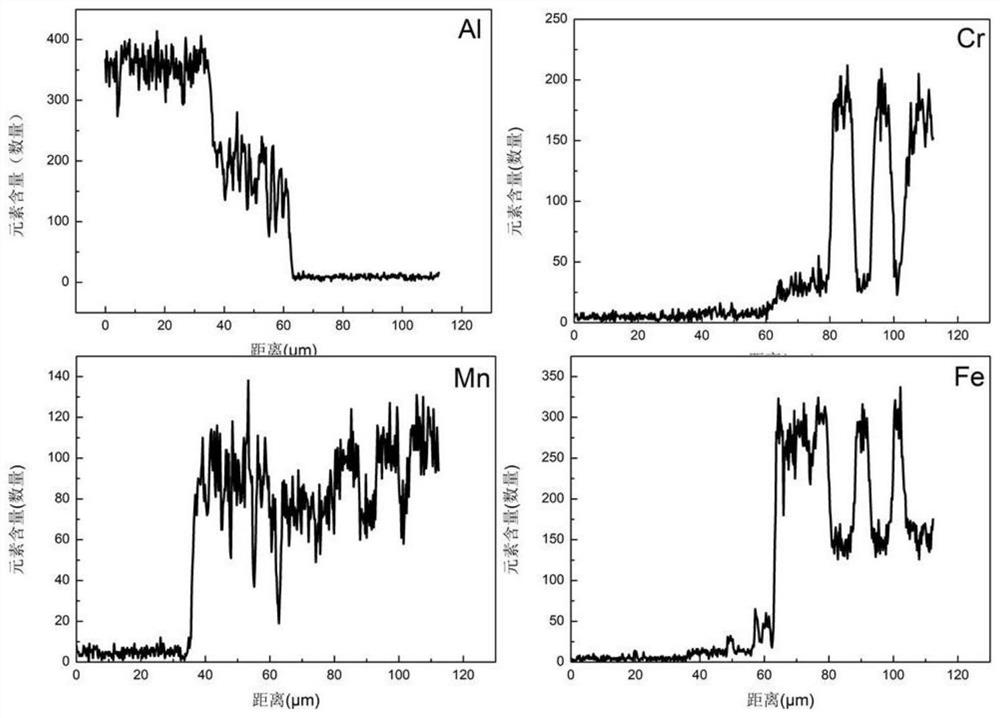

ZTA ceramic particles coated with aluminothermic reduction reaction powder as well as preparation method and application of ZTA ceramic particles

PendingCN114406258AEnhanced metallurgical interfacial bondingImprove bindingGrain treatmentsMetal matrix compositeWear resistance

The invention discloses aluminothermic reduction reaction powder coated ZTA ceramic particles and a preparation method and application thereof, and belongs to the field of metal-based composite materials and wear-resistant materials. The aluminothermic reduction reaction powder coated ZTA ceramic particles are of a ZTA ceramic particle / aluminothermic reduction reaction powder core-shell structure, metallized ZTA ceramic particles obtained by conducting self-propagating sintering on the aluminothermic reduction reaction powder coated ZTA ceramic particles are combined with an alloy matrix, and the wear-resistant composite material is prepared. The prepared wear-resistant composite material is used as a part of a wear-resistant part and is combined with an application part (a roller mill roller sleeve, a vertical mill roller or a lining plate), so that the wear resistance of equipment is improved. Through the improvement of the preparation method, an interface with the width of 20-50 microns can be formed between the ZTA ceramic particles and the matrix, and the wear resistance of the wear-resistant composite material can be remarkably improved through the formation of the interface.

Owner:华清平耐磨科技(苏州)有限公司

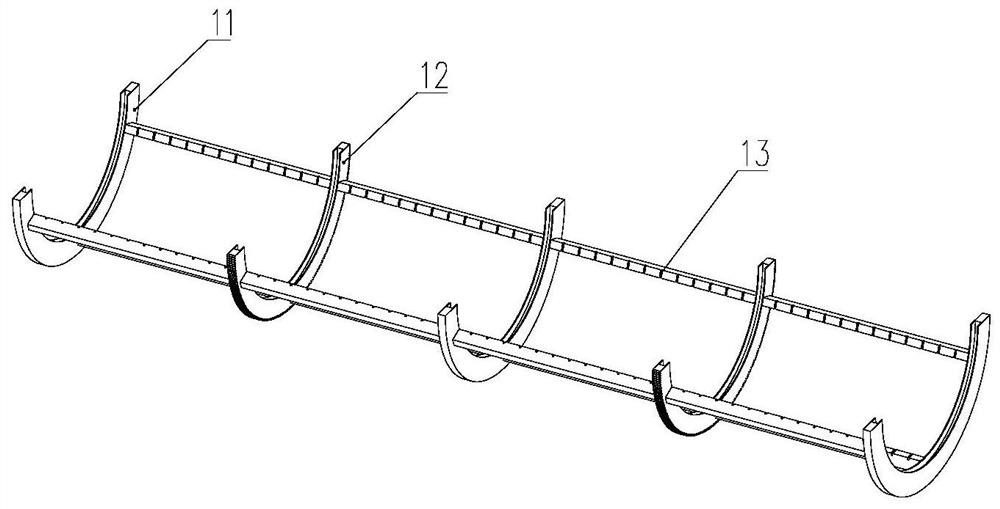

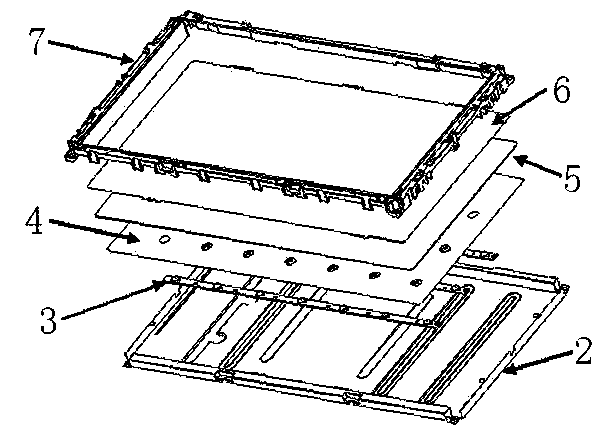

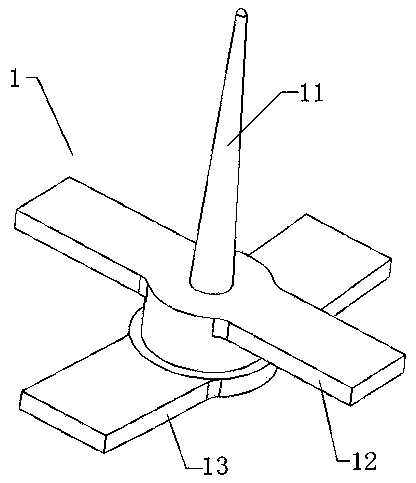

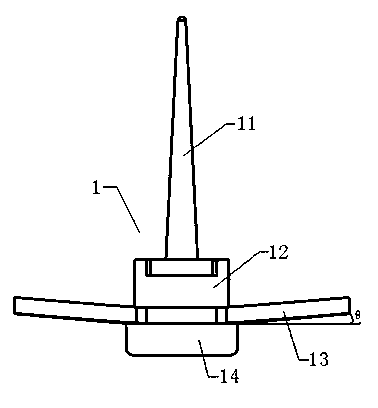

Support and direct-lit LED backlight module with same

InactiveCN103697420ASimple structureEasy to installPoint-like light sourceLight fasteningsEngineeringLED lamp

The invention discloses a support. The support (1) comprises a diffuser push rod (11), an upper clamping structure (12) and a lower clamping structure (13). The diffuser push rod (11) is disposed above the upper clamping structure (12), the upper clamping structure (12) is disposed above the lower clamping structure (13), the upper clamping structure (12) and the lower clamping structure (13) are crossed, and the upper clamping structure (12) is shorter or narrower than the lower clamping structure (13). During use, an LED light bar base plate (3) is mounted in a light bar accommodating position at the back of a back plate (2), the upper clamping structure (12) penetrates the LED light bar base plate (3) and the back plate (2), and then the upper clamping structure (12) and the lower clamping structure (13) fix the LED light bar base plate (3) on the back plate (2) by turning the support (1). The support is simple in structure, and the backlight module with the same has the advantage that a light source can be detached easily and rapidly so as to be changed.

Owner:NANJING CEC PANDA LCD TECH

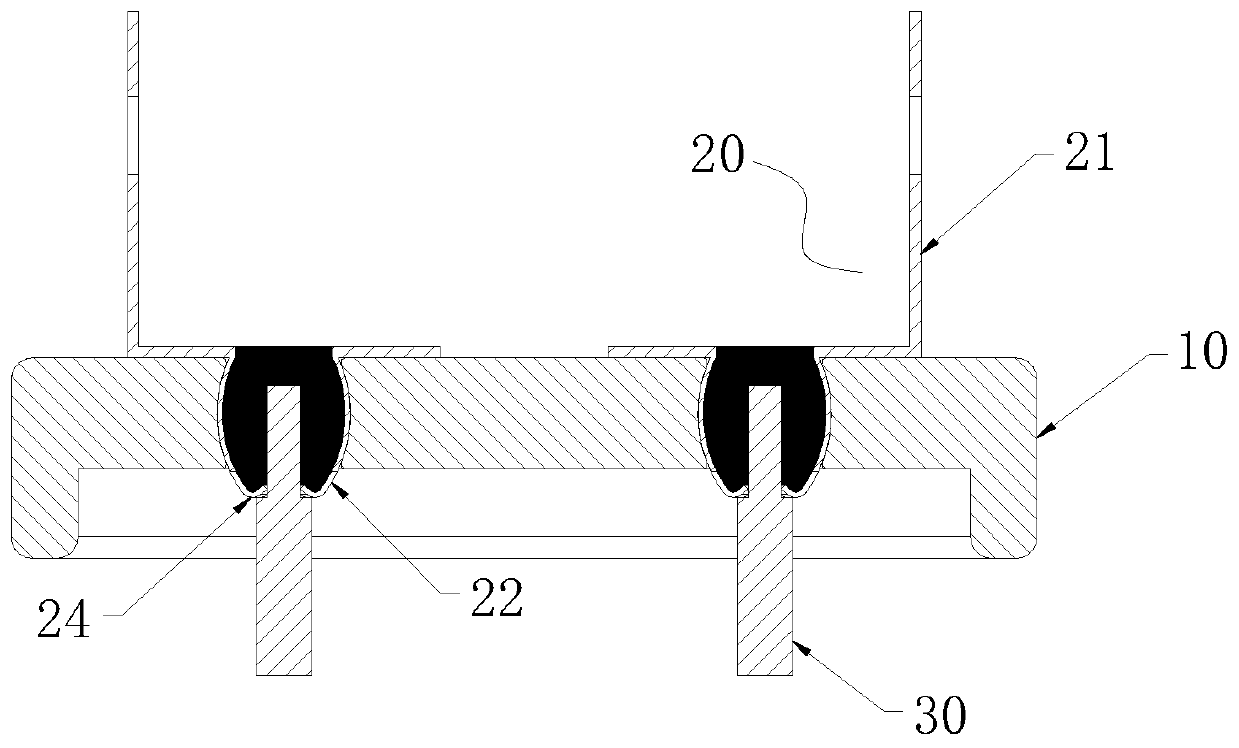

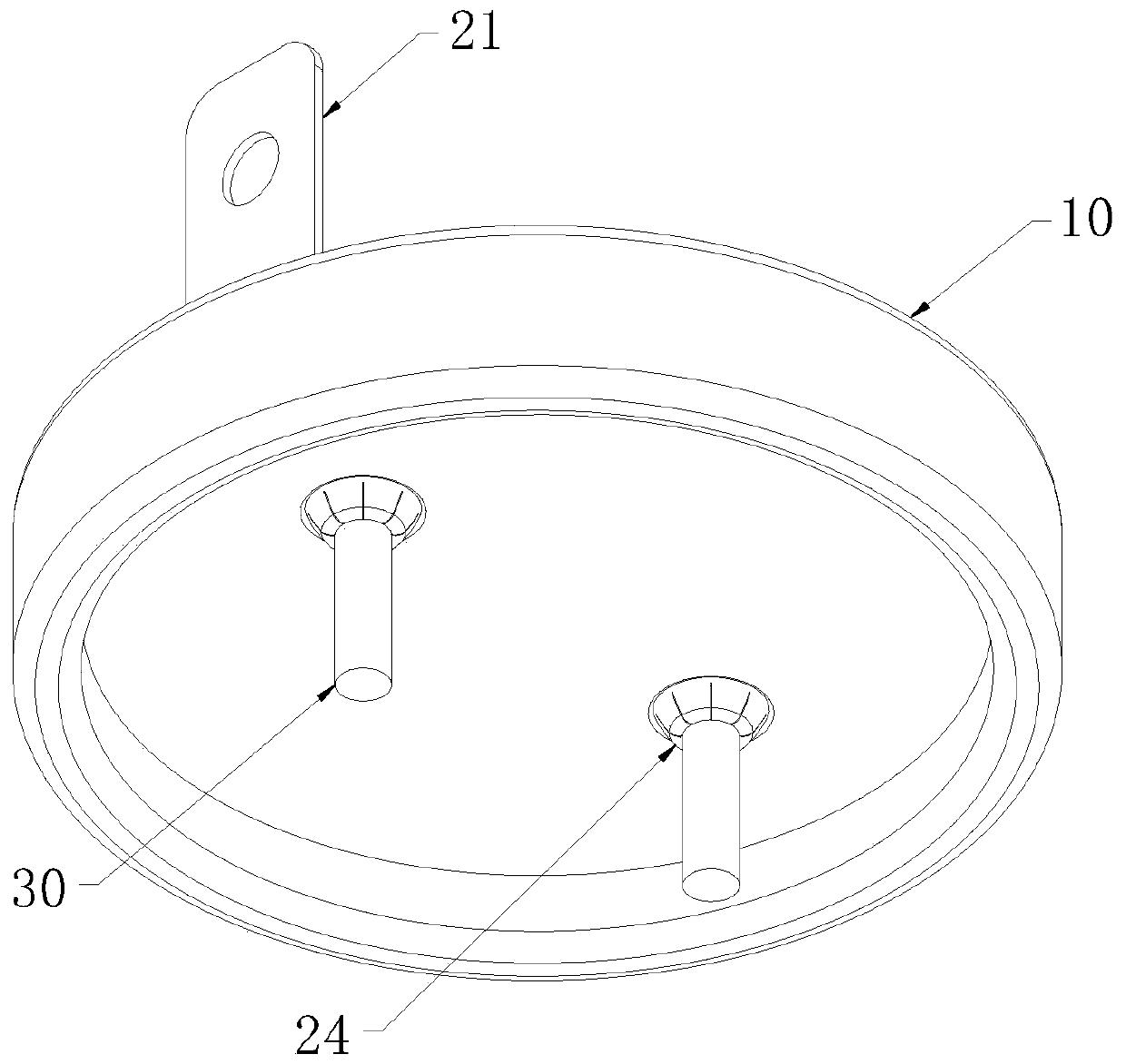

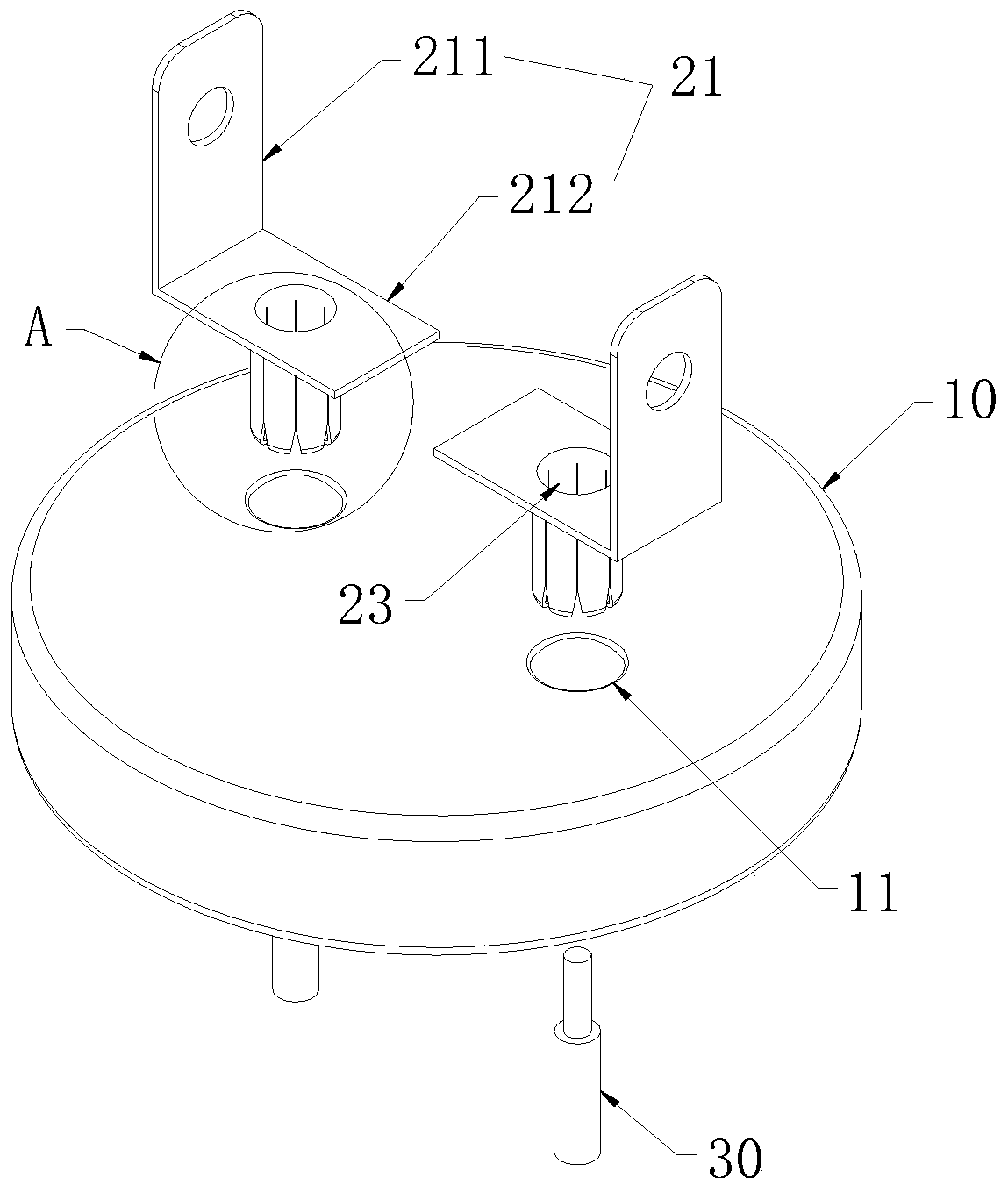

Capacitor insulation terminal cover

ActiveCN110571053AImprove welding efficiencyAvoid the problem of easy falling off from both ends of the connecting barrelFixed capacitor housing/encapsulationFixed capacitor terminalsSolderingEngineering

The invention discloses a capacitor insulation terminal cover, which comprises a cover plate, a wiring terminal and a power line, wherein the wiring terminal comprises an L-shaped wiring part and a connecting cylinder, the connecting cylinder is in a waist drum shape with a thick middle part, the cover plate is provided with a connecting hole, the connecting hole is in the shape of a waist drum identical to that of the connecting cylinder, the wiring part comprises a vertical part connected with an external wire and a horizontal part connected with the connecting cylinder, the horizontal partis provided with a tin soldering hole coaxial with the connecting cylinder, and the bottom end of the connecting cylinder is provided with a bending part extending towards the center of the connectingcylinder; and the conductive core body of a power line penetrates through the bending part and extends into the connecting cylinder, and the conductive core body of the power line and the connectingcylinder are fixed through tin soldering filing. According to the capacitor insulation terminal cover, the problem that the tin soldering part is easy to fall off from the two ends of the connecting cylinder after being aged can be avoided; the conductive core body of the power line is fixed through the bending part, so that the complicated process of auxiliary fixing of the power line is avoided,and the welding efficiency is improved.

Owner:ANHUI SAFE ELECTRONICS

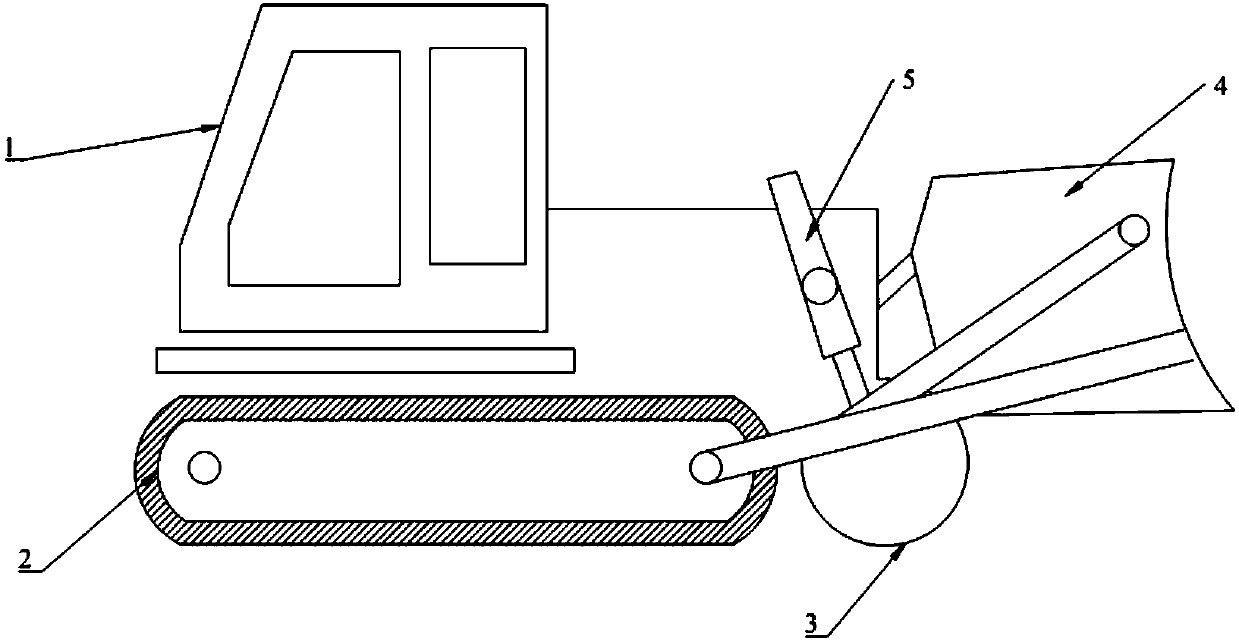

Road rolling and bulldozing integrated machine

InactiveCN107558333AAvoid rolling and complicated processesAvoid complicated proceduresMechanical machines/dredgersRoads maintainenceEngineeringRoad surface

The invention discloses an all-in-one machine for rolling and bulldozing, which belongs to the field of mechanical equipment and mainly solves the problem that the current road roller is mainly used for compacting the road surface. For the bulldozing operations of building, road building and dam building, the soil needs to be pushed away by the bulldozer first. Afterwards, it is operated by a road roller, which cannot meet people's demand for high efficiency. The cab is installed on the frame as a whole, and the bottom of the cab is equipped with a running device. Installed on the frame, the left and right sides in front of the traveling device are provided with connecting rods, the connecting rods are equipped with bulldozing blades through pin shafts, and the right side of the bulldozing blades is equipped with elevating rods. In the present invention, the road roller and bulldozer are integrated, and the bulldozer can be used simultaneously for bulldozing and rolling during use, which avoids the problem that the bulldozer bulldozes the soil separately, and then is rolled by the road roller. complete, high work efficiency.

Owner:朱英

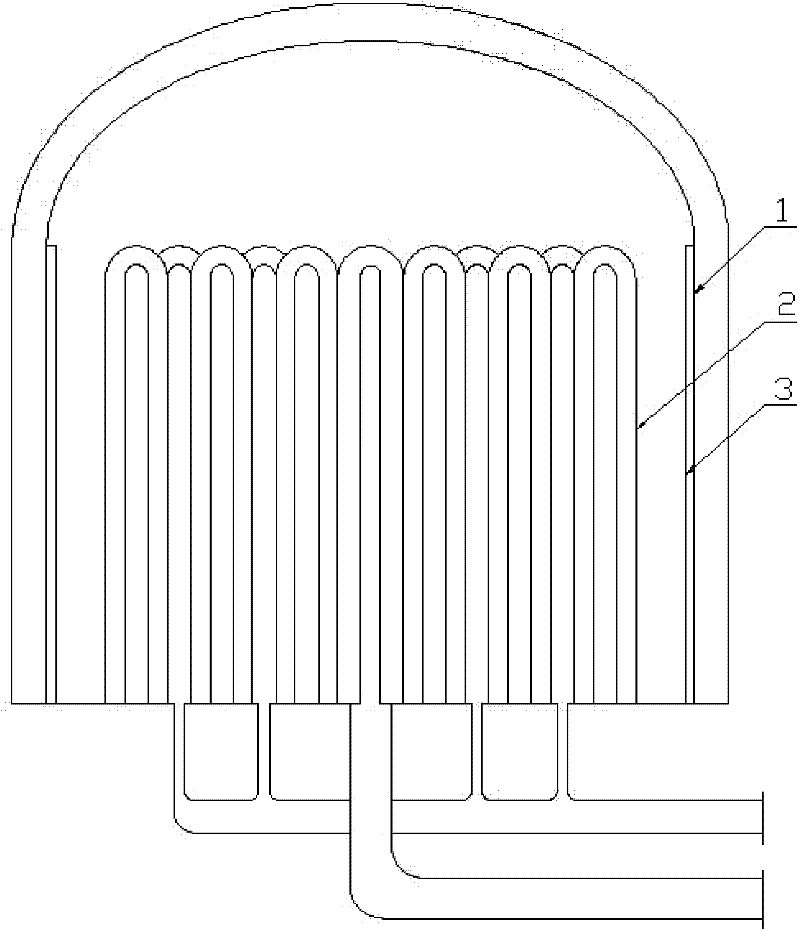

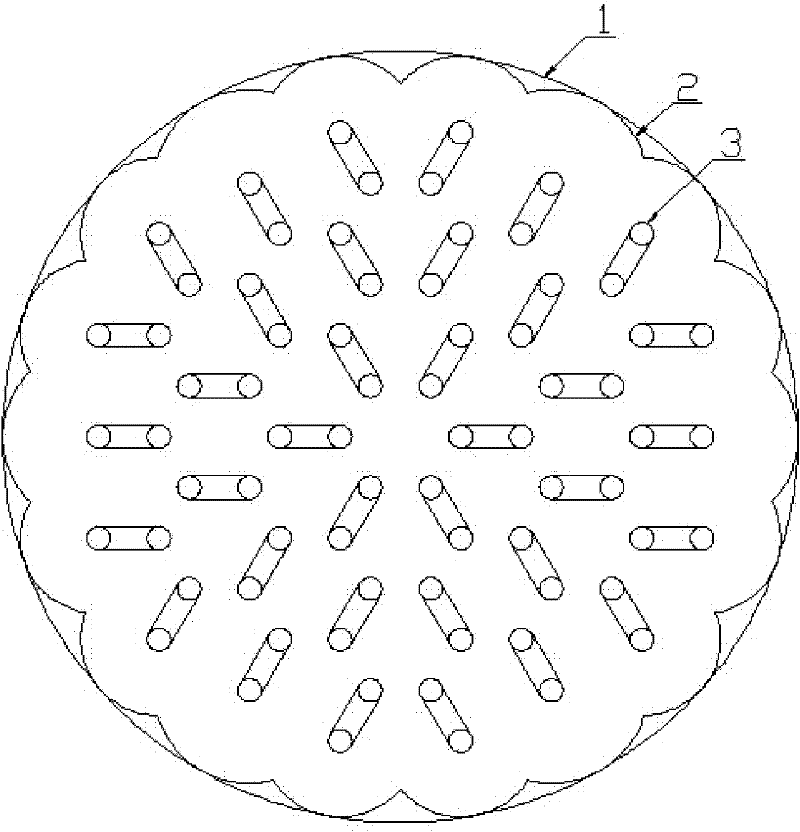

Polysilicon reduction furnace with concave mirror surfaces on inner wall and concave mirror surfaces for polysilicon reduction furnace

InactiveCN102211772ATake advantage ofReduce energy lossMirrorsSilicon compoundsEnergy lossPolycrystalline silicon

The invention discloses a polysilicon reduction furnace with concave mirror surfaces on an inner wall and the concave mirror surfaces for the polysilicon reduction furnace. The reduction furnace is characterized in that the concave mirror surfaces with a high polishing degree are installed on the inner wall of the reduction furnace; various concave mirror surfaces are tightly adjacent in turn andare fixed on the inner wall of the furnace body through bolts; the number of the installed mirror surfaces is equal to that of silicon rods at the outermost ring inside the furnace, the mirror surfaces are in one-to-one correspondence with the silicon rods at the outermost ring, and the axis of the concave surface of the mirror surface is coincided with the axis of the silicon rod corresponding to the mirror surface. Through the concave mirror surfaces with the high polishing degree, the energy which is radiated to the inner wall of the furnace body by virtue of the high temperature silicon rod is reflected back to the inside of the furnace, and the reflected energy is focused on the silicon rod, thus by using a photospot technique, the energy loss caused by the high temperature radiationof the silicon rod is further reduced on the basis of polishing the inner wall of the furnace body, and a complicated process that multi-polishing is carried out on the inner wall of the furnace bodyis avoided, thereby greatly reducing the production cost of the polysilicon reduction furnace.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com