Capacitor insulation terminal cover

A technology for insulating terminals and capacitors, applied in the field of capacitors, can solve the problems of weak welding, large power supply creepage distance, falling off or virtual welding, etc., and achieve the effect of improving welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

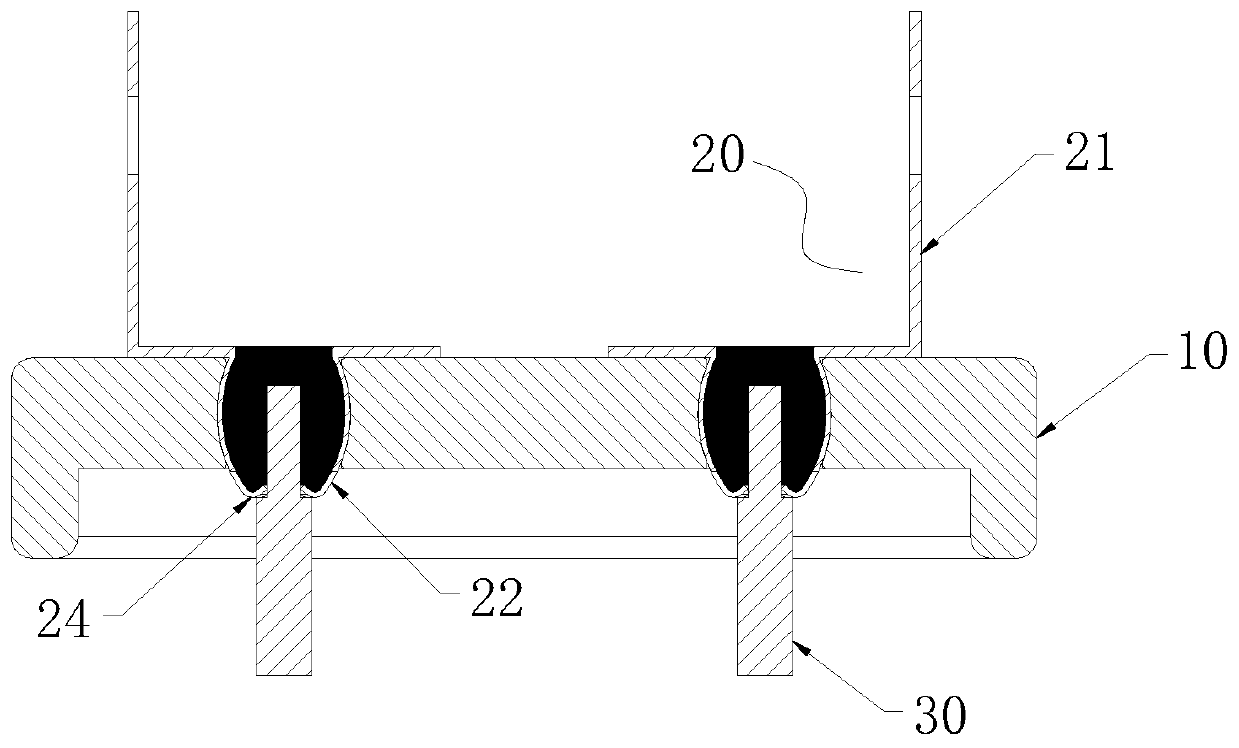

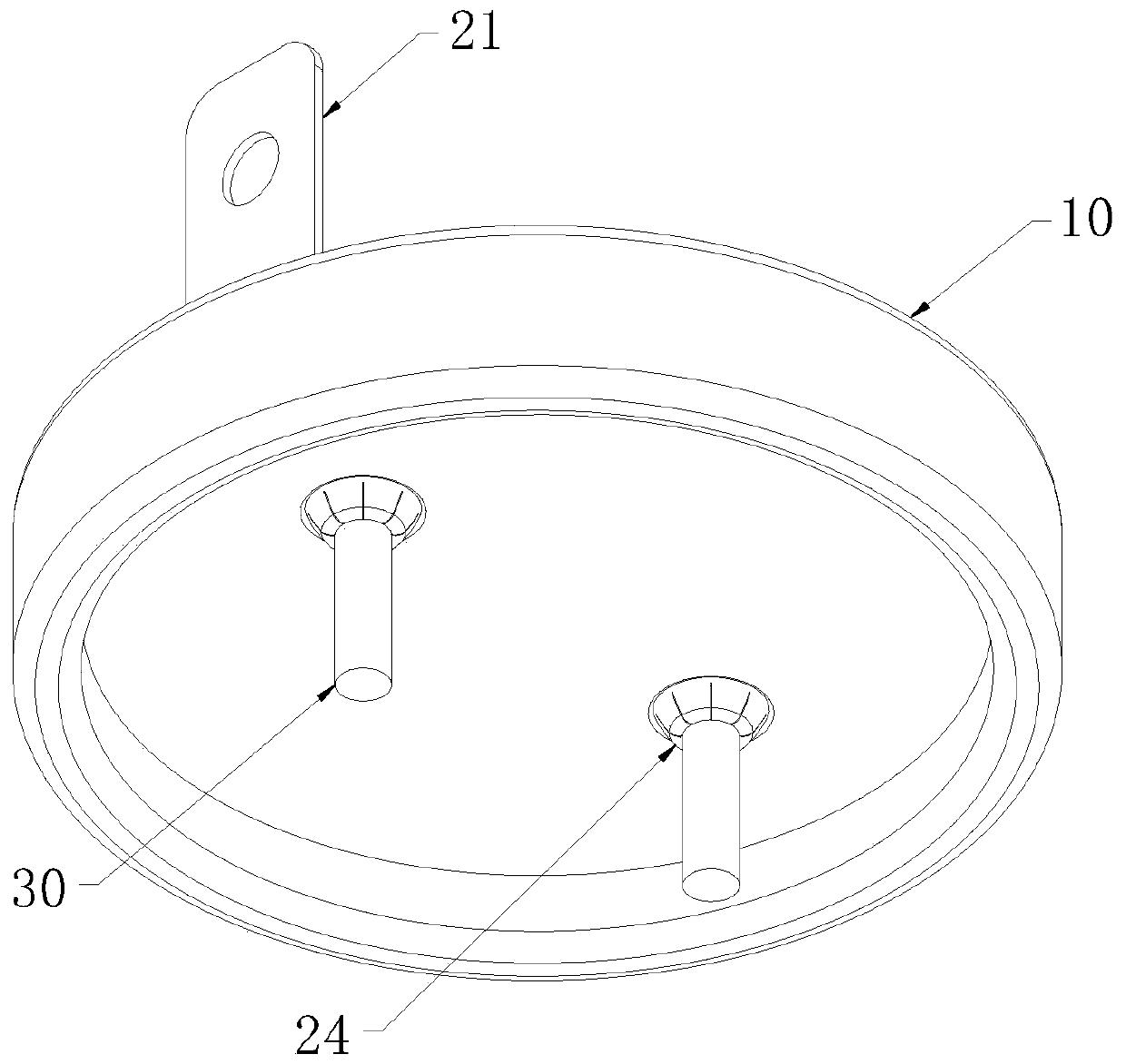

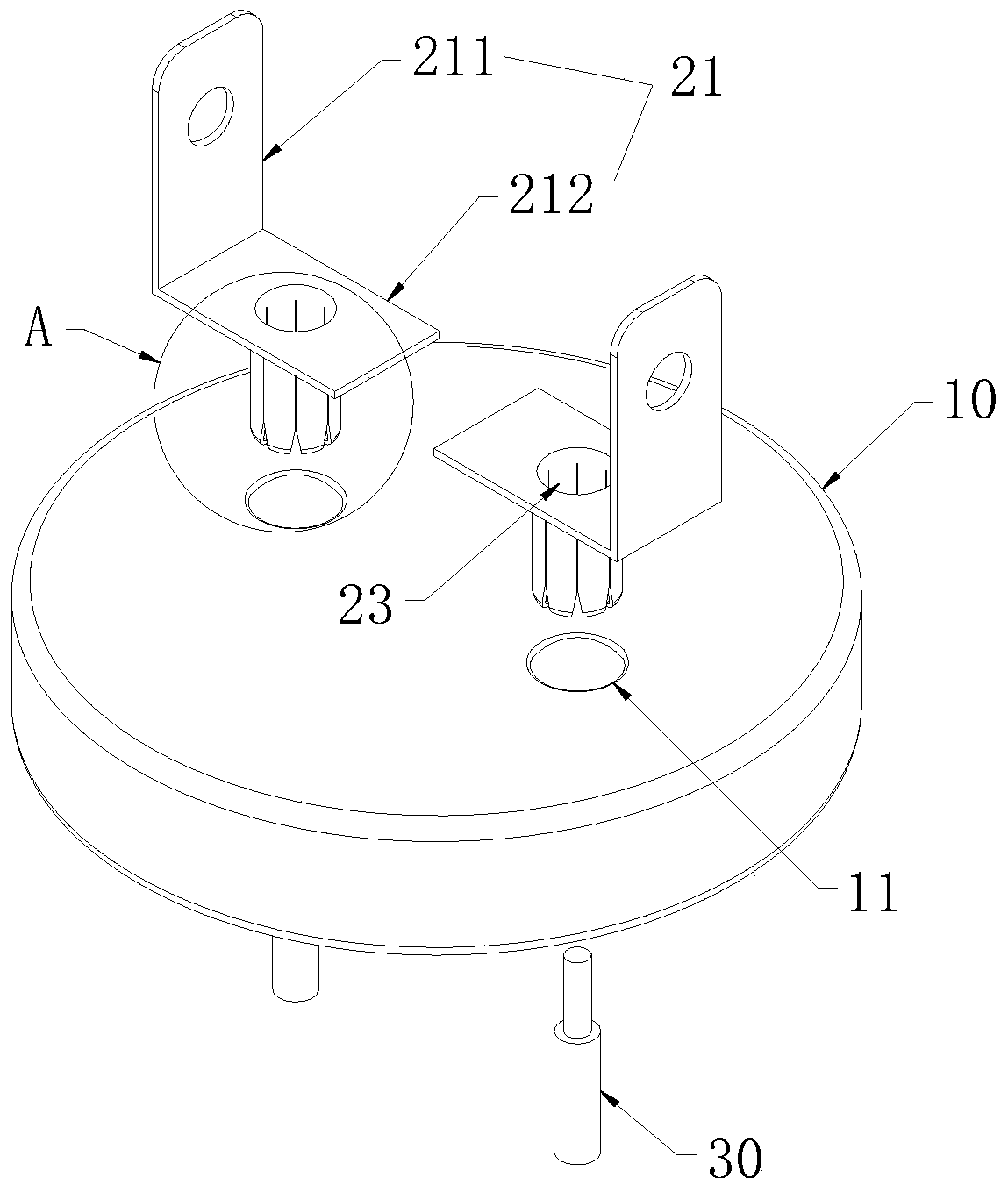

[0018] Such as Figure 1~3 As shown, the capacitor insulated terminal cover includes a cover plate 10 made of insulating material, a terminal 20 and a power line 30 arranged in the capacitor case. The connecting cylinder 22 at the bottom of the part 21, the connecting cylinder 22 is in the shape of a thick waist drum in the middle, the cover plate 10 is provided with a connecting hole 11 for inserting the connecting cylinder 22, and the connecting hole 11 is in the shape of the connecting cylinder 22 The same drum shape, the wiring part 21 includes a vertical part 211 connected to the external wire and a horizontal part 212 connected to the connecting cylinder 22, the horizontal part 212 is provided with a soldering hole coaxially arranged with the connecting cylinder 22 23. The bottom end of the connection cylinder 22 is provided with a bending portion 24 extending toward the center of the connection cylinder 22; the conductive core of the power cord 30 extends into the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com