Extraction method of geranium oil

An extraction method and geranium oil technology are applied in the directions of fat oil/fat production, fat generation, etc., which can solve problems such as organic solvent residues and safety problems, and achieve the effect of increasing the extraction rate of geranium leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

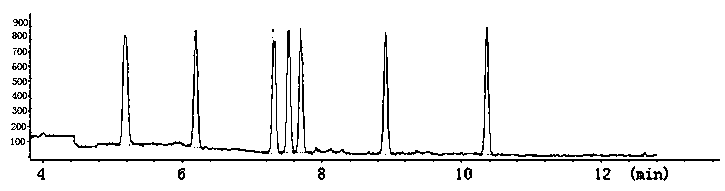

Image

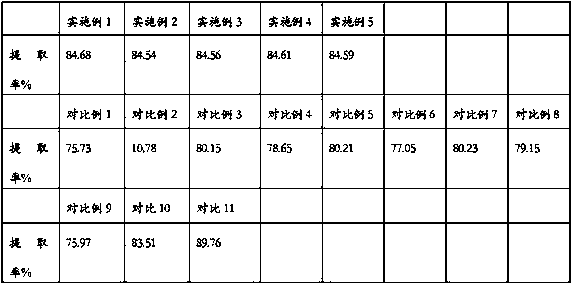

Examples

Embodiment 1

[0048] (1) In June, take the stems and leaves of Pelargonium geranium, wash and dry them, then cut the stems of geranium geranium into sections, and cut the leaves of geranium geranium into an area of 1-4cm 2 small pieces of

[0049] (2) Add the segmented geranium geranium stems and small pieces of geranium geranium leaves in (1) into water, the solid-liquid weight ratio of geranium geranium stems and geranium geranium leaves to water is 1:3, smash into a paste;

[0050] (3) Adjust the temperature of the pasty material to 50°C, add cellulase to the material in an amount of 0.3% of the total weight of the pasty material, enzymatically hydrolyze for 30 minutes, and inactivate the enzyme at 95°C for 9 minutes;

[0051] (4) Add yeast powder to the enzymolysis solution in (3), the amount added is 0.3% of the weight of the enzymolysis solution; keep at 40°C for 20 minutes;

[0052] (5) Keep the raw materials in (4) at 100°C for 15 minutes;

[0053] (6) Place the material in (5)...

Embodiment 2

[0063] On the basis of Example 1, continue to step (10), add activated carbon to the geranium oil in (9), heat to 55° C., stir at a speed of 30 r / min, and filter to obtain geranium oil.

Embodiment 3

[0065] (1) In May, take the stems and leaves of Pelargonium geranium, wash and dry them, then cut the stems of geranium geranium into sections, and cut the leaves of geranium geranium into an area of 1-4cm 2 small pieces of

[0066] (2) Add the segmented geranium geranium stems and small pieces of geranium geranium leaves in (1) into water, the solid-to-liquid weight ratio of geranium geranium stems and geranium leaves to water is 1:2, smash into a paste;

[0067] (3) Adjust the temperature of the pasty material to 55°C, add cellulase to the material in an amount of 0.2% of the total weight of the pasty material, enzymatically hydrolyze for 40 minutes, and inactivate the enzyme at 95°C for 9 minutes;

[0068] (4) Add yeast powder to the enzymolysis solution in (3), the amount added is 0.2% of the weight of the enzymolysis solution, and keep at 40°C for 20 minutes;

[0069] (5) Keep the raw materials in (4) at 100°C for 15 minutes;

[0070] (6) Place the material in (5) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com