Polysilicon reduction furnace with concave mirror surfaces on inner wall and concave mirror surfaces for polysilicon reduction furnace

A reduction furnace and polysilicon technology, applied in the direction of mirrors, silicon compounds, inorganic chemistry, etc., can solve the problems of increasing the complexity of production operations and increasing production costs, and achieve the effects of avoiding complicated procedures, reducing energy loss, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below according to accompanying drawing:

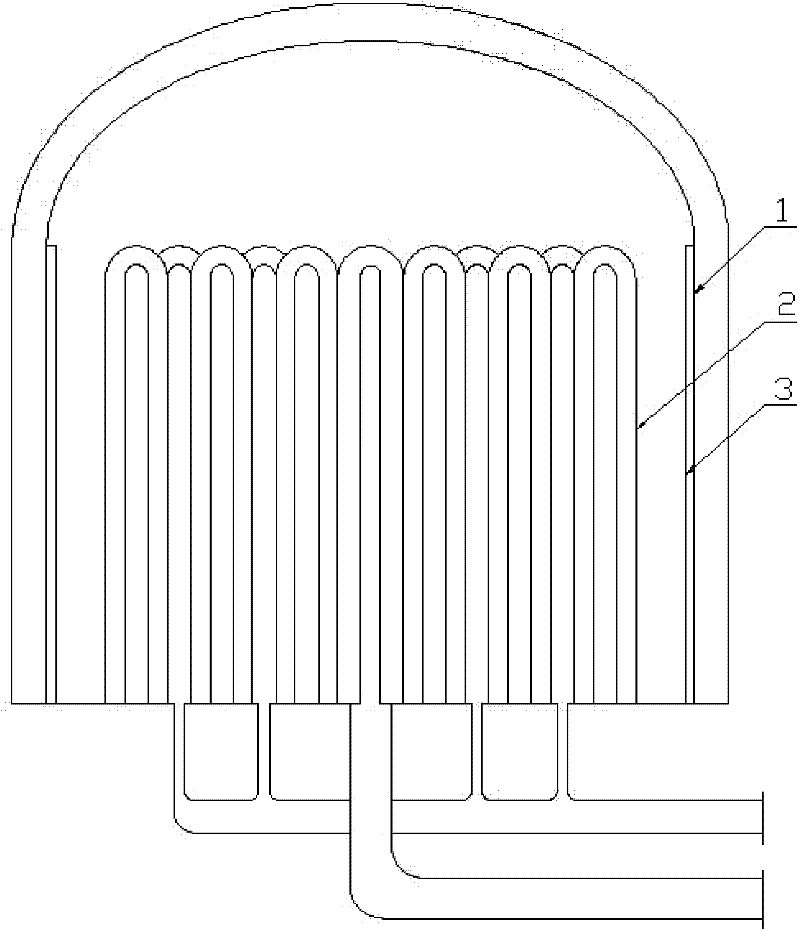

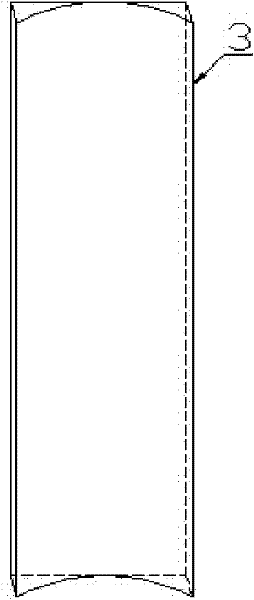

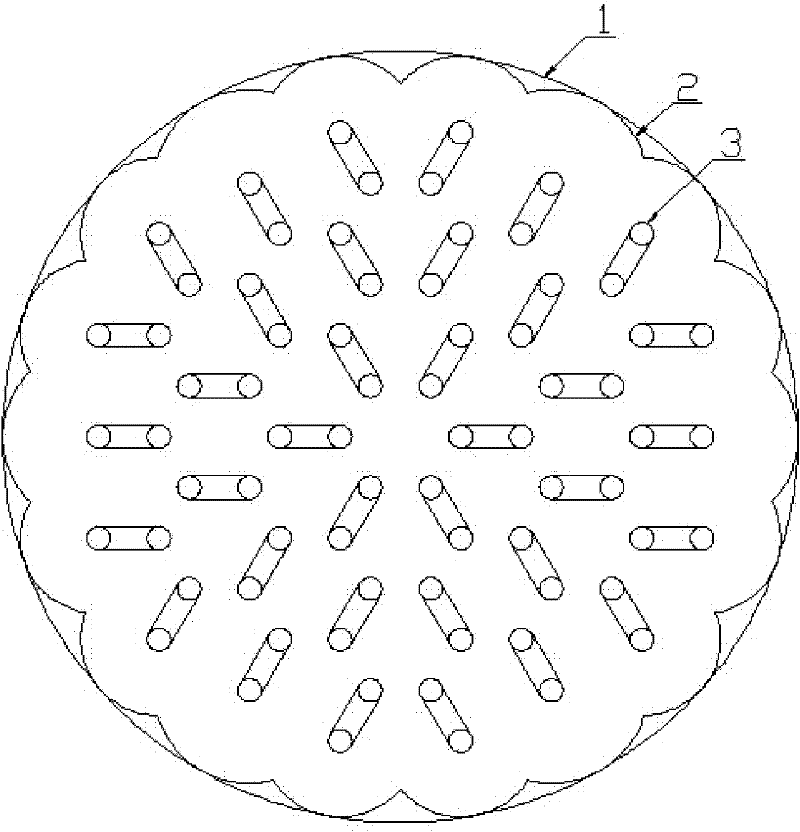

[0023] Such as figure 1 , image 3 As shown, the polysilicon reduction furnace with concave mirrors installed on the inner wall of the present invention has highly polished concave mirrors 3 installed on the inner wall 1 of the furnace, and the degree of polishing can reach Ra0.008 μm. Bolts are fixed to the inner wall of the furnace. Weld the bolts to the appropriate position on the inner wall of the furnace, and at the same time open bolt holes on the corresponding positions of the concave mirrors, and fix the concave mirrors on the inner wall of the reduction furnace by connecting bolts and nuts during installation. The number of concave mirrors 3 installed on the inner wall of the furnace should be equal to the number of silicon rods 2 in the outermost ring in the furnace. The location coincides. Such as figure 2 As shown, one side of the mirror surface 3 is fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com