Femtosecond laser direct writing preparation method of two-dimensional submicron butterfly-shaped metal microstructure

A technology of metal microstructure and femtosecond laser, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of multiple procedures and complicated process, and achieve the goal of simple process, simple technical method and overcoming complicated procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

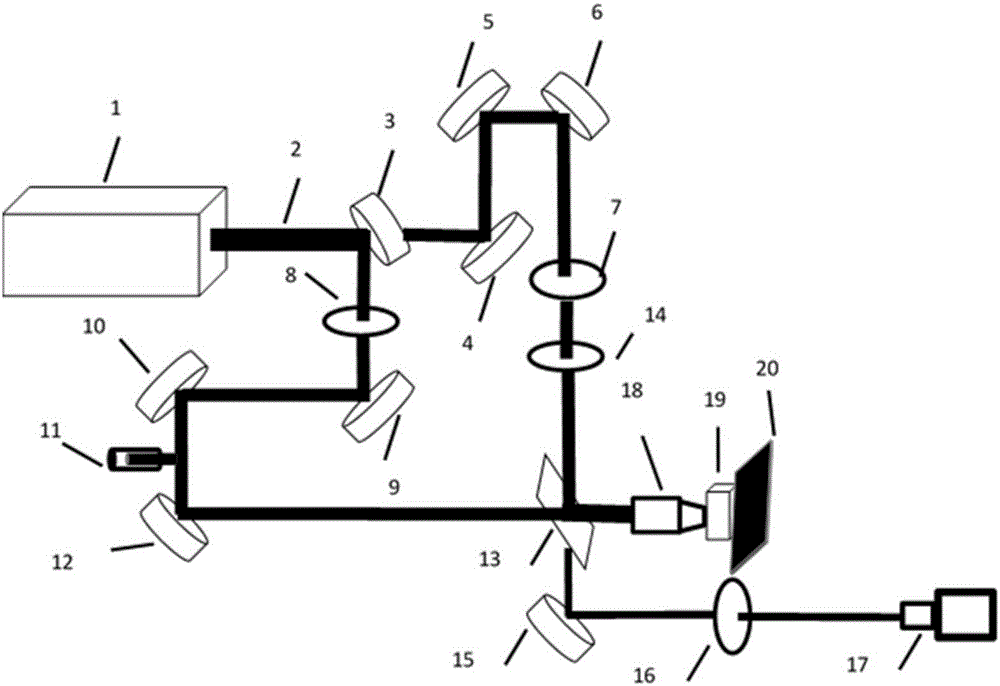

[0040] Such as figure 1 As shown, the femtosecond laser 2 with a center wavelength of 800 nanometers and a pulse width of 50 femtoseconds is output from the laser amplifier 1, and the vibration direction of the outgoing femtosecond laser is along the horizontal direction, which is a linearly polarized laser. Through the semi-transparent and semi-reflective lens 3, the single-beam femtosecond laser is converted into a double-beam femtosecond laser whose propagation directions are perpendicular to each other, and the double-beam femtosecond laser passes through the mirrors 4, 5, 6, 9, 10, 12 to change the propagation direction, The double beams of laser beams finally meet through the beam combining plate 13, and the reflector is adjusted so that the combined double beams propagate along a straight line in the same direction. Insert half-wave plate 7 in the optical path afterwards, make the polarization direction in this optical path change from horizontal polarization to vertica...

Embodiment 2

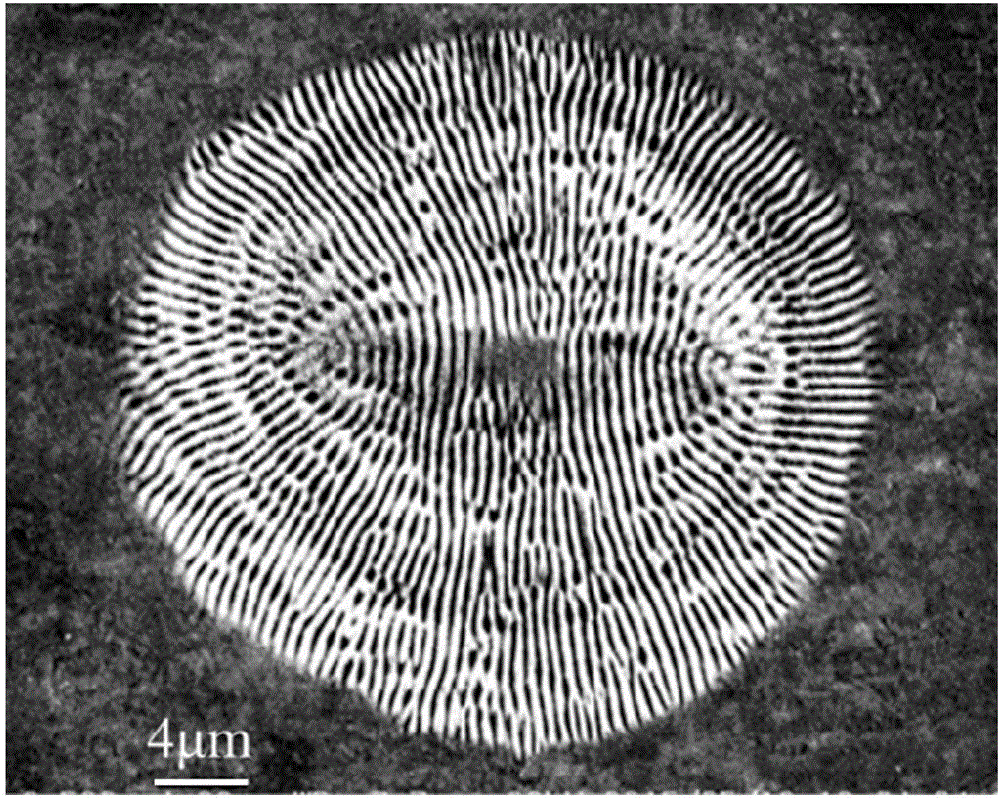

[0042] The metal target sample material is a metal tungsten sample material. On the basis of the optical path in Example 1, a neutral attenuation sheet 16 is used to adjust the laser power of the dual optical path so that the femtosecond laser of the dual optical path passes through the beam combining sheet. The power is equal, the total power of the measured laser is 2 microjoules, the metal tungsten sample target surface is 200 microns away from the focal point of the objective lens, when the delay time is 10 picoseconds, and the number of pulses N=100, the diameter obtained on the surface of the metal tungsten sample material is Scanning electron micrographs of 31 μm butterfly microstructures, as figure 2 Shown, where the magnification is 2500 times.

Embodiment 3

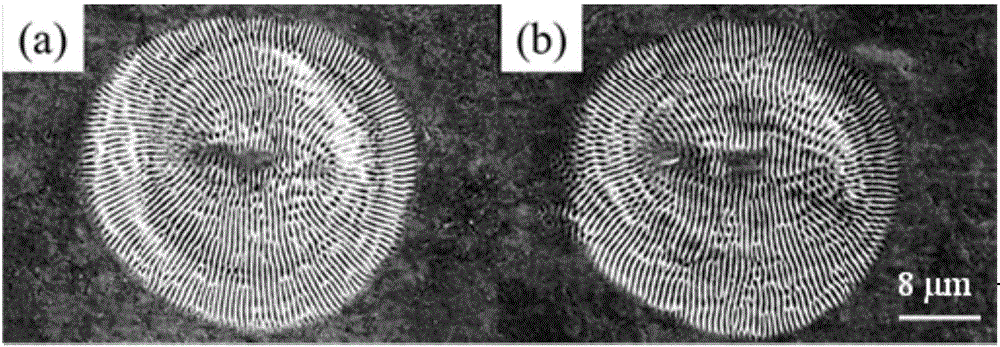

[0044] The metal target sample material is a metal tungsten sample material. On the basis of the optical path in Example 1, a neutral attenuation sheet is used to adjust the laser power of the dual optical path, so that the laser power of the femtosecond laser of the dual optical path exits through the beam combining sheet. Equal, at the position before they are incident on the focusing objective lens, the measured total laser power is 2 milliwatts micro-focus, the target surface of the metal tungsten sample is 200 microns away from the focal point of the objective lens, the number of pulses N=100, and the delay time is positive 5 pico The scanning electron micrographs of the butterfly microstructure were obtained on the surface of the metal tungsten sample material at minus 5 picoseconds, such as image 3 As shown in a and b, they are scanning electron micrographs of a butterfly microstructure with a diameter of 30 microns obtained on the surface of the sample material, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com