Multi-continuous-containing bread baking box and machining technique thereof

A baking box and main body technology, which is applied in the field of multi-packed bread baking boxes and the processing technology of bread baking boxes, can solve the problems of multi-packed bread baking boxes with complex structure, complicated manufacturing process, and cumbersome process, and achieve good consistency , simple process and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

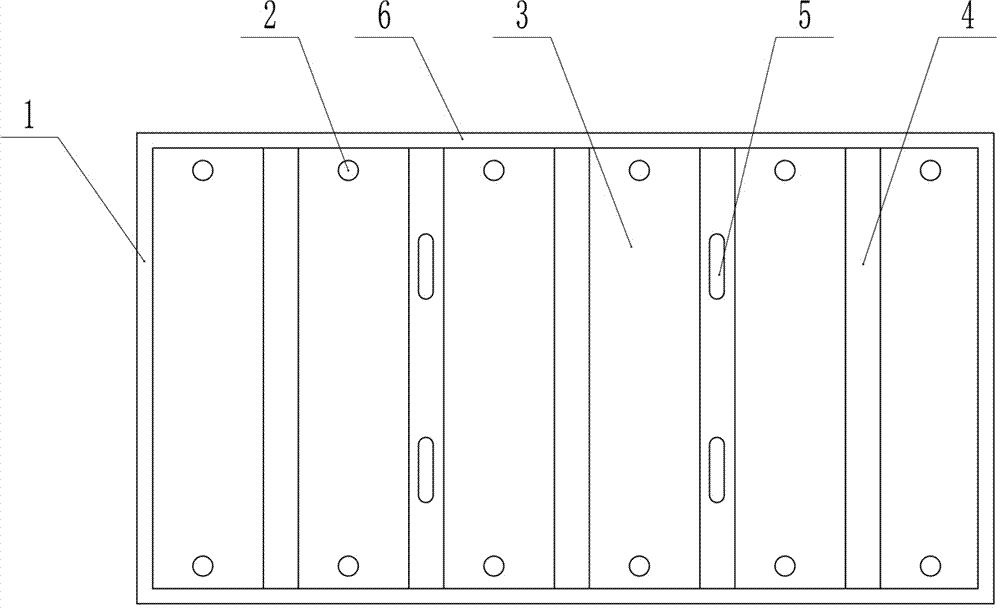

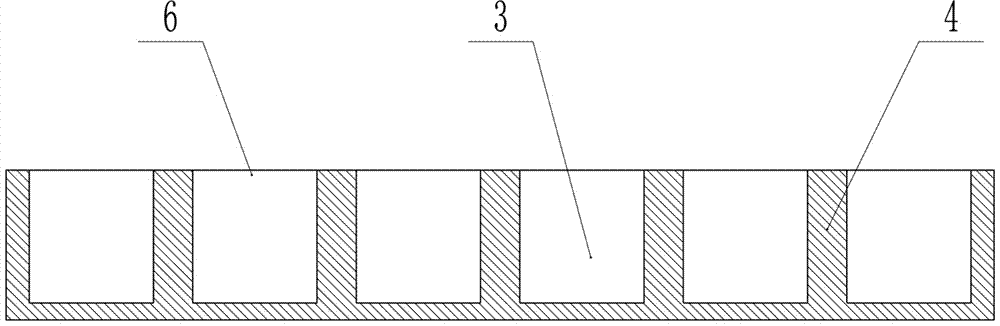

[0023] A multi-packed bread baking box, comprising an integrally formed aluminum-plated multi-packed baking box main body 1, a main body positioning hole 2, a closing plate 6 and a cover plate positioning hole 5, the multi-packing baking box body includes several parallel rows The elongated groove-shaped mold cavity 3 of cloth, is provided with dividing plate 4 between adjacent two elongated groove-shaped mold cavities 3, and described cover plate positioning hole 5 is arranged on described dividing plate 4, each elongated groove-shaped mold cavity 3 The two ends of the bottom surface are provided with the main body positioning holes 2, and the main body positioning holes 2 in each long groove-shaped mold cavity 3 are arranged at equal intervals. Blocking the long groove mold cavity 3.

[0024] The processing technology of the multi-pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com