Support and direct-lit LED backlight module with same

A backlight module, direct-type technology, applied in the field of direct-type LED backlight modules, to achieve the effect of easy and quick replacement of light sources, simple bracket structure, avoiding the cost of procedures and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

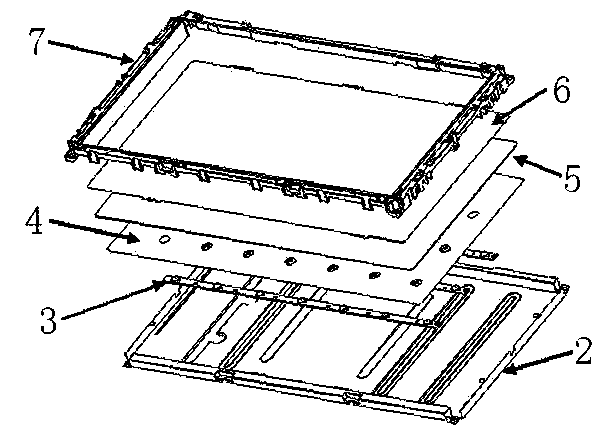

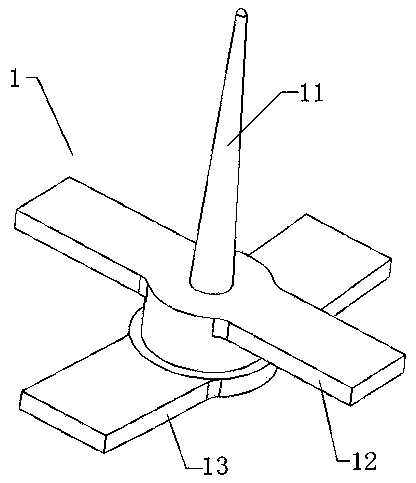

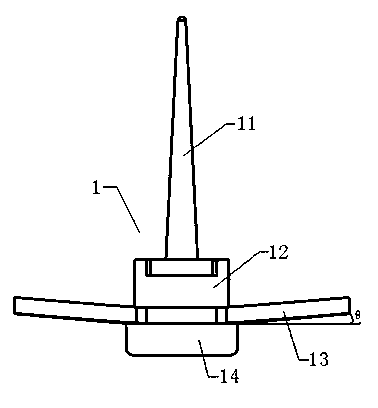

[0023] like Figure 2-3 As shown: a bracket, the bracket 1 includes a diffuser plate thimble 11, an upper clamping structure 12 and a lower clamping structure 13, the diffusion plate thimble 11 used to make a diffuser plate is located on the upper clamping structure 12, the upper clamping The engaging structure 12 is located above the lower engaging structure 13 and the two are staggered, the angle between the upper engaging structure 12 and the lower engaging structure 13 is 30°-90° and the length of the upper engaging structure 12 and / or The width is smaller than the length and / or width of the lower engaging structure 13 so as to stably clamp the LED light bar substrate 3 on the back plate 2 . In order to make the bracket easy to use, the lower engaging structure 13 is set with an upwardly set inclination angle θ and the inclination angle θ is 3° to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com