Anti-corrosive anti-pollution environment-friendly plastic brake valve with flexible seal and machining process thereof

An environmentally friendly plastic and soft sealing technology, applied in shaft seals, sliding valves, valve details, etc., can solve the problems of inconvenient processing, secondary pollution of fluids, and high manufacturing costs, and achieve the effects of convenient processing, energy saving, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

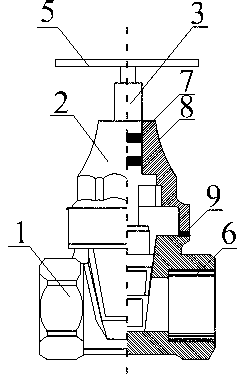

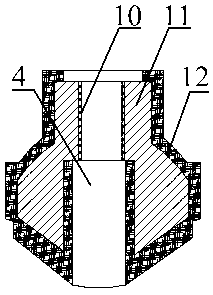

[0029] Such as figure 1 , 2 As shown, the anti-corrosion and anti-pollution soft-sealed environmental protection plastic gate valve is designed based on the inertness of plastic chemical reactions and the characteristics of plastics that will not be decomposed by water, non-toxic and tasteless, while retaining the advantages of the channel structure of the existing soft-sealed gate valve Basically, the main parts of the sealed gate valve: the valve body 1 and the valve cover 2 are made of modified polyphenylene ether, and the iron is replaced by plastic, which not only solves the problem that the traditional soft-sealed gate valve easily causes secondary pollution to the fluid, but also The production cost of the valve is greatly reduced, and the product has a very broad market prospect.

[0030] The valve body 1 is a three-way pipe structure, and the top of the valve body 1 is provided with external threads, while the inner wall of the bonnet 2 is provided with internal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com