Fixed-length profile blanking device

A profile and fixed-length technology, which is used in metal processing machinery parts, metal processing, measuring/indicating equipment, etc., can solve the problems of diversification of profile blanking, and achieve the effect of improving the degree of automation, avoiding complicated procedures and reducing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

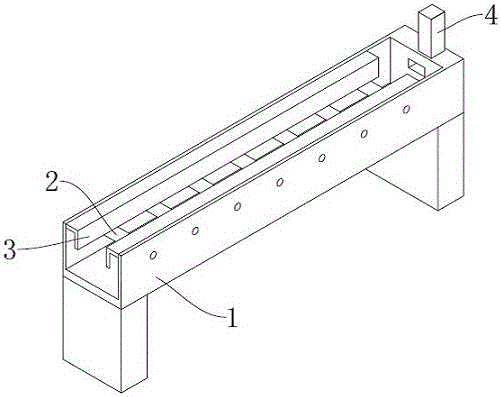

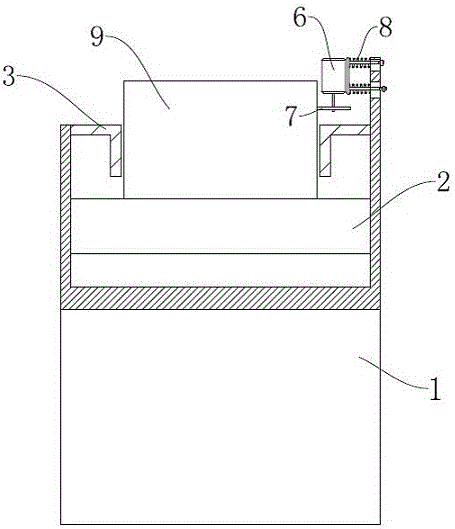

[0015] Such as figure 1 , figure 2 As shown, the fixed-length profile blanking device includes a frame 1, and seven rollers 2 are arranged horizontally on the frame 1. The seven rollers 2 form a conveying surface on the frame 1, and are respectively arranged on both sides of the conveying surface. There are guide plates 3, the channel between the guide plates 3 is a guide channel, the distance between the two guide plates 3 can be adjusted according to the size of the profile 9, a cutting device 4 is arranged at the exit of the guide road, and the cutting device 4 is a hydraulic cylinder and a cutting tool, the cutting tool is connected to the piston rod end of the hydraulic cylinder, and the motor is connected to the shaft end of the roller 2 through a shaft coupling.

[0016] exist figure 2 Among them, the profile 9 is placed on the roller 2, the encoder 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com