Molten-metal-cladding hot isostatic pressing preparation method for particle-reinforced metal-matrix composite

A composite material, hot isostatic pressing technology, applied in the field of materials, can solve the problems of strong light and smoke, limited production efficiency, poor environmental friendliness, etc., to reduce production energy consumption and cost, simple production and assembly, breakthrough The effect of the simple structure of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Using 2024Al as the jacket material to prepare 35wt.%SiC p / 2024Al composite material, the specific steps are as follows.

[0059] 1. Mixing of raw materials: SiC ceramic particles and 2024Al alloy powder are uniformly mixed according to the designed composition ratio to obtain the first mixture.

[0060] 2. Cold isostatic pressing: put the first mixture into a cylindrical soft film mold, and cold-press the blank with a certain density, strength and shape by cold isostatic pressing.

[0061] 3. Production of sheathing: Select 2024Al thin plate as the sheathing material, bend it into a cylindrical surface, punch out the end surface of the cylinder, and use the cylindrical surface and the end surface of the cylinder as the sheathing.

[0062] 4. Assembly: Coat the inner surface of the package with BN release agent, then put the cylindrical cold compact blank prepared in step 2 into the package formed by splicing the cylindrical surface and the cylindrical end surface, an...

Embodiment 2

[0067] 20wt.%B was prepared by using 2024Al as the jacket material 4 C p / 6061Al composite material, the specific steps are as follows.

[0068] 1. Raw material mixing: mix B 4 The C particles and the 2024Al alloy powder are evenly mixed according to the designed composition ratio to obtain the first mixture.

[0069] 2. Cold isostatic pressing: put the first mixture into a cuboid soft film mold, and form a compacted plate with a certain density, strength and shape by cold isostatic pressing.

[0070] 3. Envelope production: select pure Al thin plate enveloping material, and wire-cut the six planes required for cuboid enveloping.

[0071] 4. Assembly: Coat the inner surface of the package with BN release agent, then put the cuboid compacted plate into the package made of six planes, and then put it into the graphite crucible.

[0072] 5. Hot isostatic pressing: Put the compacted plate, jacket and graphite crucible assembled in step 4 into the hot isostatic pressing furnace...

Embodiment 3

[0075] Cu is used as the sheath material to prepare 8wt%.Al 2 o 3 / Cu composite material, the specific steps are as follows.

[0076] 1. Raw material mixing: Al 2 o 3 The particles and the Cu powder are evenly mixed according to the designed composition ratio to obtain the first mixture.

[0077] 2. Cold isostatic pressing: put the first mixture into the soft film mold of the hemisphere, and press it into a green hemisphere with a certain density, strength and shape by cold isostatic pressing.

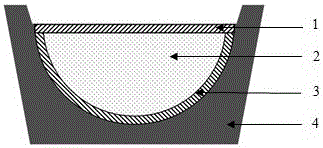

[0078] 3. Production of sheathing: select Cu metal block as sheathing material, use lathe to turn out hemispherical sheathing upper piece and circular sheathing lower piece, such as figure 1 shown.

[0079] 4. Assembly: Coat the inner surface of the package with graphite release agent, then put the hemispherical compacted hemisphere into the spliced package, and then put it into the graphite crucible. Its structure is as follows figure 1 shown.

[0080] 5. Hot isostatic pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com