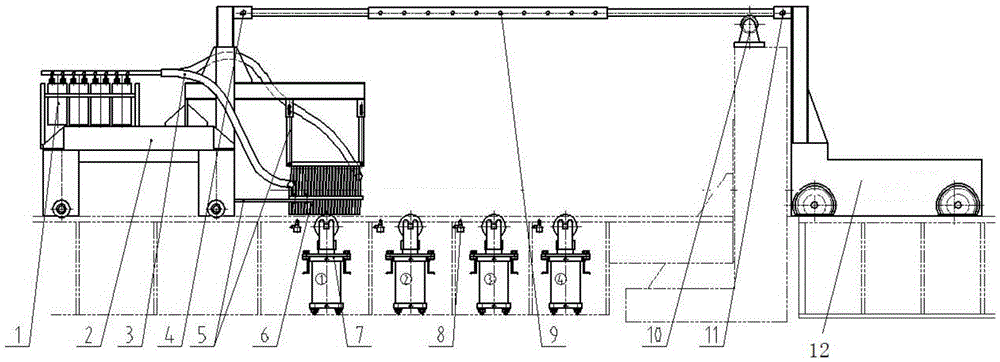

Drawing, expanding and follow-up heating device of cold-drawing unit

A heating device and unit technology, applied in the field of follow-up heating devices, can solve the problems of increasing mold specifications and manual labor time, increasing the company's fixed production costs, and limited production and processing capabilities, so as to improve competitiveness and increase diversity , to avoid the effect of complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0023] like figure 1 As shown, the present invention discloses a follow-up heating device for drawing and expanding a cold drawing unit, including a high-voltage electric heating capacitor group 1, a follow-up trolley 2, a water cable 3, an insulating pull rod 5, a pin 4, and a pin 2 11 , induction heating coil 6, lifting roller 7, traction rod 9, travel switch 8 and traction rod supporting wheel 10, there are two water cables 3, one end of the water cable 3 is connected with the high-voltage electric heating capacitor group 1, and the other end is connected with the induction The heating coils 6 are connected; one end of the insulating pull rod 5 is fixed on the follower trolley 2, and the other end is connected to the induction heating coil 6. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com