Stress transmitter

A transmitter and pressure sensor technology, which is applied in the field of shrapnel contact pressure transmitters, can solve the problems of poor pressure sensitivity and inconvenient operation, and achieve the effects of convenient operation, convenient viewing, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

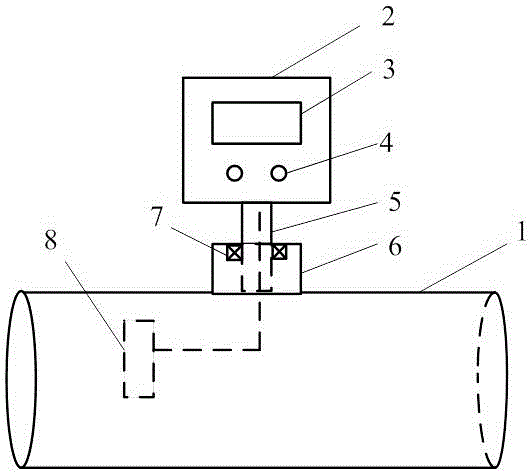

[0017] like figure 1 As shown, a pressure transmitter includes a detection tube 1 , a control device 2 , a display screen 3 , an adjustment button 4 , a rotating shaft 5 , a limit device 6 , a bearing 7 and a shrapnel contact pressure sensor 8 .

[0018] A pressure transmitter, comprising a detection tube, a control device, a limit device and a shrapnel contact pressure sensor, the detection tube is arranged horizontally, both ends of the detection tube are open, and the limit device is fixedly clamped on the outside of the detection tube, The limit device is rotationally connected with one end of the rotating shaft through the bearing, the limit device is fixedly connected with the outer ring of the bearing, the rotating shaft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com