Multifunctional loading pipeline overall buckling experiment system

A buckling experiment and multi-functional technology, applied in the field of structural engineering, can solve problems such as single loading function and lack of systematic research on the overall buckling characteristics of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

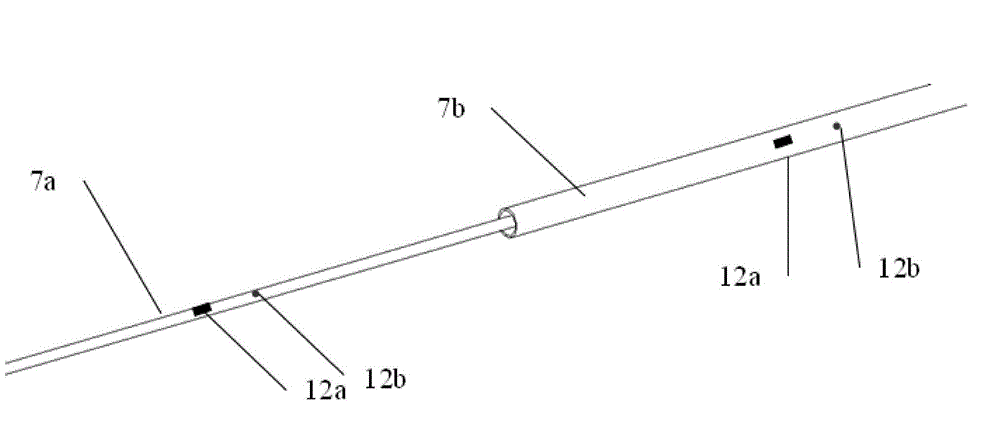

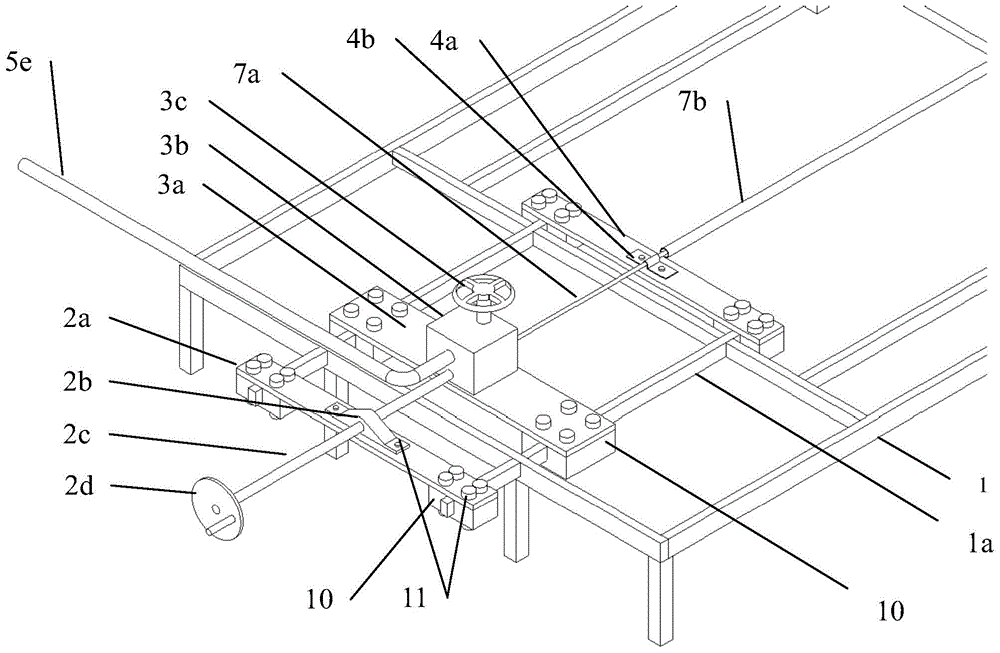

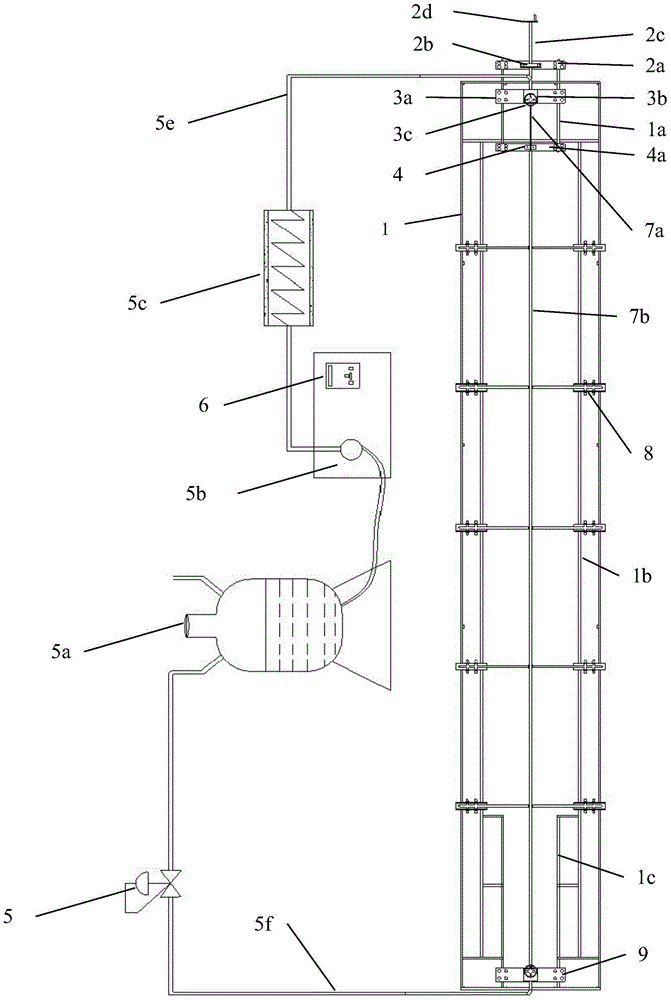

[0036] Ordinary mechanical loading method. If the ordinary mechanical loading method is used, the liquid circulation device 5 and the temperature and pressure control device 6 are not required to participate in the test. Such as Figure 1-2 As shown, the general mechanically loaded pipe overall buckling simulation test device proposed in the patent embodiment of the present invention includes a self-balancing reaction frame 1, a mechanical loading device 2, a multifunctional loading block 3, a pipe guide block 4, a pipe 7, and a lateral Constraint 8, export fixed block 9, etc. First, the base 2 a , the slidable base 3 a , the guide block base 4 a and the base 9 a are fixed by the slider 10 and the fastening bolt 11 . The long screw rod 2c of the mechanical loading device 2 passes through the nut 2b and is connected to the long screw rod interface 3e of the loading block 3b. One end of pipeline 7 passes through pipeline guide block 4 and connects loading block 3b (as image...

Embodiment approach 2

[0046] Temperature and pressure loading methods. Such as Figure 1-2 As shown, the overall buckling simulation test device of the pipeline under temperature and pressure loading proposed by the patent embodiment of the present invention includes a self-balancing reaction force frame 1, a mechanical loading device 2, a multifunctional loading block 3, a pipeline guide block 4, and a liquid circulation device 5 , Temperature and pressure controller 6, pipeline 7, lateral restraint 8, outlet fixed block 9, etc. The basic assembly process of the experimental device is the same as that of Embodiment 1. It is only necessary to connect the liquid circulation device 5 and the temperature and pressure controller 6 to the self-balancing reaction frame 1, connect the inflow pipe 5e to the liquid inlet 3d of the loading block 3b, and connect the outflow pipe 5f Access to fixed block 9b.

[0047] The body fluid circulation device 5 includes: 5a is a raw material tank, 5b is a feed pump, ...

Embodiment approach 3

[0053] Temperature, pressure, mechanical mixed loading method. Such as Figure 1-2 As shown, the overall buckling simulation test device of the temperature, pressure and mechanical loading pipeline proposed in the patent embodiment of the present invention includes a self-balancing reaction force frame 1, a mechanical loading device 2, a multifunctional loading block 3, a pipeline guide block 4, and a liquid circulation Device 5, temperature and pressure controller 6, pipeline 7, lateral restraint 8, outlet fixing block 9, etc. The basic assembly process of the experimental device is the same as the second embodiment.

[0054] Before the temperature and pressure loading is carried out by the temperature and pressure controller 6, the fastening bolts 11 used to fix the multifunctional loading block 3 are first loosened to ensure that the multifunctional loading block 3 can slide axially along the loading end slide rail 1a. Rotate the turntable 2d of the mechanical loading dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com