Bending insensitive pressure sensor

A pressure sensor, bending-insensitive technology, applied in the field of micro-sensors, to achieve the effect of reducing the comprehensive elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

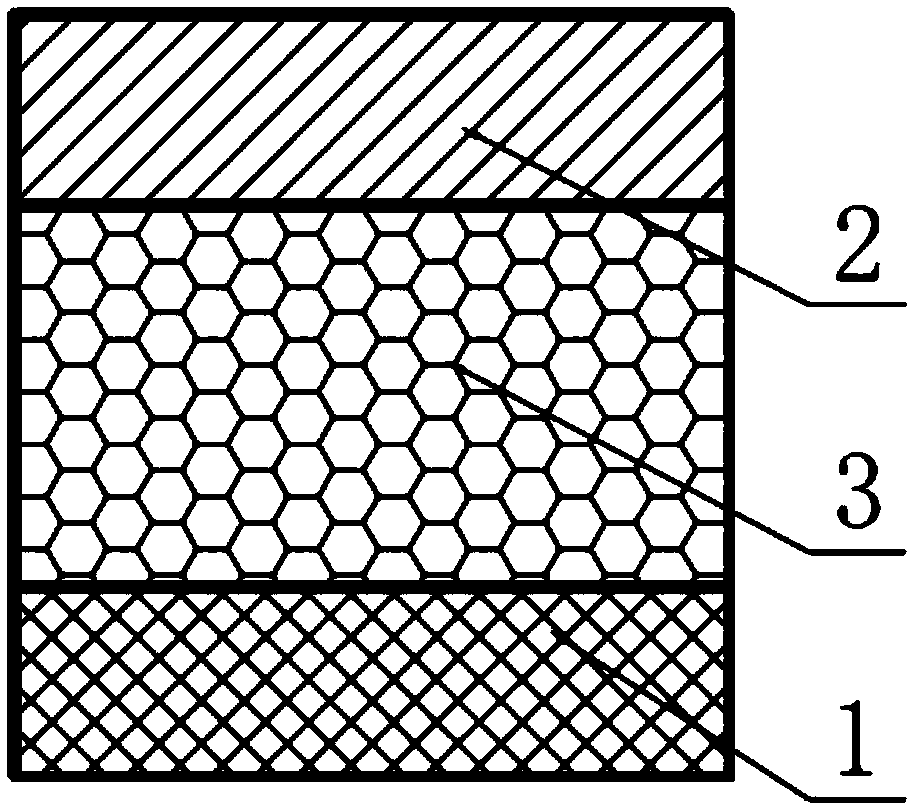

[0014] see figure 1 and figure 2 As shown, a bending insensitive pressure sensor of the present invention comprises a flexible substrate 1, a gold-plated film layer 2 coated on the flexible substrate 1, and a nanoporous structure arranged between the flexible substrate 1 and the gold-plated film layer 2 Layer 3.

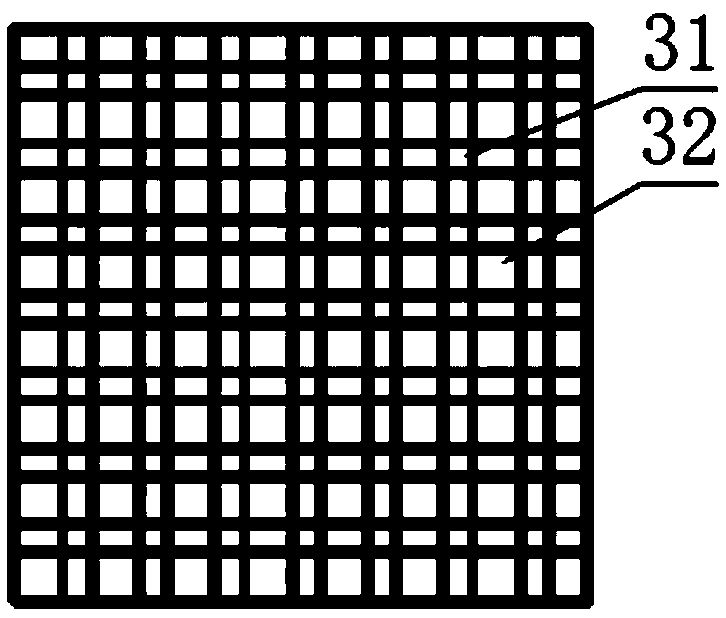

[0015] see figure 1 and figure 2 As shown, the flexible substrate 1 is made of polyethylene glycol phthalate material, and the nanoporous structure layer 3 is a porous material layer composed of nanofibers with a diameter of 500-800 nanometers and mixed conductive nanomaterials. The mixed conductive materials are located in the nanometer Inside the fiber matrix, the mass fraction is 1-2wt%; the mixed conductive material is composed of carbon nanotubes 31 with a diameter of 10-50 nanometers and graphene 32 with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com