Omni-directional rotating rebar drawing stress mechanism

An all-round, reinforced technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of small objects falling into small places, electromagnetic induction interference, difficult to take out by hand, etc., to save manpower and material resources , high work accuracy, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

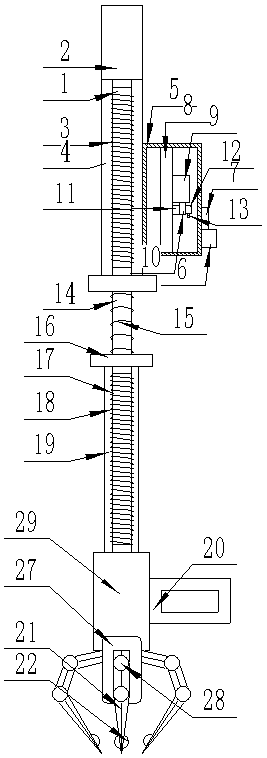

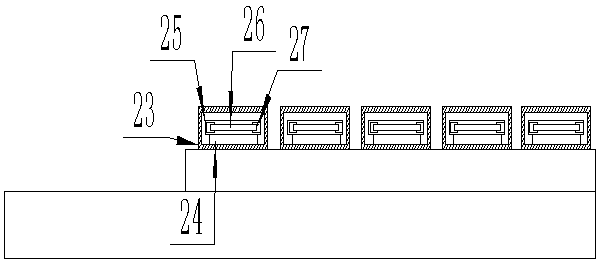

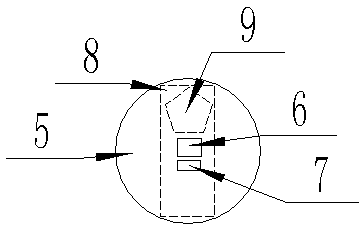

[0018] 1, the present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown in the figure, a force-bearing mechanism for pulling out steel bars that rotates in all directions includes a handle (1), an extension rod (2) is provided on one side of the handle (1), and an electromagnetic coil is wound on the handle (1). A (3), the electromagnetic coil A (3) is nested with a circular tube A (4), the circular tube A (4) is provided with a circular shell (5), the circular shell ( 5) The upper surface is provided with a touch-sensitive button (6), the lower end of the touch-sensitive button (6) is provided with a red and green indicator light (7), and the circular housing (5) is provided with a switch control panel (8) , the switch control board (8) is provided with an intelligent MCU microcomputer control chip (9), and one side of the intelligent MCU microcomputer control chip (9) is provided with a 3V auxiliary power supply (10),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com