MEMS pressure sensor and manufacturing method

A technology of a pressure sensor and a manufacturing method, which is applied in fluid pressure measurement using capacitance change, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc., can solve the problems of MEMS pressure sensor influence, poor sensitivity, etc. Sensing efficiency and sensitivity, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

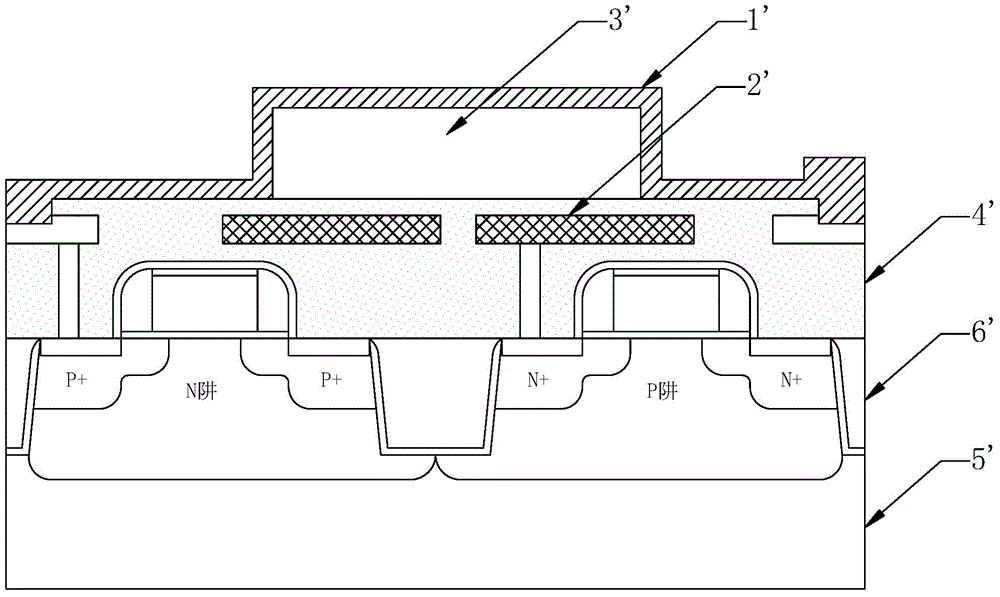

[0058] In the prior art, after the IC control circuit is completed, the MEMS pressure sensor is continued to be produced on the wafer. This MEMS pressure sensor is usually fabricated vertically on the CMOS device in the IC control circuit. Its structure is as follows figure 1 As shown, the upper and lower poles of the capacitor are composed of a deformable upper plate 1' and a fixed lower plate 2', a cavity 3' is formed between the upper plate 1' and the lower plate 2', and the lower The pole plate 2' is fixed in the oxide layer 4', and the oxide layer 4' is vertically integrated with the CMOS device 6' on the wafer 5'. This vertically integrated MEMS pressure sensor has a smaller volume and a higher reliability.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com