Radial shearing limit experiment device for axis parts

A technology of shaft parts and experimental devices, applied in measuring devices, using stable shear force to test material strength, instruments, etc., can solve the problems of difficulty in operation, insufficient shear strength, high cost, and ensure the accuracy of sliding fit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

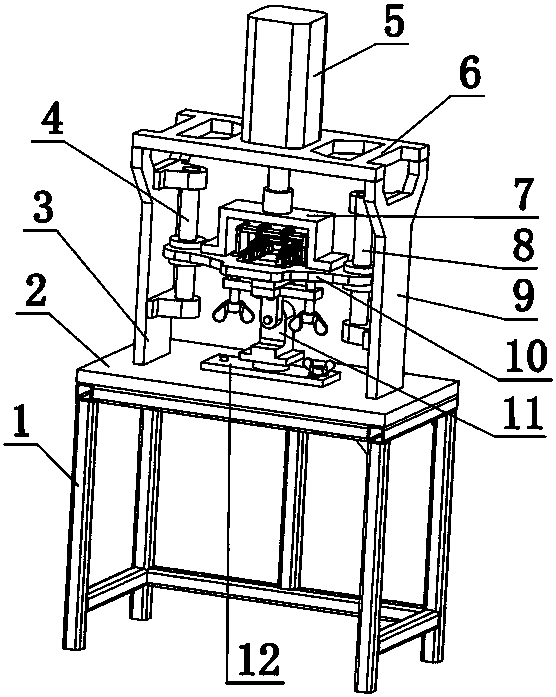

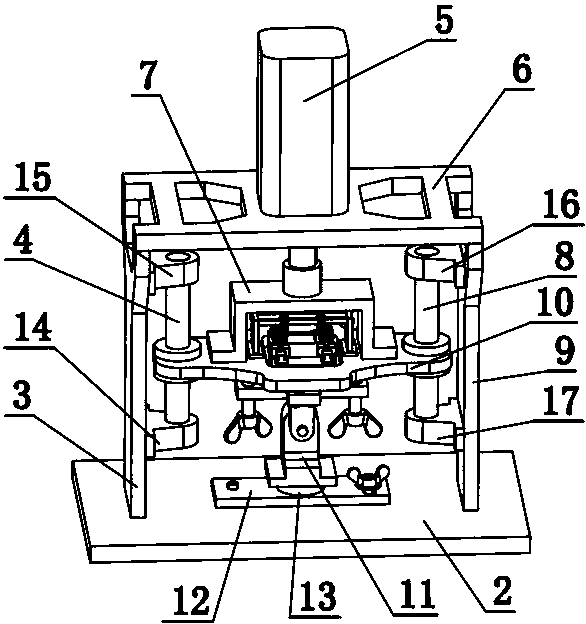

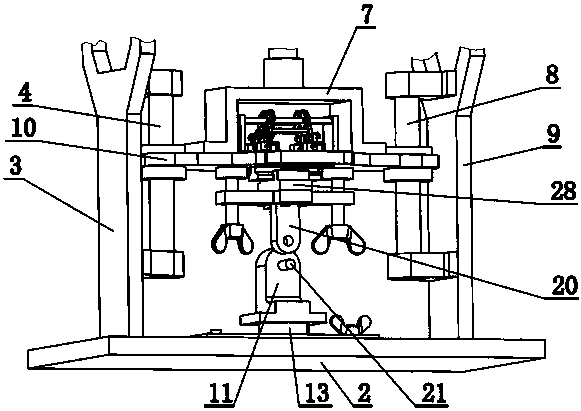

[0034] combine Figure 1-10, a radial shear limit test device for shaft parts of the present invention, comprising a lower support frame 1, a lower fixed plate 2, a left vertical plate 3, a left guide post 4, a hydraulic cylinder 5, an upper fixed plate 6, and a connecting frame 7. Right guide column 8, right vertical plate 9, lifting plate 10, lower shear seat 11, swing plate 12, pressure sensor 13, left lower seat 14, left upper seat 15, right upper seat 16, right lower seat 17, upper shear Cutting seat 20, column pin 22, dish nut 23, stud 24, dish bolt 25, compression shoe 26, loading guide rail 27, loading slider 28, left support seat 29, left guide rail flexible support device 30 , rear support bar 31, front support bar 32, right side guide rail flexible support device 33, rear synchronous bar 34, front synchronous bar 35, right support seat 36, control system, described right side guide rail flexible support device 33 comprises right front gear 3301, right rear gear 330...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com