Al-cr coating preparation and surface micro-deformation method and al-cr coating surface micro-deformation device

A micro-deformation, al-cr technology, applied in the coating, metal material coating process, hot-dip plating process, etc., to achieve the effect of improving corrosion resistance, dense coating structure, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

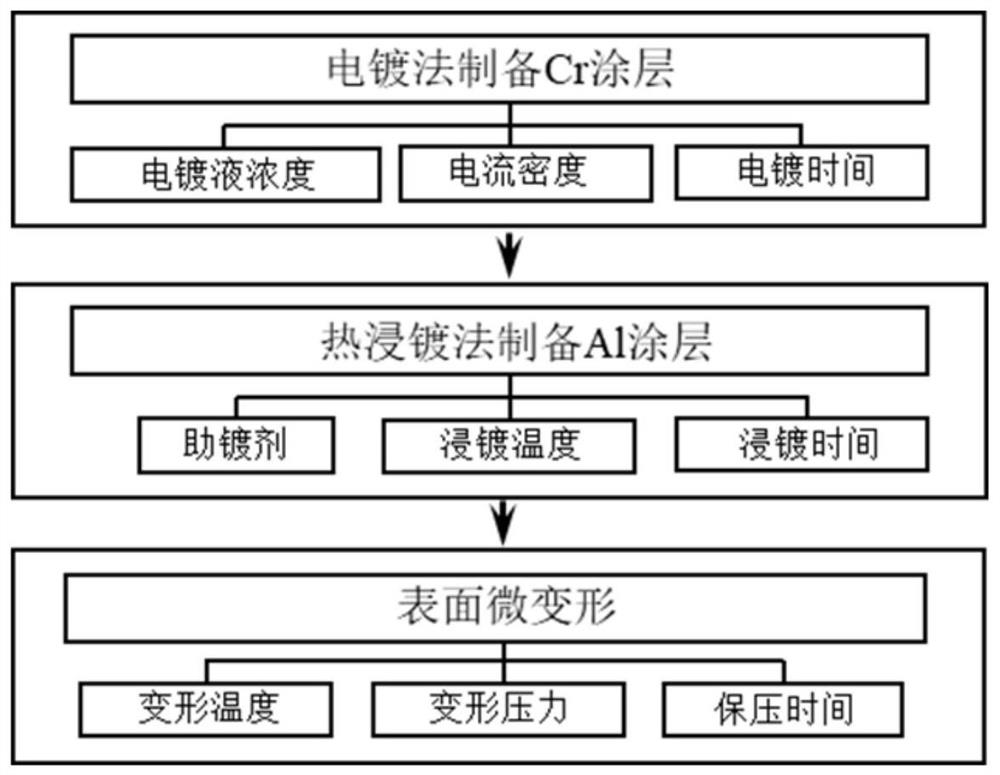

[0047] refer to figure 1 A method for preparing an Al-Cr coating with excellent corrosion resistance adopts the above-mentioned device for micro-deformation of the surface of a Al-Cr coated steel plate, comprising the following steps:

[0048] Step 1: Preparation of a Cr coating on the surface of the steel plate. The Cr coating is prepared on the surface of the steel plate by electroplating, the pure lead plate is used as the anode, the steel plate is used as the cathode, the area ratio of the cathode and the anode is 1:2, and the electroplating solution is 230g / L~250g / L CrO 3 and 1.2g / L~1.5g / L H 2 SO 4 Mixed aqueous solution, electroplating temperature is 60°C, current density is 5A / dm 2 ~10A / dm 2 , the electroplating time is 5 minutes to 15 minutes, and the thickness of the prepared Cr coating is 1 μm to 10 μm.

[0049] Step 2: Preparation of the Al coating on the surface of the Cr-coated steel sheet. First, the Cr-coated steel sheet is subjected to a fluxing treatment...

Embodiment 1

[0060] The steel plate material is Q235 low carbon steel, and the sample size is 20mm×10mm×1mm.

[0061] Step 1: Before preparing the Cr coating by electroplating, use 400#, 800#, 1200#, 2000# SiC sandpaper to grind the Q235 steel plate material step by step, 80 ° C, 20% NaOH + 5% Na 2 SiO 3 +10%Na 2 CO 3 (wt%) mixed aqueous solution for 10min degreasing treatment, 25 ℃, 10% HCl solution for 3min descaling treatment, then use cleaning, drying for later use. When the Cr coating is prepared by electroplating, pure lead is used as the anode, the area ratio of the cathode and the anode is 1:2, and the electroplating solution is 240g / LCrO 3 and 1.3g / LH 2 SO 4 Mixed aqueous solution, electroplating temperature is 60°C, current density is 10A / dm 2 , the electroplating time is 10min, and the thickness of Cr coating is 5μm. Then the Cr-coated steel plate was dehydrogenated at 200 °C for 1 h.

[0062] Step 2: In preparing the Al coating by hot-dipping method, the plating flux is...

Embodiment 2

[0066] The steel plate material is Q235 low carbon steel, and the sample size is 20mm×10mm×1mm.

[0067] Step 1: Before preparing the Cr coating by electroplating, use 400#, 800#, 1200#, 2000# SiC sandpaper to grind the Q235 steel plate material step by step, 80 ° C, 20% NaOH + 5% Na 2 SiO 3 +10%Na 2 CO 3 Mix the aqueous solution for 10 minutes of degreasing treatment, and 25 ℃, 10% HCl solution for 3 minutes of derusting treatment, then use it, wash it, and dry it for later use. When the Cr coating is prepared by electroplating, pure lead is used as the anode, the area ratio of the cathode and the anode is 1:2, and the electroplating solution is 230g / LCrO 3 and 1.2g / LH 2 SO 4 Mixed aqueous solution, electroplating temperature is 60°C, current density is 5A / dm 2 , the electroplating time is 5min, and the thickness of Cr coating is 1μm. Then the Cr-coated steel plate was dehydrogenated at 200 °C for 1 h.

[0068] Step 2: In the preparation of Al coating by hot-dipping m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com