Normal loading device for fretting fatigue test

A loading device, fretting fatigue technology, applied in the direction of measuring device, testing wear resistance, using stable tension/pressure testing material strength, etc., can solve the problems of stress concentration at the contact edge, test influence, etc., to achieve load stability, Ensure consistency and improve transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following describes the present invention in detail based on the accompanying drawings and preferred embodiments. The purpose and effects of the present invention will become more apparent. The following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

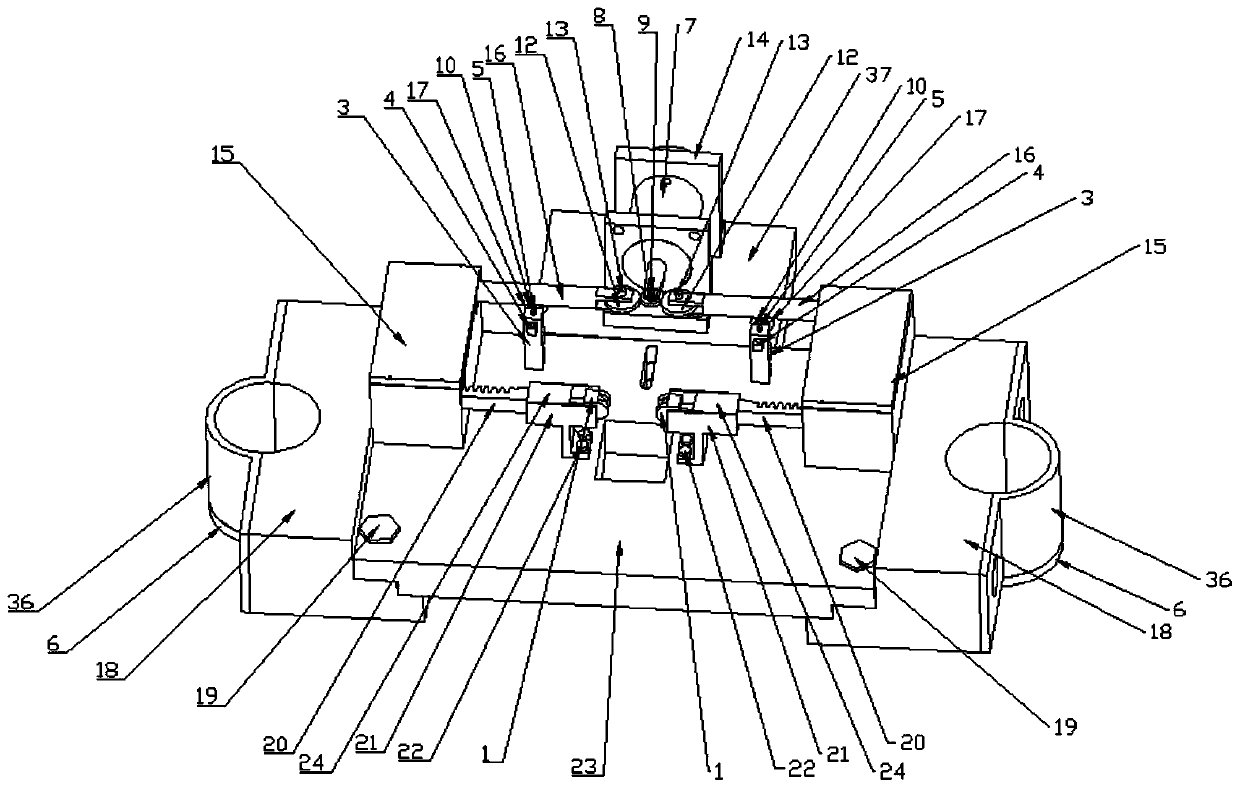

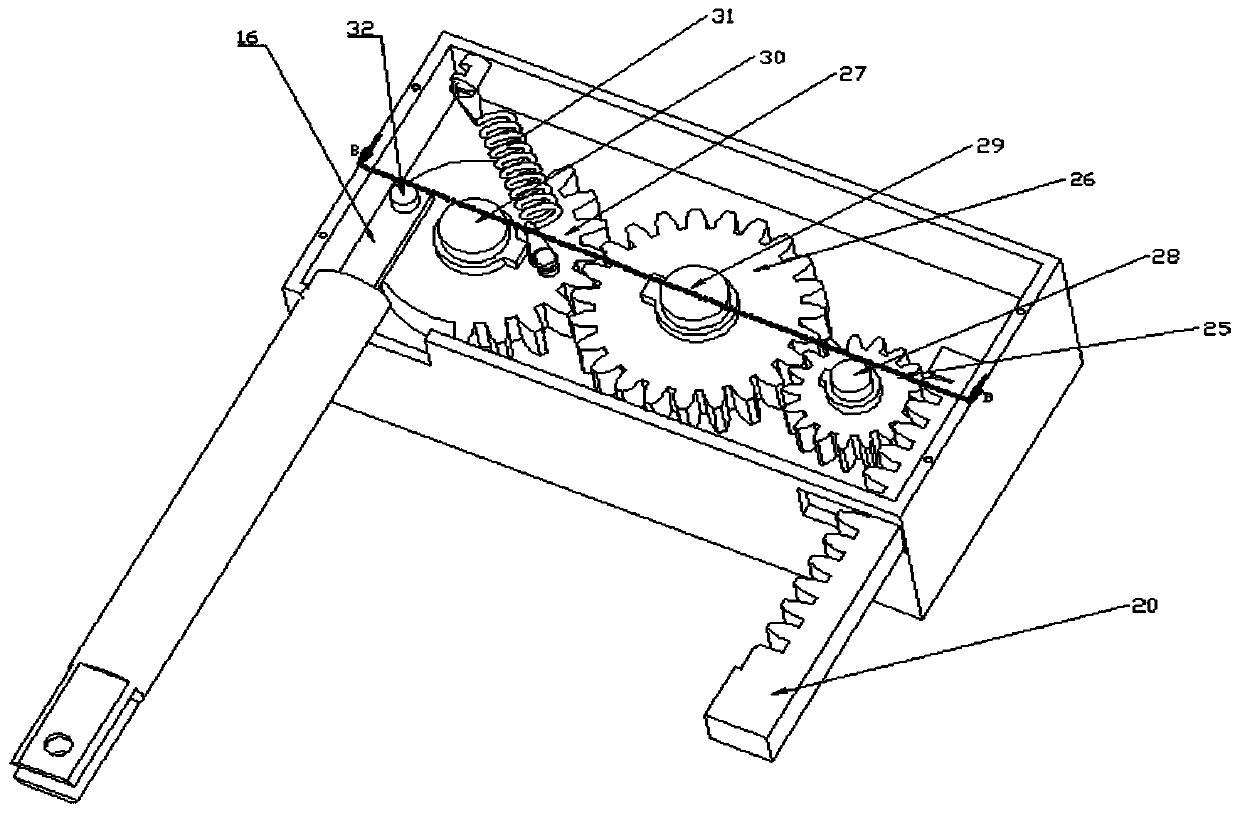

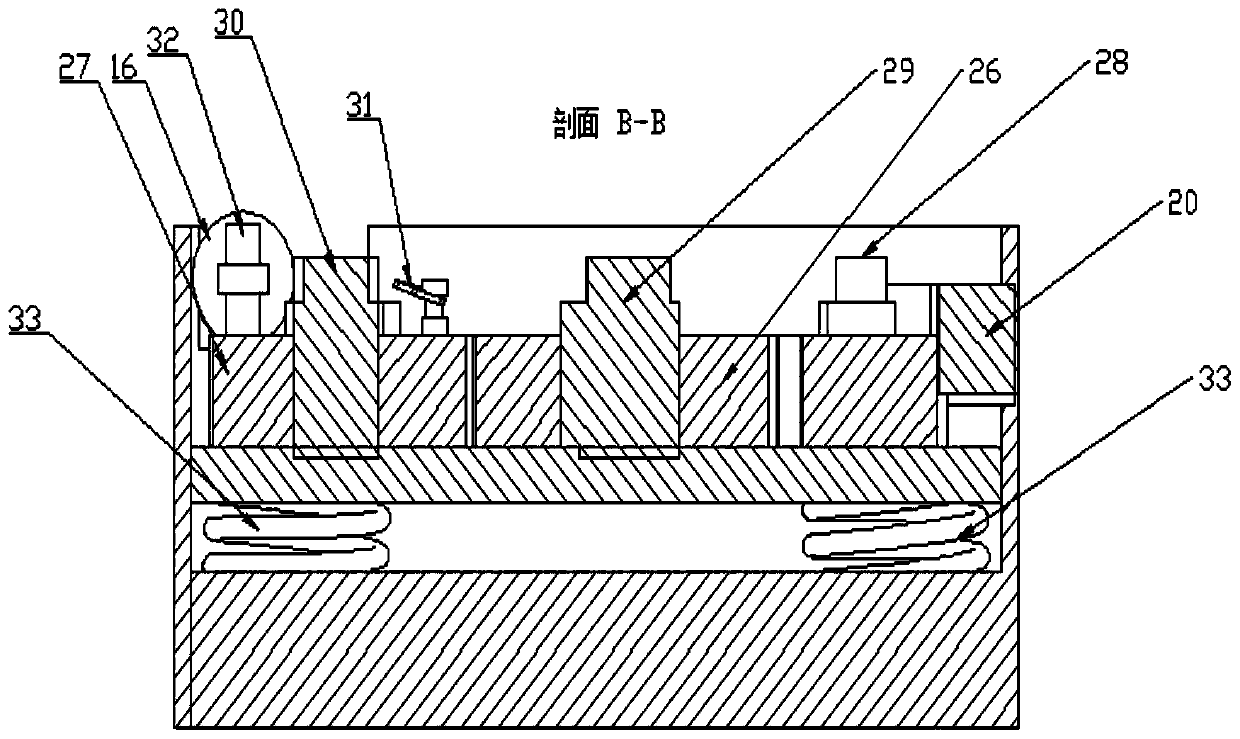

[0039] See figure 1 It can be seen that the normal loading device of a fretting fatigue test of the present invention, such as Figure 1-9 As shown, it includes a transmission device, a power source device, a supporting device, and a clamping device. The transmission device, power source device and clamping device are installed on the supporting device. Both sides of the power source device are connected with a transmission device and a clamping device. Install the test piece on the clamping device and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com