Electric control solid thruster

A thruster and solid propellant technology, which is used in machines/engines, jet propulsion devices, rocket engine devices, etc., can solve problems such as unstable thrust control, and achieve the effects of stable propellant combustion, optimized design, and improved current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

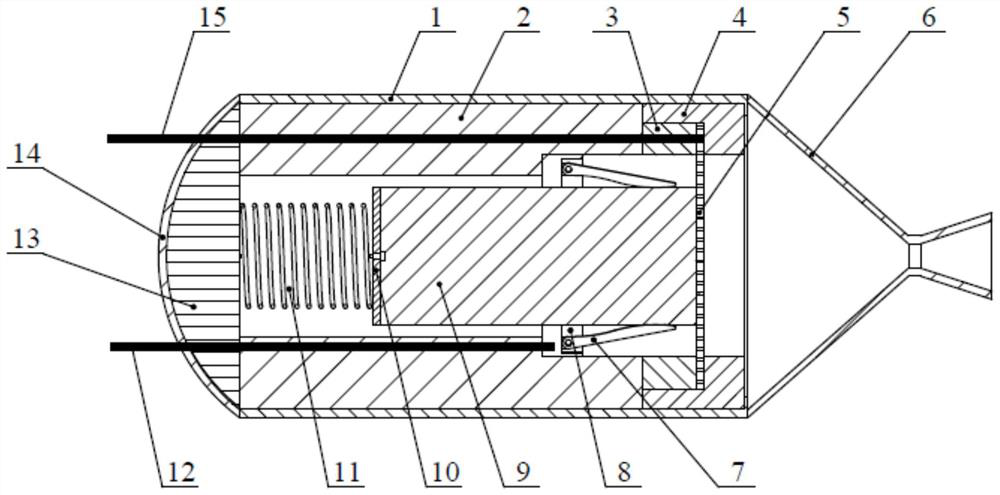

[0037] Specific implementation mode one: the following combination Figure 1~6 Describe this embodiment. An electronically controlled solid thruster described in this embodiment includes a housing 1, an adiabatic insulation sleeve 2, an electrode pressing piece 3, a combustion electrode fixing sleeve 4, a combustion electrode 5, a nozzle 6, and a square ring electrode. , electronically controlled solid propellant grain 9, propellant grain push plate 10, supply spring 11, front head baffle 13 and front head 14;

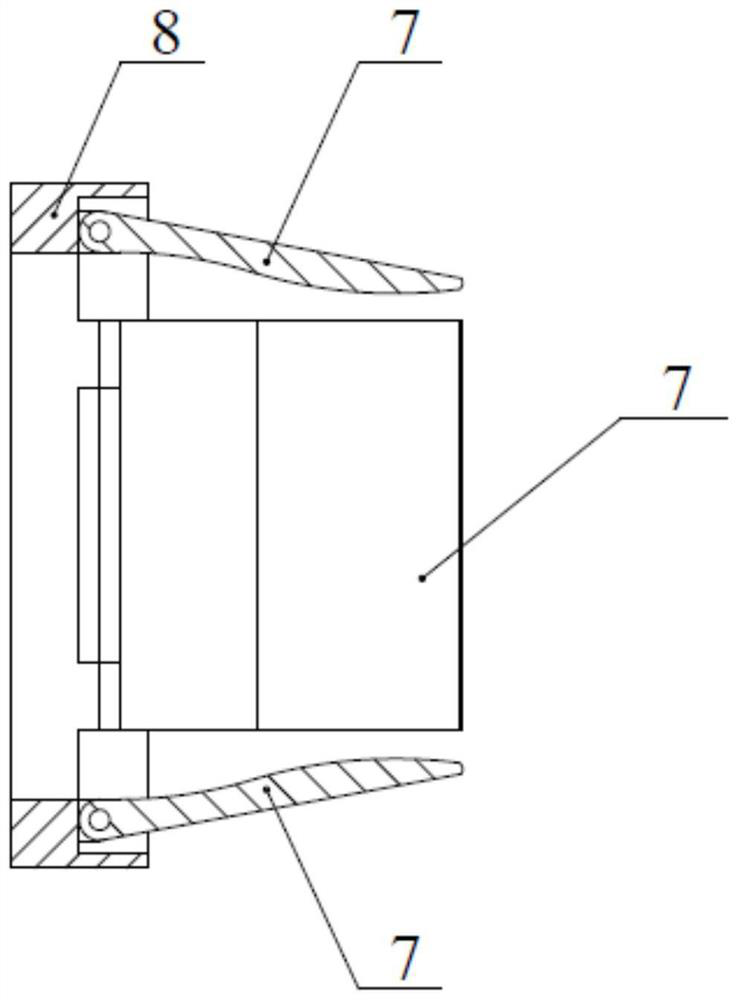

[0038] Described square annular electrode comprises four electrode sheets 7 and square fixed frame 8, and square fixed frame 8 is a conductive part, and four electrode sheets 7 are symmetrically arranged on the square fixed frame 8; All have arc-shaped contact surfaces, and the four electrode sheets 7 enclose an adjustable, axially transparent square area;

[0039] The casing 1 has an open structure at both ends, and the end of the inner cavity of the casing 1 is prov...

specific Embodiment approach 2

[0057] Specific implementation mode two: the following combination figure 2 This embodiment will be described. This embodiment will further describe Embodiment 1, and the combustion electrode 5 is a flat hole-shaped electrode. There are many exhaust holes on the combustion electrode 5, which is beneficial to the discharge of the high-temperature gas generated by the combustion of the electronically controlled solid propellant.

[0058] The combustion electrode is fixed by the electrode pressing piece 3 and the combustion electrode fixing sleeve 4. The previous combustion electrode structure is optimized, the diameter of the electrode hole is increased, the spacing between the holes is reduced, the contact area with the propellant is reduced, and the ignition power of the propellant is reduced.

[0059] As an example, the diameter of the electrode hole of the combustion electrode (5) is 2 mm, and the distance between the holes is 0.7 mm.

specific Embodiment approach 3

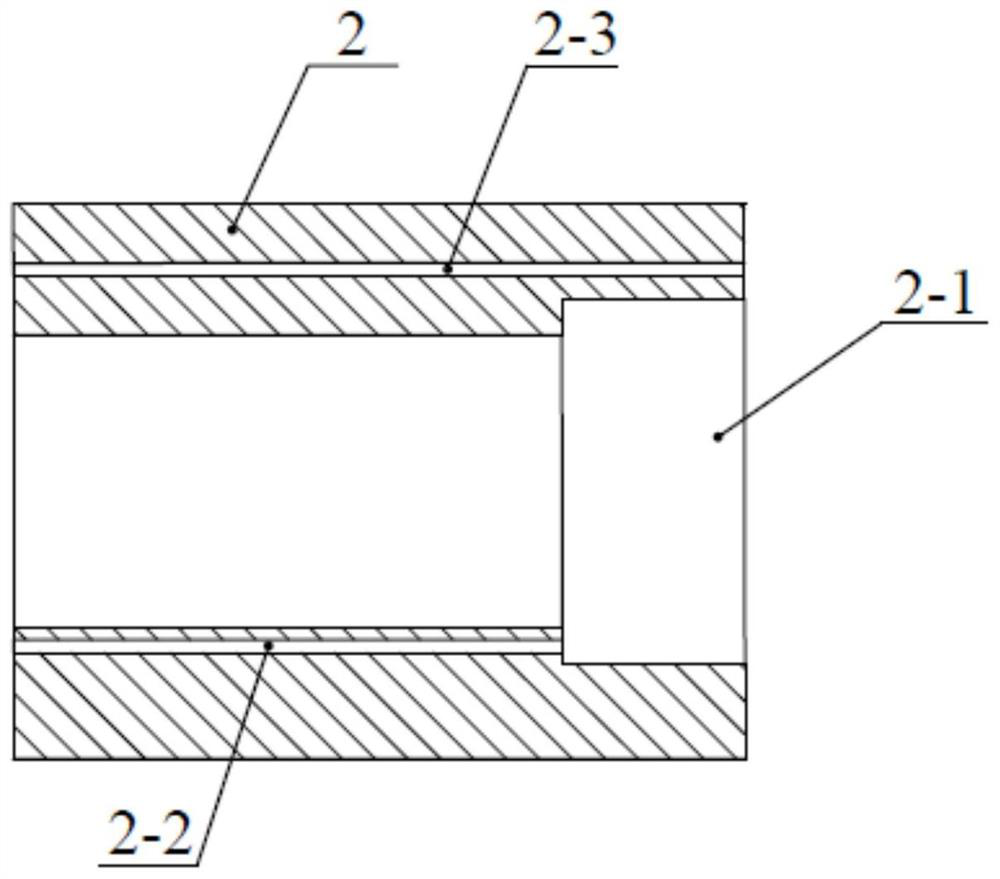

[0060] Specific implementation mode three: the following combination figure 2 The present embodiment will be described. This embodiment will further describe Embodiment 1. The heat-insulating insulating sleeve 2 is made of heat-insulating ceramic material.

[0061] The heat-insulating insulating sleeve 2 is used to isolate the high-temperature gas in the combustion chamber and the current of the terminal, and protect other parts of the thruster. The outermost layer of the thruster is the casing 1, and the nozzle 6 is at the other end, which is directly welded to the casing 1.

[0062] The integrated design of heat insulation and insulation is adopted, which simplifies the independent design structure of the heat insulation layer and the insulation layer in the past. There are grooves and through holes inside, which are used to fix the electrode piece fixing sleeve 4 and the protective electrode terminal. The use of heat-insulating ceramic materials, on the one hand, isolates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com