A garbage incinerator with remote control

A waste incinerator and remote control technology, which is applied in the field of waste incinerators, can solve the problems that the flue gas treatment effect is not good enough, the incinerator cannot be remotely controlled, etc., and achieve the effect of changing the contact time, the overall design is reasonable, and the flexibility is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

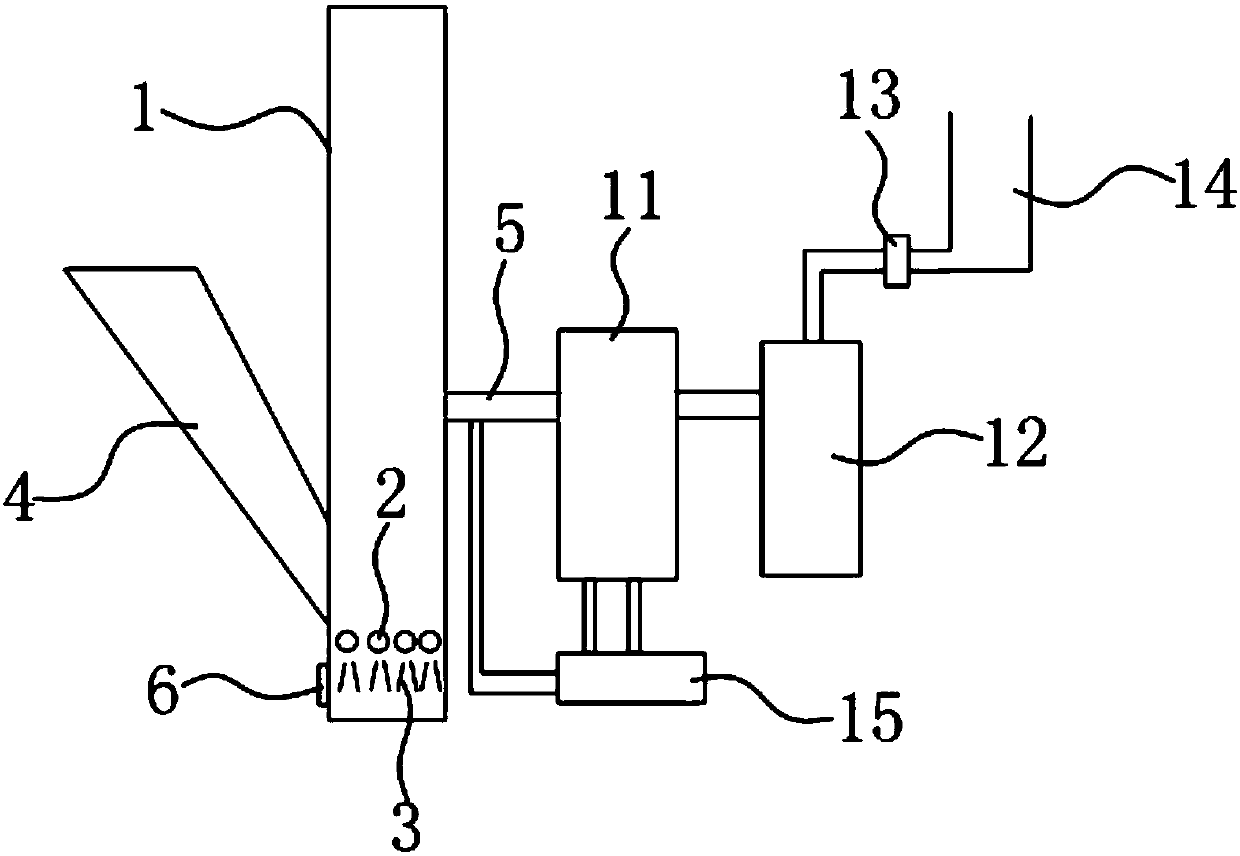

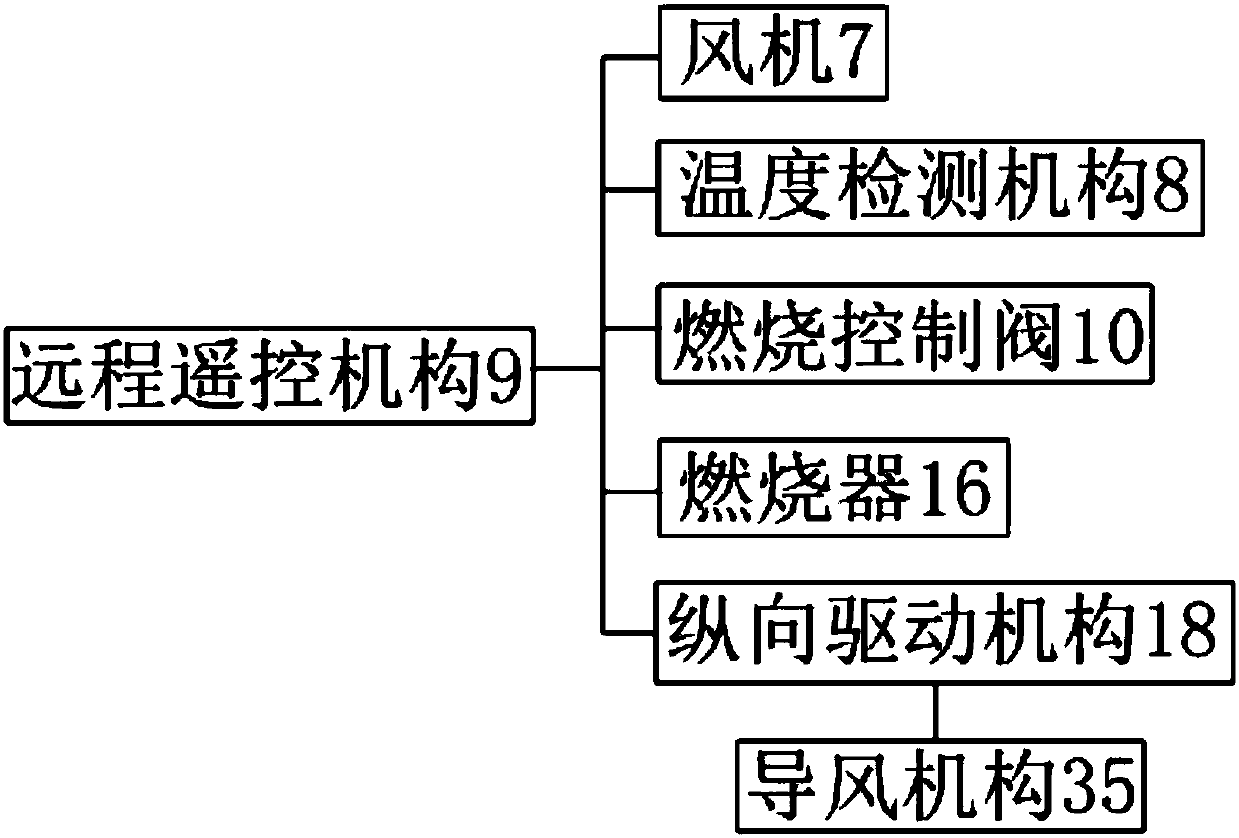

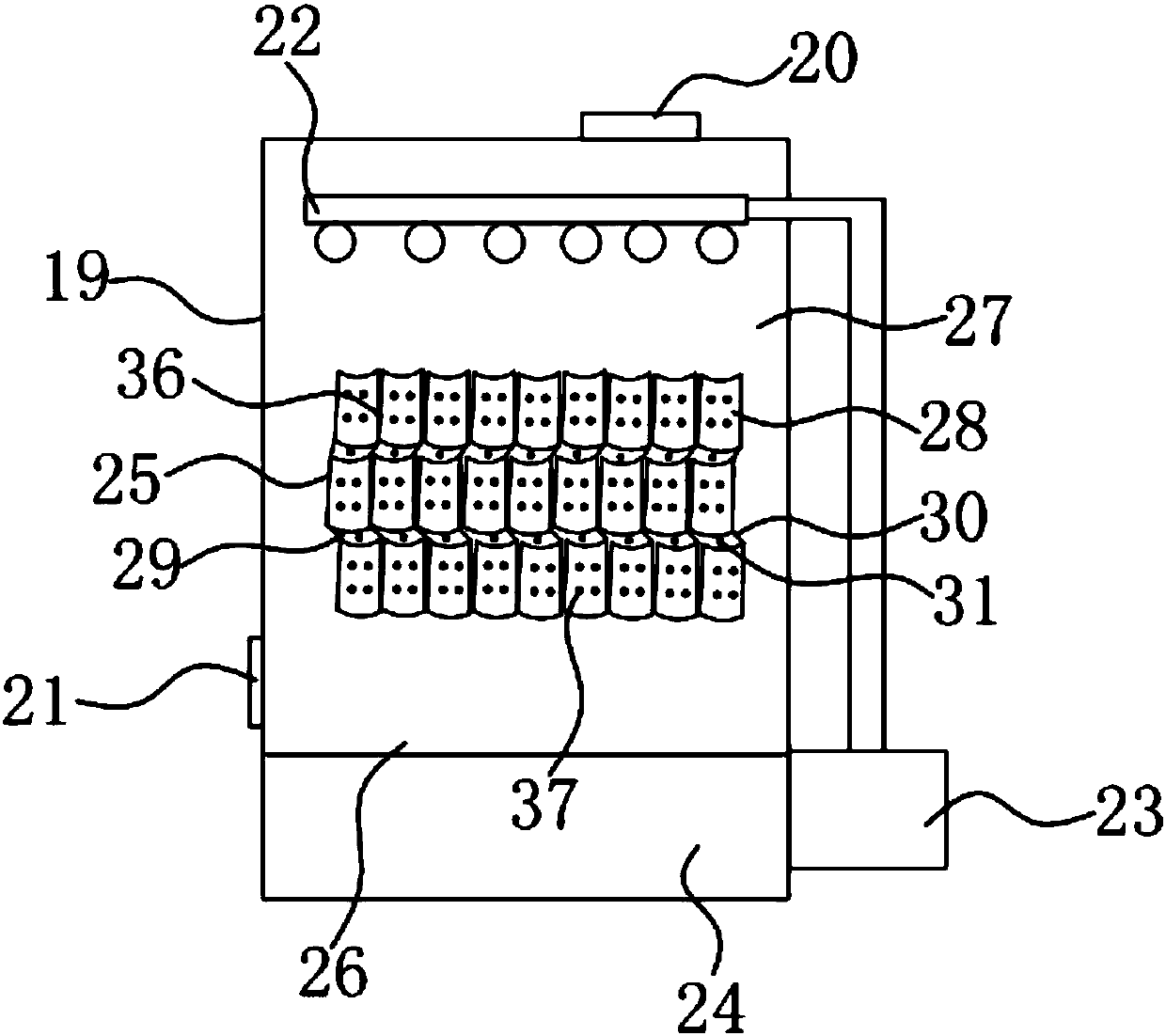

[0023] Such as Figure 1 to Figure 5 As shown, the garbage incinerator with remote control includes an incinerator body 1, a fire grate 2 is arranged inside the incinerator body 1, a combustion nozzle 3 is arranged at the bottom of the fire grate 2, and a slope is connected to one side of the incinerator body 1. Garbage feeding hopper 4 is provided, the other side of the incinerator body 1 is connected to the flue gas purification system through the flue gas output pipe 5, and the incinerator body 1 has a vent 6, and the vent 6 is connected to the fan 7 through the pipeline. connected, the incinerator body 1 is provided with a temperature detection mechanism 8 capable of detecting the incineration temperature, the temperature detection mechanism 8 is connected with the remote control mechanism 9 through a wireless network, and the remote control mechanism 9 is able to control the combustion nozzle 3 through a wireless network. The combustion control valve 10 is connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com