A cable-loaded crane device and installation method for installing suspension bridge stiffeners

A technology for cable-mounted cranes and suspension bridges, which is applied in the field of cable-mounted crane devices for installing suspension bridge stiff beams, and can solve problems such as reducing the stability of cable-mounted cranes, inability to realize on-load walking, and deflection and twisting of main cables. Achieve short lifting distance, improve efficiency, and solve the effect of deflection, twist, stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

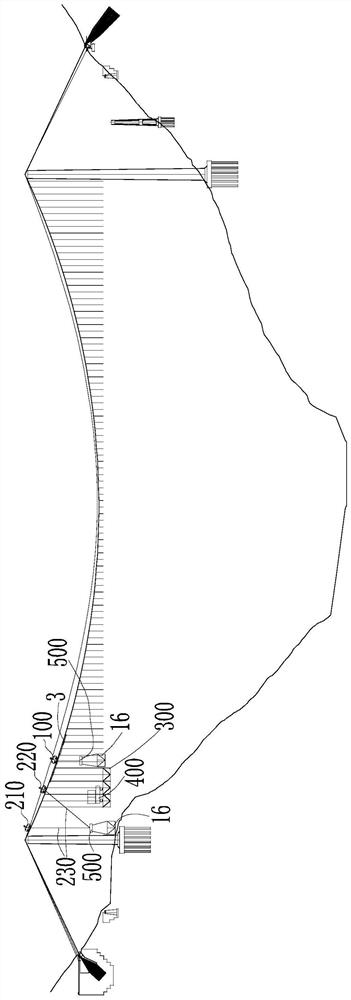

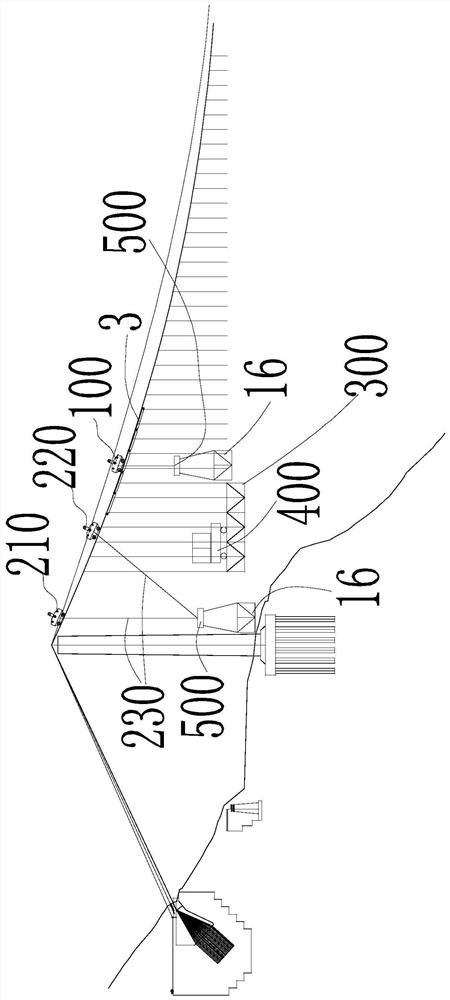

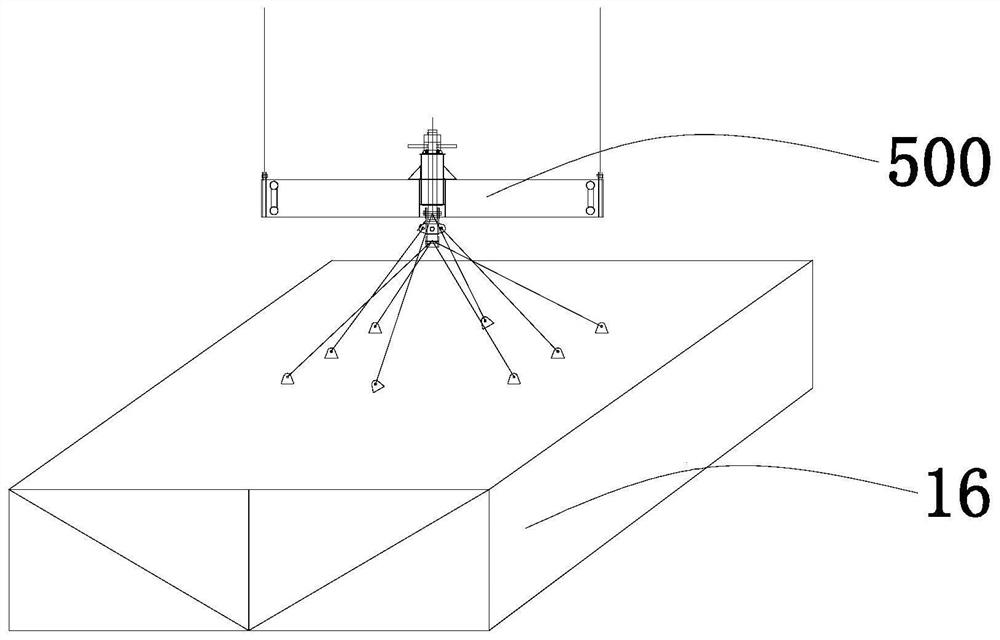

[0074] Such as figure 1 and figure 2 As shown, the cable-mounted crane device for installing the stiff beam of the suspension bridge in this embodiment includes a cable-mounted crane 200 and a mobile cable-mounted crane 100 installed on the main cable 10 of the suspension bridge and arranged at intervals, and The trolley 400 arranged on the stiff beam section 300, the stiff beam section 300 is assembled from a plurality of stiff beam sections 16, the trolley 400 is used to carry the stiff beam section 16 and can move along the longitudinal direction of the main cable 10 Move back and forth.

[0075] The cable-loaded crane 200 for lifting is arranged on one side of the stiff beam section 300 , and the cable-loaded crane 200 for lifting is used for hoisting the stiff beam section 16 onto the stiff beam section 300 . The hoisting cable-carrying crane 200 comprises a first cable-carrying crane 210 and a second cable-carrying crane 220 arranged at intervals on the main cable 10,...

Embodiment 2

[0109] Such as Figure 13 As shown, this embodiment is basically the same as Embodiment 1, and the only difference is that there are two sets of cable-mounted crane devices, and the two sets of cable-mounted crane devices are respectively arranged at both ends of the suspension bridge. This scheme installs stiff beams from both ends to the middle, which can further improve the installation efficiency of stiff beams.

[0110] Repeat step S2-step S7 to install the stiff beams of each segment in sequence, that is, install the stiff beams from the two towers to the mid-span.

Embodiment 3

[0112] Such as Figure 14 As shown, this embodiment is basically the same as Embodiment 1, and the only difference is that: both sides of the lifting cable crane 200 are provided with a stiff beam section 300 and a carrying cable crane 100 . This solution installs stiff beams from the middle to both ends, which can not only further improve the installation efficiency, but also reduce equipment investment.

[0113] Repeat step S2-step S6 of embodiment 1 to install the stiff beams of each segment in sequence, that is, install the stiff beams from the mid-span to the two cable towers; install the two mid-span stiff beams according to the method of step S7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com