Rail dual-purpose mobile breaking platform

A dual-purpose, platform technology, used in loading/unloading, mechanical conveyors, grain processing, etc., can solve the problems of insufficient sorting effect, high purchase cost, oil filter blockage, etc., to achieve circular economy utilization, advance and retreat moving speed Fast, moving with low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] The rail dual-purpose mobile crushing platform is a rail dual-purpose mobile landing integrated crushing platform, which crushes various aggregates such as construction gravel, waste rock tailings, coal mines, non-ferrous metal chemical mines, metallurgical slag, and construction waste.

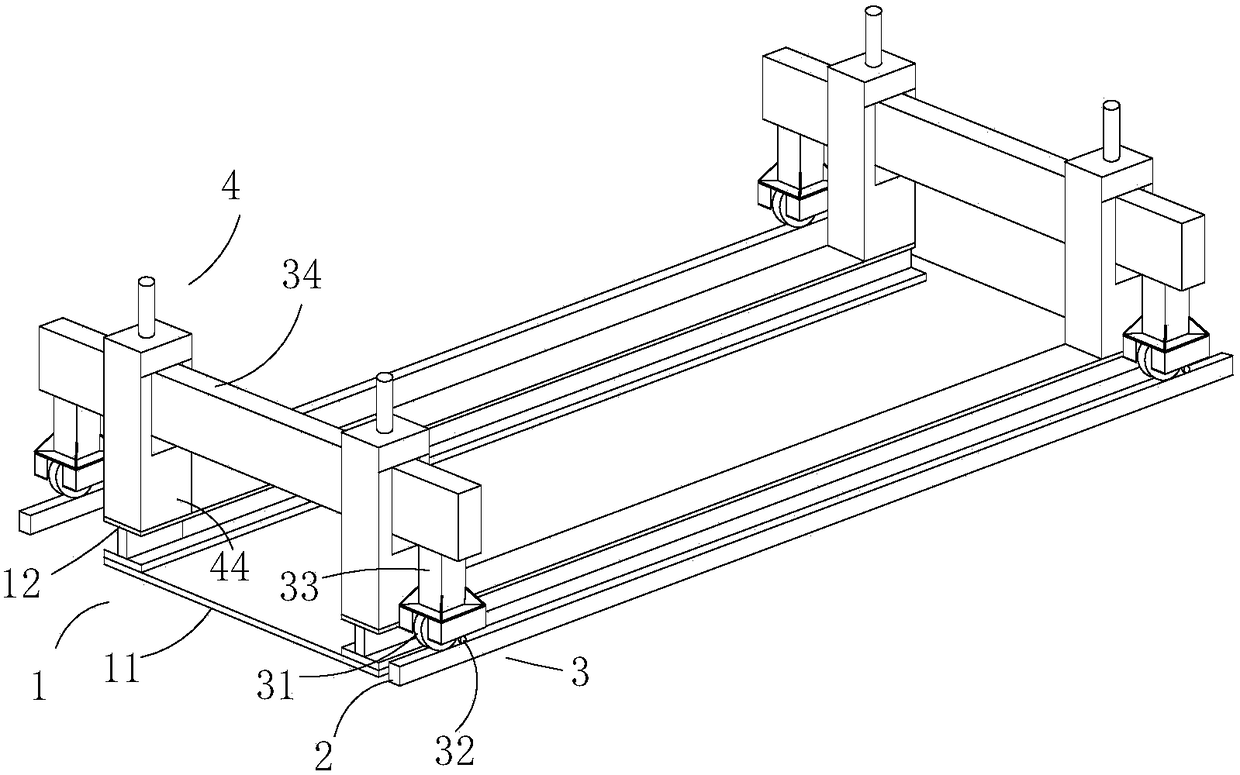

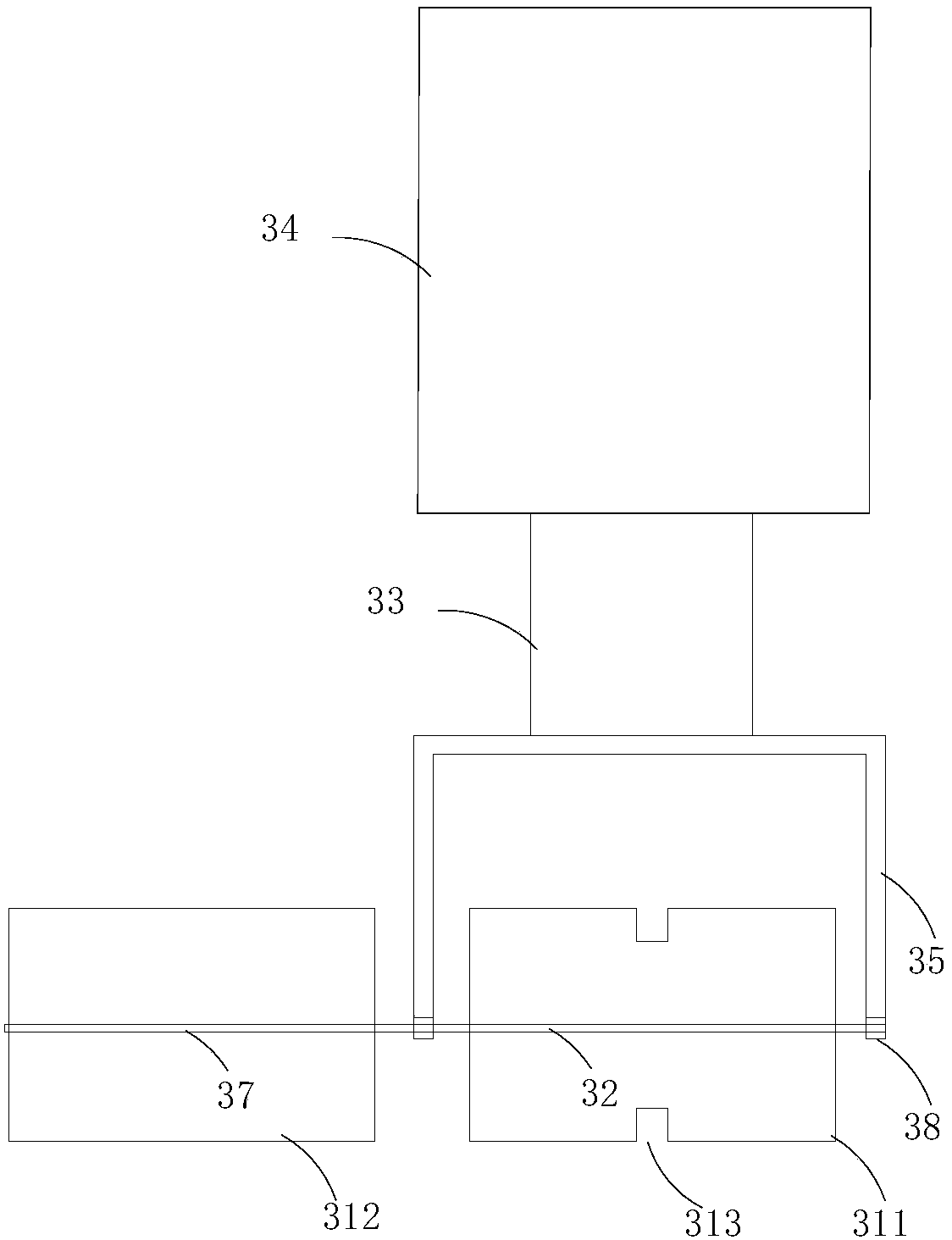

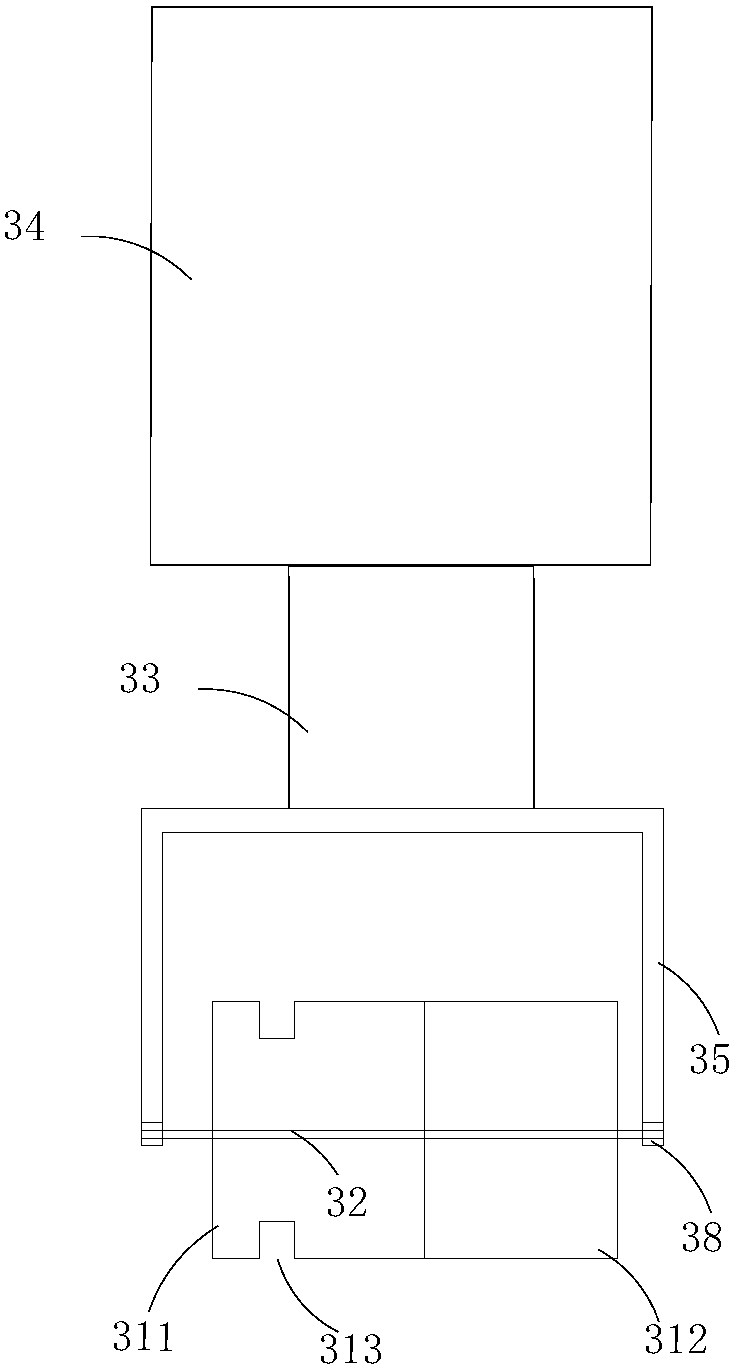

[0038] Such as figure 1 Shown is a schematic structural view of the rail dual-purpose mobile breaking platform in the present invention.

[0039]The rail dual-purpose mobile crushing platform realizes the movement without the traction of a dedicated vehicle. The movement only use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com