Roll-to-roll type continuous electroplating conductive device

A conductive device, roll-to-roll technology, applied in the current conduction device, electrolysis process, electrolysis components, etc., can solve the problem that the electroplating sheet affects the quality of the coating, reduce the possibility of coating and corrosion, prolong the replacement cycle, and resist corrosion. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The application will be described in further detail below in conjunction with the accompanying drawings.

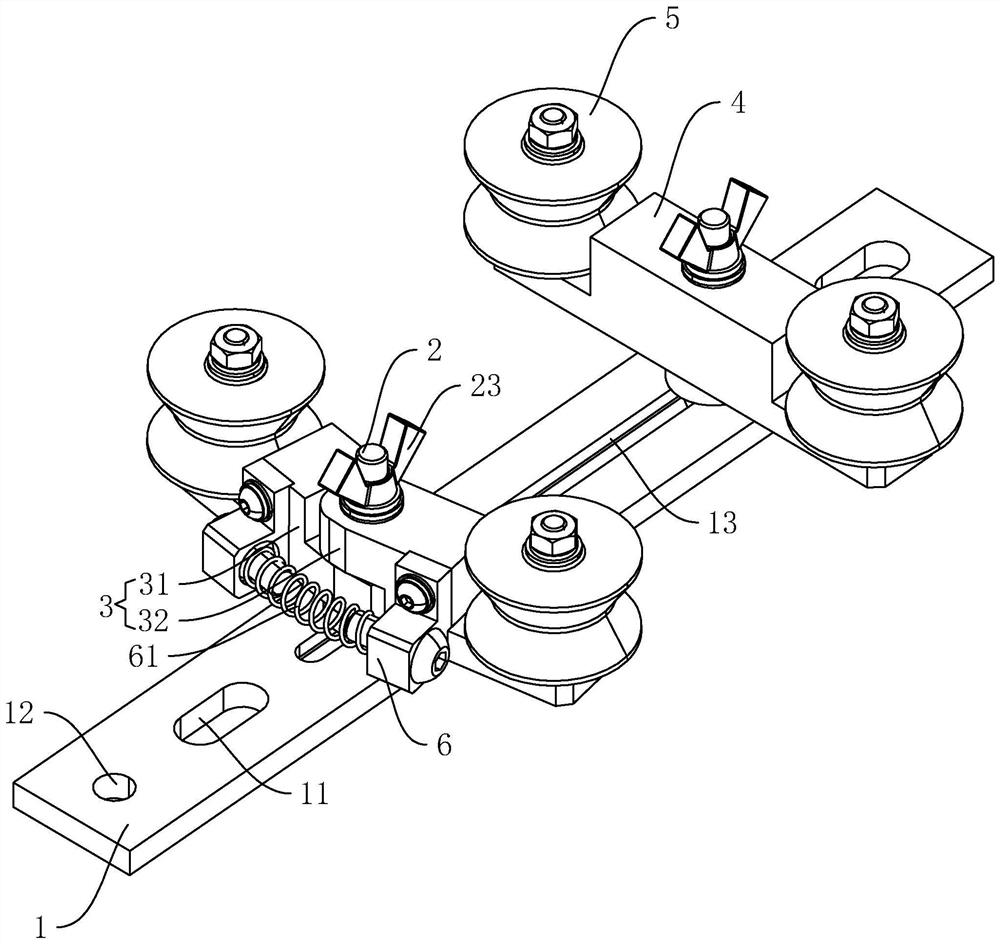

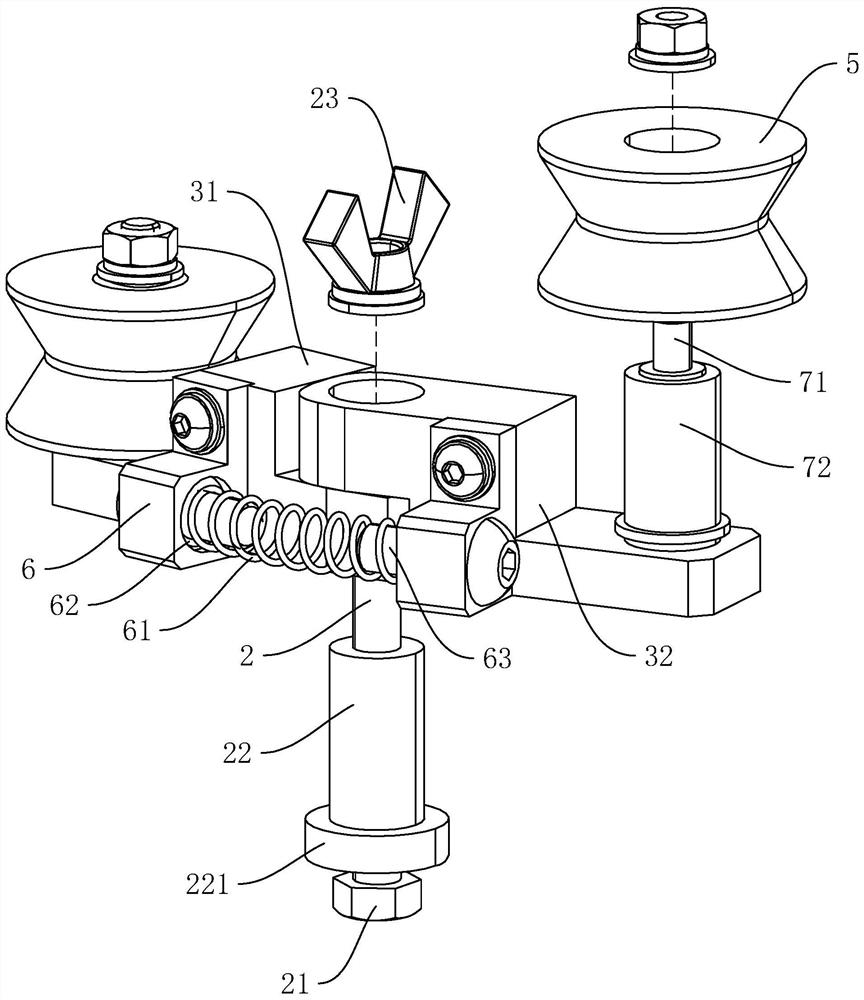

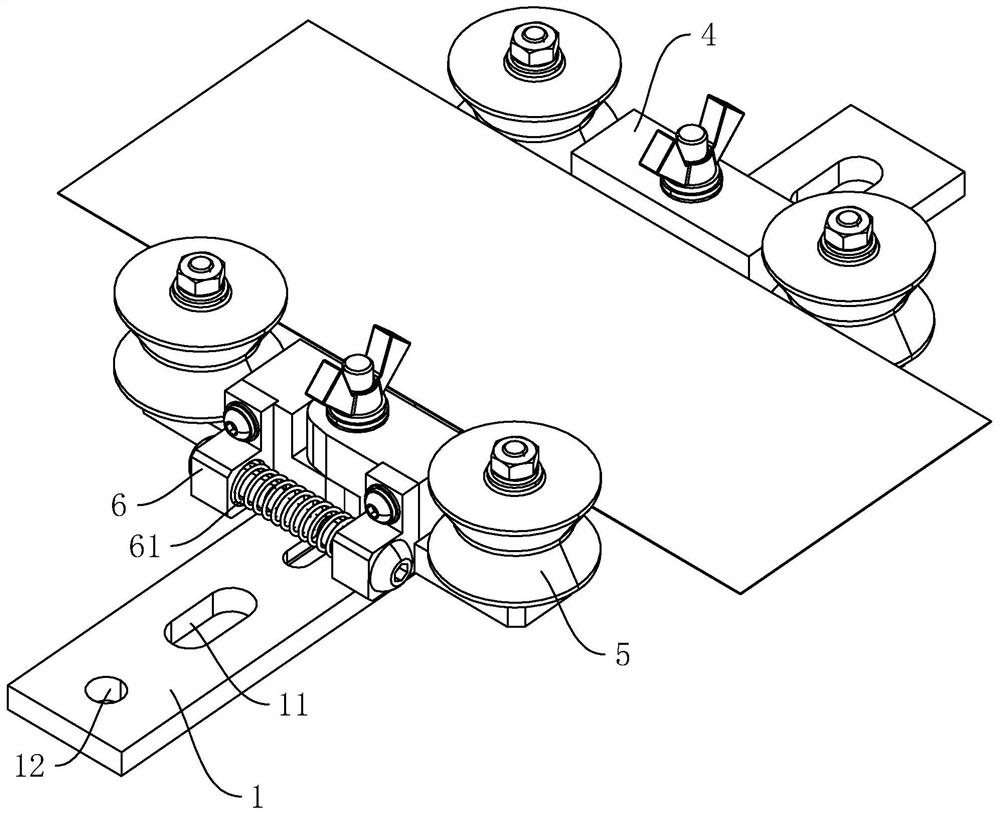

[0039] The embodiment of the present application discloses a roll-to-roll continuous electroplating conductive device. refer to figure 1 The roll-to-roll continuous electroplating conductive device includes a mounting base 1, two rotating shafts 2 vertically installed on the mounting base 1, a first mounting base 3 and a second mounting base 4 respectively rotating and sleeved on the two rotating shafts 2 , and the conductive wheel 5 installed on the first mounting base 3 and the second mounting base 4, the two rotating shafts 2 are distributed at intervals.

[0040] Both ends of the mounting base 1 are provided with mounting holes 11 for installing and fixing the mounting base 1, and one end of the mounting base 1 is provided with a wiring hole 12, and the wiring hole 12 is used to connect the power cord of the power supply.

[0041] The first mounting base 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com