Heat exchange tube cleaning machine

A technology for heat exchange tubes and washing machines, which is applied in the directions of flushing and cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of high pressure water pipes prone to slipping and the center of gravity shift, and achieves easy slippage, low load, no Easy to wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

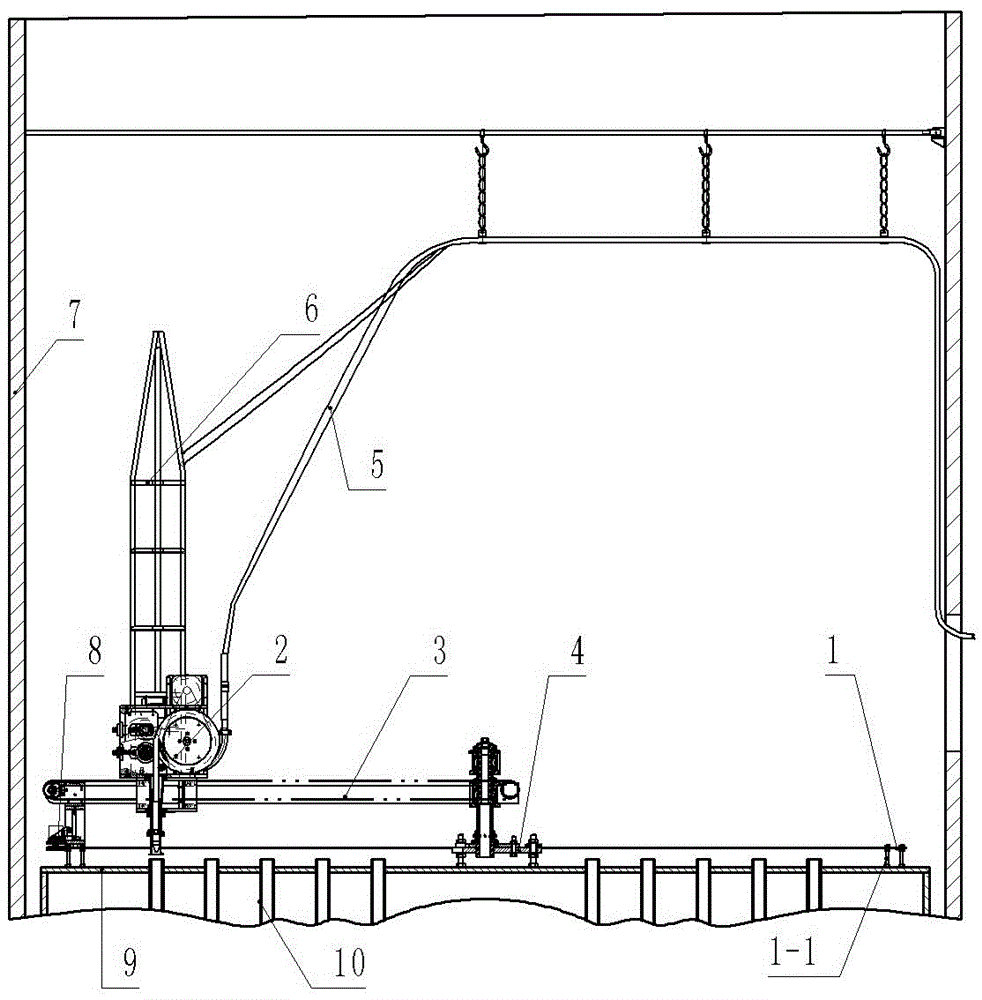

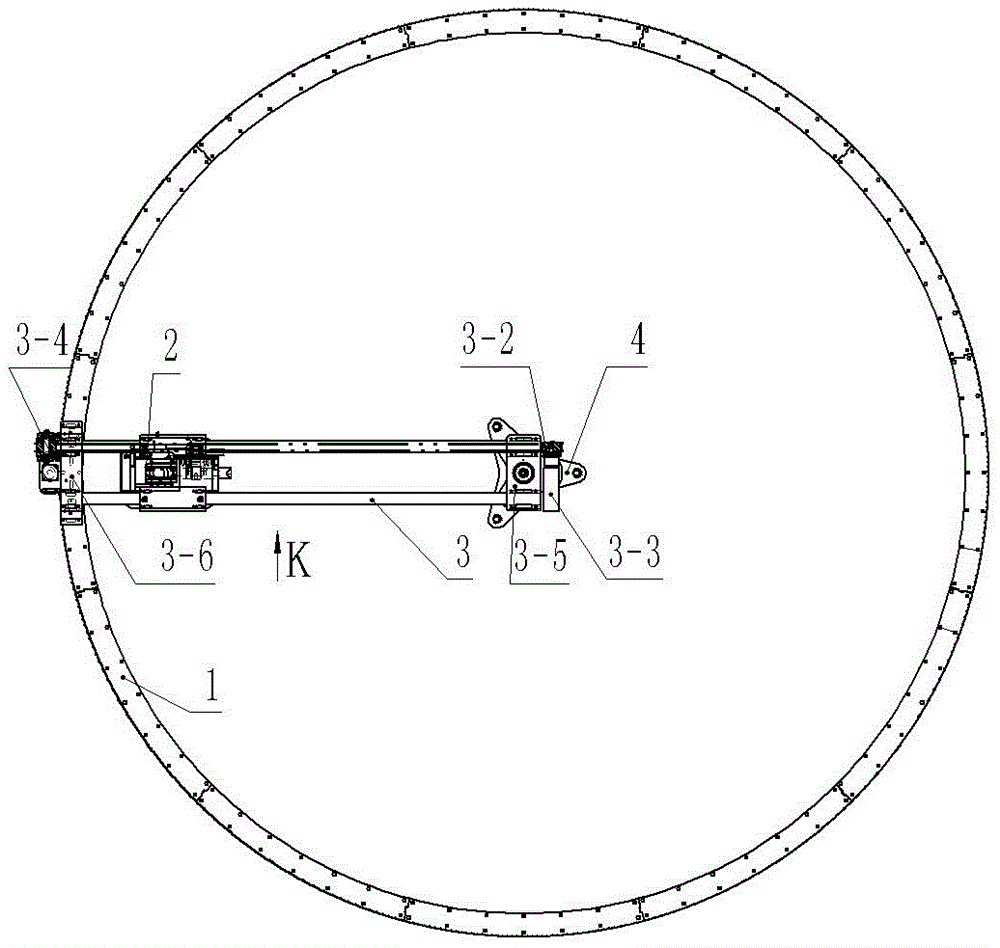

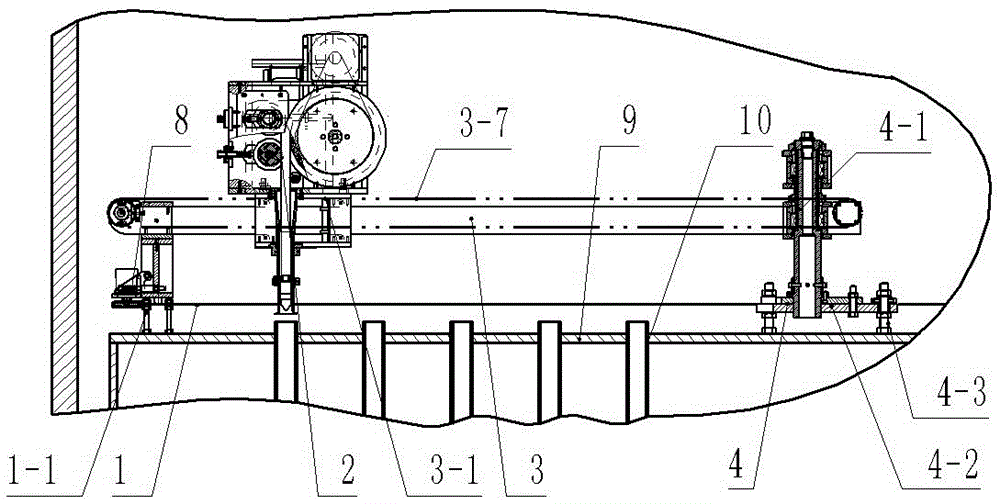

[0025] Such as figure 1 and figure 2 The shown heat exchange tube cleaning machine includes an end plate 9 installed in the cylinder body 7, and a plurality of heat exchange tubes 10 protruding from the end surface of the end plate 9 are installed on the end plate 9, and at the end near the side wall of the cylinder body 7 The plate 9 is equipped with a circular guide rail 1, and teeth are distributed on the outer ring of the circular guide rail 1. The circular guide rail 1 of this embodiment is composed of a plurality of arc-shaped guide rail plates 1-2 that are sequentially clamped head to tail. One end of the plate 1-2 is provided with a protrusion and one end is provided with a gap, and the protrusion of the latter arc guide plate 1-2 is engaged with the gap of the previous arc guide plate 1-2; the adjacent arc guide plate The fit of 1-2 is clearance fit, such as Figure 6 As shown; multiple arc-shaped guide rail plates 1-2 are fixedly welded on the end plate 9 through ...

Embodiment 2

[0028] The diameter D of the traction sheave 2-6 is 4 times of the diameter d of the clamping sheave 2-2, and other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com