A steel plate oiling machine

A technology of oiling machine and steel plate, which is applied in the direction of coating and liquid coating device on the surface, etc. It can solve the problems of affecting the quality of steel plate, wear and scratches, and the inability to ensure uniform grease application, so as to save production time and maintain Convenience, guaranteed application quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

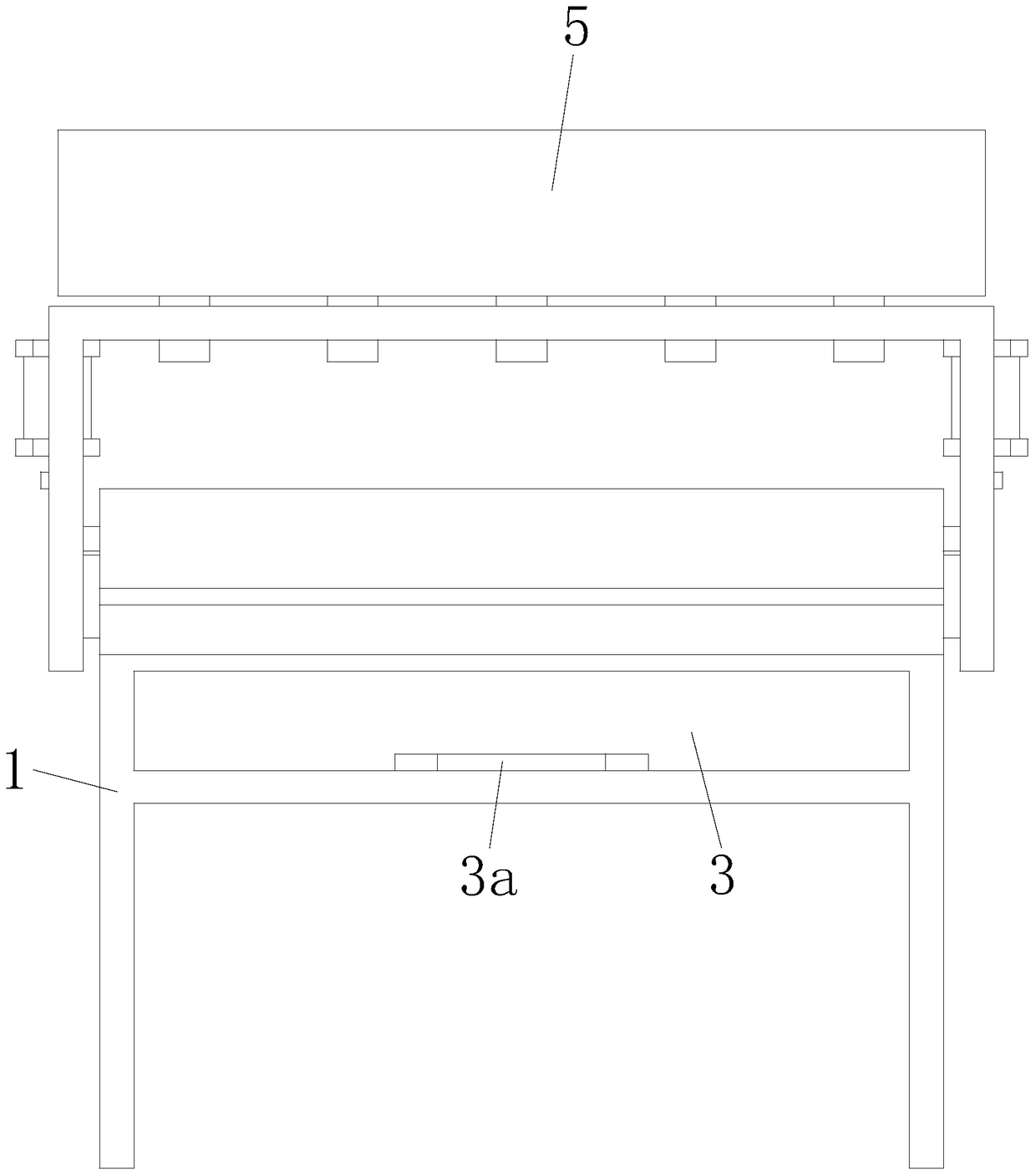

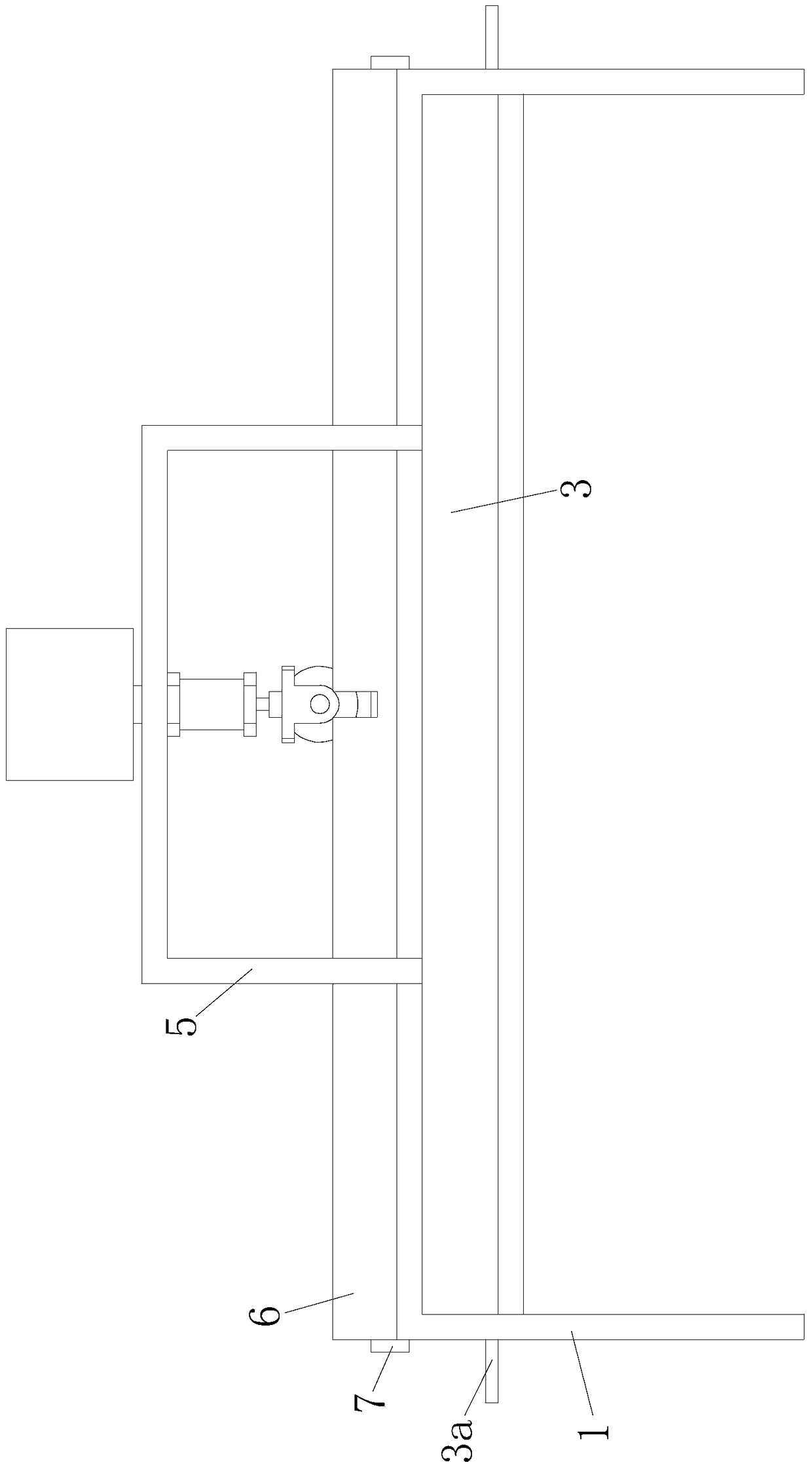

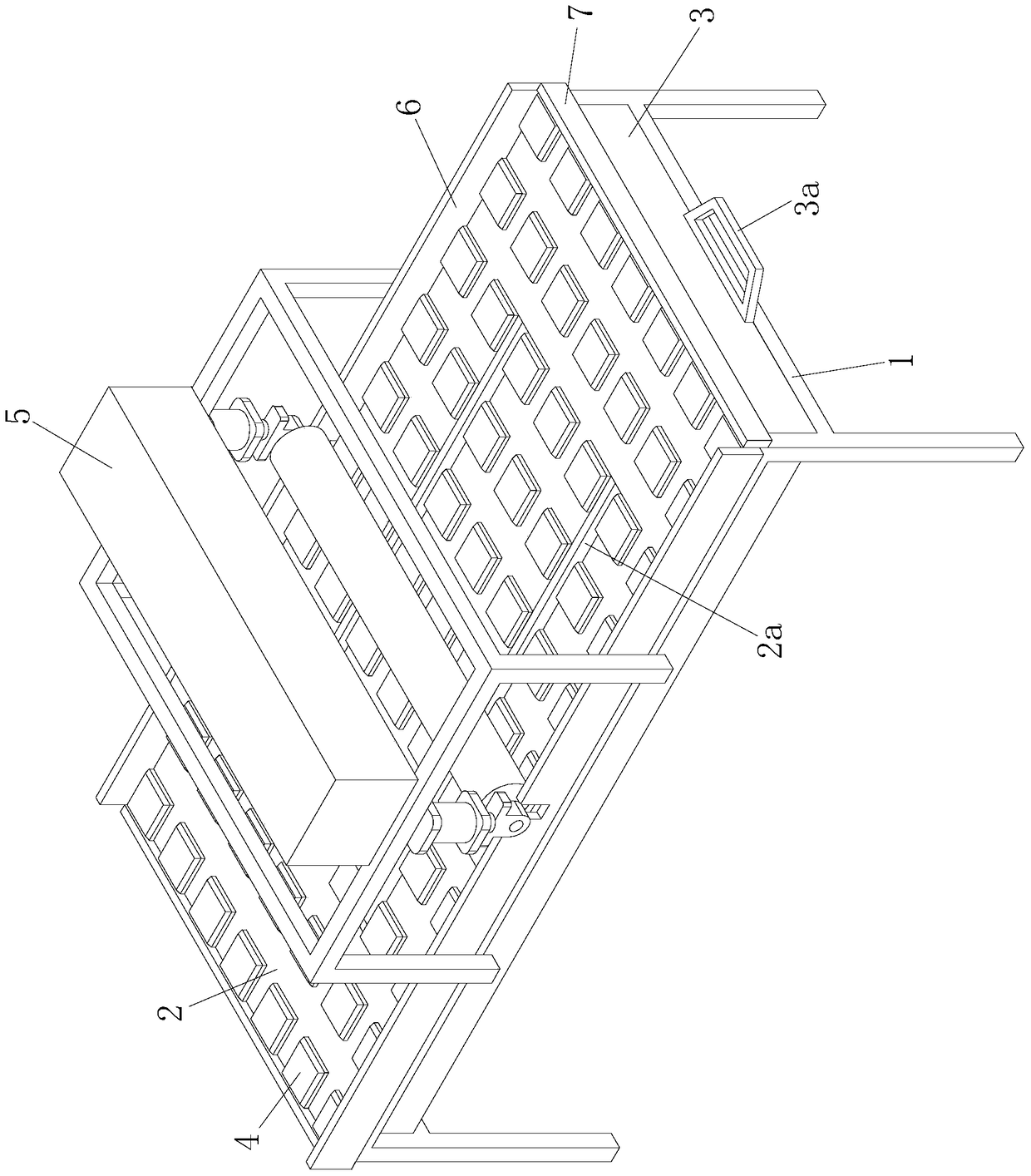

[0022] like Figure 1 to Figure 5 As shown, a steel plate oiler includes a support frame 1, the upper end of the support frame 1 is fixed with a mounting plate 2, and the lower end of the mounting plate 2 is provided with an oil collection tank 3 that can slide along the support frame 1. The oil sump 3 is provided with a handle 3a. During use, the oil collecting tank 3 collects the oil dirt on the mounting plate 2 .

[0023] The upper end of the mounting plate 2 is uniformly fixed with a sliding block 4 . When in use, the sliding block 4 supports the steel plate, increases the contact area of the steel plate, and reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com