Tobacco leaf baking loading and unloading device and using method thereof

A technology of tobacco leaf and conveying device, which is applied in the fields of tobacco, application, and preparation of tobacco, etc. It can solve the problems of increasing the cost of tobacco farmers, low work efficiency, and high labor intensity, and achieves the effects of saving manpower, easy operation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

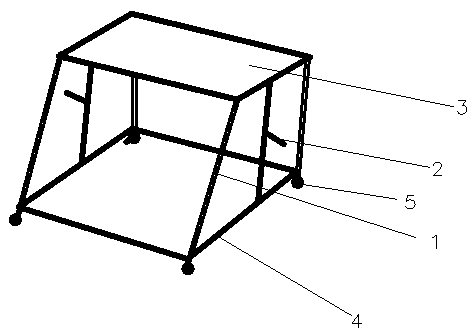

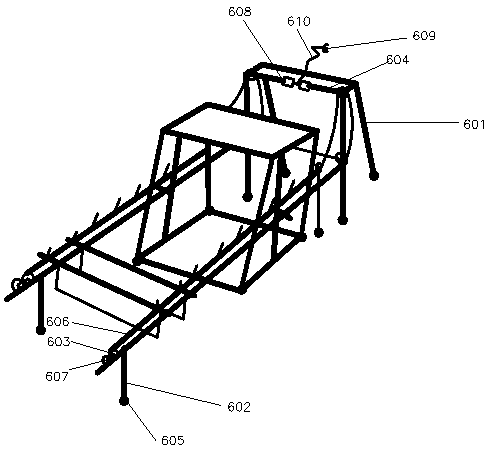

[0031] as attached figure 1 And attached figure 2 shown.

[0032] The invention provides a device for loading and unloading tobacco leaves, which includes a telescopic rod 1 , a handle 2 , a panel 3 , a fixed rod 4 , universal wheels 5 , and a conveying device 6 .

[0033] The telescopic rod 1 is connected with the panel 3 and the fixed rod 4 by screws, the handle 2 is located in the middle of the two telescopic rods 1 in the middle, the universal wheel 5 is located at the bottom of the telescopic rod 1 and connected with the telescopic rod 1 through the axle, and the transport device 6 is connected with the telescopic rod 1. The telescopic rod 1 is connected by screws.

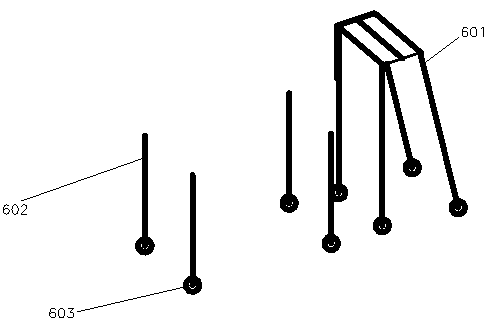

[0034] The conveying device 6 includes a bracket 601 , a support rod 602 , a gear 603 , a bearing 604 , a wheel 605 , a chain 606 , a tensioning device 607 , a driving device 608 , an external power plug 609 , and a wire 610 .

[0035] The bracket 601 is connected with the support rod 602 by screws, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com