One-driving-four manipulator and high-ray CNC matched type automatic charging and discharging system

A technology of automatic loading and unloading and manipulators, applied in the field of machinery, can solve the problems of being unable to promote the industrial automation process of the high-gloss automation industry, disrupting the vertical and horizontal planning of the machine, and uneven quality of processed products, so as to achieve flexible and controllable production capacity , saving transit space, and the effect of a safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention more clear, the following will be described in detail in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

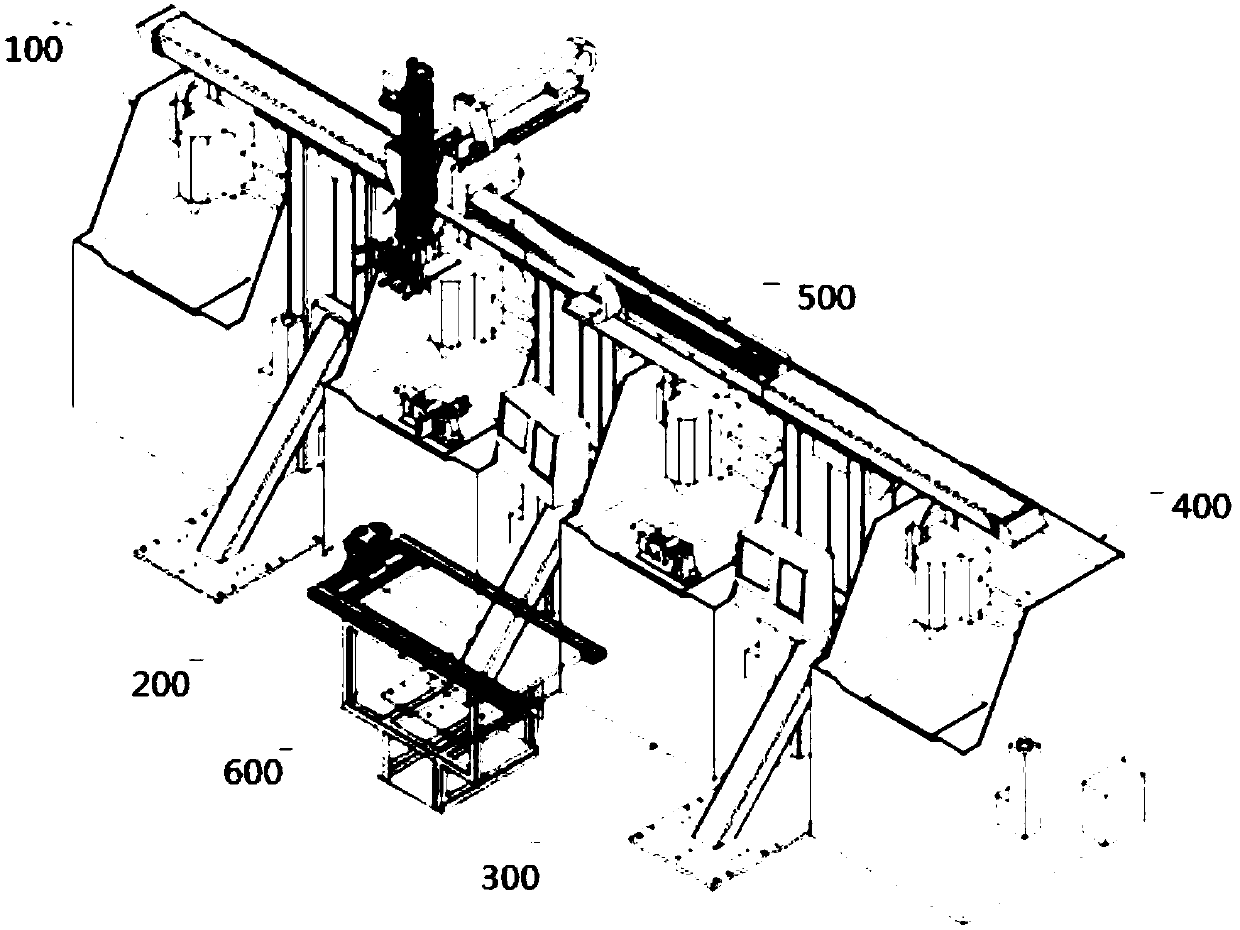

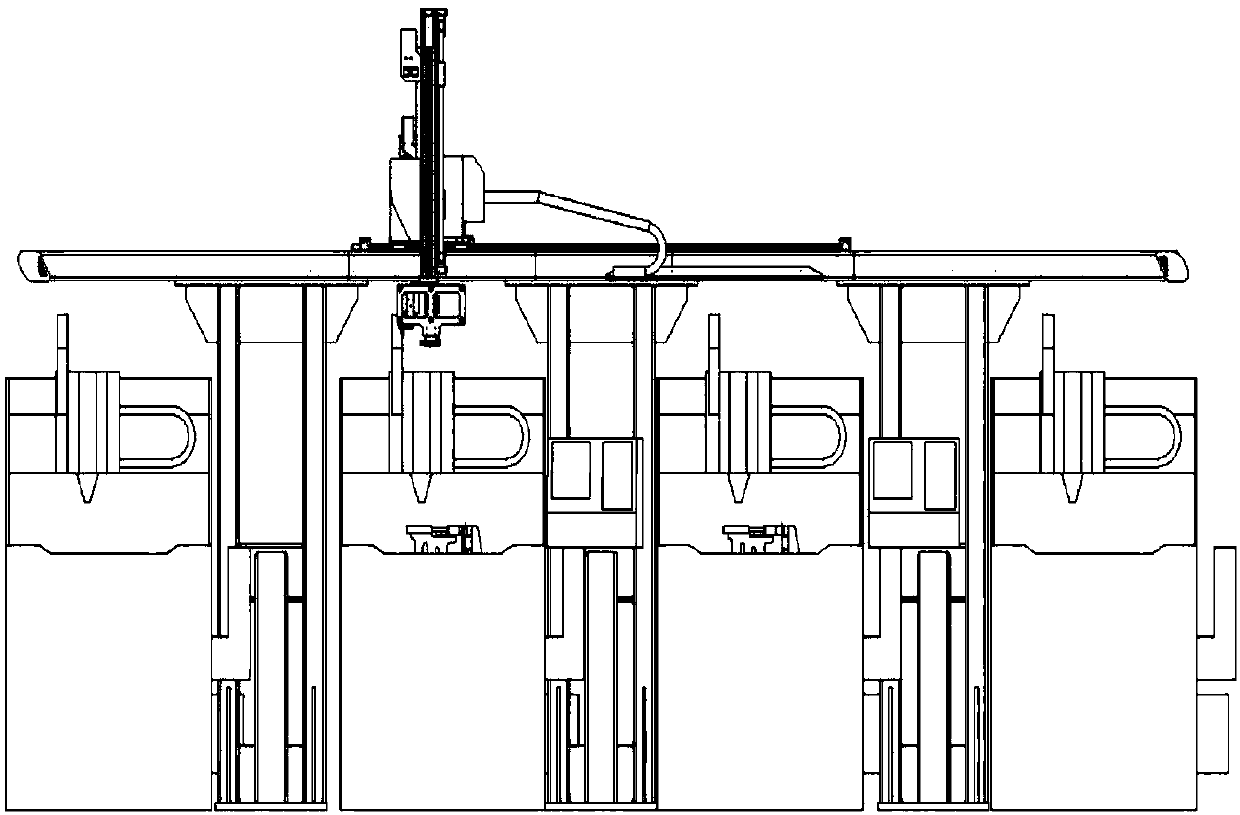

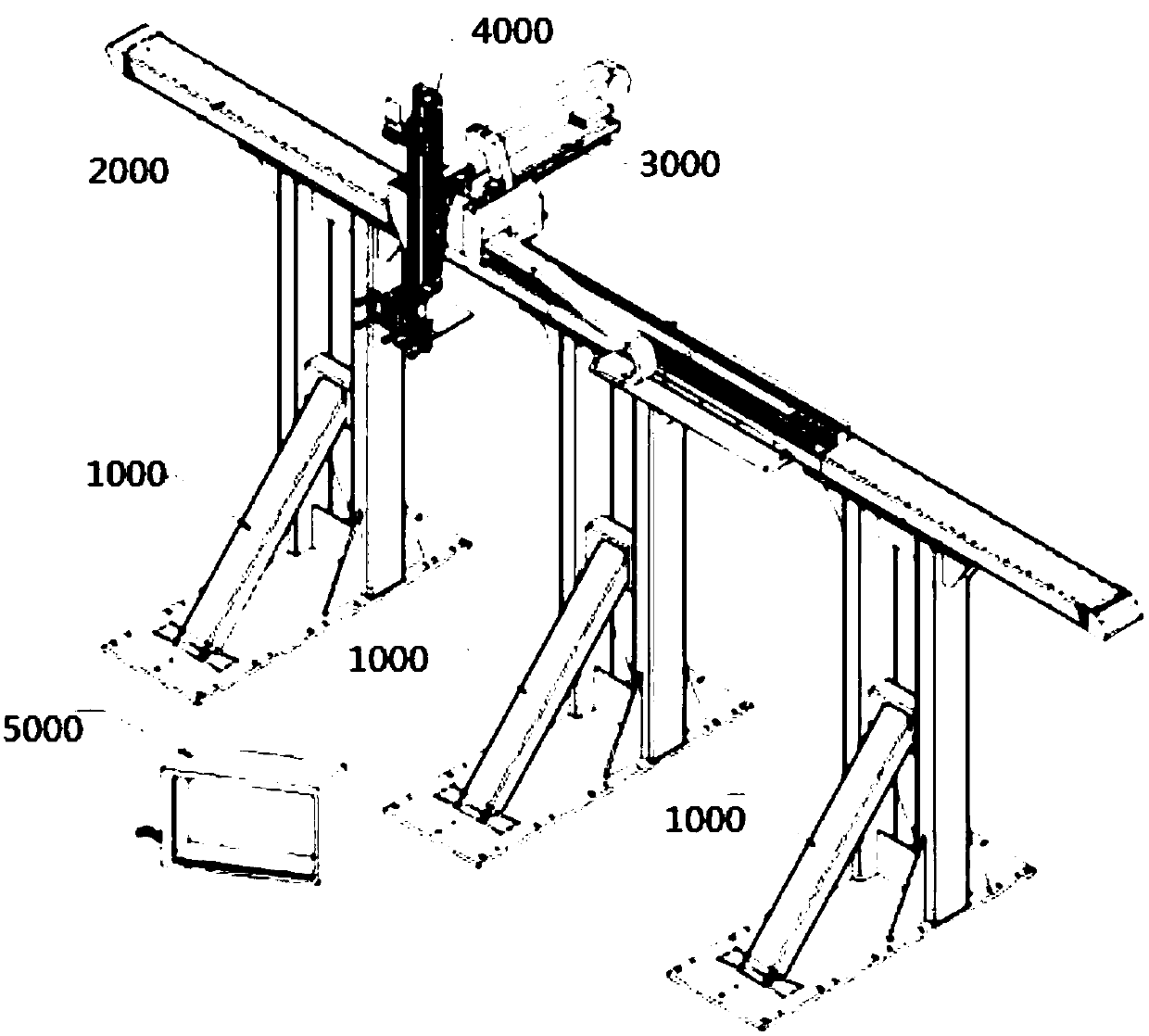

[0029] combine Figure 1-8 , the one-drag-four manipulator provided in this embodiment cooperates with the high-gloss CNC automatic loading and unloading system, including one-drag four-manipulator, the high-gloss CNC processing automatic feeding mechanism, the manipulator control box, the first high-gloss CNC machine 100 and the second high-gloss CNC machine 200, the first high-gloss CNC machine 200, the second high-gloss CNC machine The third high-gloss CNC machine 300 and the fourth high-gloss CNC machine 400, the first high-gloss CNC machine, the second high-gloss CNC machine, the third high-gloss CNC machine, and the fourth high-gloss CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com