Sample preparation device for food safety detection

A food safety and sample box technology, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of increasing the cost of food safety testing, reducing the reliability of testing data, and high production costs, so as to reduce the cost of food safety testing. Cost, simple structure, and the effect of protecting rights and interests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

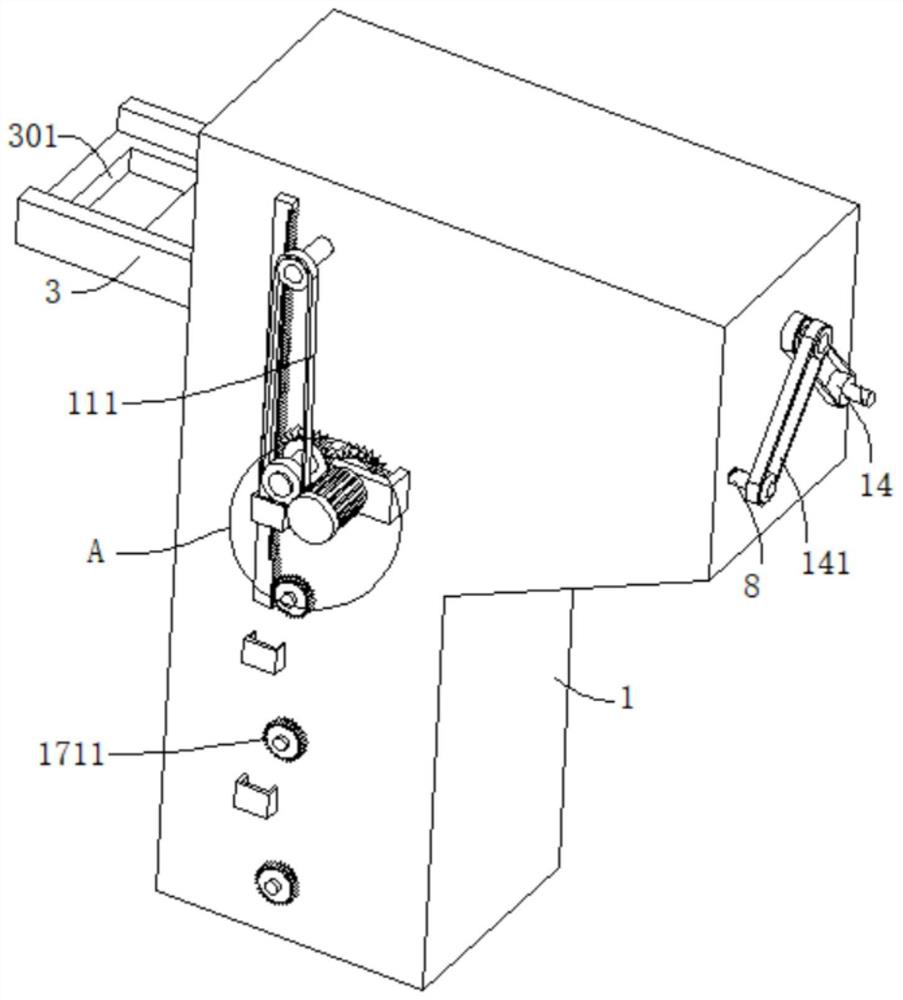

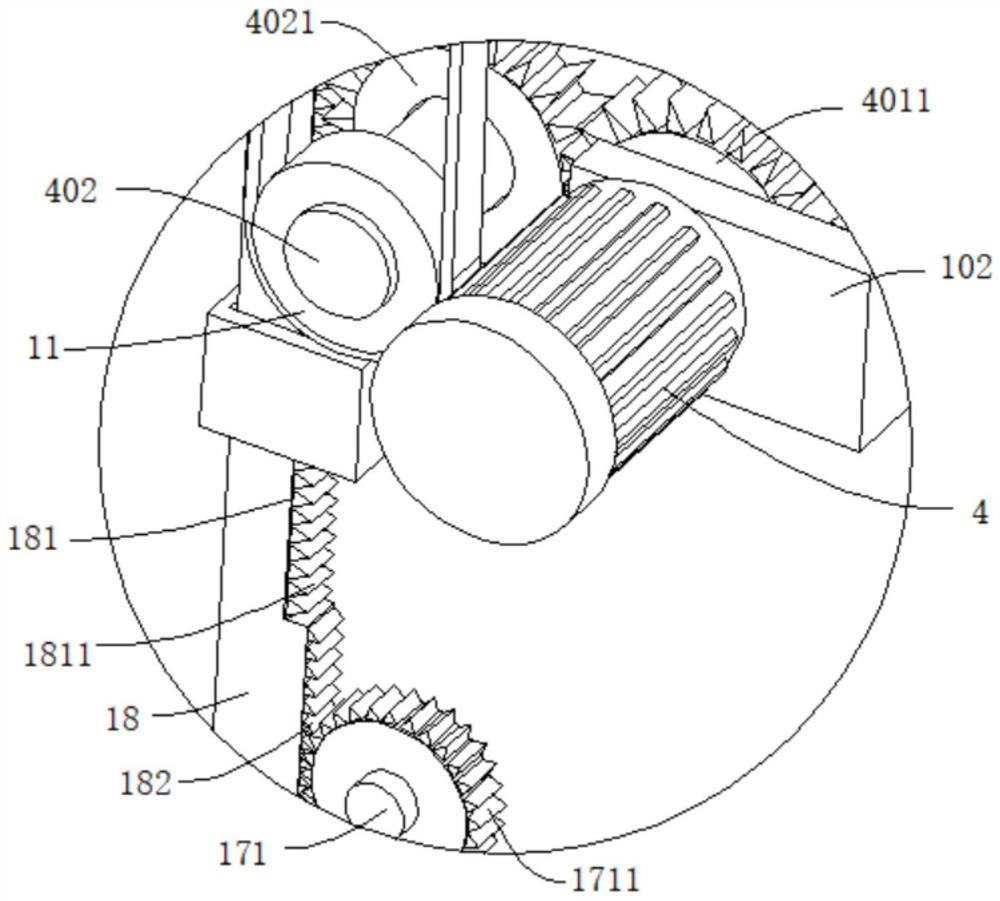

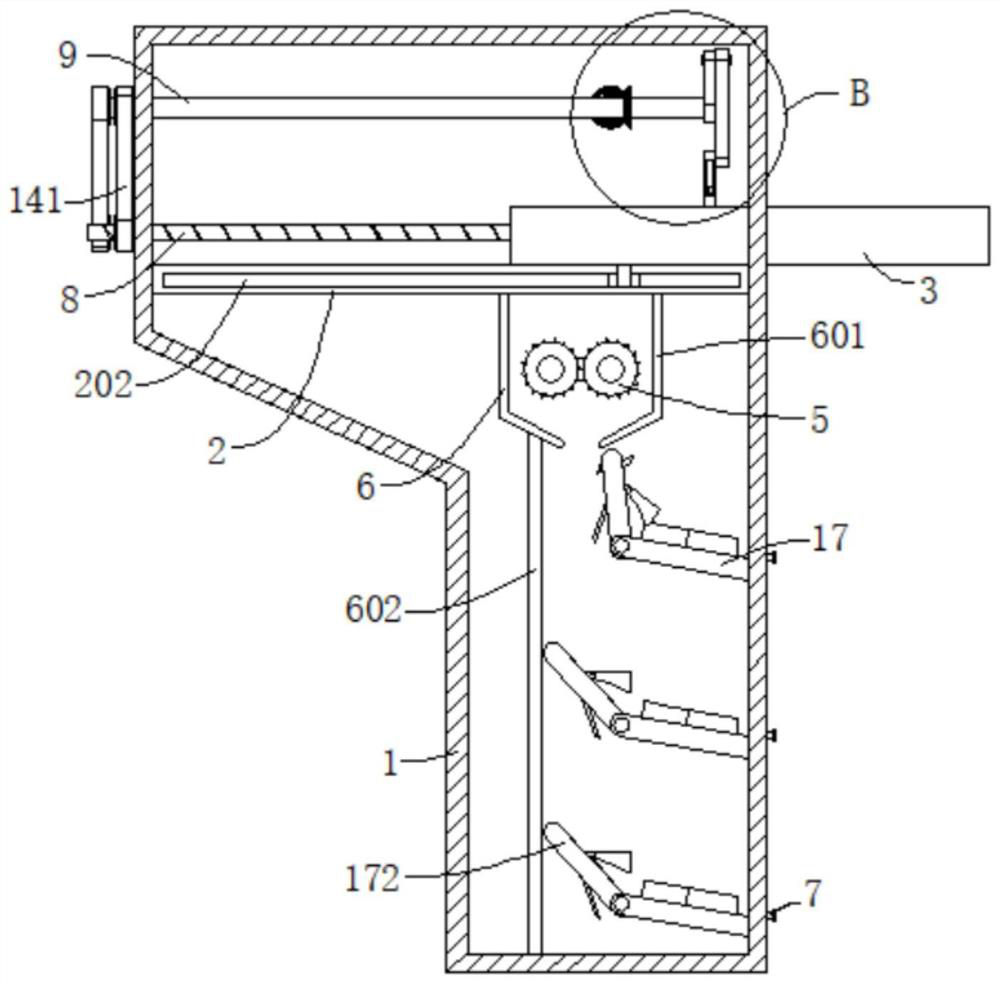

[0034] refer to Figure 1-7, a sample preparation device for food safety testing, comprising a sample preparation box 1, the inner wall of the sample preparation box 1 is fixedly connected with a fixed plate 2, the outer wall of the sample preparation box 1 is dug with an inlet 101, and the inlet 101 is placed above the fixed plate 2, The inner wall of the sample preparation box 1 is also rotatably connected with a screw mandrel 8 and a rotating shaft 9, the outer wall of the screw mandrel 8 is threadedly connected with a placing plate 3, the placing plate 3 is slidably connected to the outer wall of the fixed plate 2, and the outer wall of the rotating shaft 9 is connected with a cutting mechanism. The mechanism is placed above the placing plate 3, the outer wall of the fixing plate 2 is dug with a through hole 201, the outer wall of the placing plate 3 is dug with three feeding ports 301 matching the through holes 201, and the outer wall of the sample preparation box 1 is con...

Embodiment 2

[0044] refer to Figure 5-7 , a sample preparation device for food safety testing, which is basically the same as that of Embodiment 1, furthermore, the outer walls on both sides of the placement plate 3 are connected with sliders 302, and the outer walls of the fixed plate 2 are dug to match the sliders 302 Chute 202; improve the stability of the placement plate 3 during sliding.

[0045] The outer walls on both sides of the swing plate 172 are respectively connected with a first baffle plate 1721 and a second baffle plate 1722, and the outer wall of the inclined plate 17 is connected with a coaming plate 173; Plate 1722, the broken sample that is convenient to slide down from the swing plate 172 will not fall in the connection gap between the swing plate 172 and the inclined plate 17, which will affect the rotation of the swing plate 172, and the setting of the surrounding plate 173 is convenient for the sample to be discharged quickly. feed port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com