Automatic small trash fish slitting device and slitting method thereof

A longitudinal cutting device, a technology for small trash fish, which is applied in the directions of slicing fish, processing fish, slaughtering, etc., can solve problems such as increasing cost, limiting processing speed, and different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

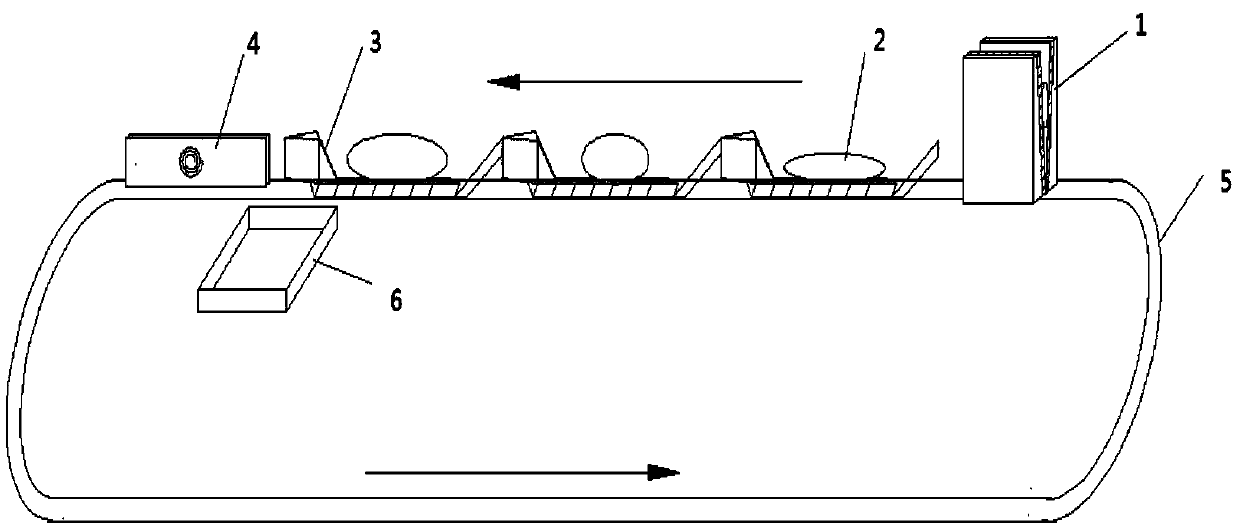

[0031] An automatic small miscellaneous fish longitudinal cutting device, such as figure 1 Shown: comprise track 5, conveying trolley 3, feeding device 1, spring splint 4 and connecting plate 6; Described feeding device 1 and described spring splint 4 are vertically arranged on track 5, and described track 5 is fed from The feeding device 1 and the spring splint 4 pass through the bottom; the conveying trolley 3 is located on the track 5, and the conveying trolley 3 passes the feeding device 1 and the spring splint 4 sequentially through the track 5; Connecting tray 6, wherein, the track 5 is a closed track 5; the conveying trolley 3 can run reciprocally on the track 5, and the closed track 5 includes a parallel track 5 part and an arc track 5 part, and the feeding The device 1 and the spring clamp 4 are placed vertically on the parallel rail 5 part.

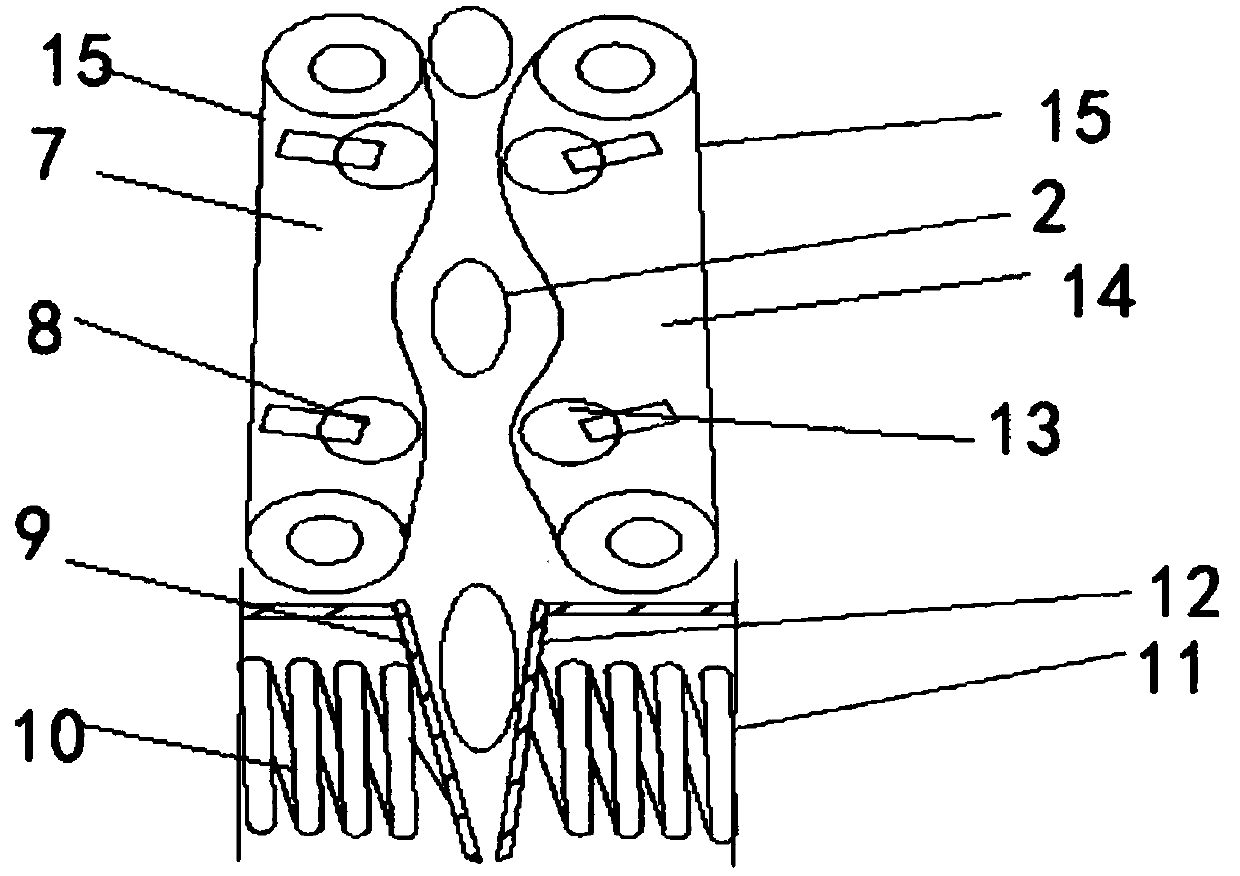

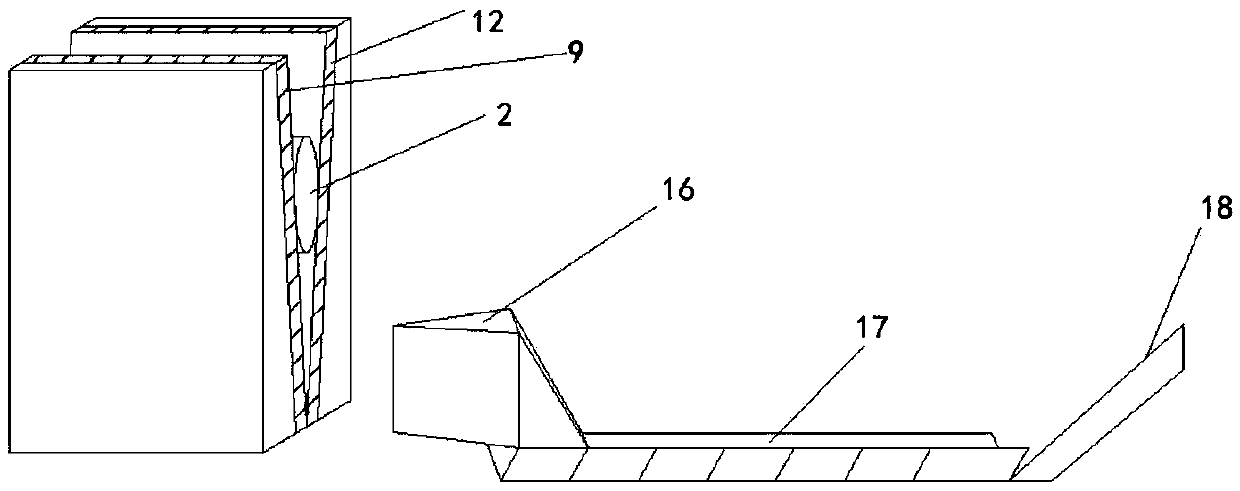

[0032] Such as figure 2 Shown: the feeding device 1 includes a first conveyor 7, a second conveyor 14, a first elastic pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com