Thread stripper

A wire stripper and rectangular technology, which is applied in the direction of cable installation devices, electrical components, equipment for removing/armoring cables, etc., can solve the problems of not being able to use one device for two purposes, increasing the space occupied by items, and additional purchase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

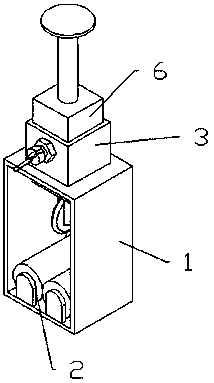

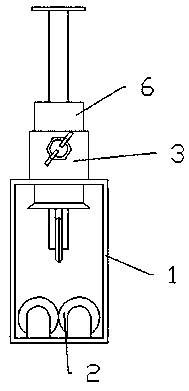

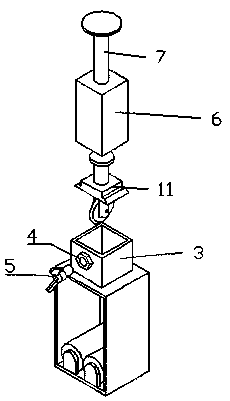

[0016] Such as Figure 1-5 As shown, a wire stripper includes a support frame 1, a rotating roller 2, a guide groove 3, a fixed nut 4, a fastening pin 5, a guide post 6, a push rod 7, a rectangular card slot 8, a cylindrical slot 9, and a compression spring 10. Stripping body 11, the supporting frame 1 is a rectangular structure, and the bottom of the inner wall of the supporting frame 1 is provided with two rotating rollers 2 of the same size, the two rotating rollers 2 are axially parallel and the outer walls are tangent, so The top of the support frame 1 is vertically provided with a guide groove 3 of a rectangular structure, the guide groove 3 runs through the top surface of the support frame 1 up and down, the outer wall of the guide groove 3 is provided with a fixing nut 4, and the fastening pin 5 and the fixing nut 4 Threaded connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com