Road deicing device

A technology of roads and racks, which is applied in the field of road deicing devices, can solve the problems of great environmental damage, broken teeth, and high energy consumption, and achieve the effect of improving crushing efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

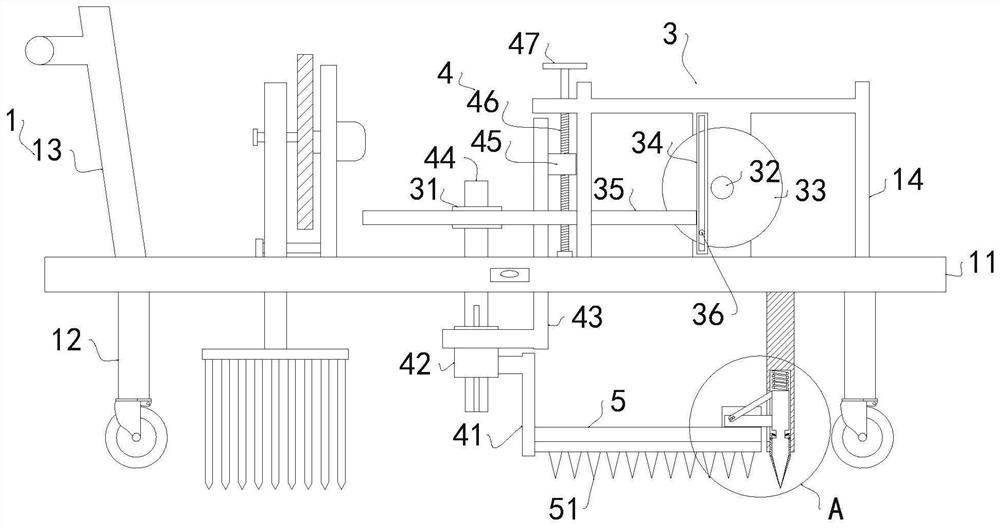

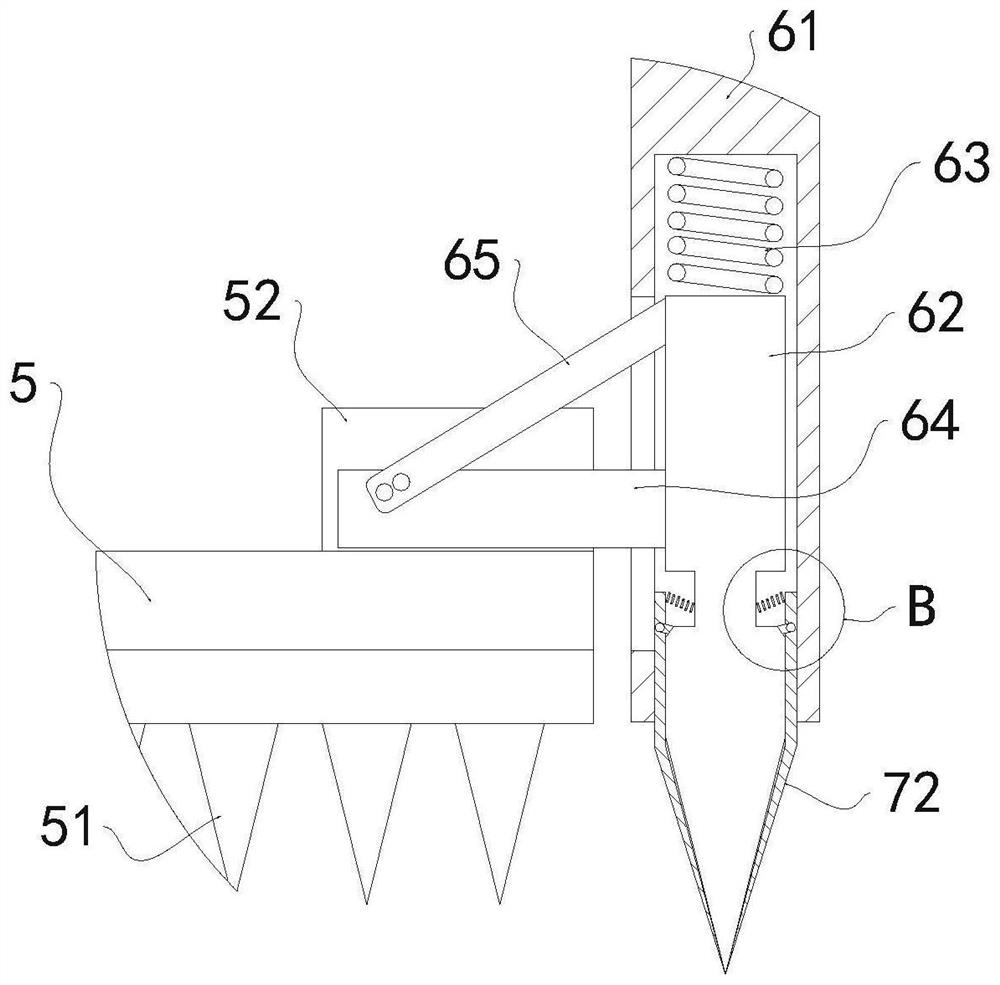

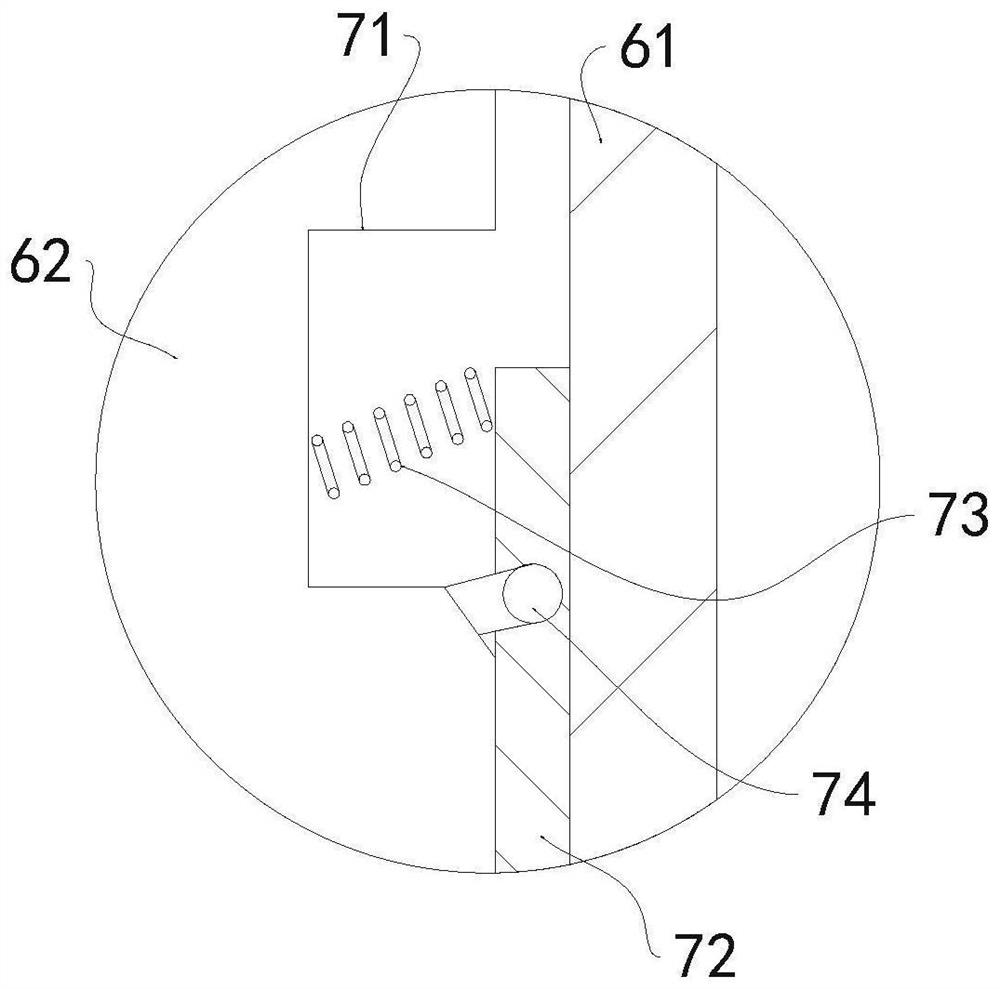

[0039] see Figure 1-7 , a road deicing device, including a shelf 1, a driving assembly 3, a moving assembly 4, a scraper plate 5 and a hammer driving member 6; The roller 12, the hand push frame 13 fixed on the upper end of the horizontal frame 11 and the top frame body 14 fixed on the upper end of the horizontal frame 11; the driving assembly 3 and the moving assembly 4 are installed on the frame 1 for driving the scraper plate 5 to move up and down , swinging back and forth; the scraper plate 5 is located at the lower side of the cross frame 11, and broken scraper teeth 51 are evenly distributed on the lower end of the scraper plate 5, and the upper end surface of the tooth scraper plate 5 is set in a wave shape; the hammer driver 6 is fixedly installed on the The lower end of the horizontal frame 11 is in front of the scraper plate 5 along the moving direction of the frame 1; the hammer driving part 6 includes a hammer cylinder 61, a breaking hammer 62, a compression sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com