Patents

Literature

32 results about "Roll slitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole (the 'log') and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults (short for multiple) or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths, (frequently many tens of kilometres), onto one bobbin.

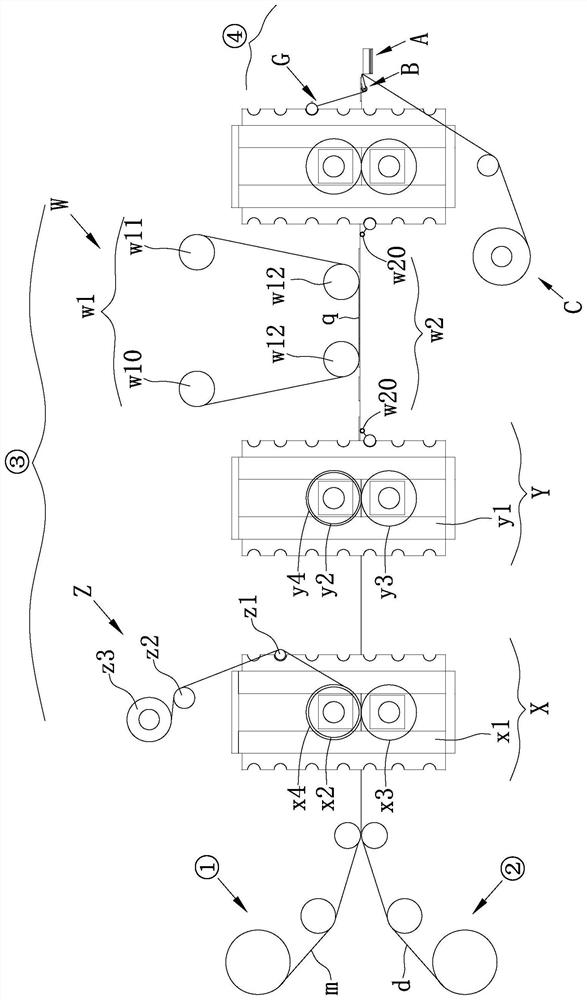

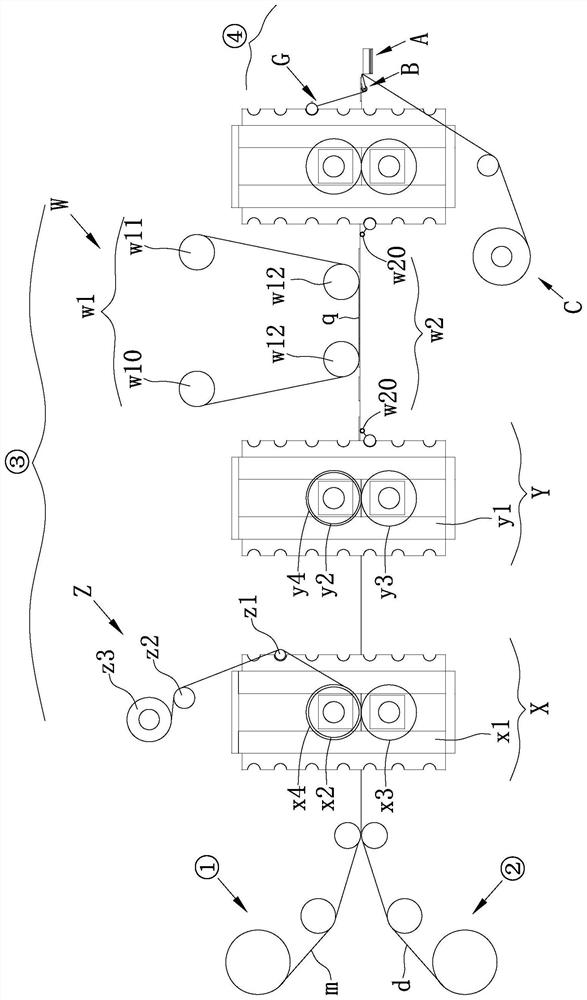

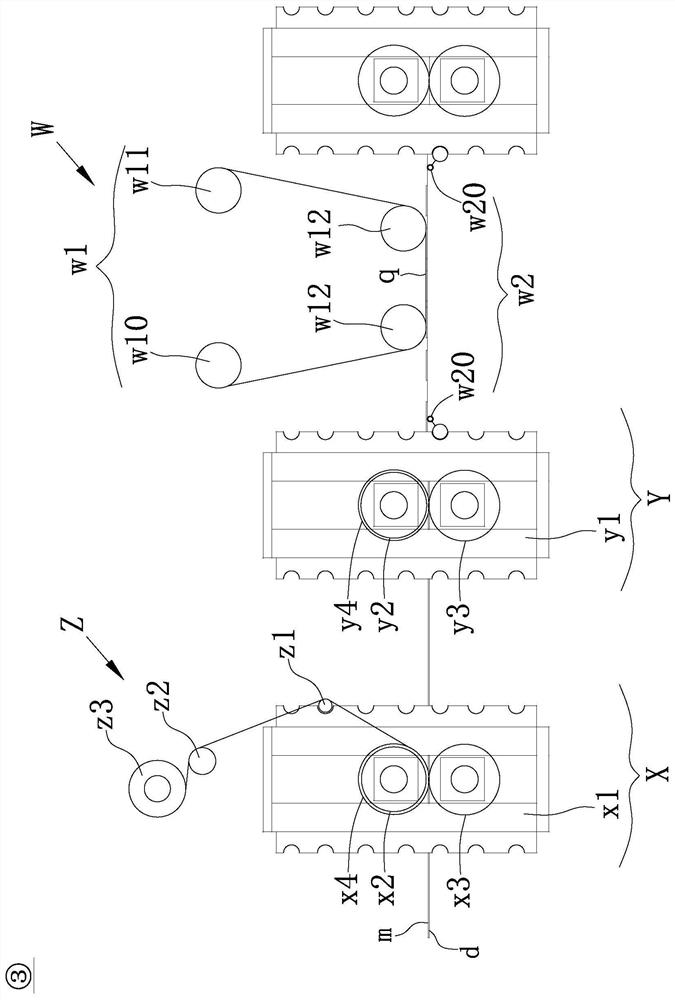

Rolling method and device for headless continuous casted and rolled ultra-low carbon steel roll ferrite used for ultra-deep drawing

PendingCN107597845AReduce rolling pressureCompact structureTemperature control deviceWork treatment devicesCarbon steelRoll slitting

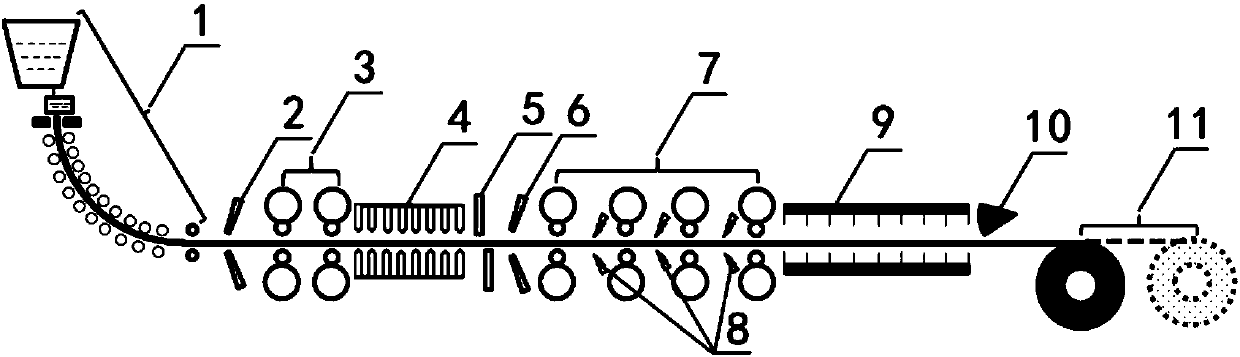

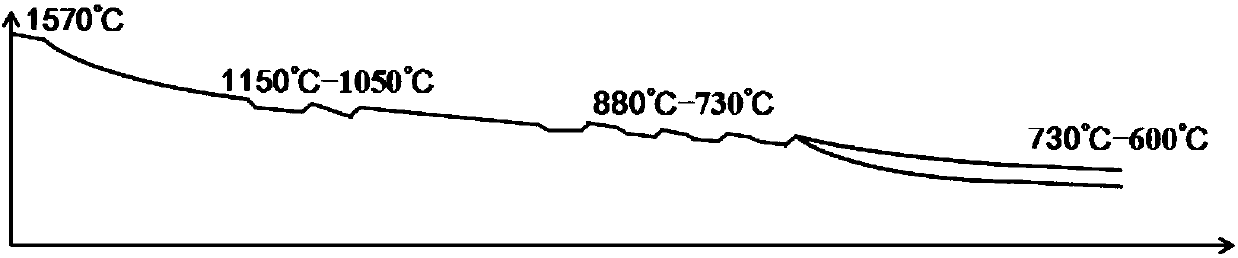

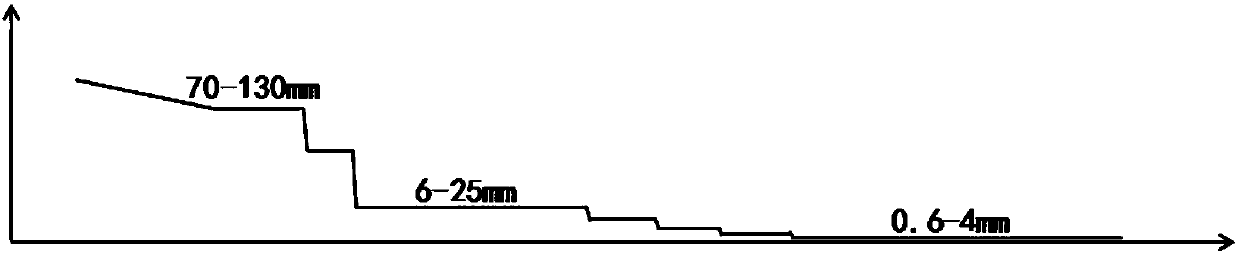

The invention provides a rolling method and device for headless continuous casted and rolled ultra-low carbon steel roll ferrite used for ultra-deep drawing, and belongs to the field of metallurgicalrolling. The process of the rolling method is continuous casting for billet forming, high pressure water descaling, coarse rolling through a coarse rolling machine set, rapid cooling (controlling phase change), high pressure water descaling, ferrite rolling through a fine rolling machine set (blowing and sweeping water between racks), cooling through a layer cooling device, high speed flying shearfor roll slitting and coiling through a coiling machine. By means of the rolling method, the difficult problems that the heating temperature of a heating furnace before coarse rolling in a conventional hot rolling process is high, the time of temperature waiting for cooling time between coarse rolling in an Austenite area and fine rolling in a ferrite area is long, and the fine rolling temperature, the steel coil surface quality, forming performance and the like of continuous casting and rolling process of a thin plate which is represented by CSP are difficult to stably control are solved, the rolling method has the advantages of being compact in layout, few in investment, high in production efficiency, safe, reliable, energy-saving, environmental-protection, low in cost and the like, andthe ultra-low carbon steel coil for ultra-deep drawing is produced through headless continuous casting and rolling and ferrite rolling.

Owner:UNIV OF SCI & TECH BEIJING

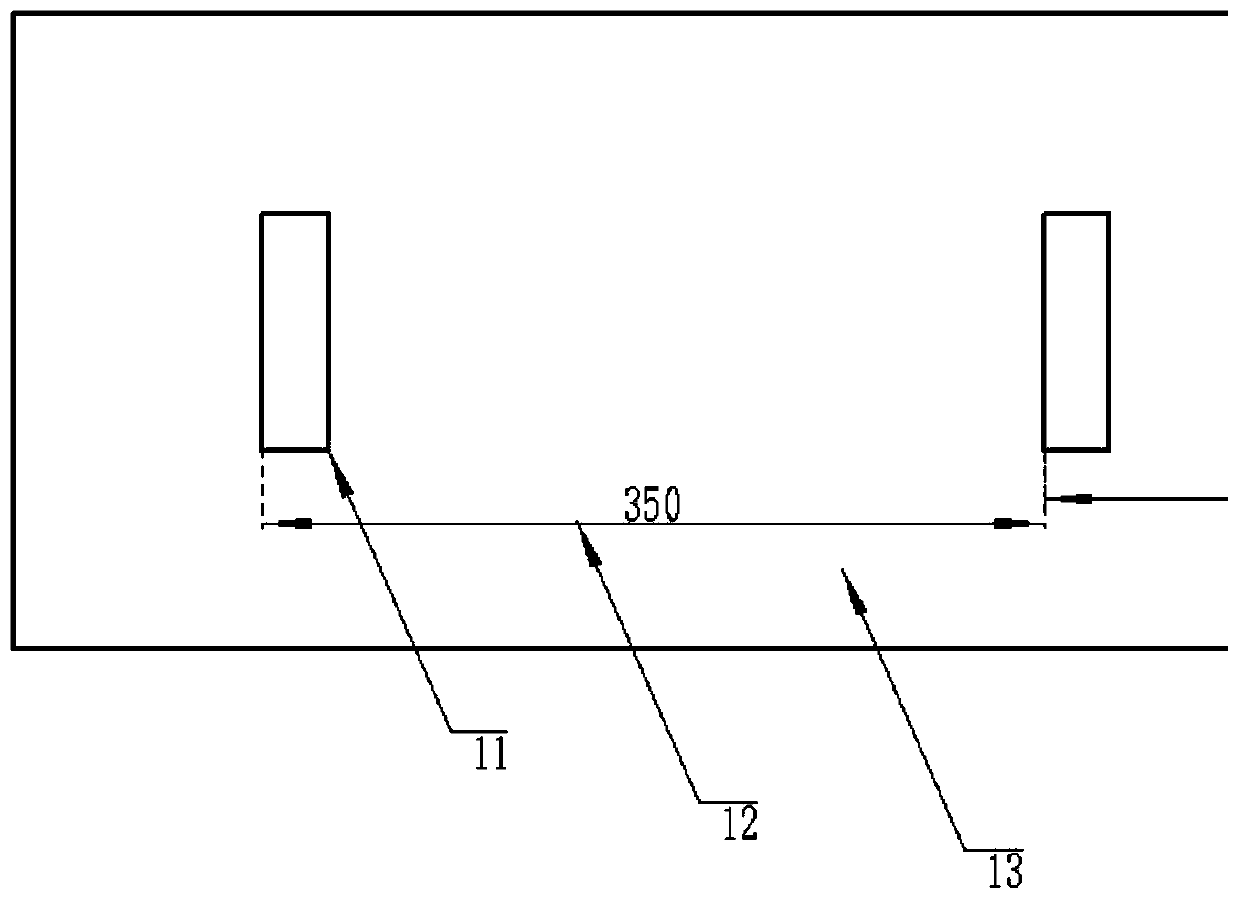

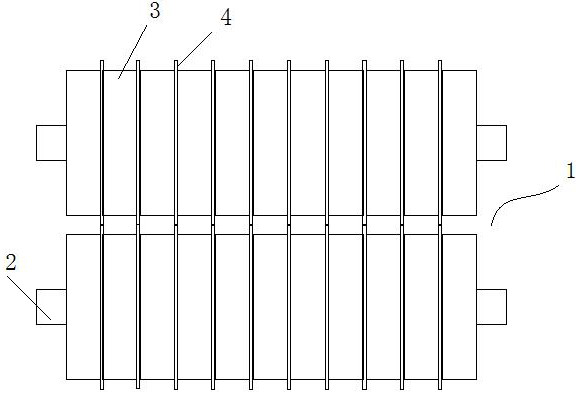

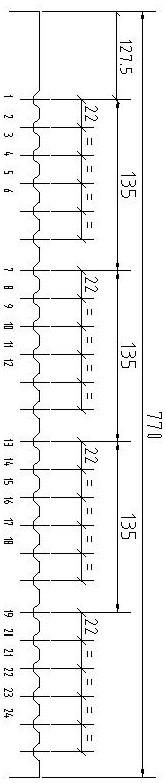

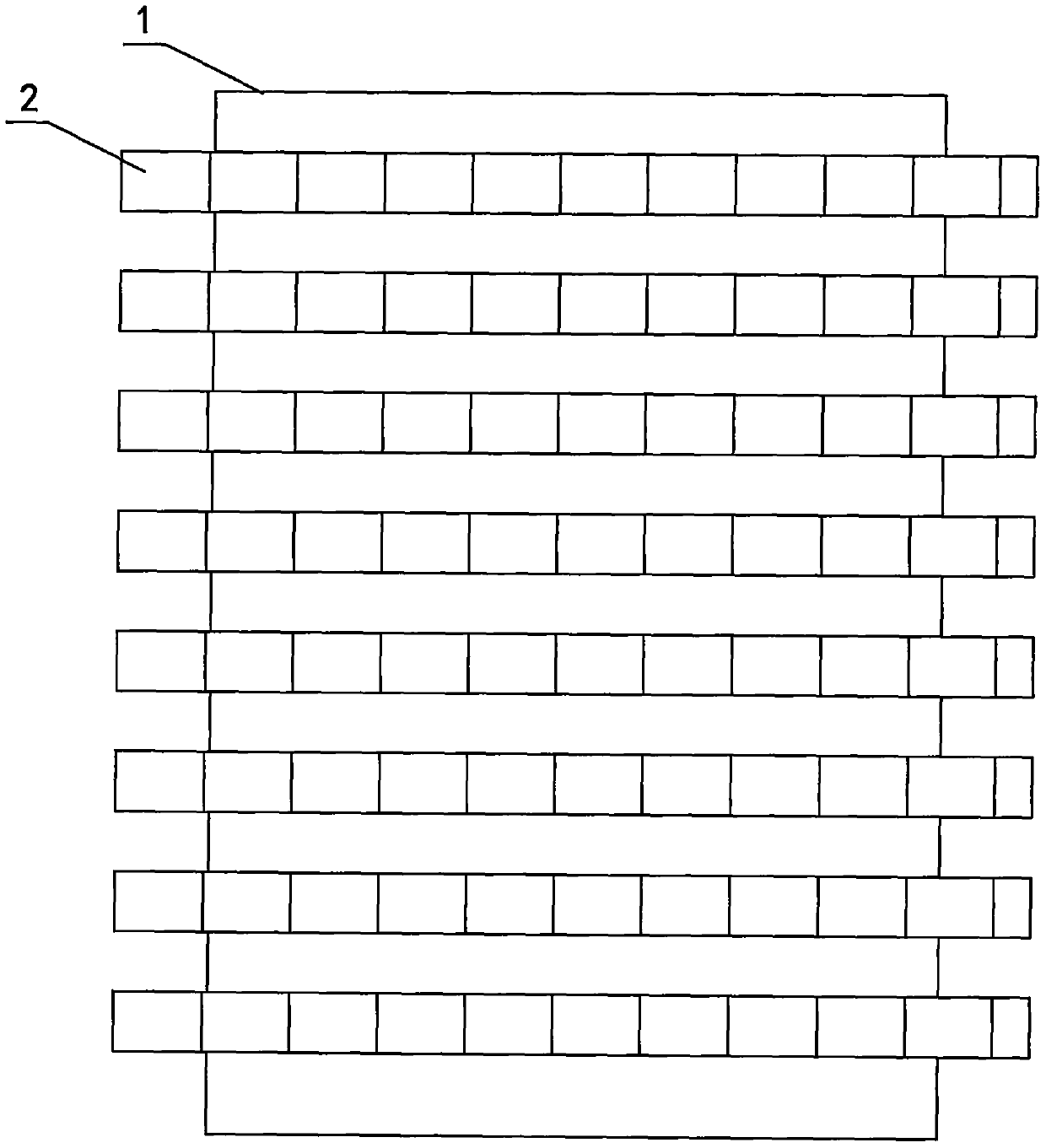

Medium- and finish-rolling pass structure for four-strand slitting in continuous rolling of phi12 deformed bars

ActiveCN102909218AConsistent cross-sectional areaReduce the number of pre-slitting rolling passesMetal rolling stand detailsMetal rolling arrangementsStrip millRoll slitting

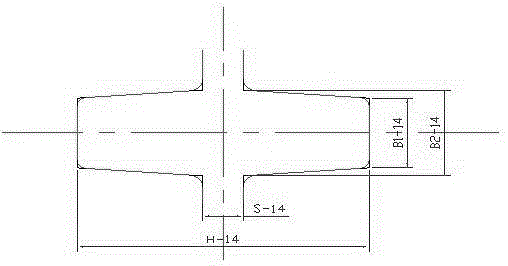

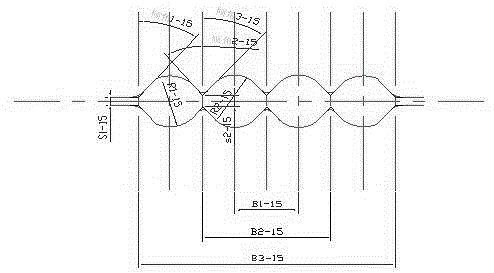

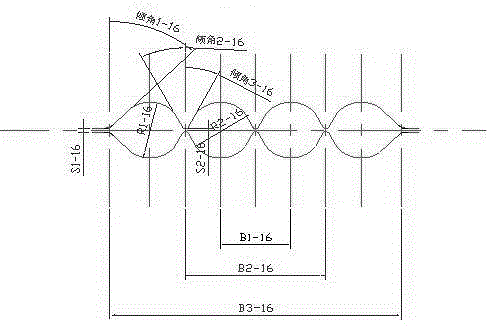

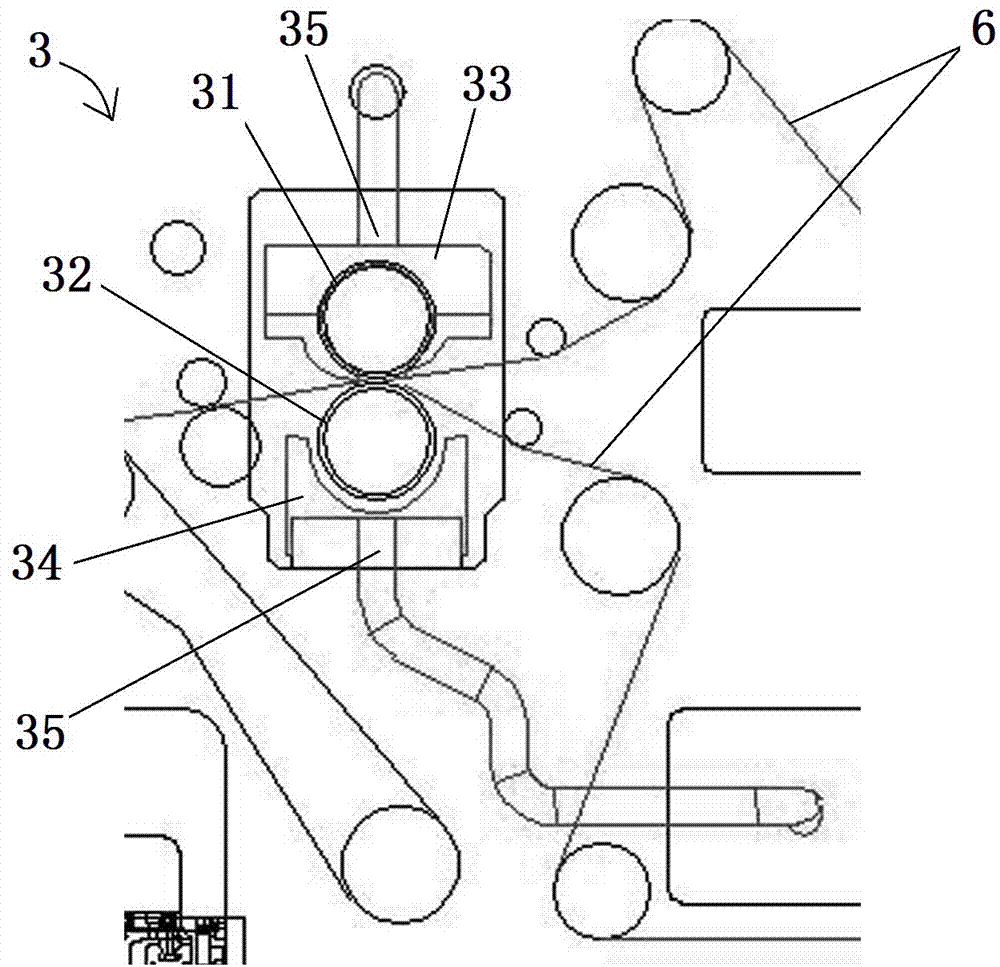

The invention relates to a medium- and finish-rolling pass structure for four-strand slitting in continuous rolling of phi12 deformed bars and belongs to the technical field of steel rolling process. According to the technical scheme, No.7 to No.10 frame rolls of an intermediate mill share a pass. When four-strand splitting for rolling of ph12mm deformed bars is performed, steel from an outlet of a No.12 frame mill is phi45mm in size, a No.11 frame mill is used for plane-roll pass-free rolling, a No.12 frame edging mill is idle, a No.13 frame mill of a finishing mill is used for plane-roll pass-free rolling, a No.14 frame edging mill is provided with vertical box type pass, a No.15 frame plane-roll mill is provided with pre-slitting pass, a No.16 frame mill of vertical-horizontal transformation is provided with plane-roll slitting pass, a No.17 frame plane-roll mill is provided with planar elliptic pass, and a No.18 frame mill of vertical-horizontal transformation is provided with plane-roll final pass. Four-strand rolling of phi12 deformed bars is achieved by single pre-slitting only with a No.15 frame mill of the finishing mill, and one frame pre-slitting rolling pass is omitted from the traditional double pre-slitting in four-strand slitting of phi12 deformed bars.

Owner:HEBEI TANGYIN IRON & STEEL +1

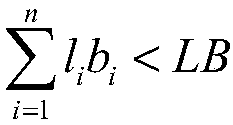

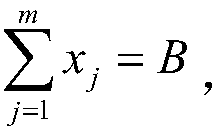

Roll paper slitting and scheduling optimization method and system based on non-linear integer programming

InactiveCN109272145AImprove solution efficiencyImprove work efficiencyForecastingResourcesNonlinear integer programmingRecording duration

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

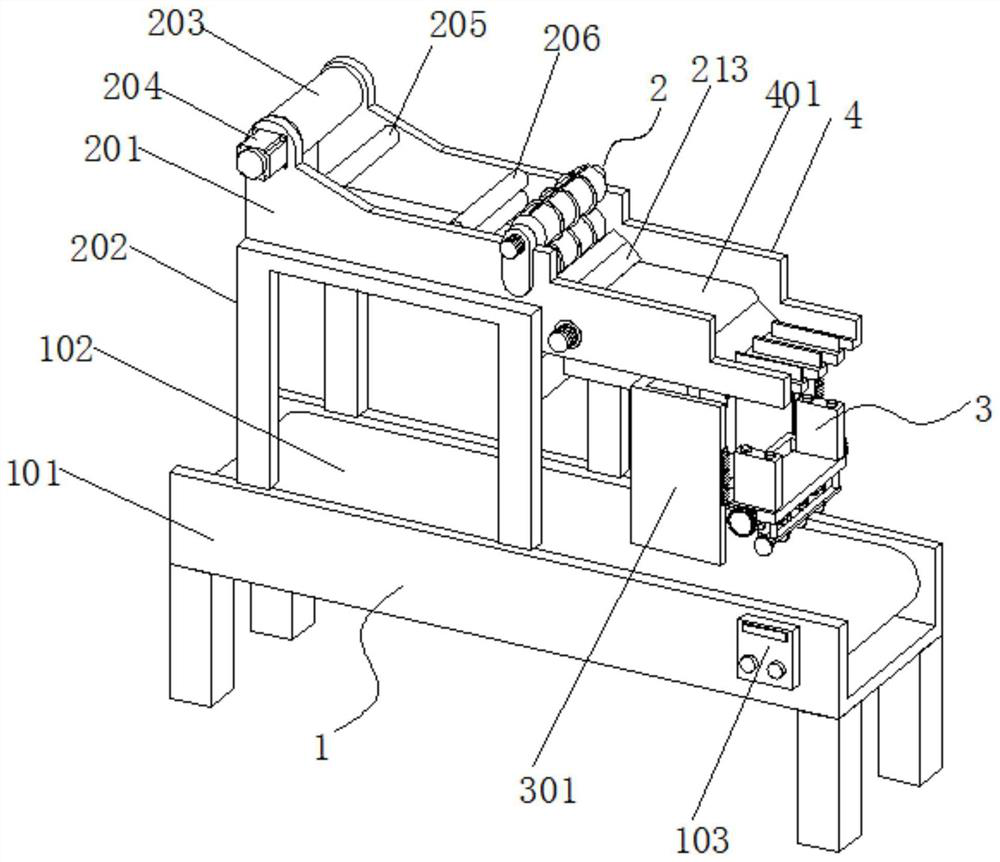

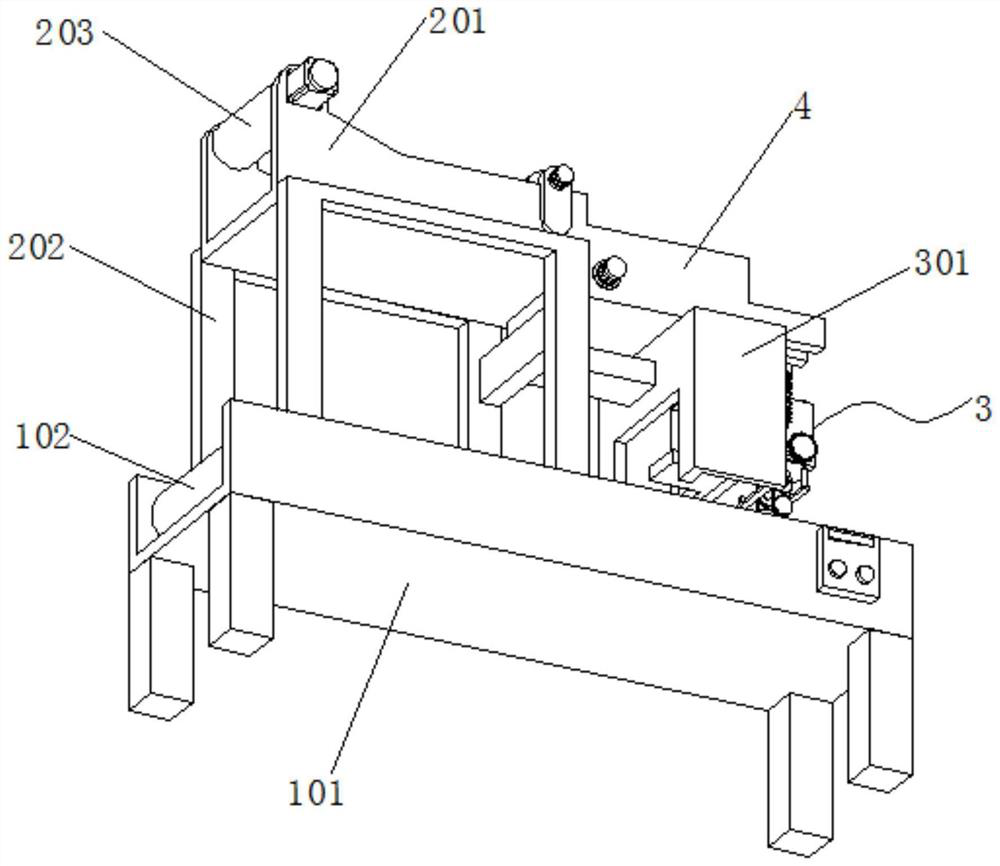

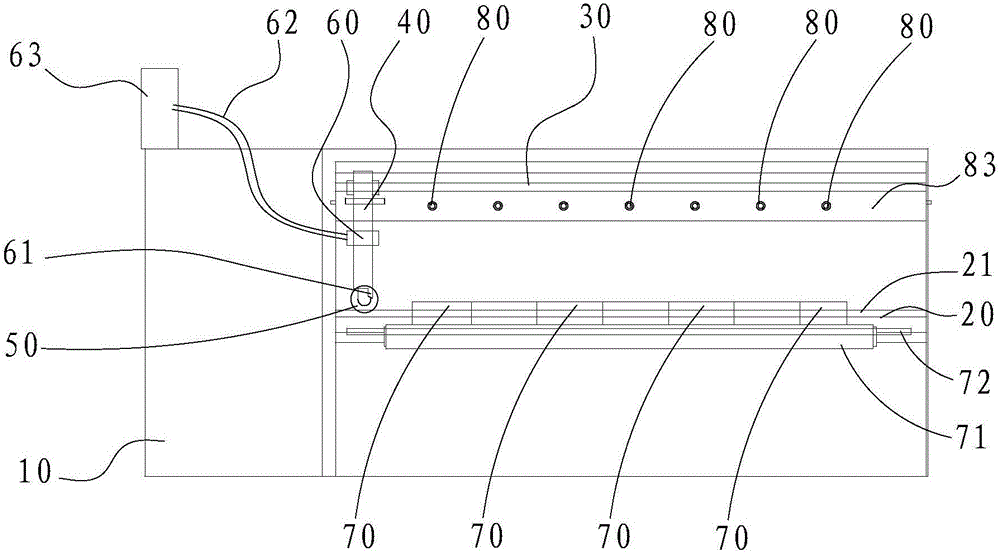

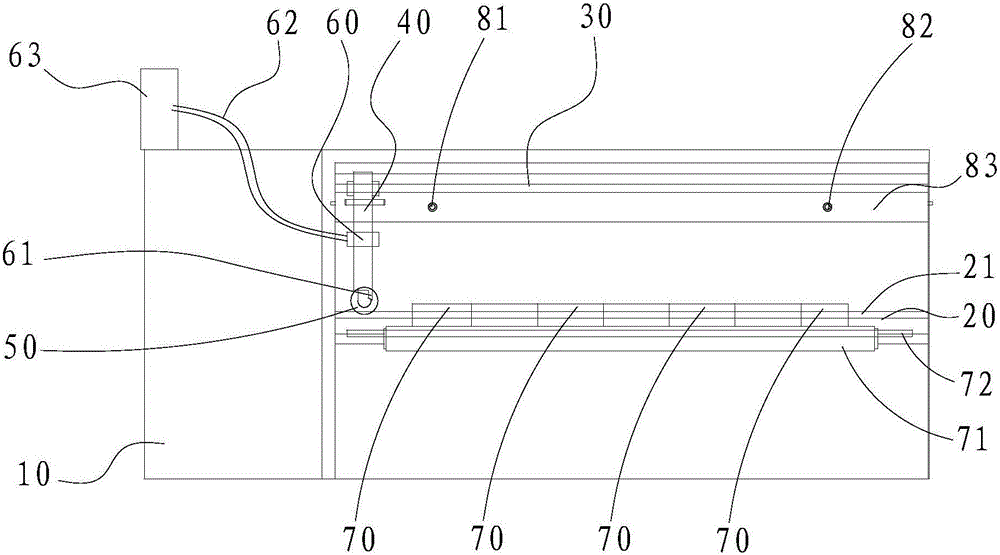

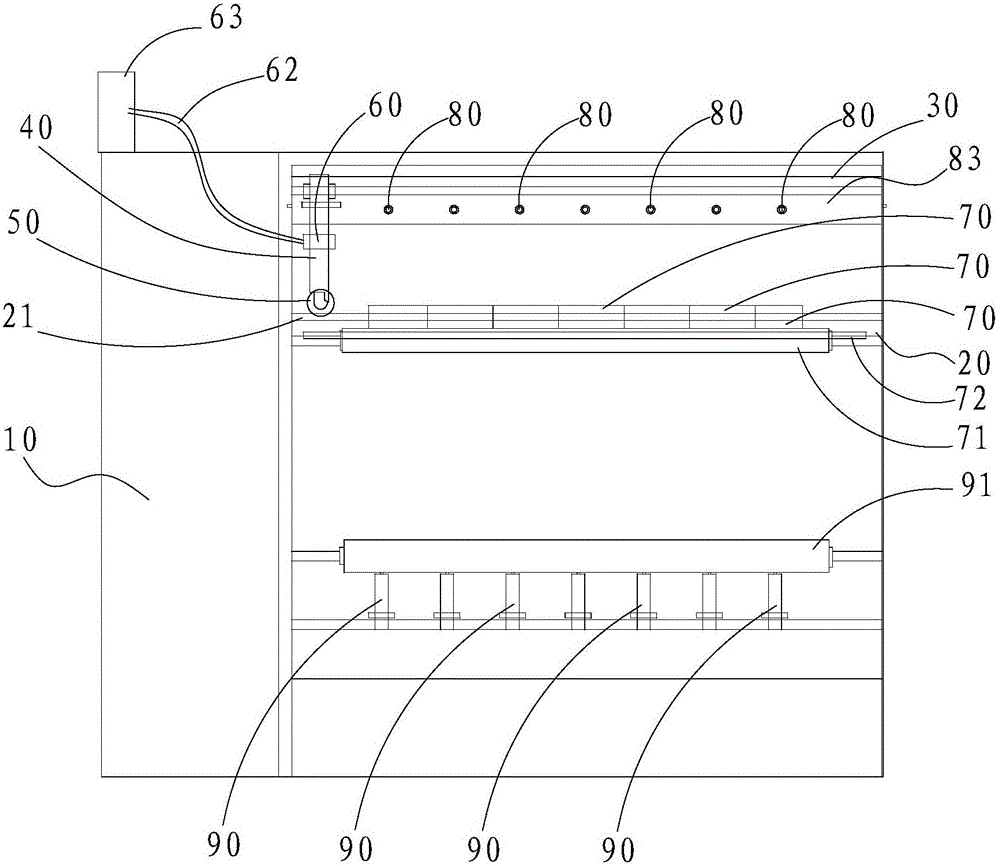

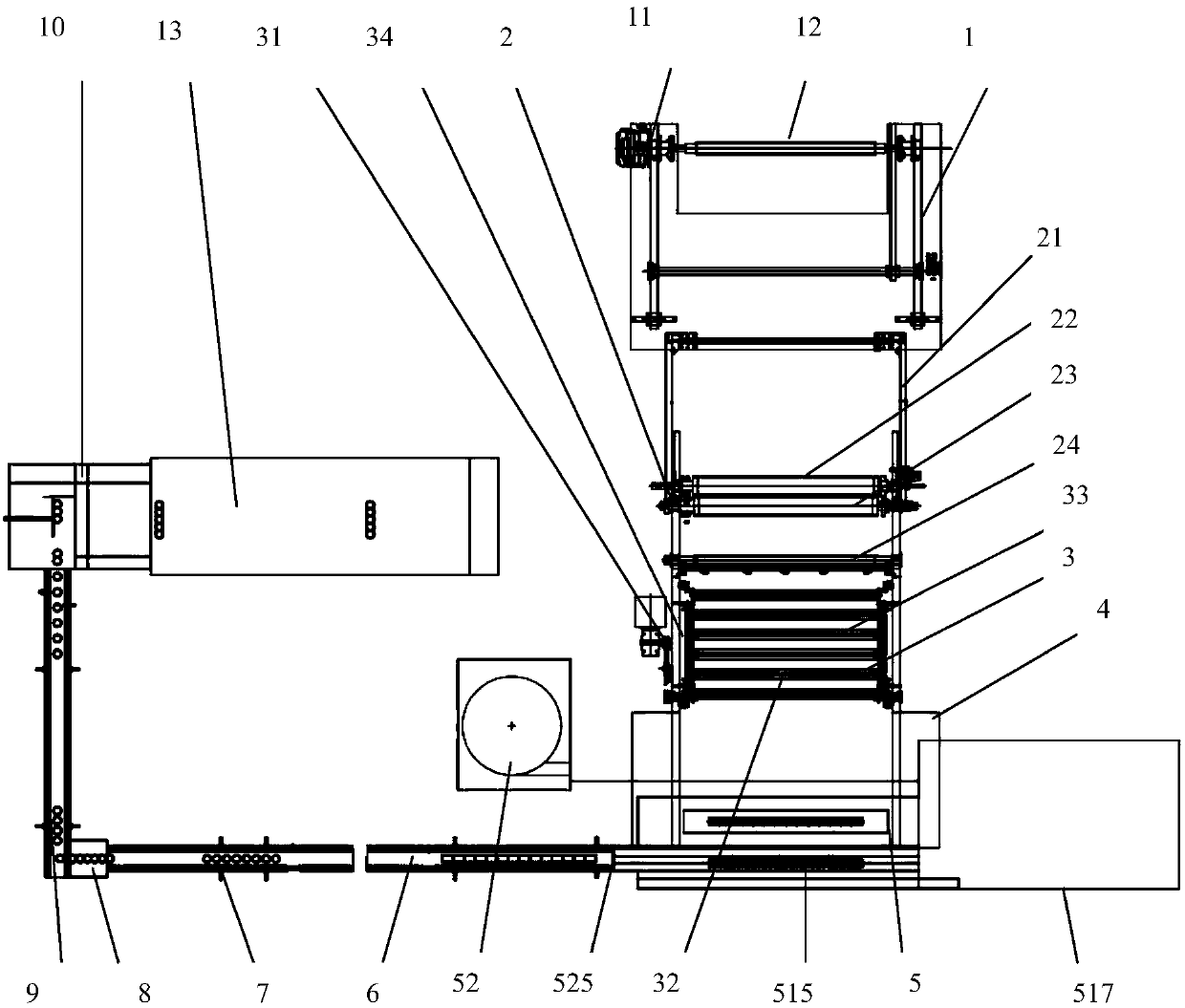

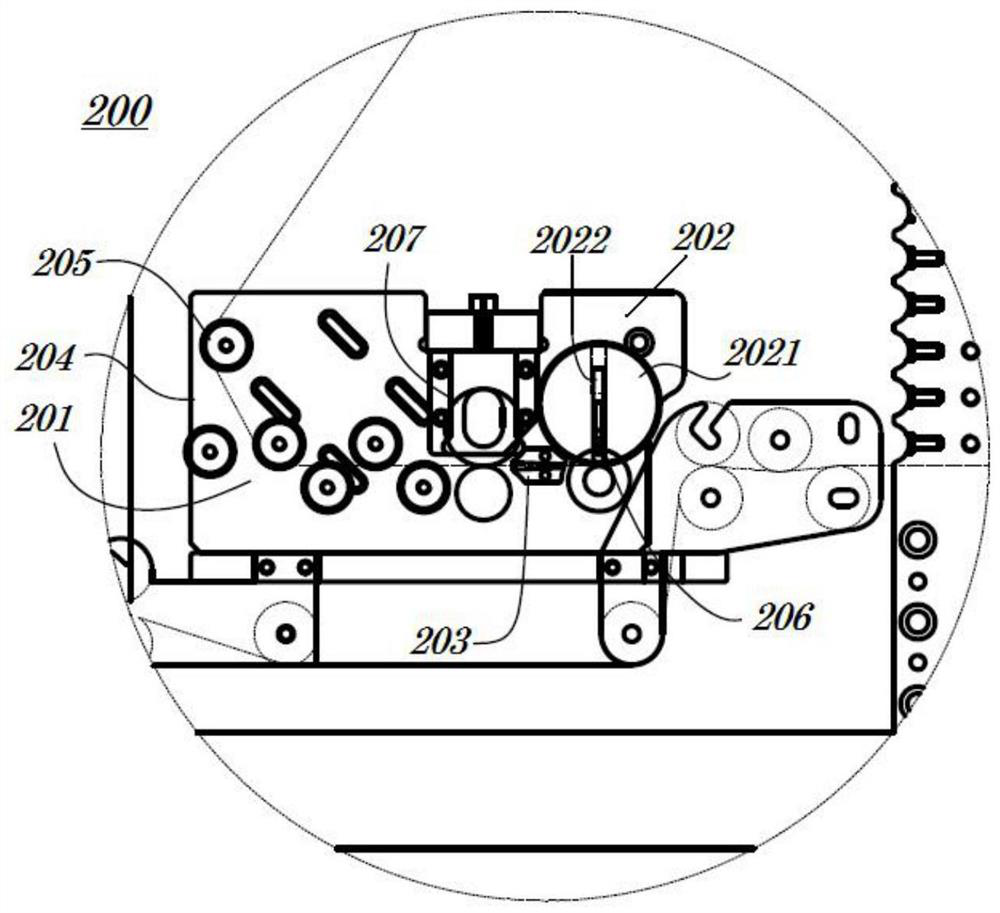

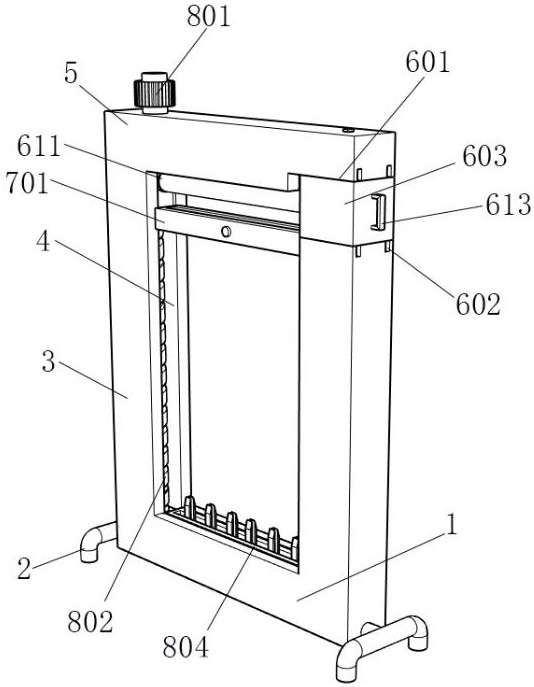

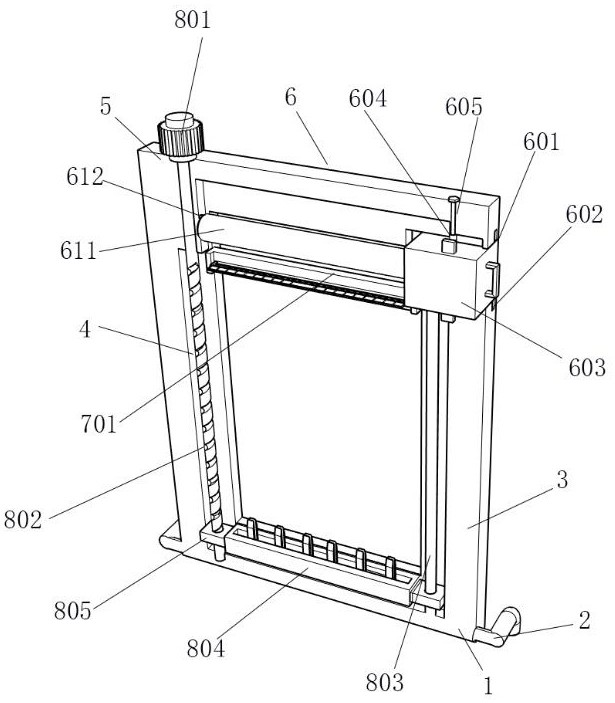

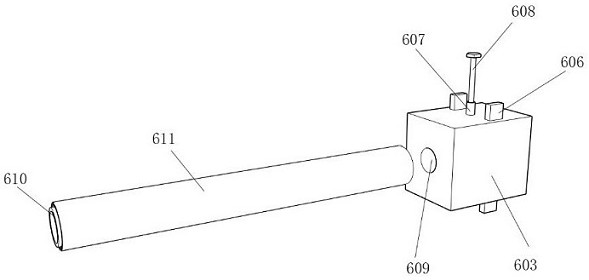

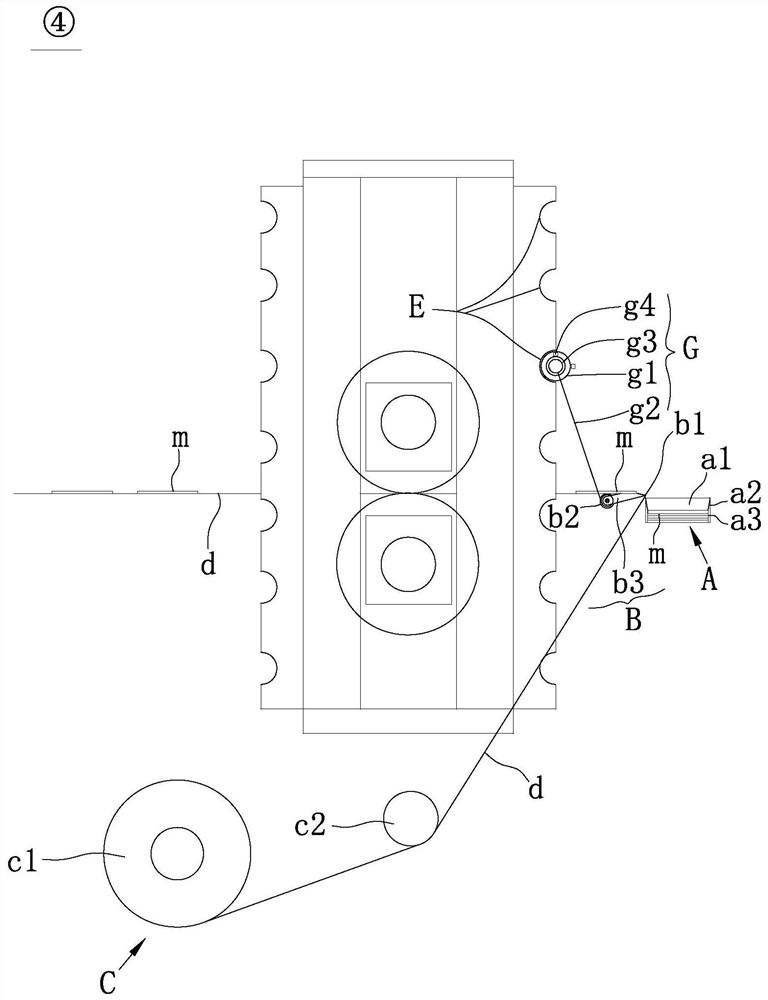

Full-automatic storage battery protective mesh mounting equipment

ActiveCN112248464AImprove cutting efficiencyAvoid lostAssembling battery machinesFinal product manufactureRoll slittingStructural engineering

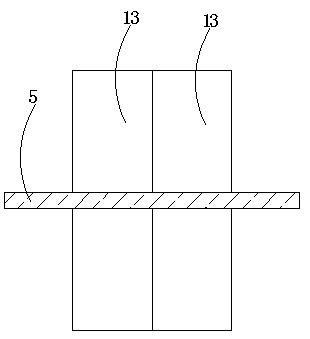

The invention relates to the technical field of storage battery production, processing and setting equipment, in particular to full-automatic storage battery protective mesh mounting equipment. The full-automatic storage battery protective mesh mounting equipment comprises a storage battery conveying mechanism, a protective net roll slitting mechanism and a protective mesh mounting mechanism; andthe protective net roll slitting mechanism comprises a slitting machine frame arranged above a conveying machine frame, a roll discharging roller is rotationally arranged at the upper left end of theslitting machine frame, a material guiding roller is rotationally arranged in the slitting machine frame and located on the lower right portion of the roll discharging roller, two material clamping rollers are rotationally arranged in the slitting machine frame and located on the right side of the material guiding roller and are symmetrically arranged up and down, and an upper slitting roller anda lower slitting roller are arranged in the slitting machine frame and located on the right side of the material clamping rollers. According to the whole protective mesh mounting mechanism, a protective mesh can be automatically adsorbed, aligned and automatically mounted, the machining efficiency is high, mounting is stable, the quality after mounting is higher, and the subsequent storage batteryloss problem caused by infirm mounting of the protective mesh is effectively avoided.

Owner:厦门安科科技有限公司

Paper roll slitting and winding device

InactiveCN105965960AImprove the efficiency of winding workHigh degree of automationPaper/cardboard wound articlesRoll slittingPulp and paper industry

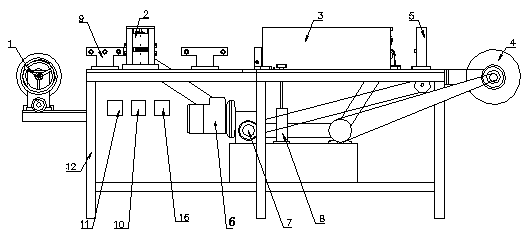

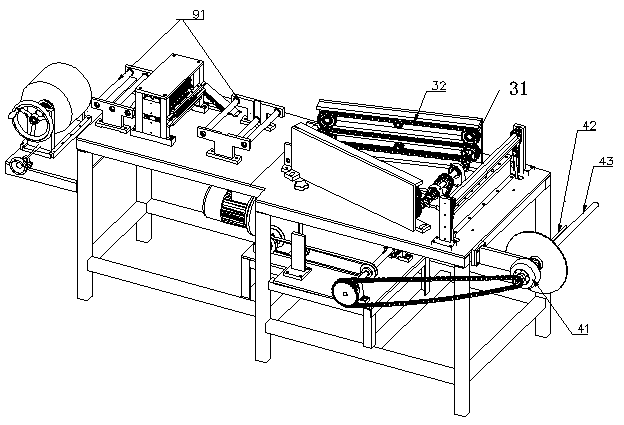

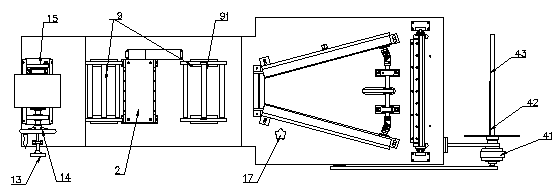

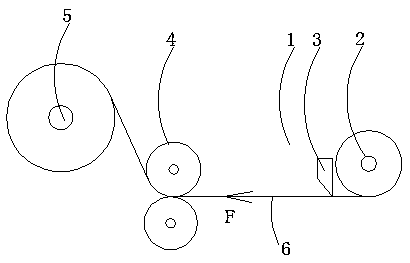

The invention discloses a paper roll slitting and winding device which comprises an unwinding mechanism, a slitting mechanism, a winding mechanism, a cutting workbench, a sliding rail, a sliding piece, a cutting piece and a glue spraying mechanism, wherein the unwinding mechanism is used for unwinding a paper roll; the slitting mechanism is used for slitting a piece of unwound paper into more than two paper strips; the winding mechanism is used for winding the paper strips to a winding drum; the cutting workbench is arranged at the output end of the winding mechanism; the sliding rail and the sliding piece are arranged above the cutting workbench; the sliding piece is matched with the sliding rail in a sliding manner; the cutting piece and the glue spraying mechanism are arranged on the sliding piece, and the cutting piece is in contact with the cutting workbench; a glue spraying head of the glue spraying mechanism is opposite to the cutting workbench. According to the paper roll slitting and winding device, a worker does not need to cut more than two paper strips with a blade, and no operator needs to coat the paper strips with an adhesive or stick double-faced adhesive tapes to the paper strips. Compared with the prior art, the paper roll slitting and winding device disclosed by the invention has the advantages that the winding working efficiency is improved, the automation degree is high, and the labor cost can be reduced.

Owner:GUANGZHOU JIUHENG BAR CODE

Pole roll slitting machine

InactiveCN107138791AImprove cut qualityAvoid vicious circleShearing machinesMaintainance and safety accessoriesRoll slittingEngineering

The invention relates to a pole roll slitting machine. The pole roll slitting machine includes the body and the upper and lower slitting knives arranged on the body. The body is also equipped with a first dust suction device. The first dust suction device includes a slitting air outlet, which is aligned with the Slitting position setting of upper and lower slitting knives. Using the pole roll slitting machine of the present invention, the slitting position air outlet is set at the position of the slitting knife in the pole roll slitting process, and the root position where the most dust and metal scraps are generated during the slitting process is sucked and dedusted, It can not only significantly reduce the dust and metal filings content inside the slitting machine and on the coil, reduce the influence of dust and metal filings on the coil, but also remove the metal filings on the slitting knife to avoid sticking of the slitting knife. Attached metal shavings lead to a decrease in slitting quality due to the existence of metal shavings in the subsequent slitting process, resulting in a vicious circle of more metal shavings and improving the slitting quality of the slitting knife.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

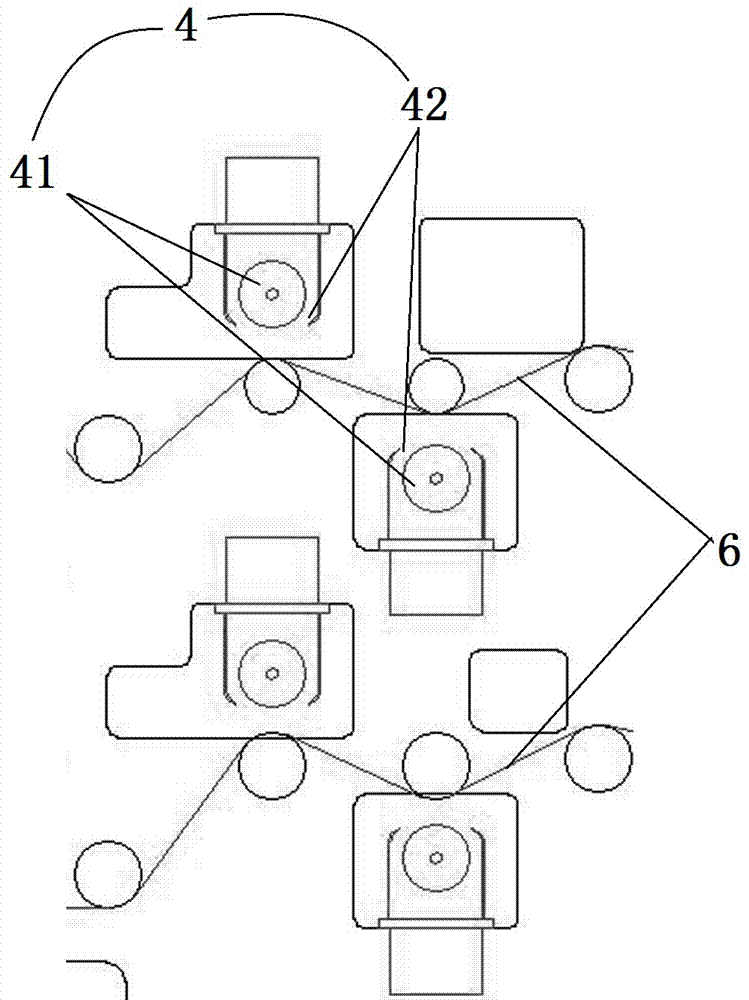

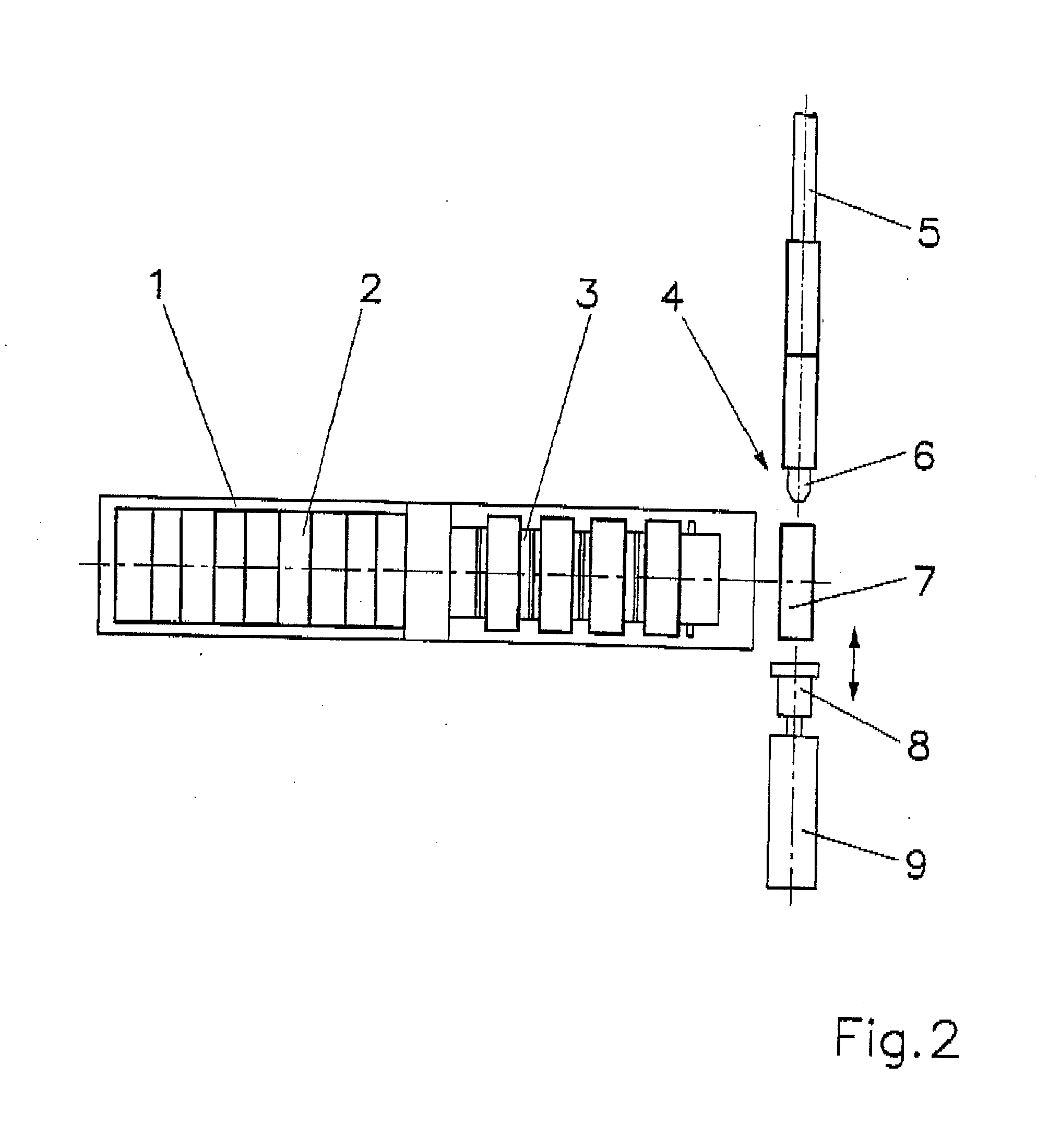

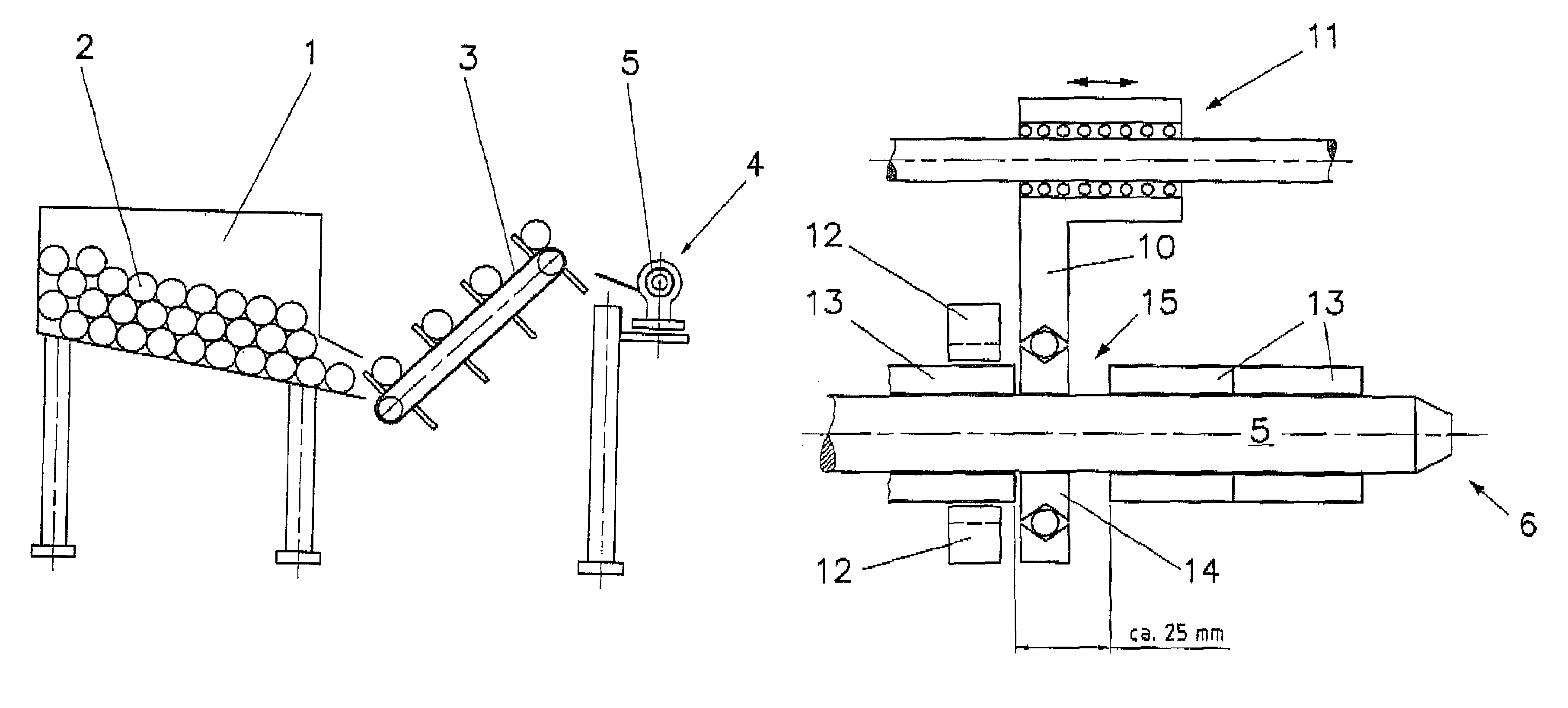

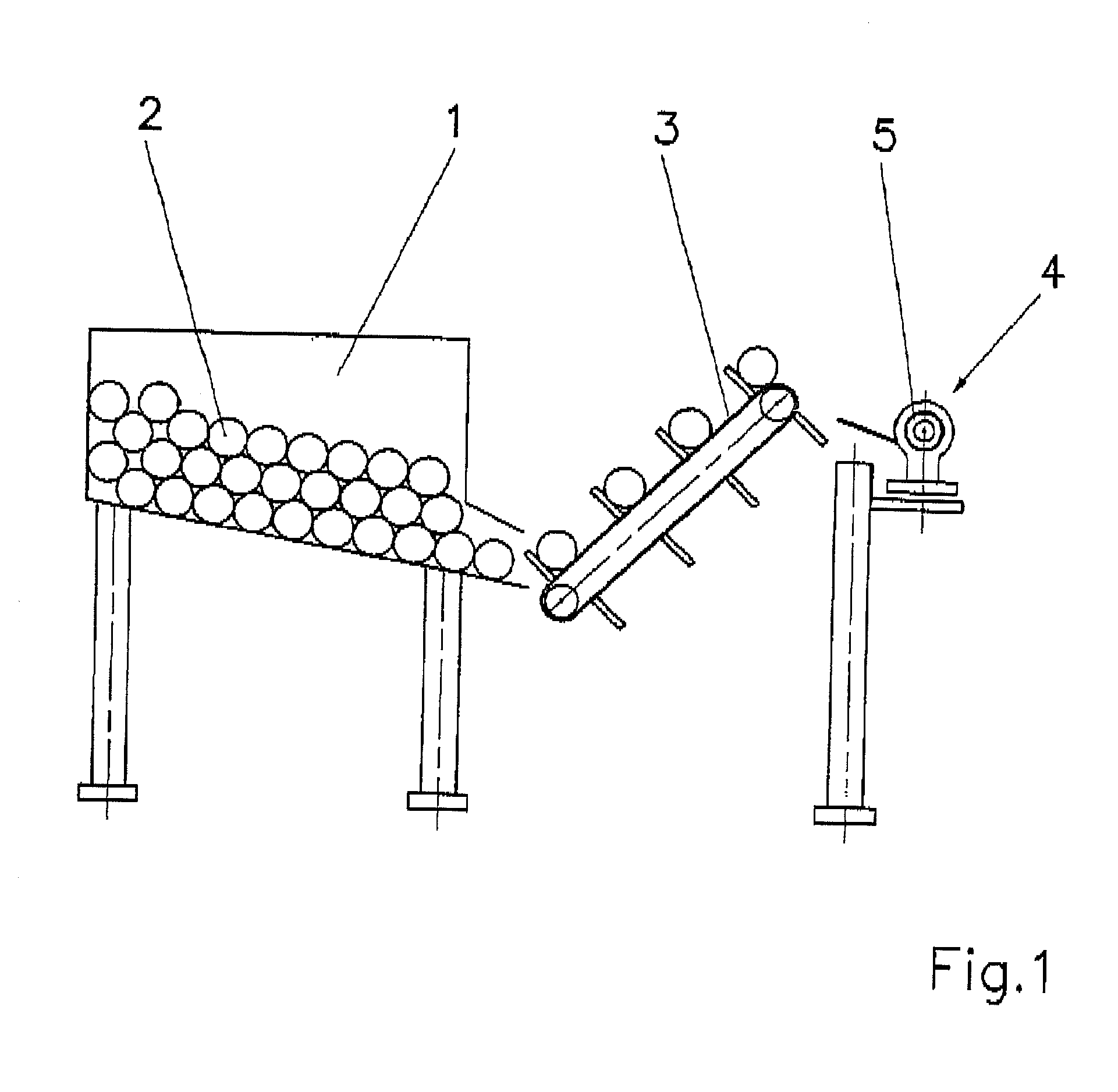

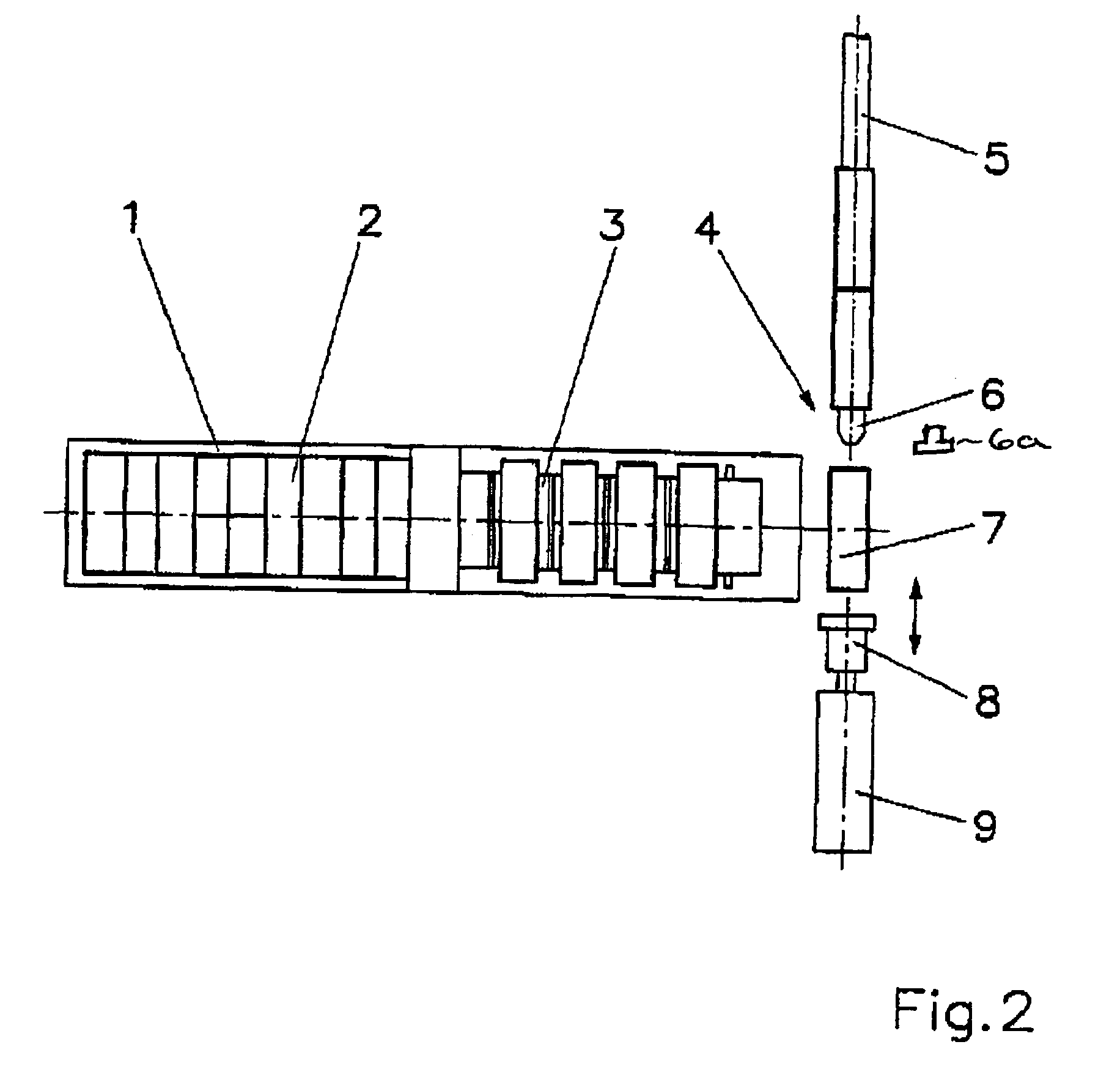

Automated sleeve filling for winding shafts on roll slitting and winding machines

A method for automatic sleeve filling of a winding shaft on roll cutting and winding machines is provided in which, in an exemplified embodiment, in a first step at least two empty winding sleeves are slid onto a free end of a winding shaft so that the winding sleeves are adjacent to one another, in a second step the last winding sleeve slid on by a freely positionable fork piece of a freely programmable draw-off plate along the winding shaft is slid over the winding shaft until the last winding sleeve has reached a predetermined position, in a third step the next-to-last winding sleeve slid on is grasped by tongs freely positionable along the winding shaft and is slid over the winding shaft to the point where in a fourth step the fork piece can dip into the gap produced by the tongs so that the next-to-last winding sleeve is positionable along the winding shaft by the fork piece.

Owner:SECAP GROUPE PITNEY BOWES S

Full-automatic high-speed rotary bag making machine

PendingCN112172256ARealize integrated horizontal and vertical sealingIncrease productivityBag making operationsPaper-makingRoll slittingEngineering

The invention discloses a novel full-automatic high-speed rotary bag making machine. The bag making machine comprises a feeding mechanism, a bag body, a bag making mechanism and a rotary die cutting mechanism, wherein the bag making mechanism is provided with a tension control sensor corresponding to the bag body; an unwinding traction transmission roller, a slitter edge cutting knife set, a frontrotary transverse sealing and longitudinal sealing bottom roller, a rear rotary transverse sealing and longitudinal sealing bottom roller and a tension stabilizing traction transmission roller are sequentially arranged in the bag making mechanism corresponding to the output end of the bag body; a waste recycling pipeline is arranged in the bag making mechanism corresponding to the slitter edge cutting knife set; and the rotary die cutting mechanism is provided with a film tension stable swing frame, a rear die cutting tension transmission roller, a rotary cutting die roller controlled by a servo motor electronic technology shaft, and a bag collecting mechanism corresponding to the output end of the bag body. The full-automatic high-speed rotary bag making machine has the advantages that produced plastic bags are integrally subjected to transverse sealing and longitudinal sealing, waste edges cut off from the plastic bags are directly cleaned up and discharged in the production process, and the production efficiency of the plastic bags is improved.

Owner:刘超

Aluminum strip billet collating device on rewinding machine

ActiveCN105032931AReduce investmentReduce production inputMetal rolling arrangementsWinding machineRoll slitting

The invention discloses an aluminum strip billet collating device on a rewinding machine. The aluminum strip billet collating device comprises oppositely-arranged machine frames, an aluminum strip billet supporting shaft and a transverse beam are sequentially arranged between the two machine frames from bottom to top, and the aluminum strip billet supporting shaft is connected with a first motor; side cutting devices are arranged at the two ends of the transverse beam respectively, at least one slitting device is arranged between the side cutting devices, and a waste side leading-out device is arranged at the position corresponding to each side cutting device / slitting device; each slitting device comprises a slitting knife holder, and two parallel disc-shaped dividing knives which are arranged in a spaced manner are installed below each slitting knife holder and are basically the same in size and shape; the axes of the dividing knives are parallel to the axis of the aluminum strip billet supporting shaft in the same plane in the longitudinal direction, and the slitting knife holders can move along the transverse beam; and a winding machine of the rewinding machine drives an aluminum strip billet to move, movement of the aluminum strip billet drives the dividing knives and side cutting knives to rotate, and then the aluminum strip billet is slit. Side cutting and slitting of the aluminum strip billet can be achieved, large-winding-diameter multi-roll slitting of the aluminum strip billet can be achieved, cut-off waste can be led out, and the production efficiency and the yield can be greatly improved.

Owner:贵州中铝铝业有限公司

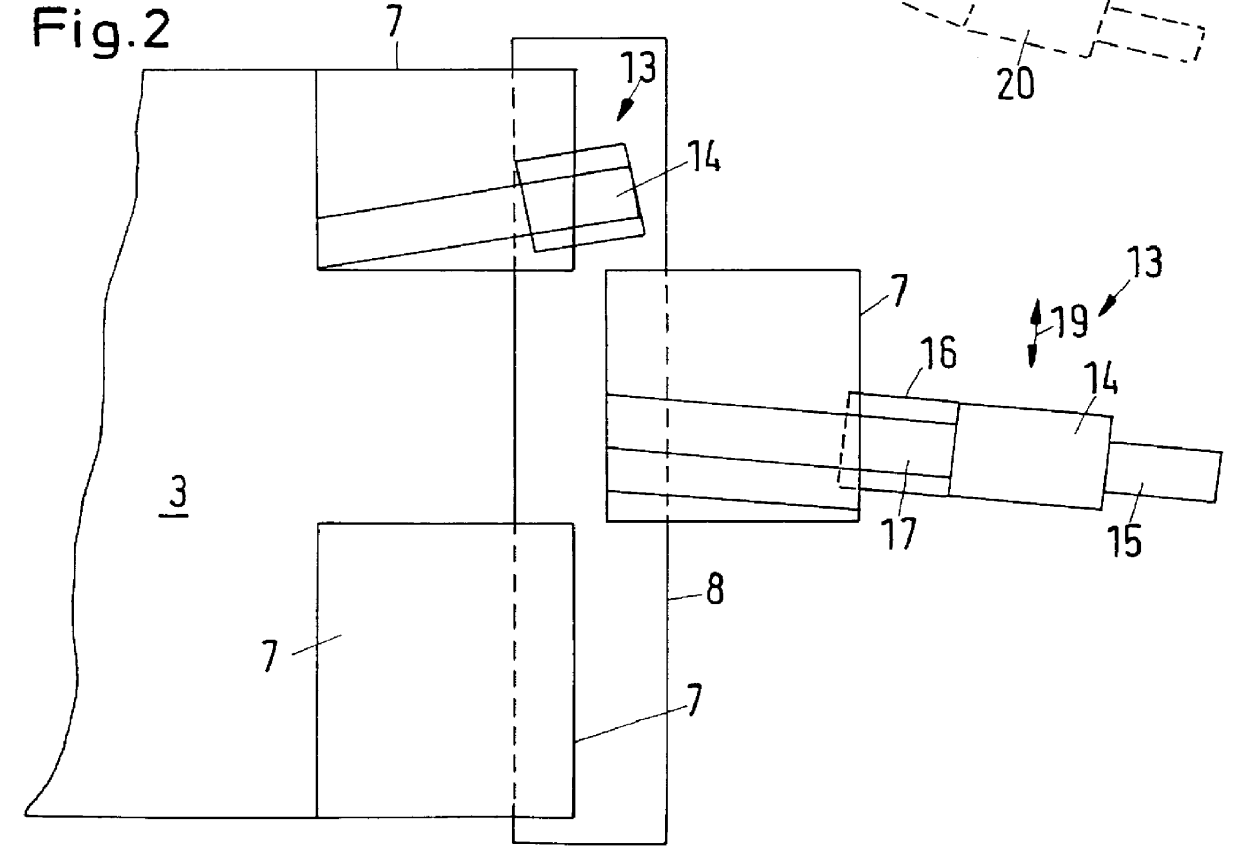

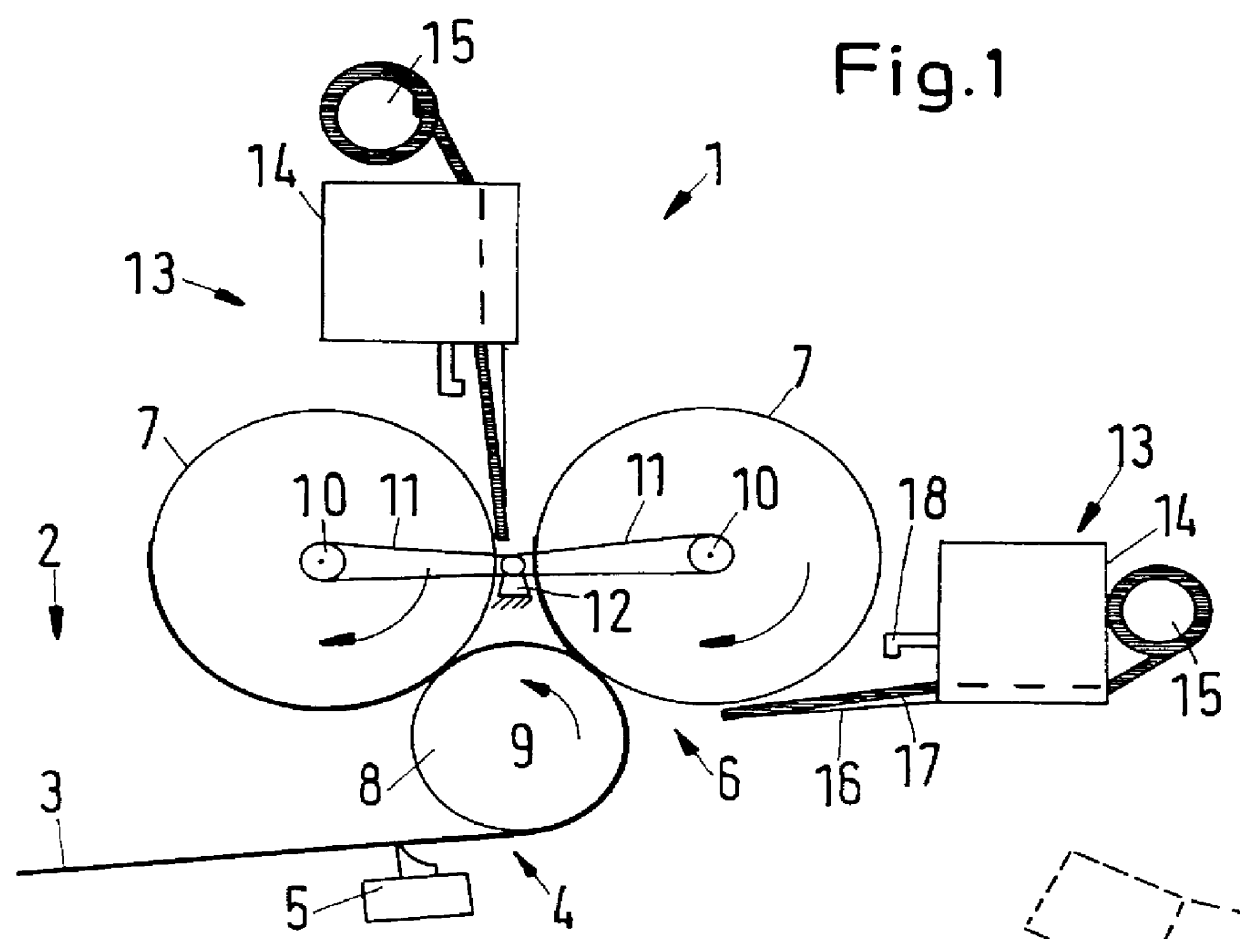

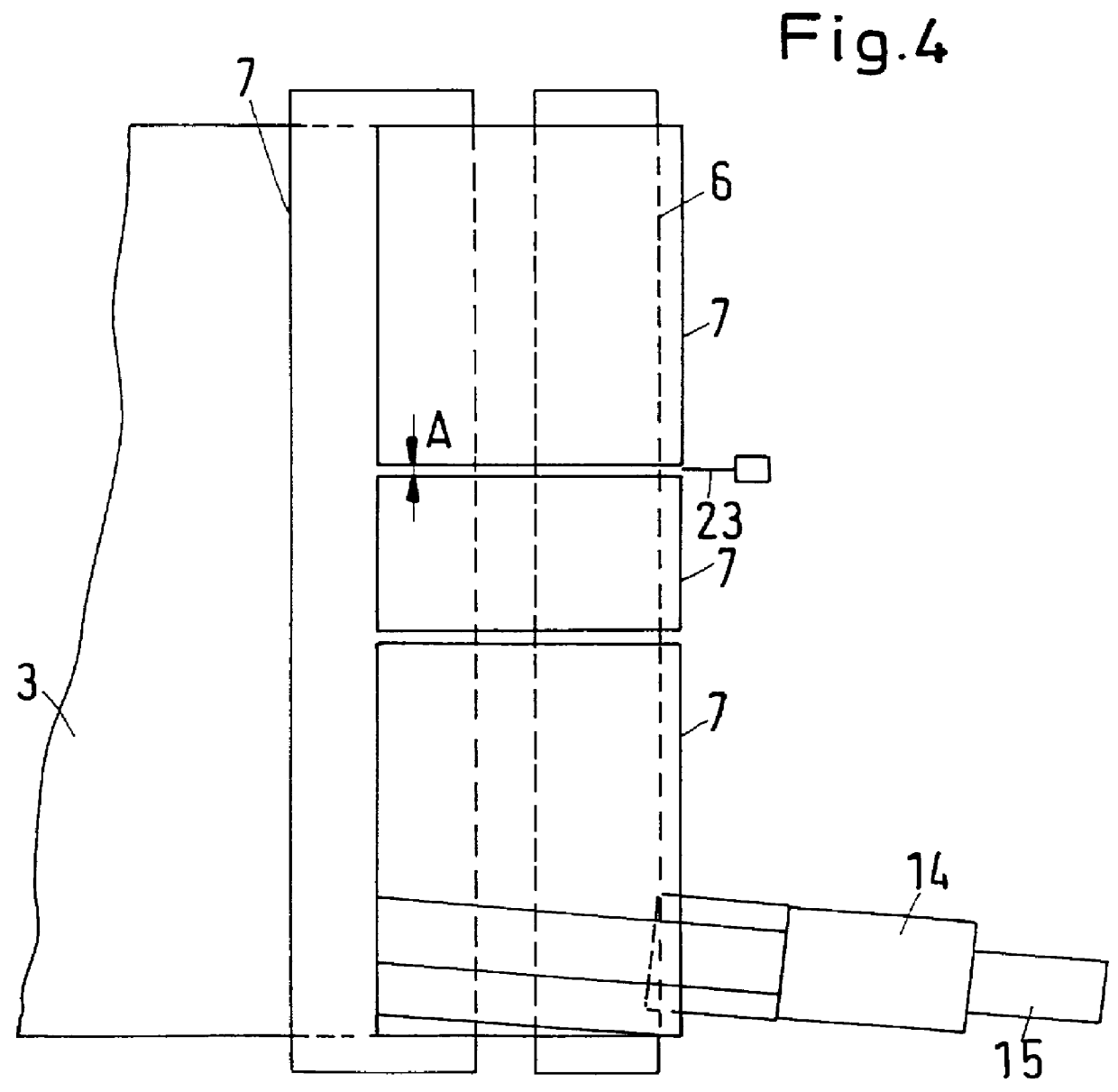

Reel slitting device and method

InactiveUS6044619AEasy to producePaper article packagingBinding material applicationRoll slittingEngineering

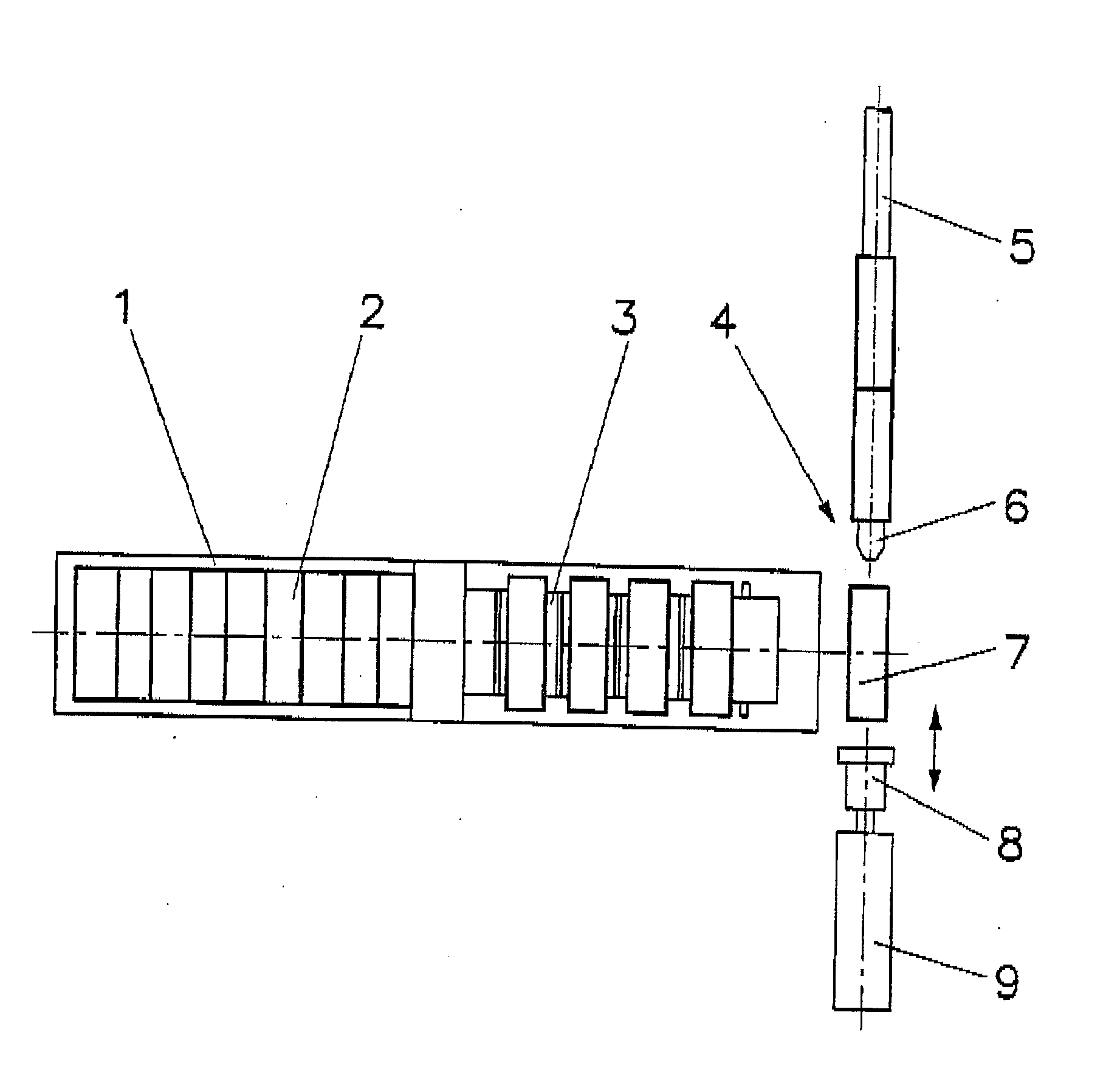

Reel slitting device for a web that includes a web supply section, a longitudinal slitting section, and a reeling section, and method for packaging partial rolls in the reeling section of the roll slitting device. The device includes at least one propelling device for reeling at least one partial roll and a packaging device that packages at least a periphery of the at least one partial roll. The the packaging device utilizes the at least one propelling device. The method includes slitting a web sheet into a plurality of partial webs, reeling the partial webs, in the reeling section, into a plurality of partial rolls, attaching a packaging web to a peripheral portion of at least one of the plurality of partial rolls in the reeling section, and rotating the at least one of the plurality of partial rolls to wind the packaging web around a radial surface of the at least one of the plurality of partial rolls.

Owner:VOITH PAPER GMBH

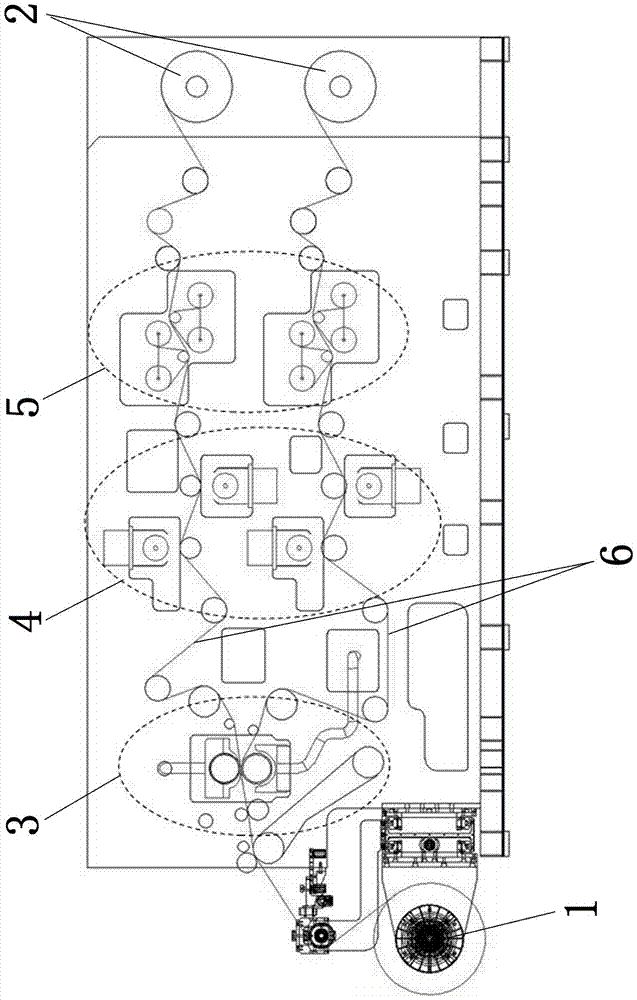

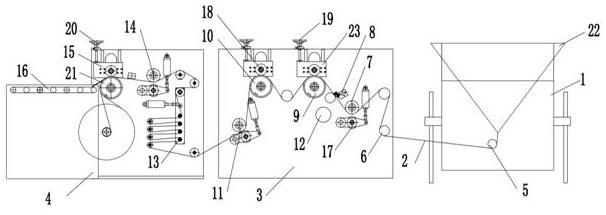

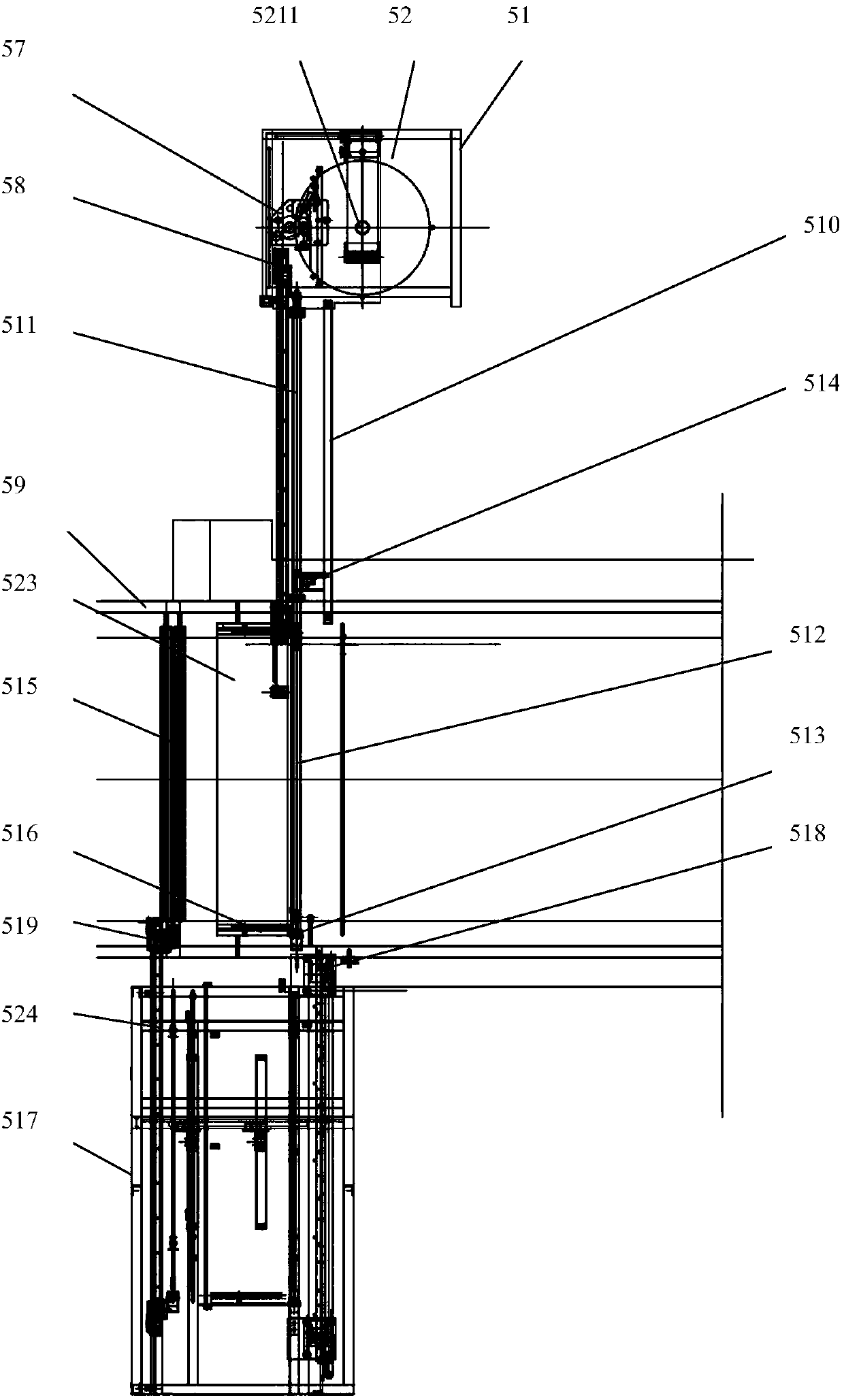

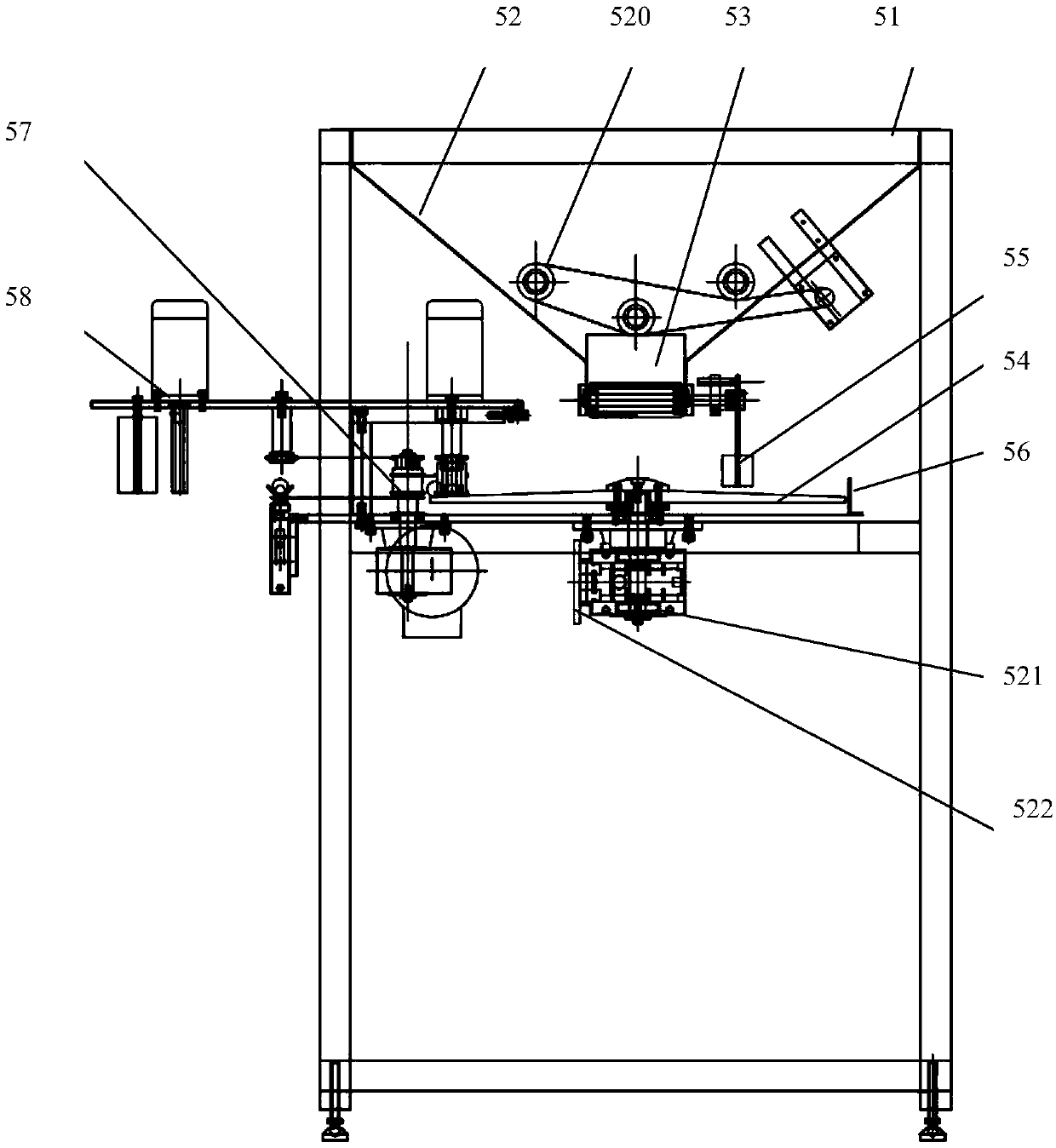

Automatic printing and small-roll slitting machine

PendingCN108016926ALabor savingSmall footprintPackaging automatic controlRotary letterpress machinesRoll slittingEngineering

The invention discloses an automatic printing and small-roll slitting machine. The automatic printing and small-roll slitting machine comprises a paper feed device, a flexible printing device, a paperstorage device, a small-roll slitting device, an automatic roll core penetration device, a first conveying device, a second conveying device, a roll core flattening device, a third conveying device,a packaging device, a heat shrinkage device and a main control cabinet, wherein the paper feed device comprises a first rack and a rotary shaft; the flexible printing device is arranged on a downstream station of the paper feed device; the paper storage device is arranged on a downstream station of the flexible printing device; the small-roll slitting device is arranged on a downstream station ofthe paper storage device; the automatic roll core penetration device is arranged on a downstream station of the paper storage device; the roll core flattening device is arranged on a downstream station of the second conveying device; the third conveying device is arranged on a downstream station of the roll core flattening device; and the heat shrinkage device is arranged on a downstream station of the packaging device. According to the automatic printing and small-roll slitting machine, centralized control is achieved; and particularly by adoption of the paper storage device, deviation of multicolor overprinting is avoided during printing and particularly during multicolor printing, and the requirements for printing and slitting of products are met.

Owner:SHANGHAI GUANGPING PRINTING EQUIP

Mask slicing machine

PendingCN112406153AAvoid replacementOvercome the problem of not being able to actually play the role of roll cuttingDomestic articlesProtective garmentUltrasonic weldingRoll slitting

The invention provides a mask slicing machine. The mask slicing machine comprises an unwinding device, a nose bridge strip roller cutting device, an ultrasonic welding device, a flattening and code spraying device and a roller cutting device. According to the mask slicing machine, the cutting edge is inserted into a roller cutter body in the radial direction, the cutting edge can be independentlyreplaced when the cutting edge needs to be replaced, and the whole roller cutter is prevented from being replaced; an ultrasonic mechanism is arranged below a welding roller, so that the ultrasonic mechanism does not hinder the replacement of the welding roller; by adopting an ink-jet marking mode, the manufacturing cost of the mask is reduced; meanwhile, the ink-jet marking mode is simple in process, repeated debugging is not needed, and the actual production and manufacturing requirements of the mask are met; by additionally arranging a cutting die bottom roller which is detachably arranged,the cutting die bottom roller and a shape cutter form a roller cutting space, and therefore the shape cutter is prevented from being directly pressed on a drive roller; and during replacement, the cutting die bottom roller can be directly replaced, and the problem that the drive roller is inconvenient to replace in the prior art is solved.

Owner:SUZHOU TRAPEZE ASSEMBLY AUTOMATION CO LTD

Integrated manufacturing method for electric power internet-of-things informatization mark

PendingCN110490291AUnificationSolve the standardized constructionStampsRecord carriers used with machinesInformatizationHigh energy

The invention provides an integrated manufacturing method for an electric power internet-of-things informatization mark. The method comprises the following steps: slitting an adhesive tape mother rollinto specifications and sizes printed by a thermal transfer printer through an adhesive tape mother roll slitting machine; separating the adhesive surface and the backing paper of the slit adhesive tape through a coating machine; pasting a label on the adhesive surface through a chip mounter according to a set specification and size; the labeling adhesive surface and the bottom paper being laminated through a laminating system; writing the data into the label by using a radio frequency thermal transfer printer; printing an identification using a radio frequency thermal transfer printer. According to the method, the problems of high energy consumption, high pollution and low productivity in the traditional manufacturing process of stainless steel, aluminum alloy and enamel plate identifiers are effectively solved. The tedious technological process caused by batch manufacturing and installation of the electronic tag and the two-dimensional code identifier, the cost of batch installationof the fixed bracket and the labor cost are solved. The problem of non-uniform batch manufacturing and installation data is solved, and the unified and standardized construction of the electric powerinformatization identifier is also solved.

Owner:湖南鼎一致远科技发展股份有限公司

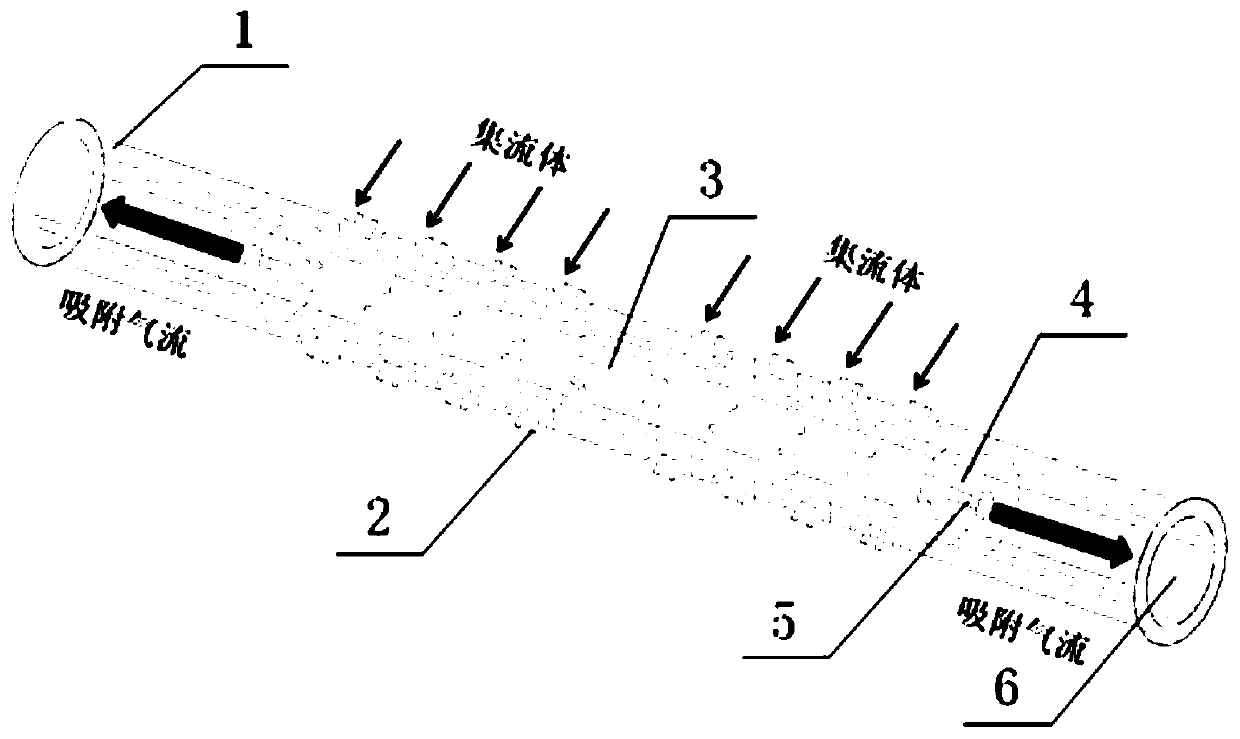

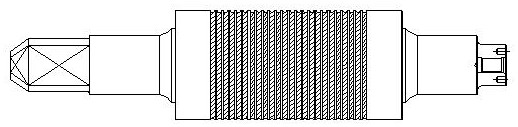

Adsorption type winding drum and winding device and method

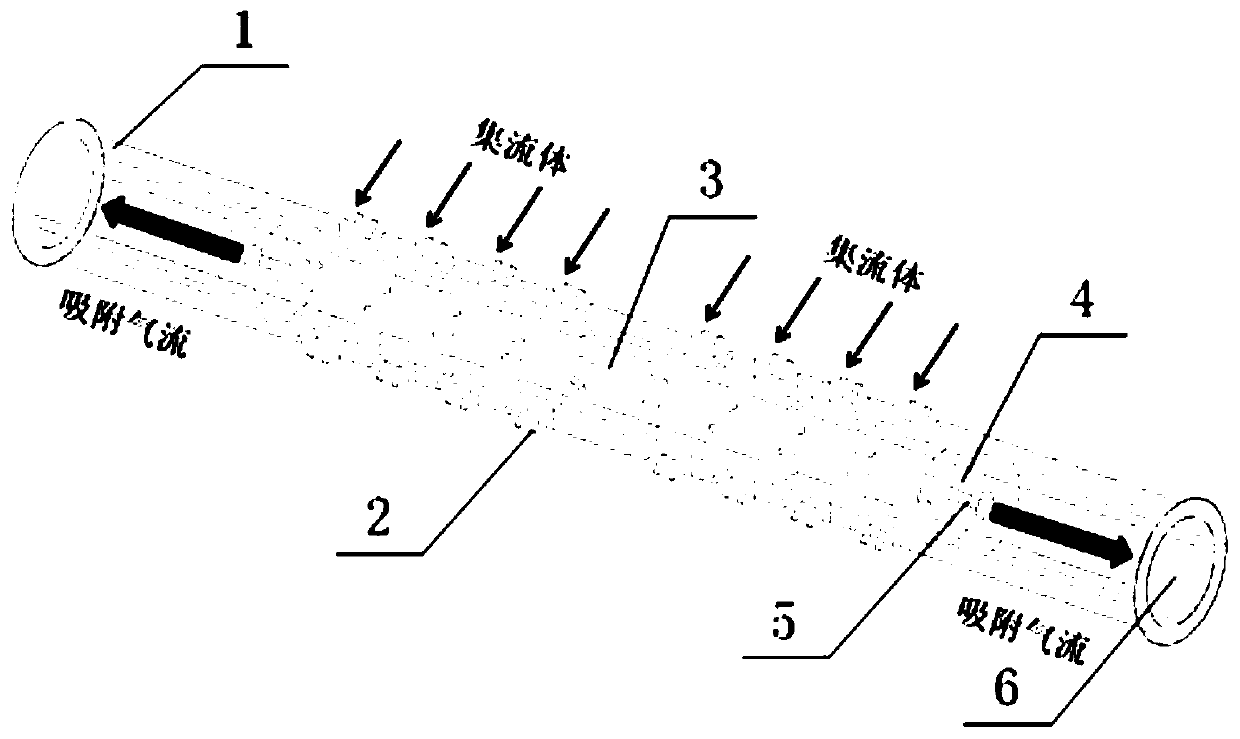

The invention discloses an adsorption type winding drum and a winding device and method. The adsorption type winding drum comprises a hollow drum body with openings in the two ends, an inner cavity ofthe drum body is divided into three parts through two cavity plates, air expansion holes are formed in the two ends of the inner cavity of the drum body, an adsorption cavity is formed in the middleof the inner cavity of the drum body, each sealing adsorption opening is a duct structure in the center of each cavity plate, the air expansion holes are in communication with the adsorption cavity through the sealing adsorption openings, and a plurality of adsorption holes are formed in the surface of an outer drum body of the adsorption cavity. According to the design of the adsorption type winding drum, the bearing capacity is large, stress is uniform, the adsorption type winding drum can be widely applied to battery coating workshops and rolling slitting workshops, the wrinkling phenomenonin the winding process of lithium battery pole pieces and diaphragms can be effectively reduced, and the product rejection rate is reduced.

Owner:成都格力钛新能源有限公司 +1

Film roll cutting device and control method thereof

ActiveCN106698054BRealize slittingImprove convenienceFunction indicatorsArticle deliveryRoll slittingEngineering

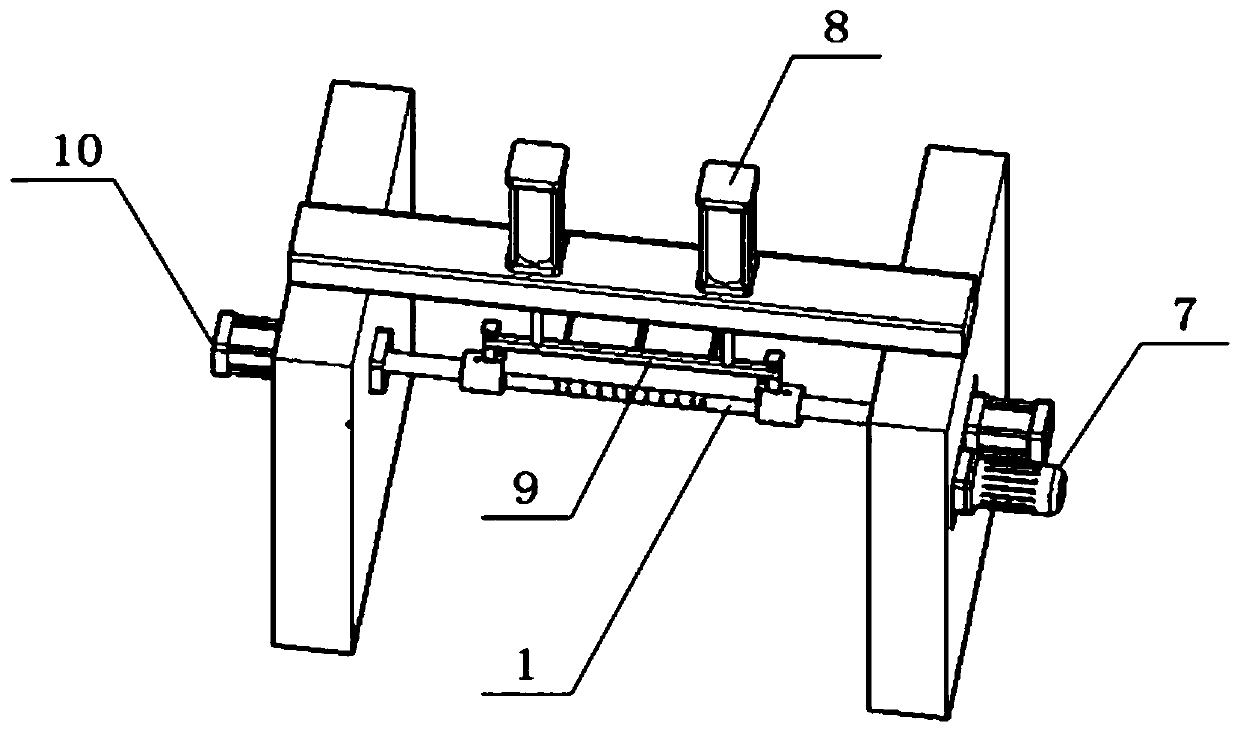

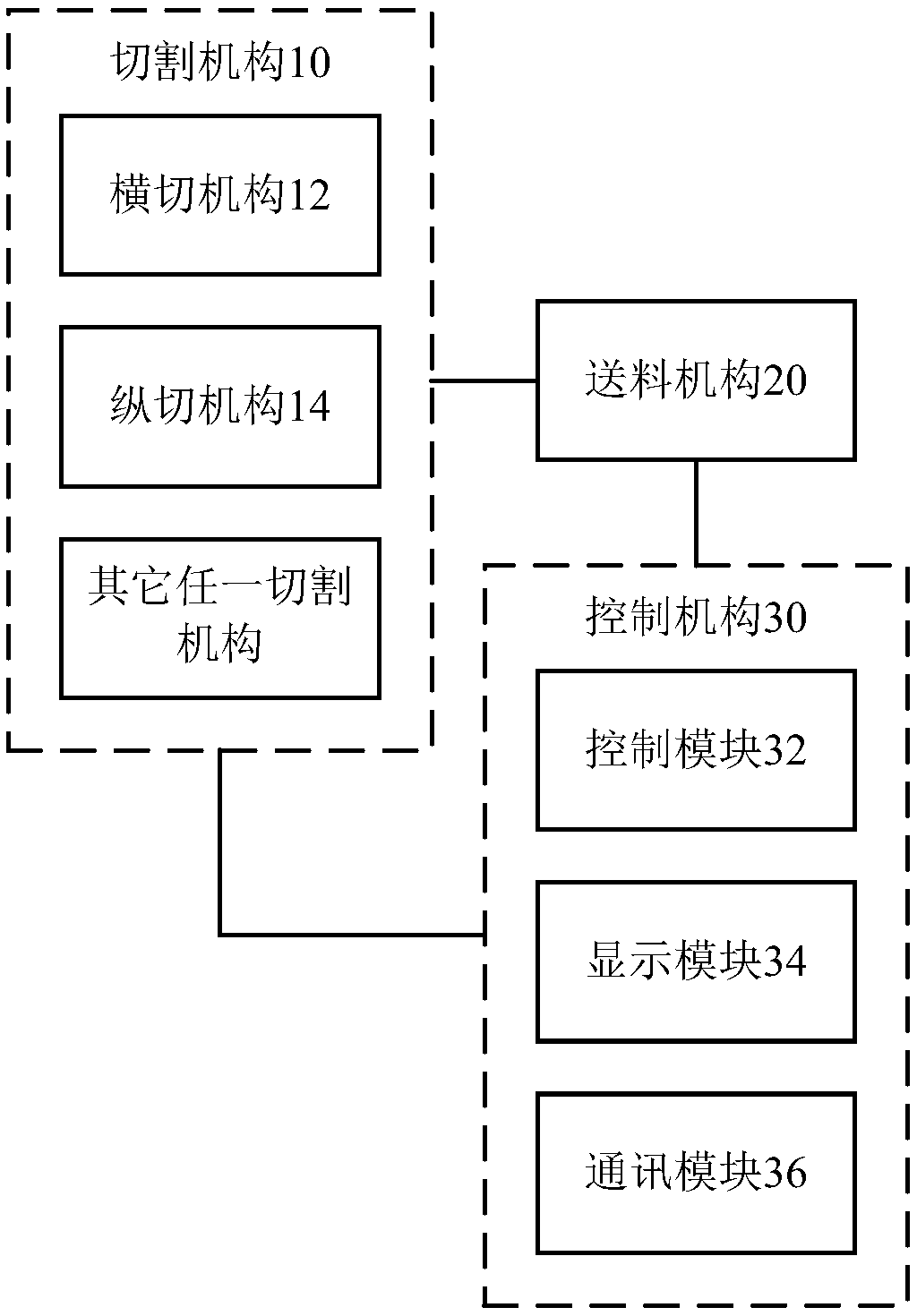

The invention discloses a film roll cutting device and its control method. The device comprises: a cutting mechanism, a feeding mechanism and a control mechanism; wherein, the number of the cutting mechanisms is more than two; more than two cutting mechanisms, Adapted to the feeding mechanism respectively, it is used to cut the film roll according to any of the cutting methods according to more than two preset cutting methods; the feeding mechanism is used to load the film roll, And convey the film roll to any of the cutting mechanisms; the control mechanism is adapted to two or more of the cutting mechanisms and the feeding mechanism; The feeding mechanism is controlled to realize cutting of the film roll by any of the cutting methods. The solution of the invention can overcome the defects of inconvenient use, low work efficiency and high cost in the prior art, and realize the beneficial effects of convenient use, high work efficiency and low cost.

Owner:GREE ELECTRIC APPLIANCES INC

Adhesive tape mother roll slitting device

ActiveCN114260952AIncrease pulldown speedImprove cutting efficiencyMetal working apparatusAdhesive beltRoll slitting

The invention relates to the technical field of slitting equipment, and discloses an adhesive tape mother roll slitting device which solves the problem that when a cutter is used for cutting, mucilage glue is prone to adhering to the surface of the cutter, and consequently the cutter becomes blunt. The adhesive tape mother roll slitting device comprises a bottom plate, supporting legs are symmetrically installed on the two sides of the bottom plate, and side plates are symmetrically installed at the top end of the bottom plate; machine body sliding grooves are formed in the sides, close to each other, of the two side plates. A top plate is installed at the top ends of the side plates. In the working process, an output chain wheel of an arranged third motor drives a chain to move, bottom screw rods on the two sides are driven to get close to each other, clamping plates on the two sides clamp an adhesive tape roll, then an output shaft of a second motor rotates reversely, a moving block is driven to move downwards, and then the adhesive tape roll is rolled out; and at the moment, the second motor stops working to adapt to different slitting lengths, and meanwhile, the moving block drives the adhesive tape roll to stretch, so that the pull-down speed is increased, and the slitting efficiency is improved.

Owner:扬州和创新材料科技有限公司

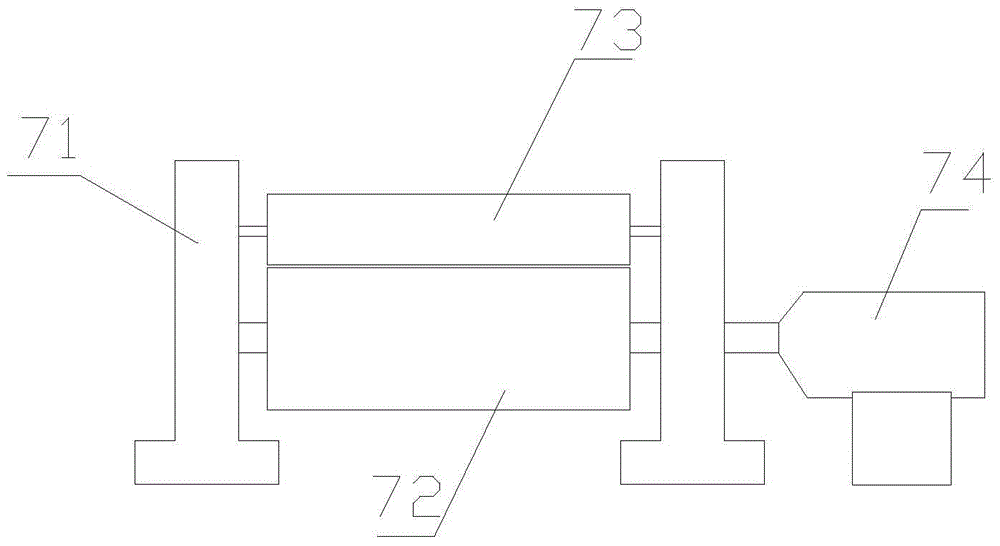

Rolling slitting device

InactiveCN110720481AEasy to operateSave human effortDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationRoll slittingAnnular cutter

The invention discloses a rolling slitting device, which relates to the field of food processing, in particular to a dough rolling and slitting device. The structure is simple, machining is convenient, and machining efficiency is improved. The device comprises a U-shaped support, the support is provided with a transverse plate, a first vertical rod and a second vertical rod, the first vertical rodand the second vertical rod are arranged in parallel, a wrapper pressing mechanism is arranged on the inner side of the first vertical rod, the wrapper pressing mechanism comprises a horizontal motorand a pressing roller, the horizontal motor is connected to the first vertical rod, and the horizontal motor drives the pressing roller; a cutting mechanism is arranged on the inner side of the second vertical rod and comprises a supporting rod, a vertical telescopic rod and a cutting plate, the supporting rod is horizontally connected to the second vertical rod, the vertical telescopic rod is connected between the supporting rod and the cutting plate, the cutting plate comprises a plate body, the vertical telescopic rod is connected with a plate body, and a plurality of annular cutters are arranged below the plate body; a tackle is arranged on the transverse plate and comprises a tackle body, and rotation wheels are arranged below the tackle body. The device is convenient to operate, andmanpower is saved.

Owner:吴雨轩

Rolling slitting method for deep-fried dough stick dough strip

The invention discloses a slitting method for a deep-fried dough stick dough strip. The method adopts a rolling slitting mode, that is, when the deep-fried dough stick dough strip is pressed by a roller, hobbing cutter edges are arranged at intervals according to the width of deep-fried dough sticks for hobbing, and the roller and a cutter are combined, so that the part, used for hobbing, of the cutter is a cutter body from the diameter of the roller to the diameter of the cutter. The method overcomes the two defects that in the prior art, the thickness of dough sheets cannot be repaired due to absence of the function of arranging the dough sheets during slitting, and the width error of the cut dough sheets is larger due to large size of a cantilever part of the cutter. Through rolling slitting, the cutter edges can be well arranged at intervals according to the width of the deep-fried dough sticks, the depth of each cutter edge is small, the size of the cantilever is reduced, and theproblem that the width error of the cut dough sheets is increased due to the fact that the cantilever of the cutter is large or the depth of each cutter edge is large is solved; and a rolling disc isused for pressing and arranging the dough sheets during slitting, so that the thicknesses of the dough sheets are repaired, the thicknesses and the widths of cut deep-fried dough stick dough strips are consistent, and the deep-fried dough sticks are uniform in shape and the same in weight.

Owner:SUZHOU GUOEN FOOD MACHINERY

Automated sleeve filling for winding shafts on roll slitting and winding machines

A method for automatic sleeve filling of a winding shaft on roll cutting and winding machines is provided in which, in an exemplified embodiment, in a first step at least two empty winding sleeves are slid onto a free end of a winding shaft so that the winding sleeves are adjacent to one another, in a second step the last winding sleeve slid on by a freely positionable fork piece of a freely programmable draw-off plate along the winding shaft is slid over the winding shaft until the last winding sleeve has reached a predetermined position, in a third step the next-to-last winding sleeve slid on is grasped by tongs freely positionable along the winding shaft and is slid over the winding shaft to the point where in a fourth step the fork piece can dip into the gap produced by the tongs so that the next-to-last winding sleeve is positionable along the winding shaft by the fork piece.

Owner:KAMPF GMBH

A zero-damage processing technology of protective film

The invention relates to a zero-damage processing technology for a protective film, which includes the following steps: 1), the membrane and the base film are unwound, the membrane is attached to the base film, and sent to the cutting system; 2), the membrane and the The bottom film first passes through the waste edge roller cutting unit to roll cut the edge of the film, and the cut waste edge is separated from the bottom film and the waste edge is recycled; 3), the excess part is rolled and collected, and the roll cut is 4) The diaphragm enters the pre-peeling area and is peeled off from the bottom film at a small angle. At this time, the diaphragm keeps moving forward in a straight line with inertia until the bottom film goes down. After moving to the peeling area, the diaphragm falls into the front diaphragm receiving frame, and the bottom film is rolled up. On the one hand, the present invention avoids the damage of the bottom film by quantitative roll cutting; Zero-damage curling.

Owner:苏州壬和控股有限公司

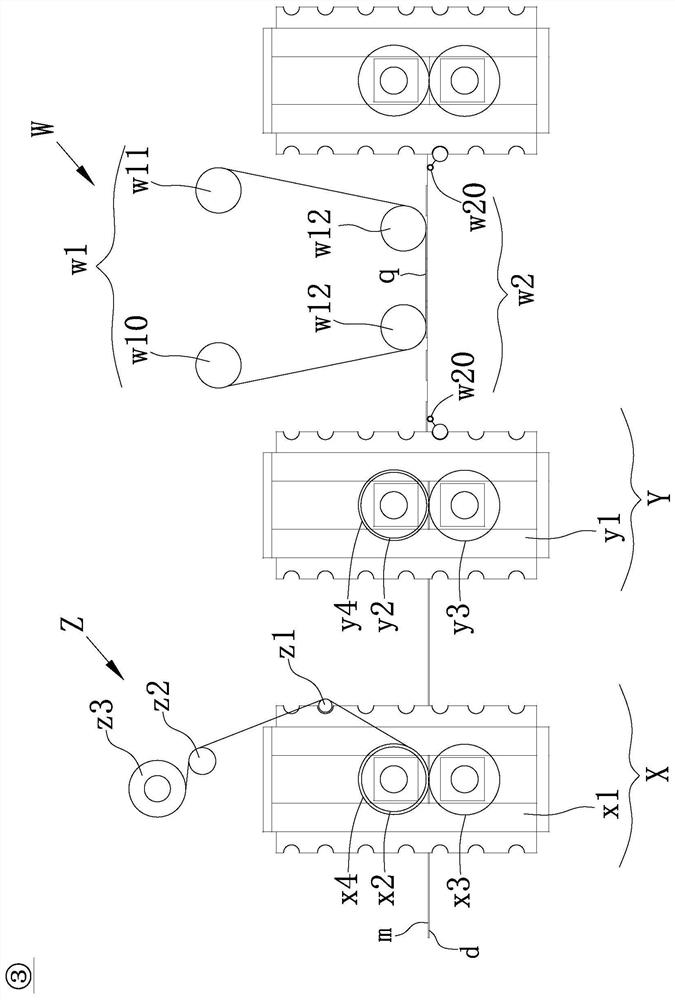

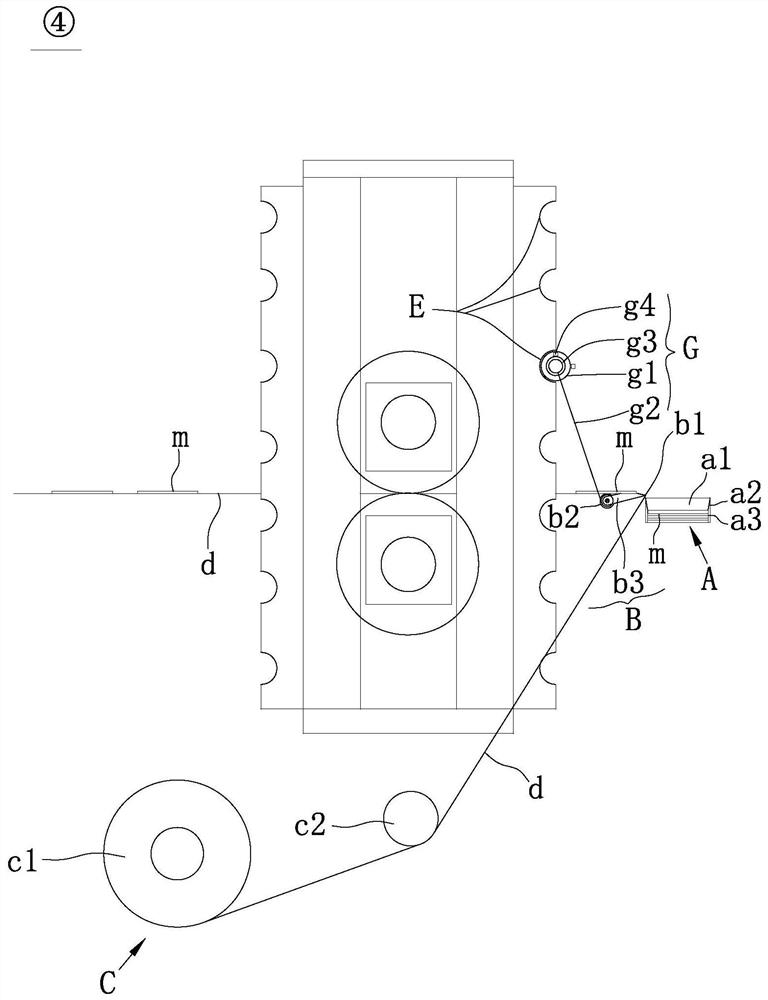

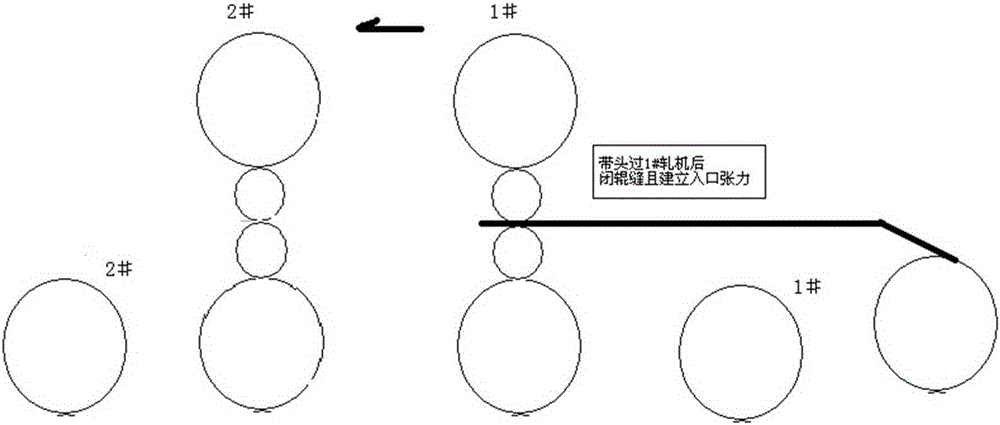

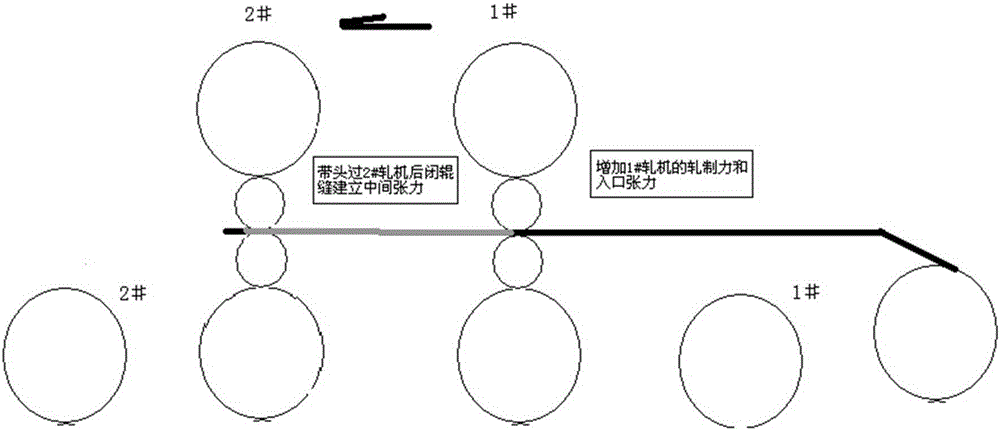

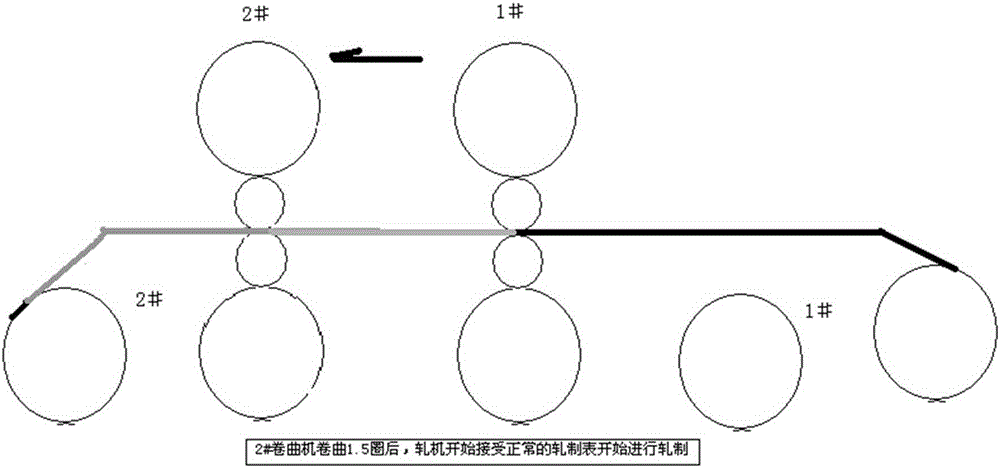

Closed Gap Strip Threading Rolling Method in Double Stand Cold Rolling Mill

InactiveCN104148383BPrevent deviationHigh yieldRoll force/gap control deviceWork treatment devicesCooling effectRoll slitting

Owner:JIGANG GRP

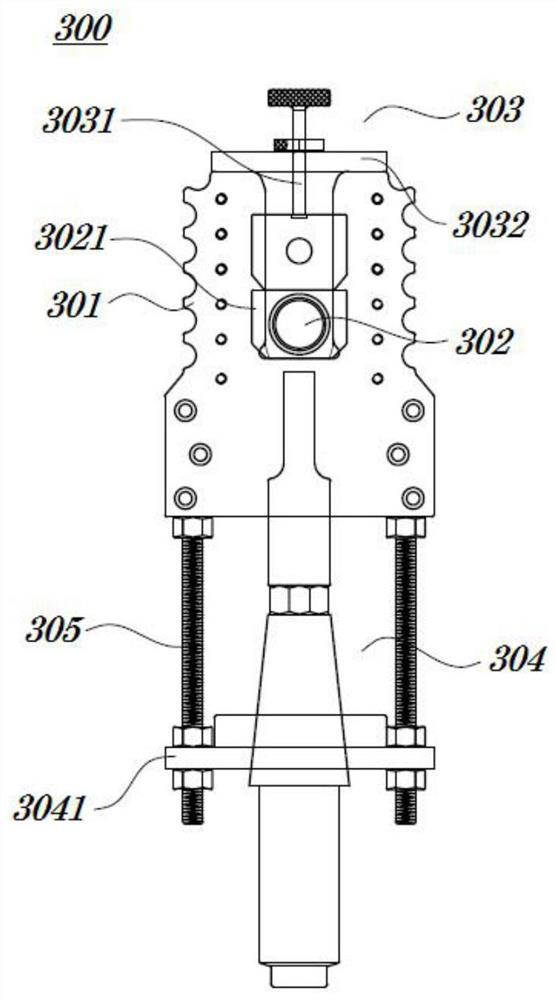

Tab laser cutting device and cutting block assembly thereof

The invention discloses a tab laser cutting device and a cutting block assembly thereof. The cutting block assembly of the tab laser cutting device comprises a shell. A supporting plate for supportinga pole piece is arranged on the front side of the shell and is in the shape of an arc. A cutting port and a waste material inlet are formed in the supporting plate. A dust chamber and a waste material chamber are formed in the shell. A dust outlet and a waste material outlet are formed in the shell. Both the waste material inlet and the waste material outlet communicate with the waste material chamber. Both the cutting port and the dust outlet communicate with the dust chamber. The cutting block assembly absorbs the advantages of rolling slitting, the cutting, without waste material edges, onpole pieces is realized, the material cost is reduced, and waste materials can be sucked conveniently.

Owner:GEESUN AUTOMATION TECH

Numerical control machining method for roll slitting pass

PendingCN112296366AAchieve high-quality processingReduce consumptionTurning machinesNumerical controlMachined surface

The invention discloses a numerical control machining method for a roll slitting pass. The method specifically comprises the following steps of 1, unit grouping; 2, unit size programming; and 3, passmachining. The numerical control machining method for the roll slitting pass is a machining method designed for roll machining and the actual use condition of a roll. According to the method, one-timemachining of the roll pass is decomposed into a plurality of machining units, only one unit is machined each time, high-quality machining of the roll is achieved, and the machining problems that theroll machining surface quality is poor, and the position precision is unqualified are solved. According to the method, a complex comprehensive program is decomposed into a plurality of simple programs, programming is simple, and operation is convenient; repeated loading is not needed during pass machining, the turning time is greatly saved, the machining efficiency is improved, and tool consumption is reduced; the surface quality and the position precision of the roll pass can be effectively ensured; and meanwhile the requirements of pass machining for the tool and machine tool performance arereduced.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Zero-damage processing technology of protective film

The invention relates to a zero-damage processing technology of a protective film. The technology comprises the following steps that 1) a membrane and a bottom film are unwound, the membrane is attached to the bottom film, and the membrane and the bottom film are conveyed to a cutting system; 2) the membrane and the bottom film pass through a waste edge roll cutting unit so as to enable an edge of the membrane to be subjected to roll cutting, and the cut waste edge is separated from the bottom film and is recycled; 3) roll cutting is conducted on a redundant part, a waste material is collected, and the roll-cut molded membrane and the bottom film are fed into a membrane collecting system; and 4) the membrane enters a pre-stripping area and is stripped from the bottom film at a small angle, at the moment, the membrane keeps inertial linear motion and horizontally moves forwards until the bottom film moves downwards to a stripping area, then the membrane falls into a membrane receiving frame in front, and the bottom film is wound. According to the technology, on one hand, damage to the bottom film is avoided through quantitative roll cutting; and on the other hand, due to the arrangement of a pre-stripping surface, a stripping process of the membrane is gradual, so that a damage rate of the membrane is greatly reduced, and meanwhile, zero-damage rolling of the bottom film can be realized.

Owner:苏州壬和控股有限公司

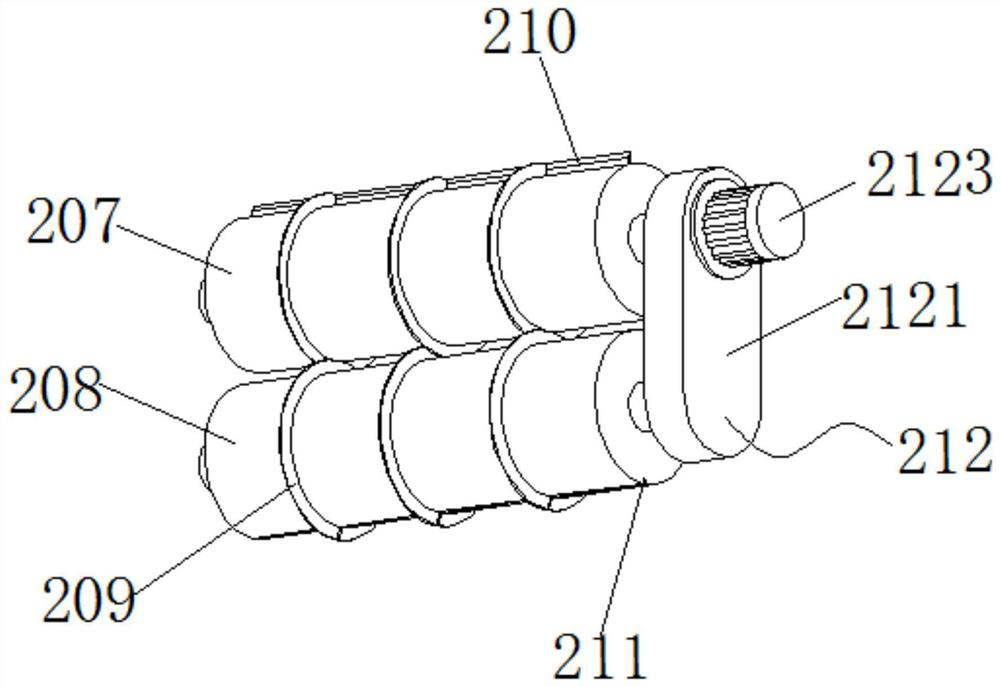

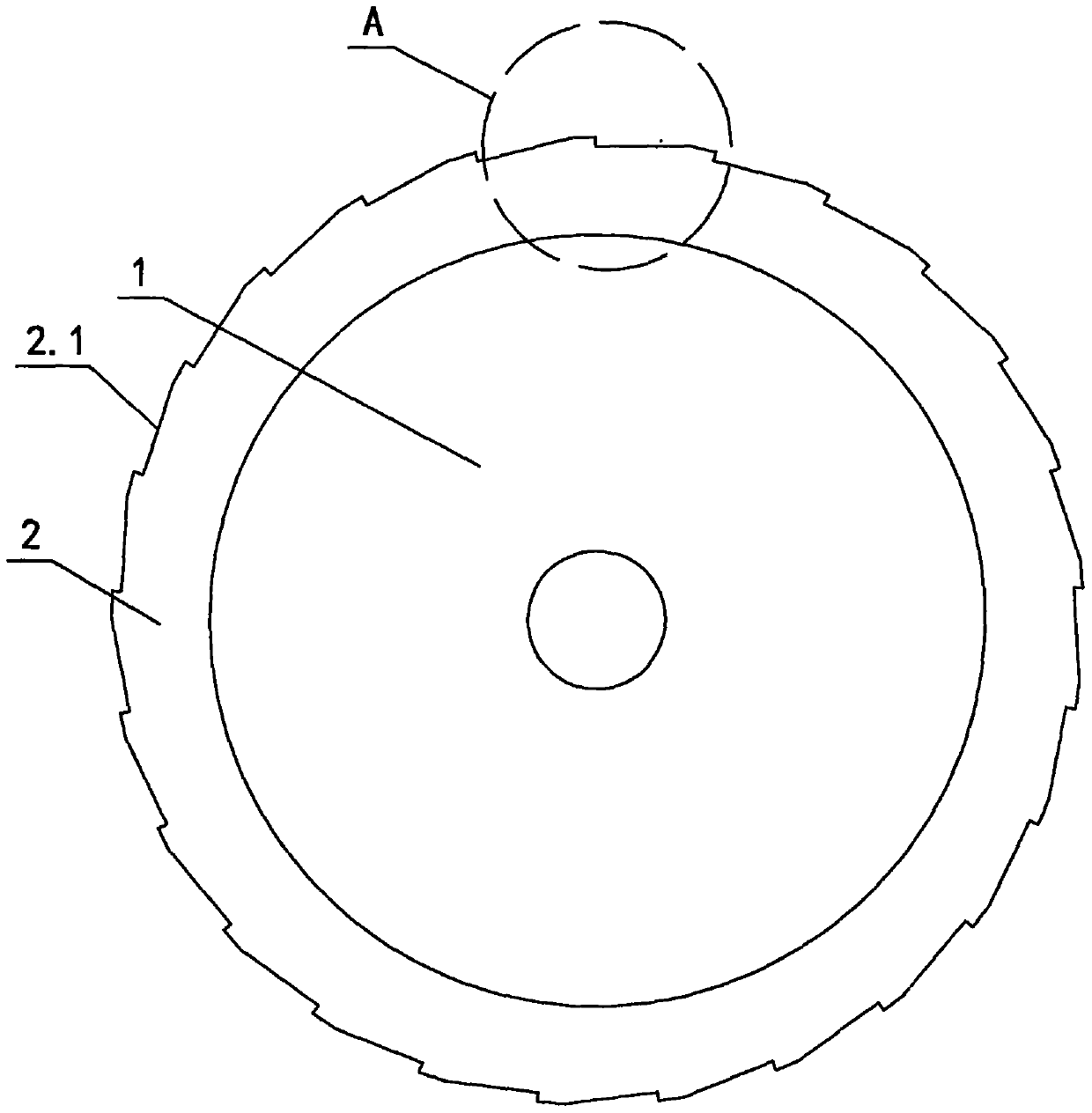

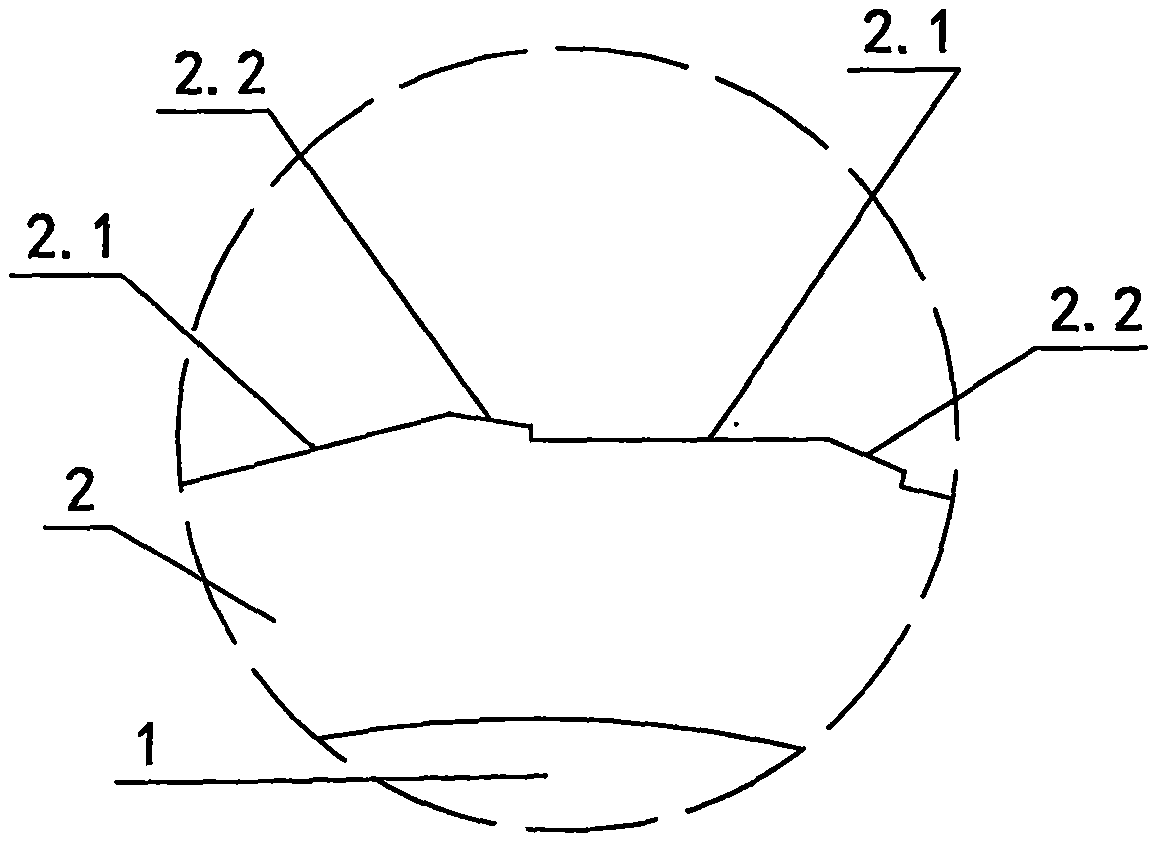

Novel special shearing roller for rail tyre particle slitting roller

The invention relates to a novel special shearing roller for a rail tyre particle slitting roller, belonging to the field of recovery technology for rail tyres. The novel special shearing roller comprises rotating shafts, wherein the rotating shafts are provided with a plurality of rolling-slitting discs used for rotary shearing and arranged at an equal interval, and the outer peripheries of the rolling-slitting discs are provided with a plurality of primary antiskid rolling-slitting surfaces. The novel special shearing roller for the rail tyre particle slitting roller is simple in structure and mainly employs a shearing manner for realizing low rotating speed and great torque, so the purposes of low noise, low dust and low maintenance are achieved.

Owner:彭明友

A kind of production technology of heat-shrinkable polyester film

The invention discloses a production technology for a heat shrinkable polyester film and relates to the package material field. The production technology comprises the following technologies: slicing, vacuum drying, melt extrusion, quenching slice casting, biaxial tension, cooling and rolling slitting. Amorphous polyethylene glycol terephthalate is selected as a raw material, amorphous polyethylene glycol terephthalate is easy to recycle, nontoxic and odourless, has good mechanical properties, and meets environment protection requirements. Heat is transferred to materials to be dried through a drier shell under the vacuum environment, and therefore the purpose of drying reinforcement is achieved. The softening point of polymers is raised effectively, adhesion and agglomeration of resin particles are avoided during the drying and melt extrusion processes, moisture in resins can be removed, and hydrolytic degradation and bubble generation of polymers containing ester groups are prevented during the melt extrusion process. The ways of segmented heating and segmented processing are beneficial for fusion of molecules, and avoid material deterioration caused by too fast heating. the intensity of the produced shrinkable film is raised, and the shrinkable film has impact resistance.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

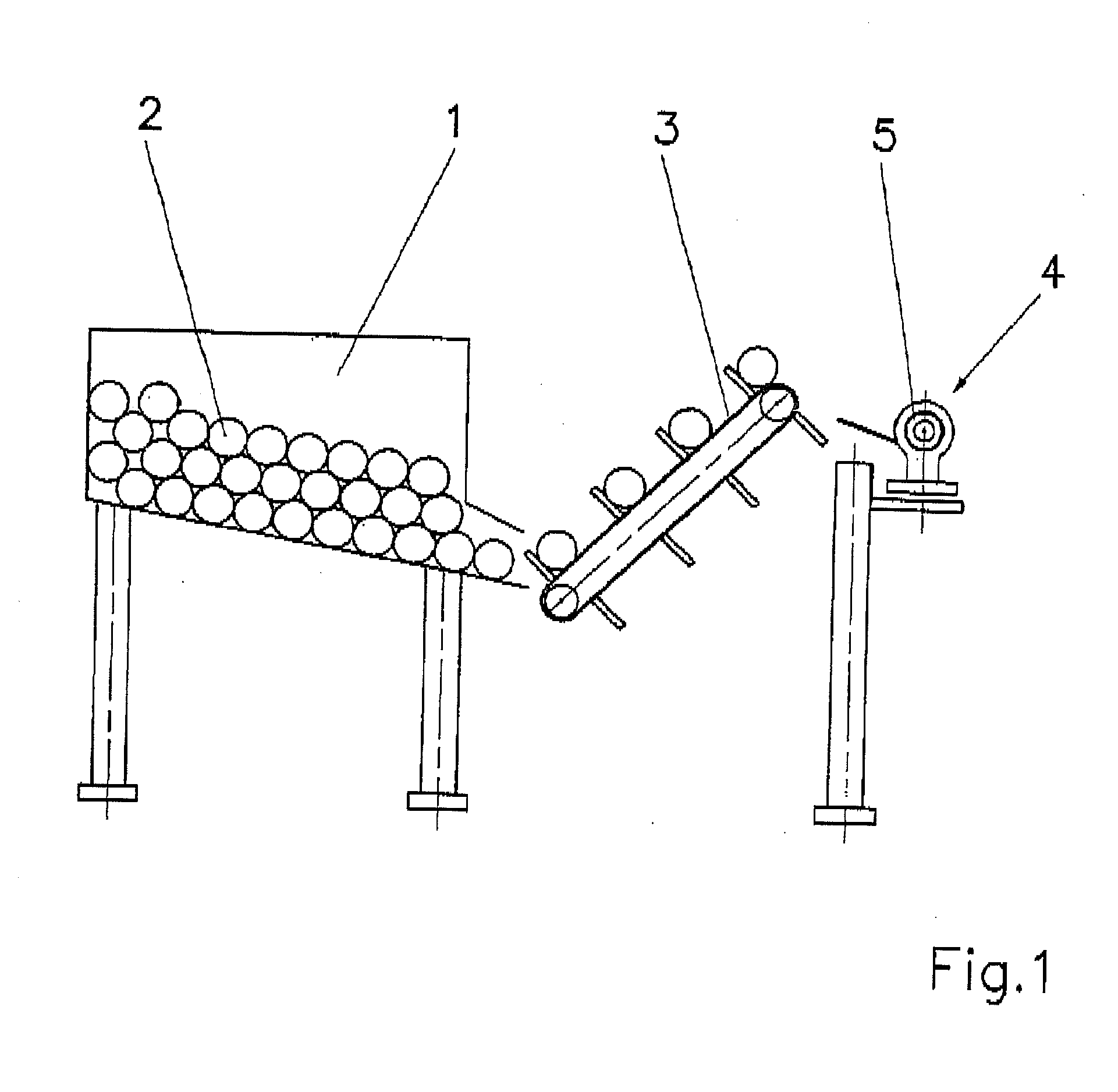

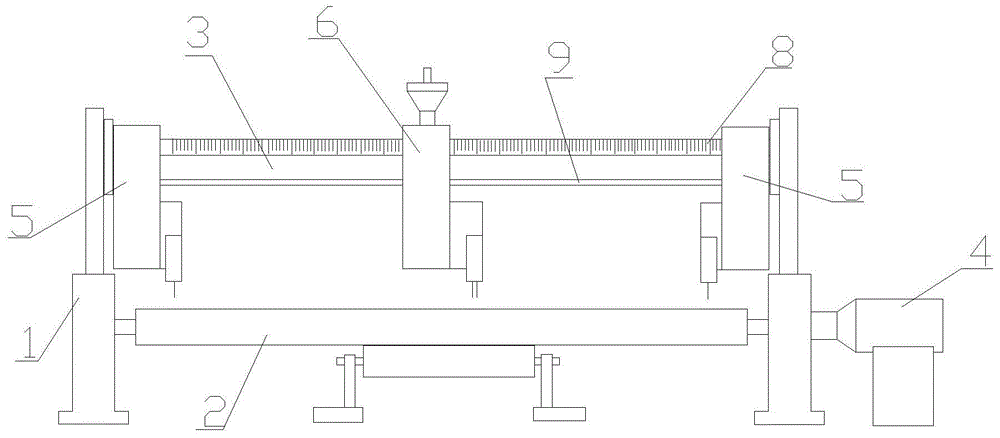

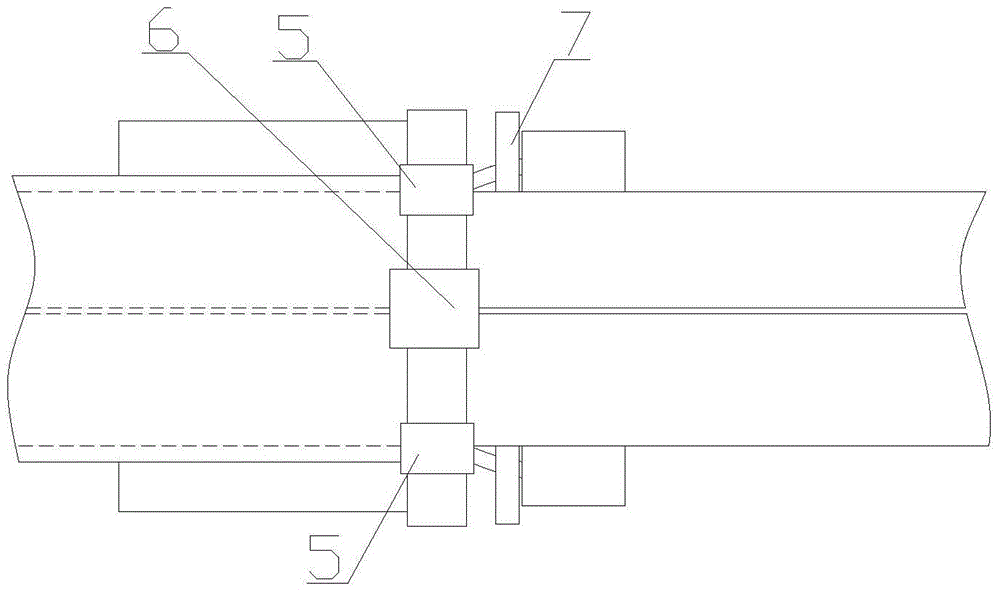

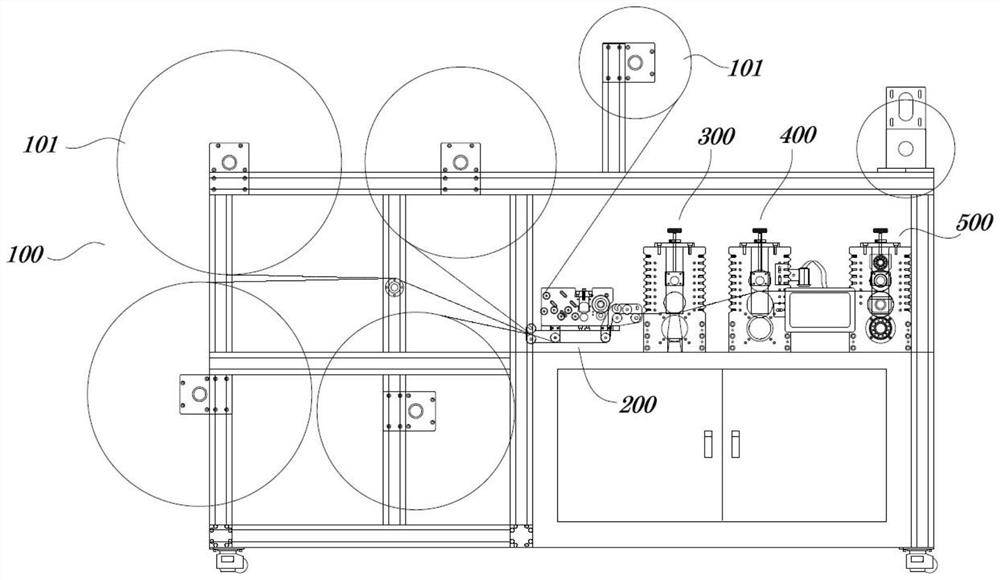

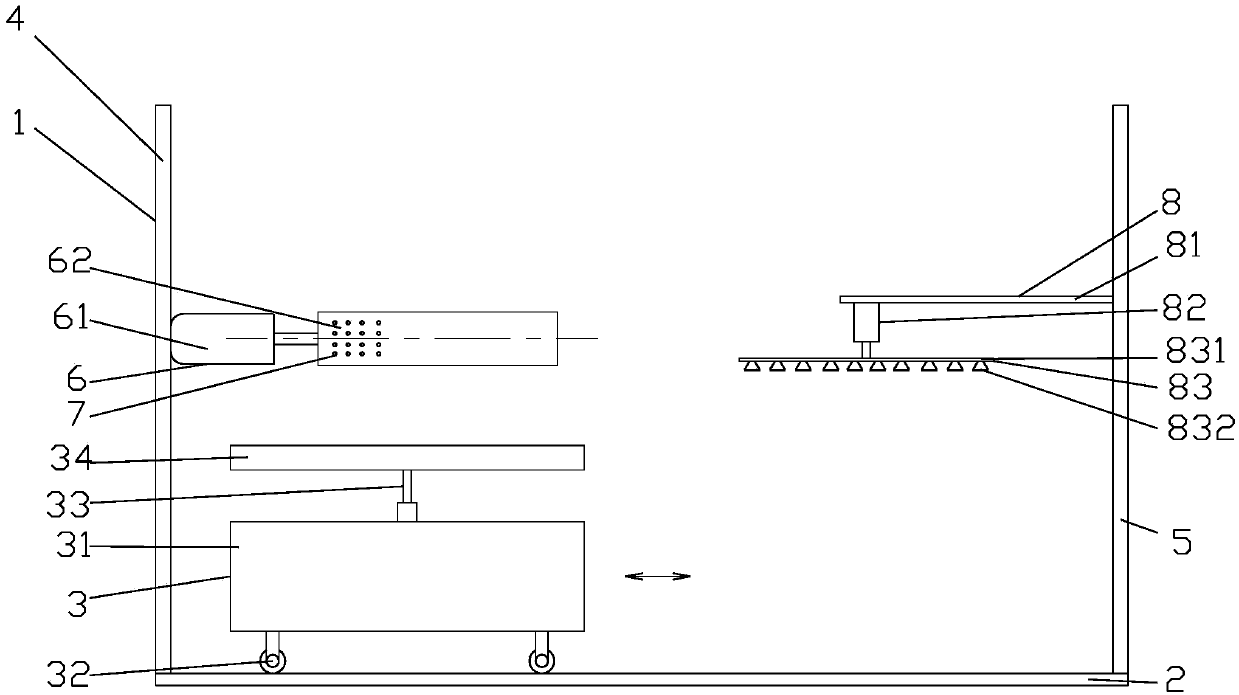

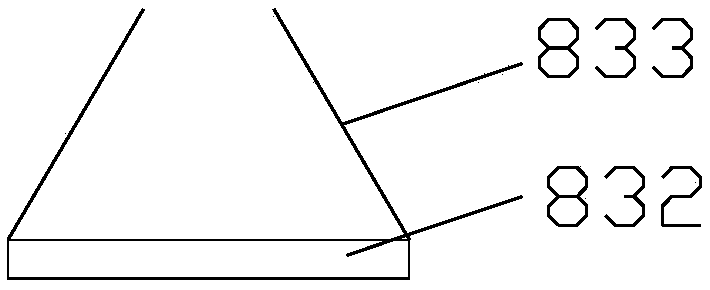

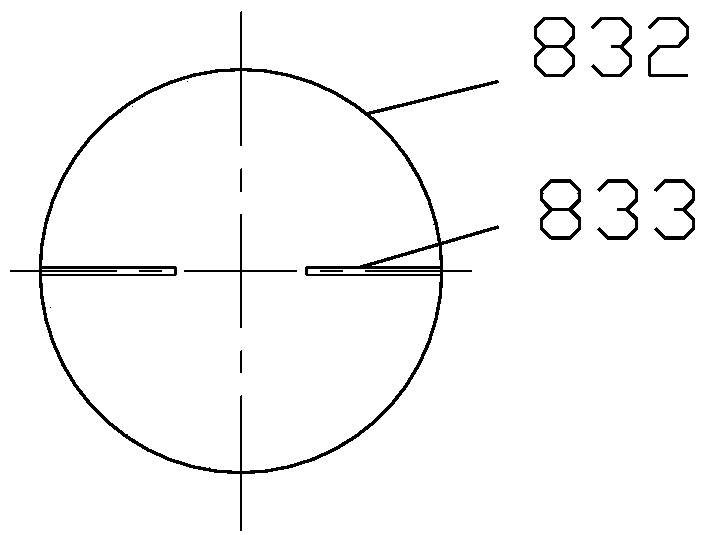

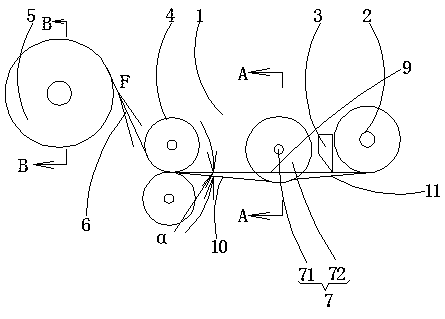

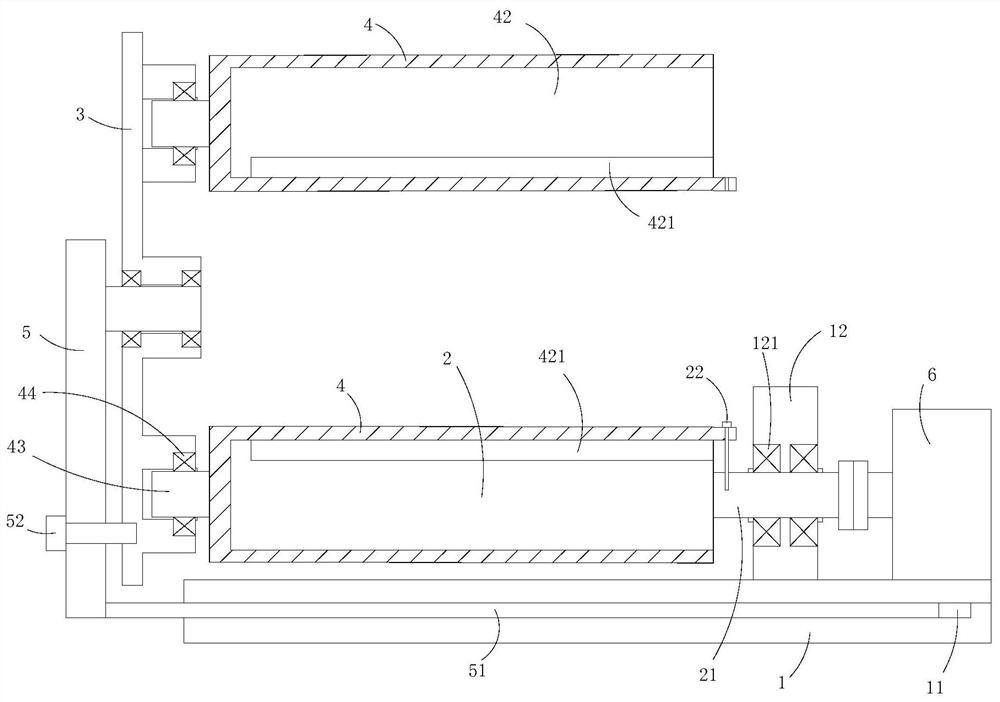

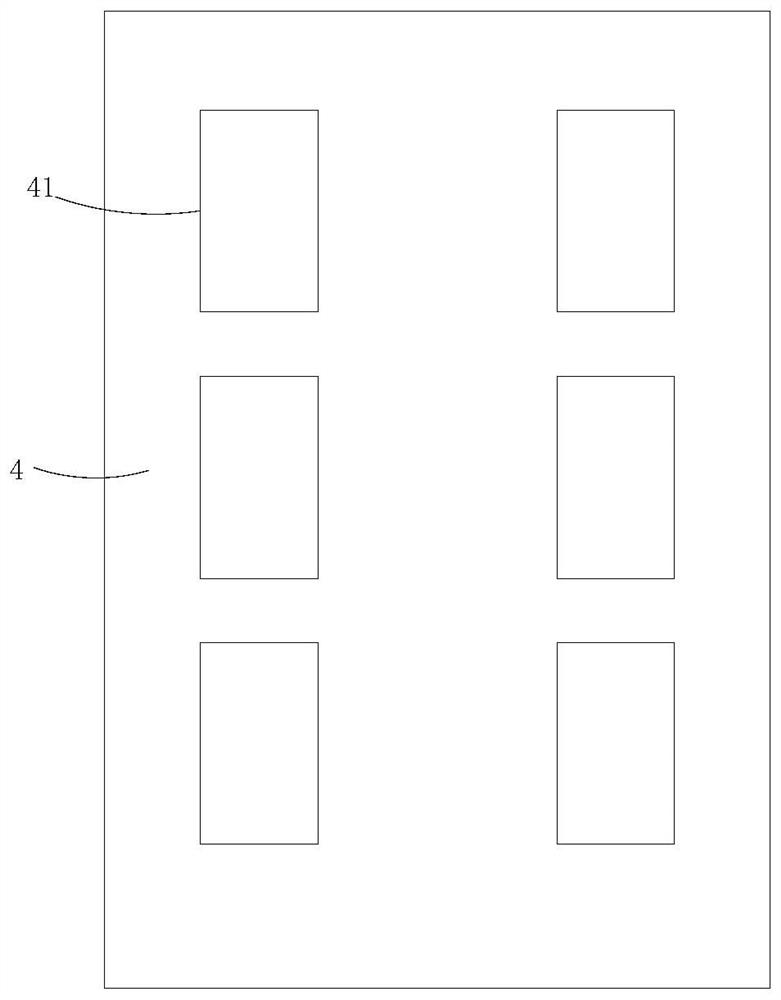

Aluminum foil roll slitting and stretching machine and matching aluminum foil roll processing method

ActiveCN107175288BAchieve breakageRealize stepless speed changeMetal working apparatusChemical storageMicrocomputer

The invention relates to automatic production equipment for barrier and explosion proofing materials filling dangerous chemical storage and transport containers, in particular to an aluminum foil coil slitting stretcher machine and an aluminum foil coil machining method matched with the same. The aluminum foil coil slitting stretcher machine and the aluminum foil coil machining method matched with the same mainly aim at solving the problem that in the prior art, the product quality control is unstable. A feeding device is installed on one side of a machine frame. A slitting device, a stretcher device and a gathering device which are driven by the same power source are further installed in the position, behind the feeding device, of the machine frame. A shaping device is arranged between the feeding device and the slitting device, and another shaping device is arranged between the slitting device and the stretcher device. A cutter device is arranged between the stretcher device and the gathering device. The aluminum foil coil slitting stretcher machine and the aluminum foil coil machining method matched with the same have the beneficial effects that the industrial automatic control mode is adopted, discharging, slitting, stretching and gathering are of the constant speed, the mechanisms are in a stepless speed change mode, the tensile strength is controlled by a microcomputer, formed coils are uniform in size, high in compactness, free of collapse and chippings after filling and high in filling compactness, the barrier and explosion proofing effects are well achieved, and safety of storage and transport of dangerous chemicals is guaranteed.

Owner:河南中联安全科技有限公司

Paper roll slitting machine

InactiveCN109051963AIncrease the gapEasy to removeArticle deliveryWebs handlingRoll slittingPulp and paper industry

The invention relates to equipment in the technical field of slitting production of paper rolls, named as a paper roll slitting machine. The paper roll slitting machine comprises a machine frame, wherein a raw material roller, a cutting knife, a running roller and a finished product roller are mounted on the machine frame from back to front; a distribution roller is also mounted on the machine frame positioned in front of the finished product roller and is provided with a distribution roller shaft; the middle part of the distribution roller shaft has a circular arc structure; the circular arcstructure is provided with an arch point; the arch point is arranged in the direction facing routes of paper sheets; the outer side of the distribution roller shaft is provided with 8 to 12 sleeves; each of the sleeves has a cylindrical structure with a hollow core; each of the hollow cores is cylindrical; the diameter of the corresponding hollow core is more 2mm to 3mm than the diameter of the distribution roller shaft; and the sleeves are symmetrically arranged on the two sides of the distribution roller shaft. The paper roll slitting machine has the advantages that a gap between the paper rolls of the produced two rolls of finished products is large, and the product is convenient to detach.

Owner:CHANGGE DAYANG PAPER CO LTD

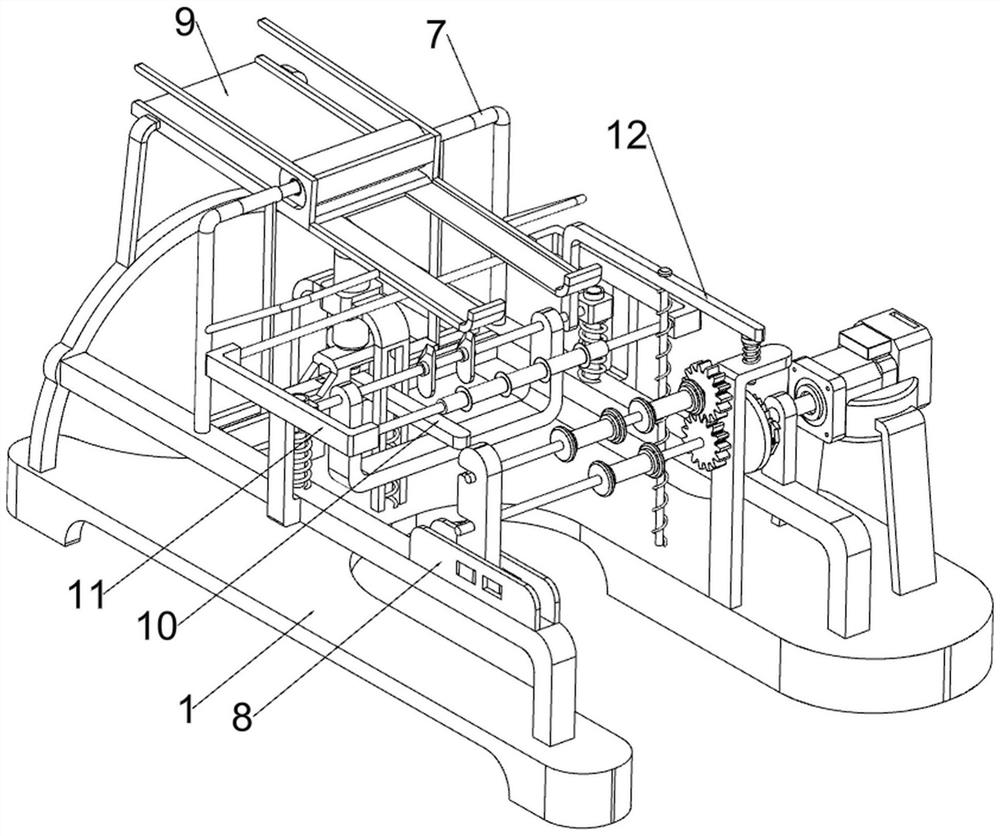

Long roll slitting equipment for woven fabric production

ActiveCN113247683AImprove work efficiencyConvenient collection workArticle deliveryWebs handlingRoll slittingEngineering

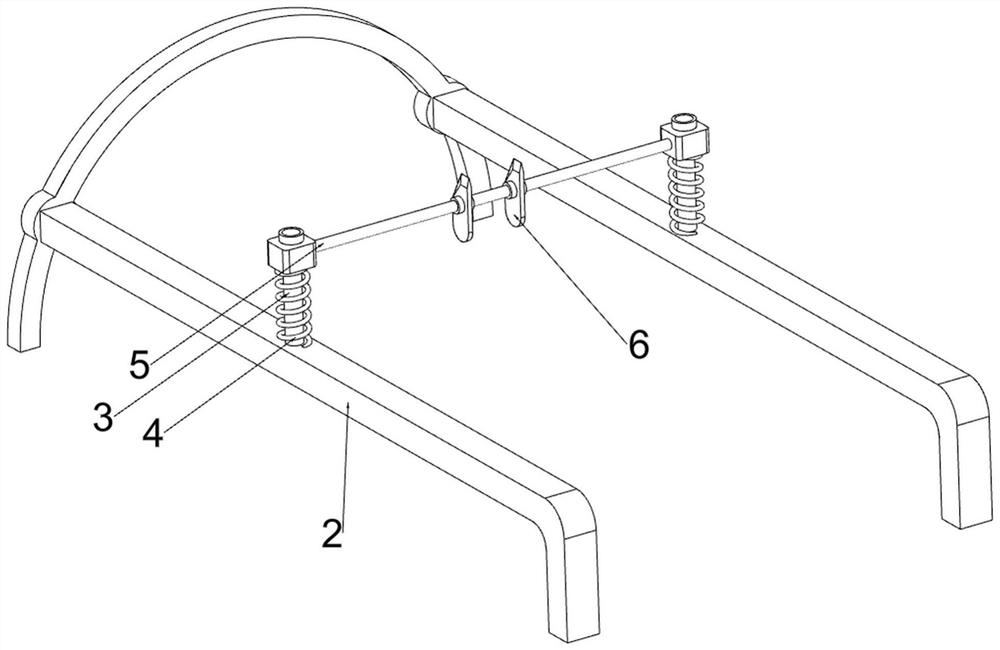

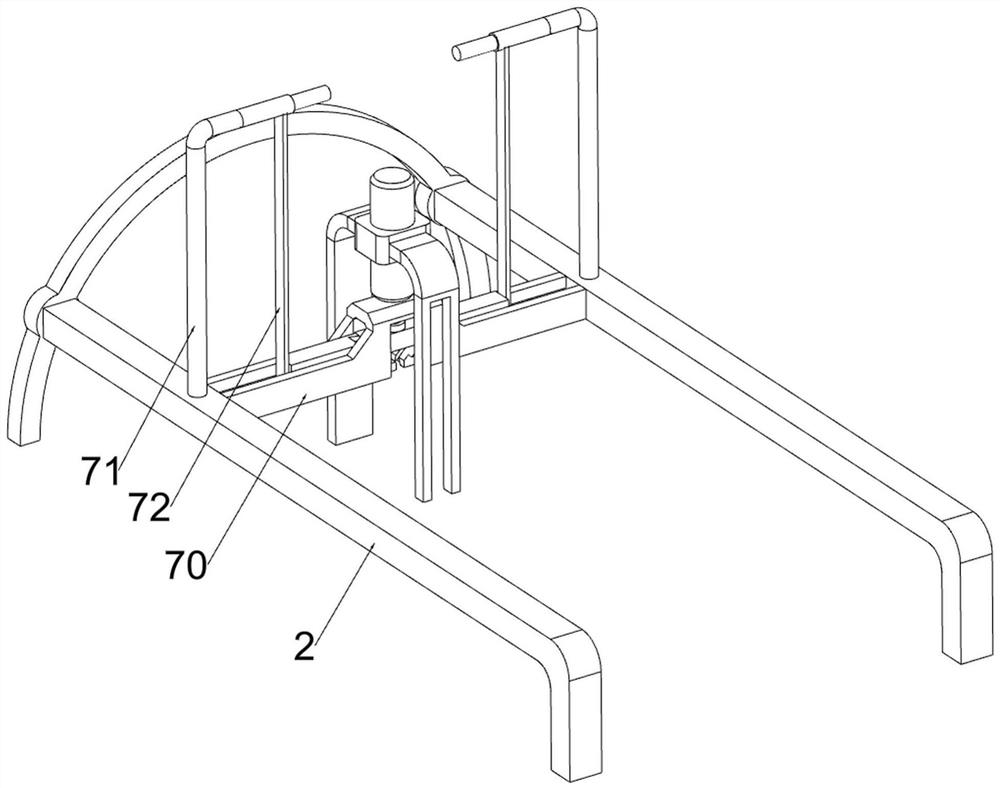

The invention relates to long roll slitting equipment, in particular to long roll slitting equipment for woven fabric production. The long roll slitting equipment for woven fabric production can conduct collection in a roll-dividing mode and can completely cut off woven fabric. The long roll slitting equipment for woven fabric production comprises a base used for installing the whole equipment, a first supporting frame arranged at the top of the base, first guide rods symmetrically arranged on the two sides of the top of the first supporting frame in a sliding mode, first springs arranged between the first guide rods and the first supporting frame, a connecting rod arranged between the tops of the first guide rods, two cutting blades arranged on the connecting rod, and a material clamping mechanism arranged on one side of the top of the base. According to the long roll slitting equipment for woven fabric production, the material clamping mechanism and a discharging mechanism are matched, a plurality pieces of of long roll woven cloth is placed in the discharging mechanism, automatic feeding and discharging work is completed through the material clamping mechanism, and then the working efficiency is improved.

Owner:赣州广建玻纤有限公司

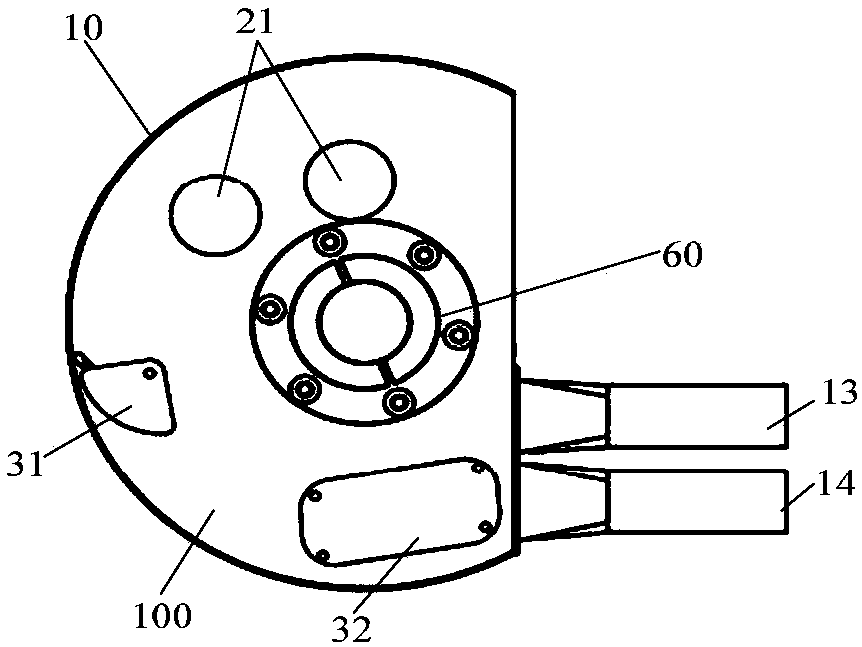

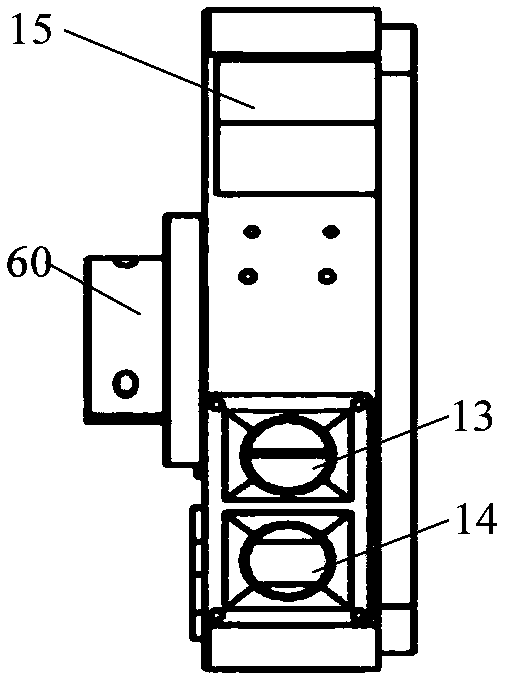

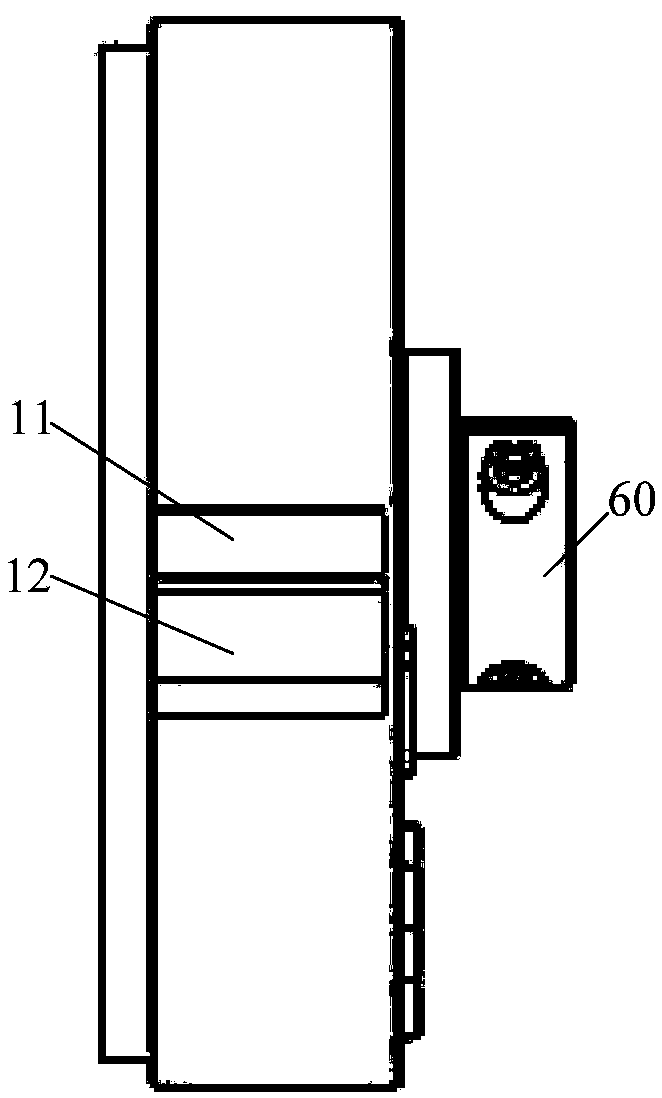

Mask roll cutting tool

ActiveCN113021522ASimple and reliable processShorten the timeMetal working apparatusRoll slittingEngineering

The invention relates to the technical field of mask processing equipment, and provides a mask roll cutting tool. The mask roll cutting tool comprises a bottom plate, a rotating disc and a plurality of cutter sleeves, wherein a driving roll shaft is rotationally connected to the upper portion of the bottom plate; the rotating disc is arranged at one side of the driving roll shaft in a sliding manner in the axial direction of the driving roll shaft; and the multiple cutter sleeves are arranged on the rotating disc in the circumferential direction of the rotating disc at intervals, the outer surface of each cutter sleeve is provided with cutting edges, the multiple cutter sleeves are arranged on the driving roll shaft in a switchable and sleeving manner, and a flow channel used for cutting materials is defined between the cutter sleeves and the bottom plate. When the cutter sleeves need to be replaced, the rotating disc can be moved to drive the cutter sleeves to be separated from the driving roll shaft, then the rotating disc is rotated to enable another cutter sleeve to rotate to correspond to the driving roll shaft, and then the rotating disc is moved to enable the cutter sleeves to be arranged on the driving roll shaft in a sleeving manner, so that the working procedure of replacing the cutter sleeves is simpler and more reliable; and meanwhile, the replaced cutter sleeves can be overhauled, so that the time for replacing the cutter sleeves is saved, and the production speed is ensured.

Owner:天长市润米生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com