Numerical control machining method for roll slitting pass

A technology of cutting pass and processing method, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of long continuous turning time, low processing efficiency, prone to errors, etc., and achieve the goal of reducing the performance of cutting tools and machine tools Requirements, ensure surface quality and position accuracy, and solve the effect of poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014]The numerical control processing method of the roll slitting pass of the present invention is specifically as follows:

[0015]The first step is to group the units. The rolls to be processed are grouped according to the roll pass, and they are divided into several processing units, that is, a group of passes used at the same time during rolling is regarded as a processing unit, and only one unit is processed at a time , After completing one unit, proceed to the next unit processing; until all processing is completed;

[0016]The second step is the unit size programming. When programming, each processing unit is programmed with a separate processing flow; based on the roll transmission end, a turning program is programmed for the outer circle of the roll body, and the outer circle is processed to the size required by the icon;

[0017]The third step is hole type processing. According to the processing technology requirements, the processes and tools of each processing unit are respectiv...

Embodiment 2

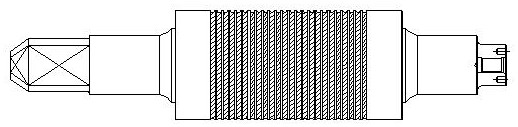

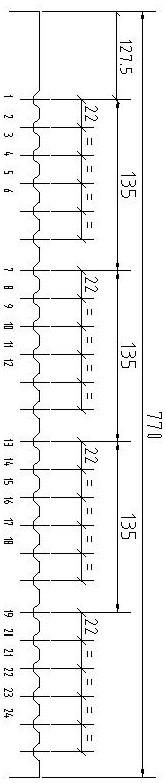

[0020]Such asfigure 1 withfigure 2The specific numerical control processing method of a certain rebar K1 roll shown in the following:

[0021]The roll has a total of 24 passes, which are rolled by four slits, and used in 6 groups, each with 4 passes; the first group is the 1, 7, 13, and 19 holes; the second group is the 2, 8 and 14 , 20 holes; the third group is holes 3, 9, 15, and 21; the fourth group is holes 4, 10, 16, and 22; the fifth group is holes 5, 11, 17, and 23; the sixth group is holes No. 6, 12, 18, and 24 holes;

[0022]When processing, take the transmission end as the benchmark, compile a turning program for the outer circle of the roll body and process it to the size required by the icon; compile the pass pattern used in the simultaneous rolling in production into one processing unit, such as 1, 7, 13, 19 hole types are compiled into 1 processing unit; it is divided into 6 processing units, and the program of each processing unit is compiled separately. (The hole size of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com