Multi-step multi-edged tool for integral hole making of laminated structure parts

A laminated structure and multi-step technology, applied in the manufacture of tools, drilling accessories, cutting blades, etc., can solve the problem of poor consistency between composite materials and metal apertures, poor metal hole wall roughness, delamination, burrs, tears, etc. problems, to achieve the effect of reducing tear damage, reducing roughness, eliminating burns and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

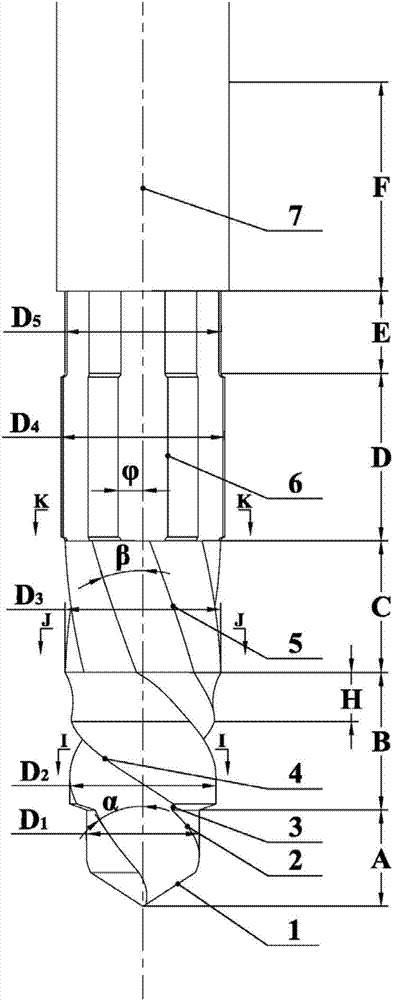

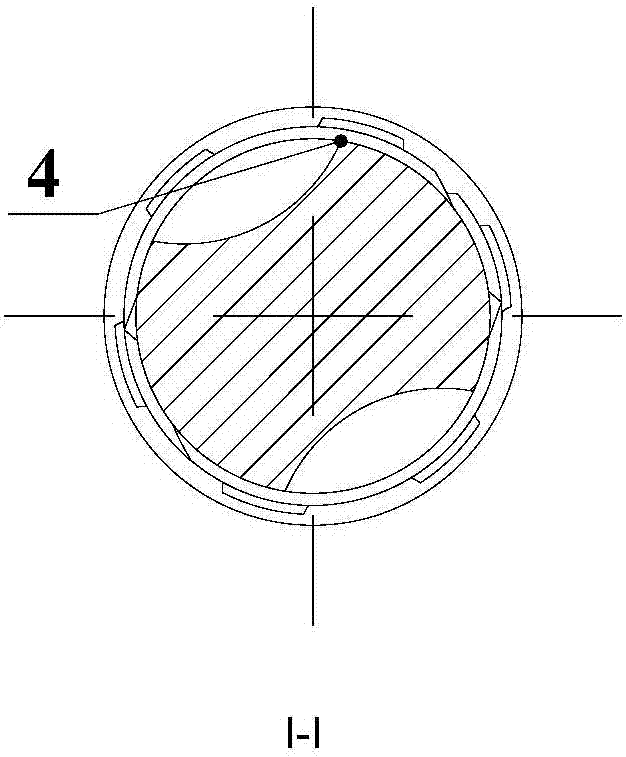

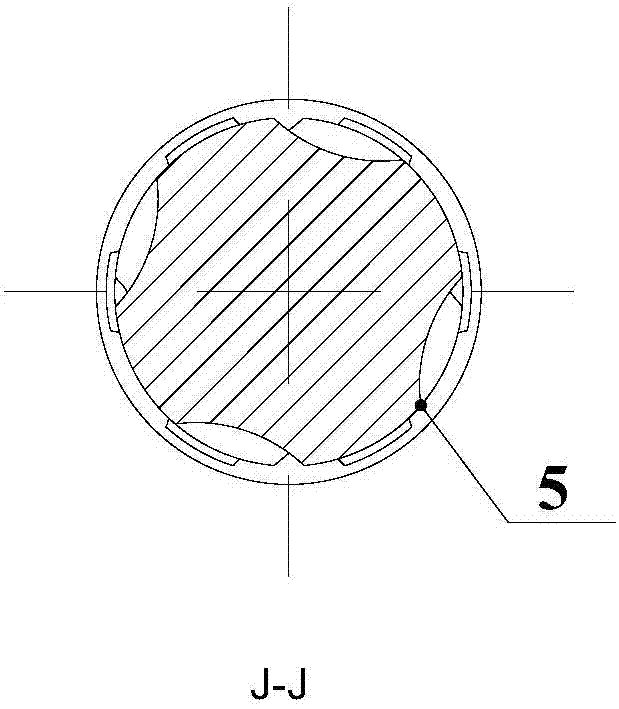

[0015] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. High-efficiency hole-making tool for carbon fiber reinforced composite material / metal laminated structure parts, and its specific embodiment tool is as figure 1 As shown, the tool is divided into the pre-drilling cutting area A formed by the envelope of the pre-drilling main cutting edge 1 and the pre-drilling minor cutting edge 2, the reaming main cutting edge 3 and the reaming minor cutting edge 4 The reaming cutting area formed by the envelope line B, the metal reaming cutting area C whose envelope line is the size of the metal end hole, the composite material reaming cutting area D whose envelope line is larger than the end hole size of the composite material, and the variable diameter area E 1, Clamping area F, a total of 6 areas, forming a multi-level ladder structure, each step has a specific blade shape, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com